Patents

Literature

56results about How to "Inhibition of isomerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

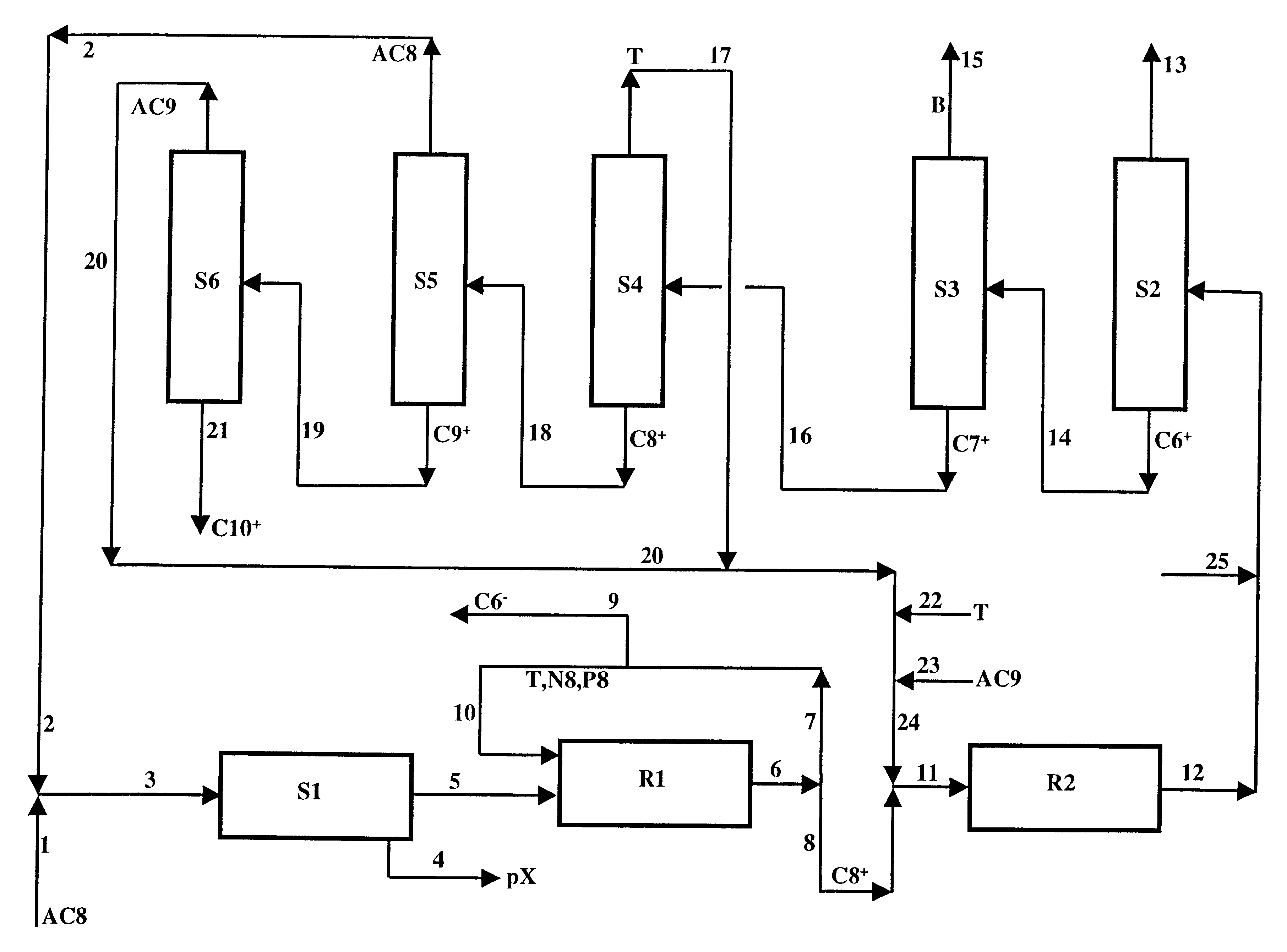

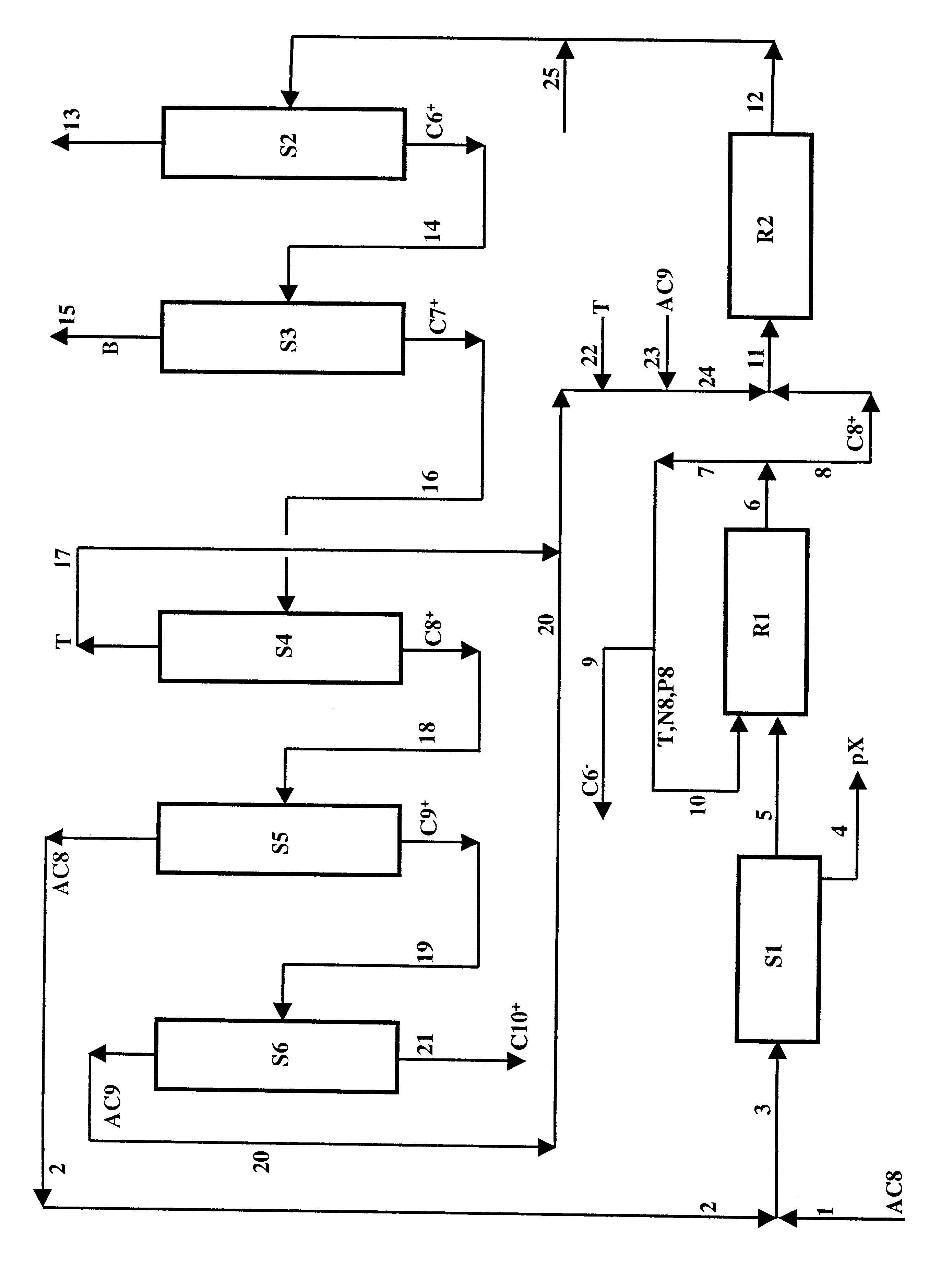

Process for the production of an isomer of xylenes in three stages: separation, isomerization in the presence of a catalyst based on an EUO zeolite and transalkylation

InactiveUS6528695B1Lower the volumeHigh purityHydrocarbon by isomerisationMolecular sieve catalystIsomerizationThree stage

The invention relates to a process for the production of at least one isomer of xylenes, preferably paraxylene, as well as benzene, starting from a C8-aromatic fraction, whereby said process comprises a zone for separation of xylenes, a zone for isomerization of aromatic compounds with 8 carbon atoms used in the presence of a catalyst that comprises at least one EUO-structural-type zeolite that is selected from among the EU-1, TPZ-3, ZSM-50 zeolites and at least one metal of group VIII of the periodic table, and finally a transalkylation zone of C7- and C9-aromatic compounds. The invention makes it possible to produce paraxylene and benzene with a high yield, starting from a C8-aromatic fraction that comprises a large amount of ethylbenzene with improved performance levels of the isomerization stage and a good conversion of ethylbenzene in the transalkylation stage.

