Modification method of grid-shaped lithium-ion battery separator with high wettability

A lithium-ion battery and wettability technology, which is applied in the field of lithium-ion battery diaphragm modification, can solve the problems of high processing equipment prices, affecting industrial use, and high raw material costs, and achieves improved electrophilicity, convenient operation, and wettability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

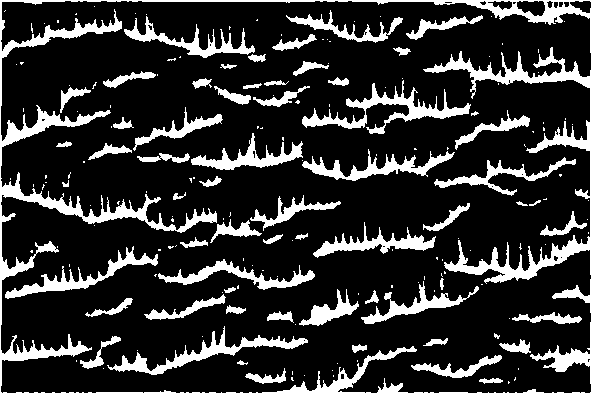

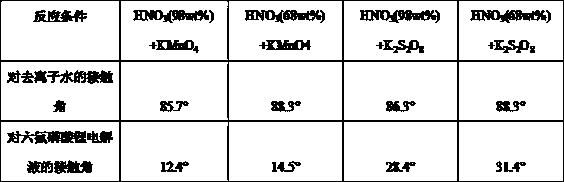

[0012] Soak the polypropylene microporous membrane in a mixed solution of nitric acid and potassium permanganate (the mass ratio of nitric acid to potassium permanganate is 60:1, and the mass concentration of nitric acid is 98%), and place it in a room at 25°C after sealing. React in a constant temperature water bath for 12 hours, then clean it with a hydrochloric acid solution with a molar concentration of 3mol / L, use deionized water as a cleaning agent, filter it under a pressure of 0.05MPa, and then dry it naturally. After trimming, place it in a vacuum at 40°C Dry in a drying oven for 24 hours to obtain a highly wettable lithium-ion battery separator.

Embodiment 2

[0014] Soak the polypropylene microporous membrane in a mixed solution of nitric acid and potassium permanganate (the mass ratio of nitric acid to potassium permanganate is 40:1, and the mass concentration of nitric acid is 68%), and place it in a refrigerator at 20°C after sealing. React in a constant temperature water bath for 72 hours, then clean it with a hydrochloric acid solution with a molar concentration of 1mol / L, use absolute ethanol as a cleaning agent, filter it under reduced pressure at 0.08MPa, dry it naturally, and place it in a vacuum at 60°C after trimming Dry in a drying oven for 12 hours to obtain a highly wettable lithium-ion battery separator.

Embodiment 3

[0016] Soak the polypropylene microporous membrane in a mixed solution of nitric acid and potassium persulfate (the mass ratio of nitric acid to potassium persulfate is 40:1, and the mass concentration of nitric acid is 98%), seal it and place it in a constant temperature water bath at 25 °C React in medium for 12 hours, then clean it with a hydrochloric acid solution with a molar concentration of 3mol / L, use deionized water as a cleaning agent, filter it under reduced pressure at 0.05MPa, dry it naturally, and place it in a vacuum drying oven at 40°C after trimming Medium drying for 24 hours to obtain a highly wettable lithium-ion battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com