Preparation method for cleaning agent high in defoaming speed

A cleaning agent and fast technology, applied in the field of cleaning, can solve the problems of shortened cleaning agent life, lower cleaning efficiency, and easy residue, etc., and achieve the effect of overcoming the long induction period, increasing the reaction rate, and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

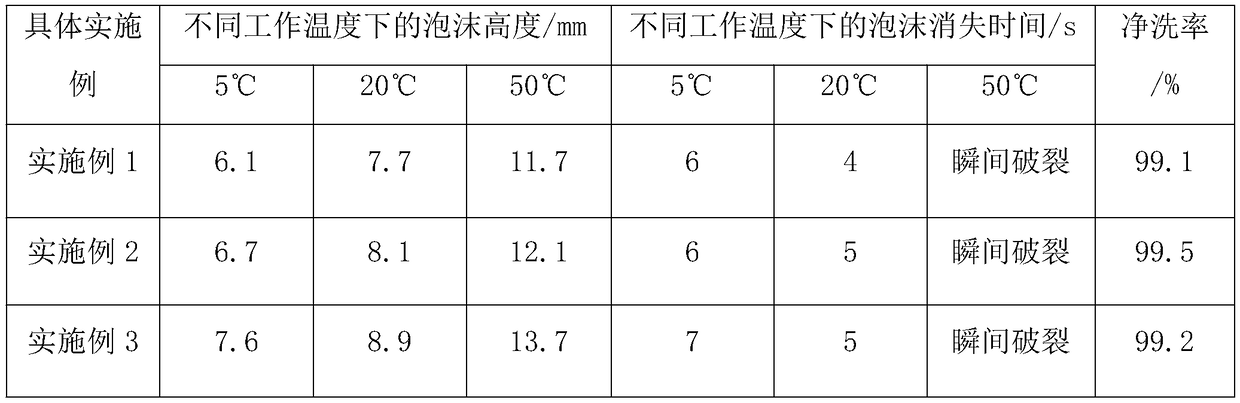

Embodiment 1

[0028] The present invention provides a kind of preparation method of the fast cleaning agent of defoaming speed, comprises the following steps:

[0029] The formula of the cleaning agent is: 0.8%-2.0% of anhydrous sodium metasilicate, 2%-4% of rust inhibitor, 2%-5% of carboxylic acid amine, 0.5%-1.0% of methyl benzotriazole, DissolvineH-403%-5%, Jimmy's quaternary ammonium salt C120228114%-6%, antifoam agent 2-5%, polyether modified silicone type defoamer 5%-8%, water balance;

[0030] Wherein the preparation method of polyether modified silicone type defoamer is:

[0031] S1: Preparation of hydrogen-containing silicone oil: use 0.15g solid superacid to catalyze 10kg of hexamethyldisiloxane, 6kg of octamethylcyclotetrasiloxane, and 8kg of tetramethylcyclotetrasiloxane, and heat in a water bath for 35 ℃, reacted for 6 hours, and filtered to obtain hydrogen-containing silicone oil;

[0032] S2: Put 10 μg of platinum catalyst, 100 μg of polyethylene glycol 300, 20 g of butyl a...

Embodiment 2

[0036] The present invention provides a kind of preparation method of the fast cleaning agent of defoaming speed, comprises the following steps:

[0037] The formula of the cleaning agent is: 0.8%-2.0% of anhydrous sodium metasilicate, 2%-4% of rust inhibitor, 2%-5% of carboxylic acid amine, 0.5%-1.0% of methyl benzotriazole, DissolvineH-403%-5%, Jimmy's quaternary ammonium salt C120228114%-6%, antifoam agent 2-5%, polyether modified silicone type defoamer 5%-8%, water balance;

[0038] Wherein the preparation method of polyether modified silicone type defoamer is:

[0039] S1: Preparation of hydrogen-containing silicone oil: use 0.2g solid superacid to catalyze 10kg of hexamethyldisiloxane, 6kg of octamethylcyclotetrasiloxane, and 8kg of tetramethylcyclotetrasiloxane, and heat in a water bath for 35 ℃, reacted for 6 hours, and filtered to obtain hydrogen-containing silicone oil;

[0040] S2: Put 20 μg of platinum catalyst, 150 μg of polyethylene glycol 300, 35 g of butyl ac...

Embodiment 3

[0044] The present invention provides a kind of preparation method of the fast cleaning agent of defoaming speed, comprises the following steps:

[0045] The formula of the cleaning agent is: 0.8%-2.0% of anhydrous sodium metasilicate, 2%-4% of rust inhibitor, 2%-5% of carboxylic acid amine, 0.5%-1.0% of methyl benzotriazole, DissolvineH-403%-5%, Jimmy's quaternary ammonium salt C120228114%-6%, antifoam agent 2-5%, polyether modified silicone type defoamer 5%-8%, water balance;

[0046] Wherein the preparation method of polyether modified silicone type defoamer is:

[0047] S1: Preparation of hydrogen-containing silicone oil: use 0.25g solid superacid to catalyze 10kg of hexamethyldisiloxane, 6kg of octamethylcyclotetrasiloxane, and 8kg of tetramethylcyclotetrasiloxane, and heat in a water bath for 35 ℃, reacted for 6 hours, and filtered to obtain hydrogen-containing silicone oil;

[0048] S2: Put 30 μg of platinum catalyst, 200 μg of polyethylene glycol 300, 50 g of butyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com