Owner:INST FR DU PETROLE

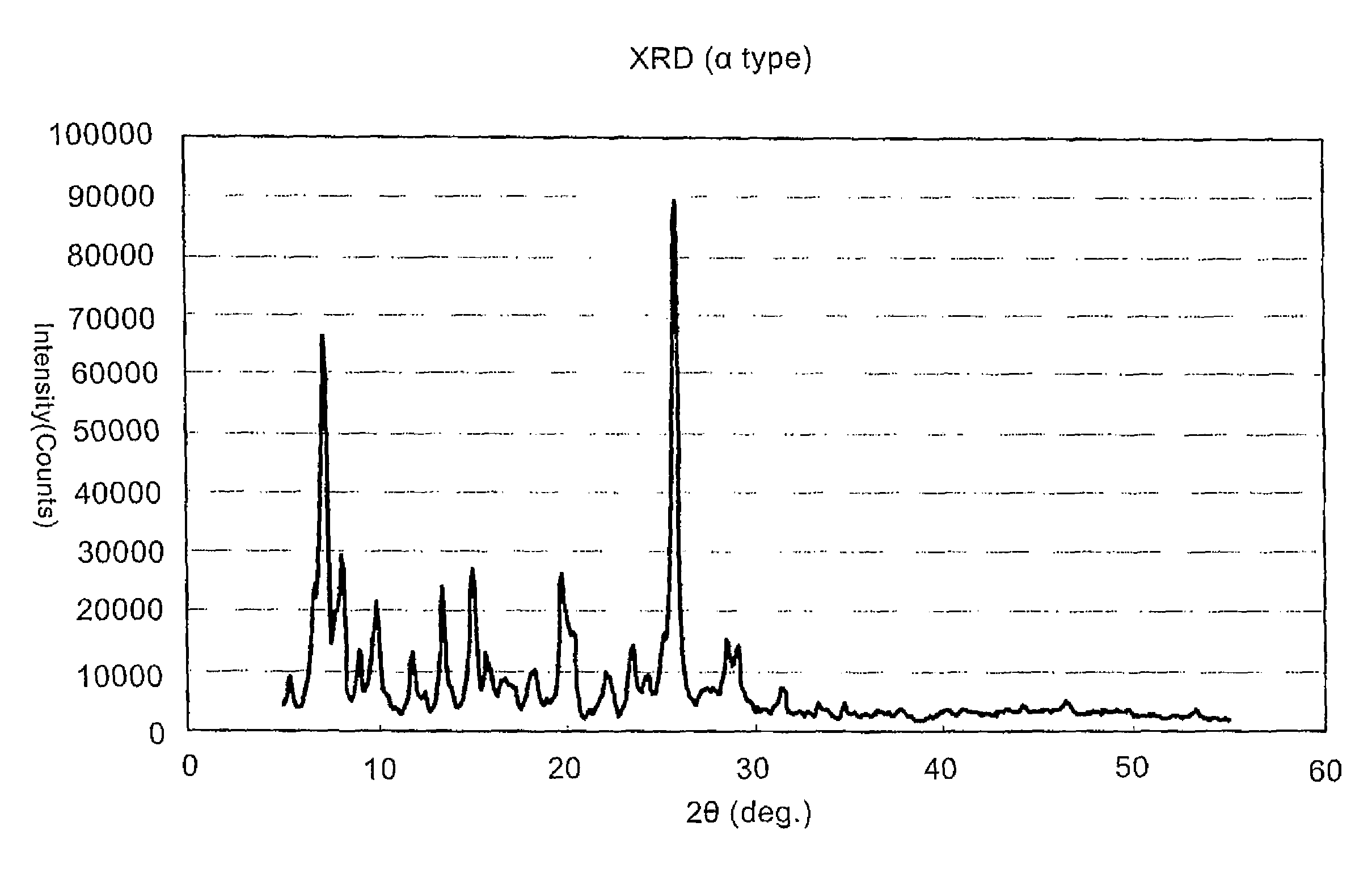

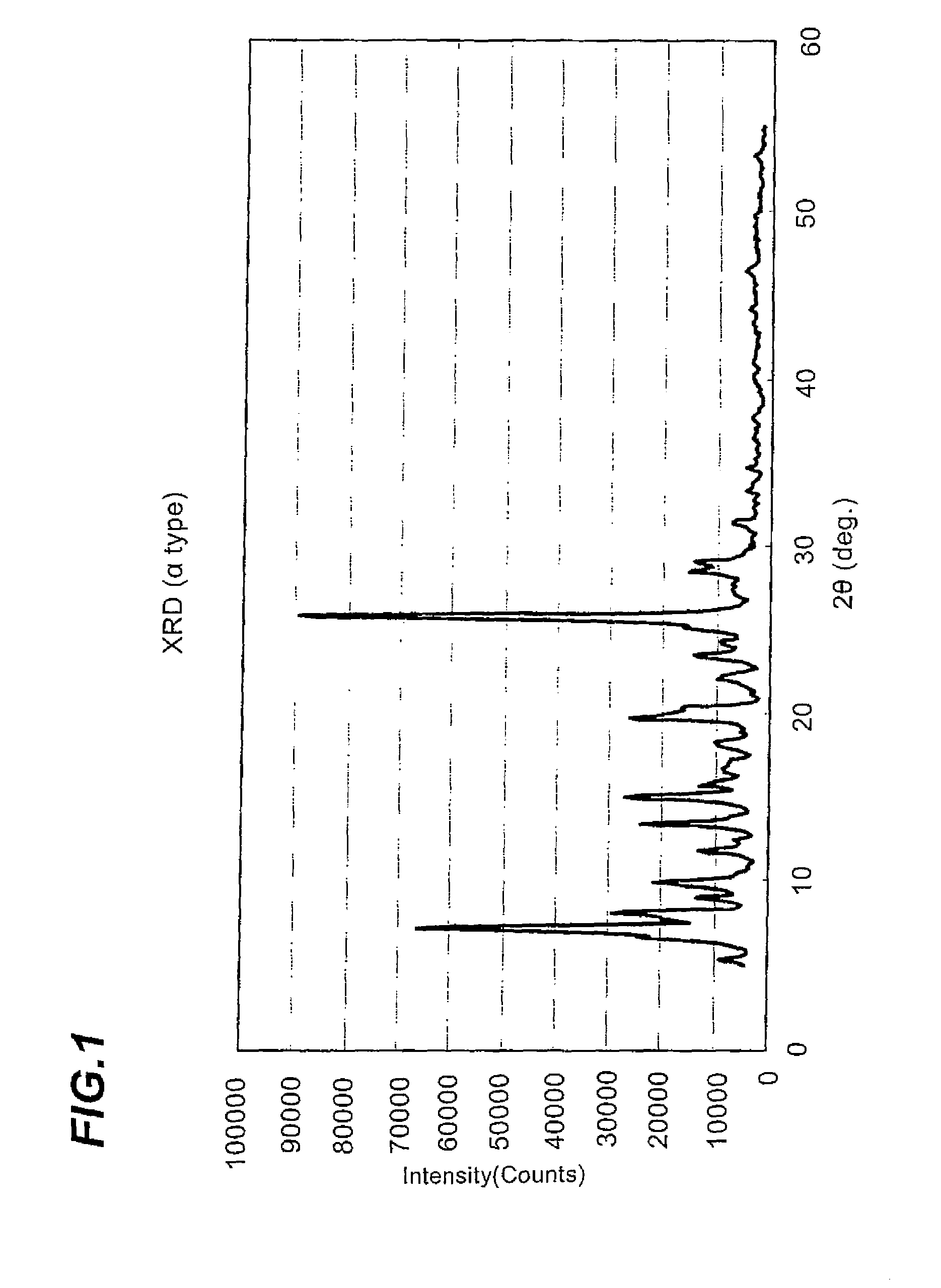

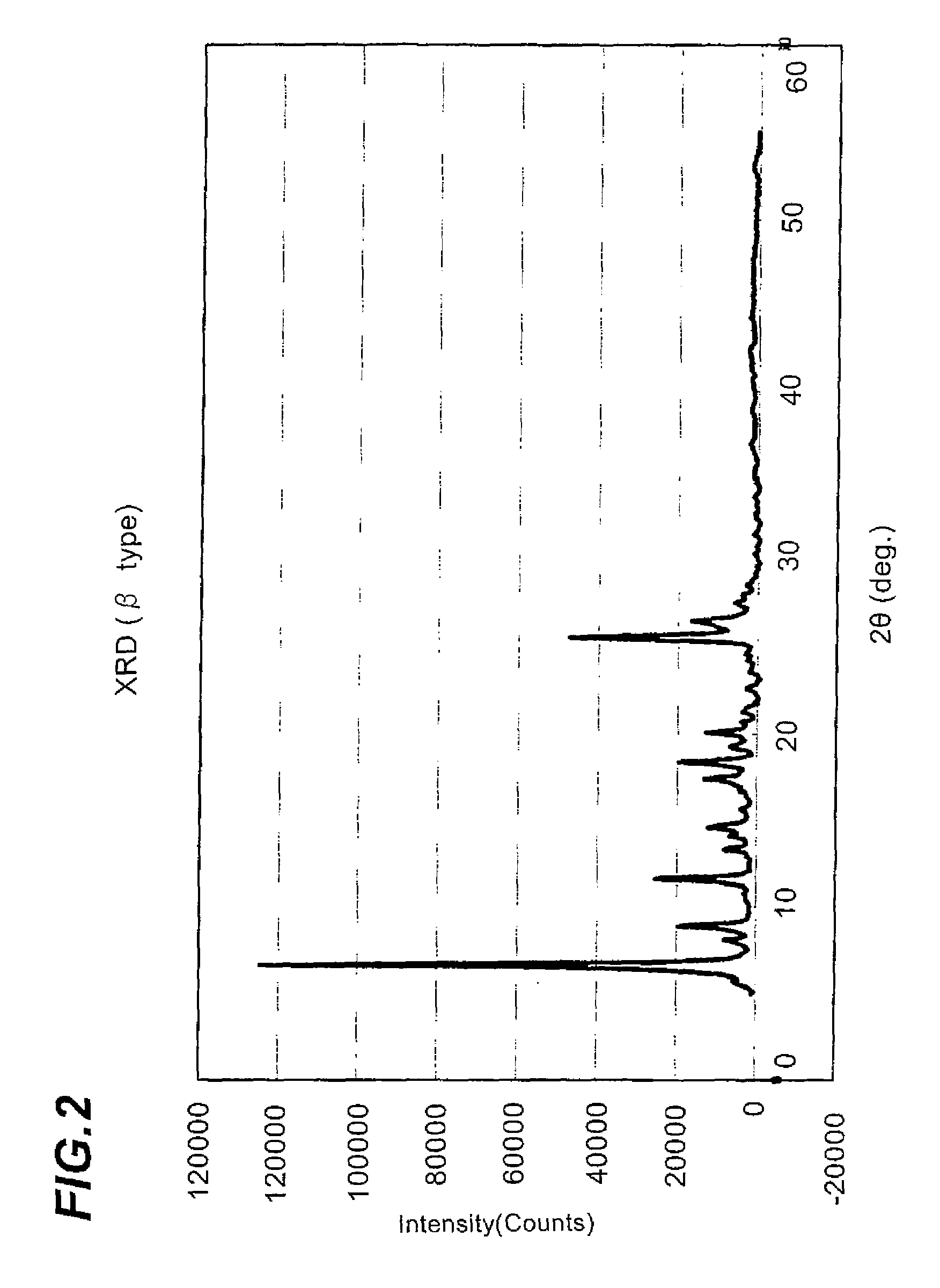

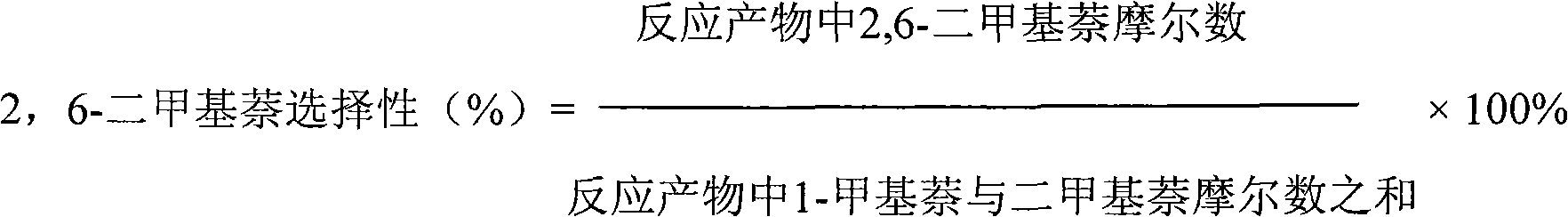

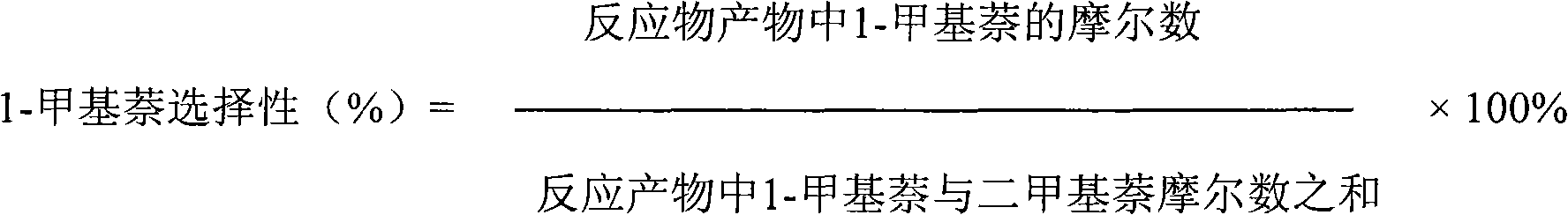

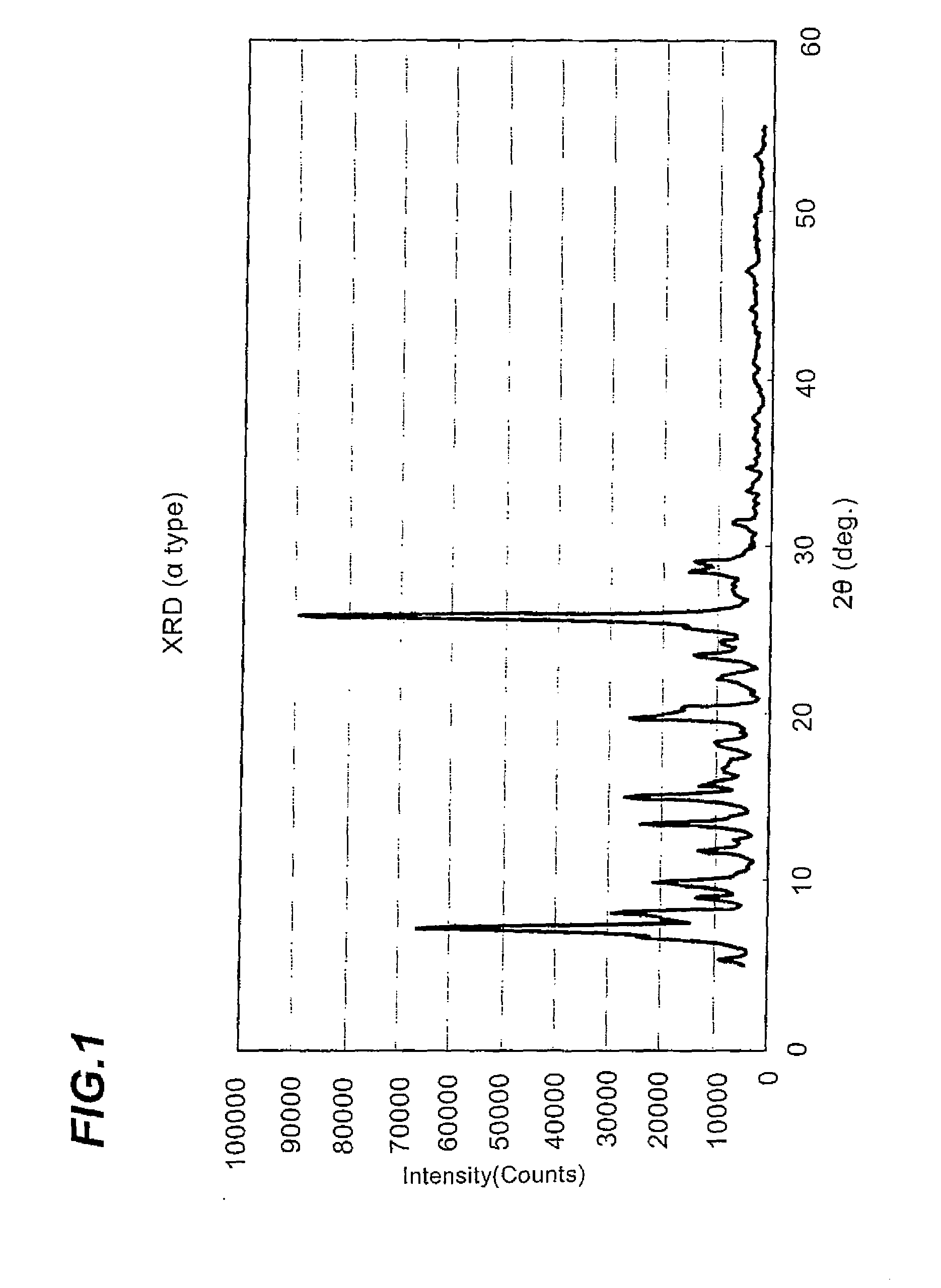

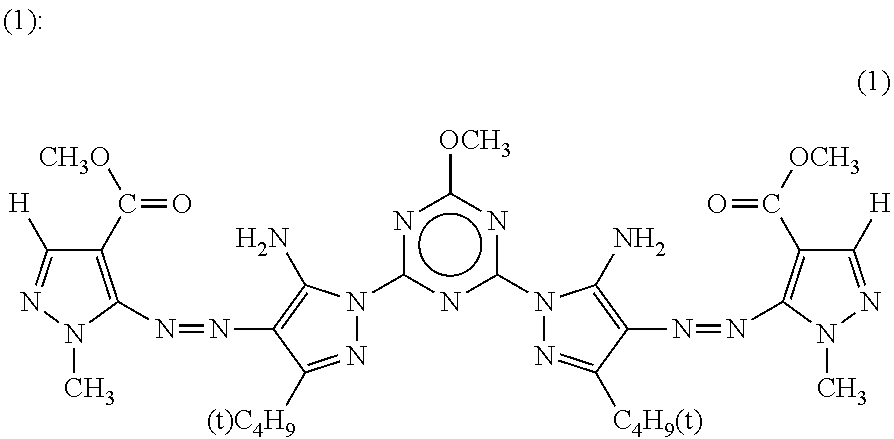

Azo pigment composition, process for producing azo pigment composition, dispersion containing azo pigment composition, coloring composition and ink for inkjet recording

ActiveUS8062383B2Good reproducibilityImprove efficiencyMonoazo dyesOrganic chemistryX-rayCharacteristic X-ray

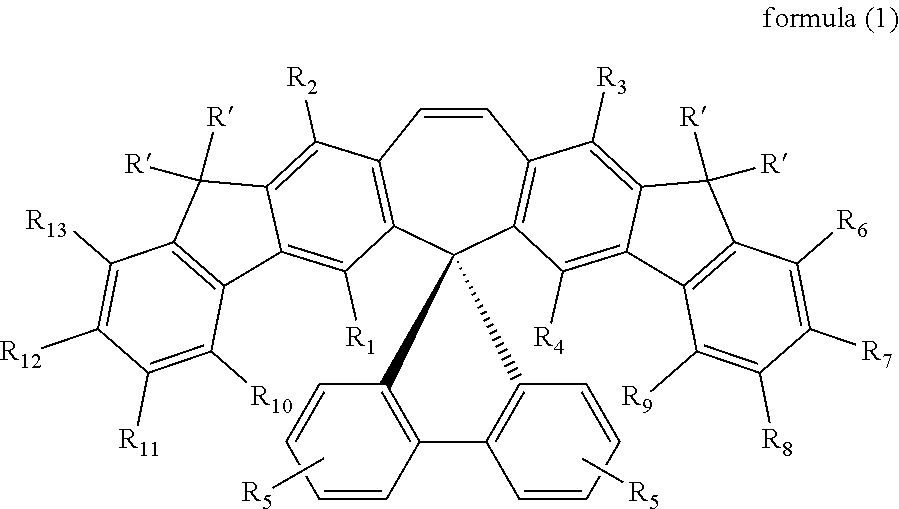

To provide an azo pigment composition having extremely good hue and extremely good light fastness and showing excellent tinctorial strength (color density) and, preferably, to provide an azo pigment composition further containing an azo pigment having characteristic X-ray diffraction peaks at different positions or a tautomer thereof An azo pigment composition which contains at least one azo pigment represented by the following formula (1) and having characteristic peaks at Bragg angles (20±0.2°) of 7.2° and 25.9° in X-ray diffraction with the characteristic Cu Kα line, or a tautomer thereof:.

Owner:FUJIFILM CORP

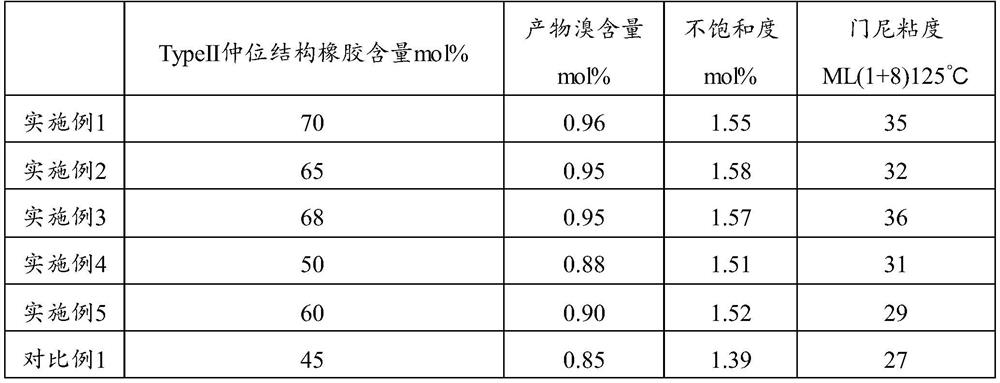

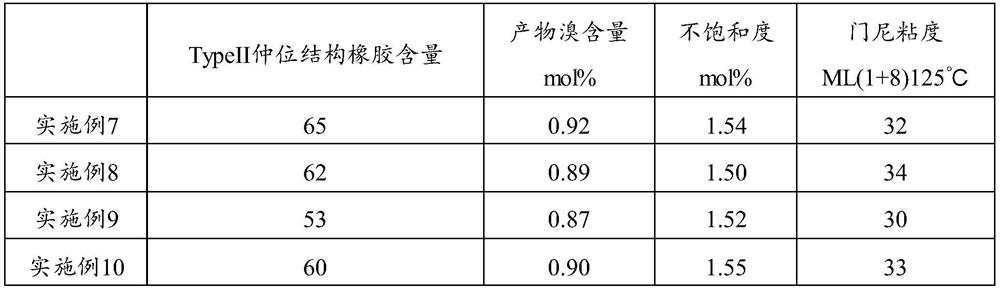

Bromination process of star-branched butyl rubber

The invention provides a bromination process of star-branched butyl rubber, which comprises the following steps: a) dissolving the star-branched butyl rubber in aliphatic hydrocarbon to obtain a rubber solution; b) mixing the glue solution with a branching agent capturing agent to obtain a mixed solution; c) performing bromination, neutralization and product recovery on the mixed solution to obtain brominated star-shaped branched butyl rubber, wherein the branching agent capturing agent is selected from one or more of ethanol, isopropanol, acetone, methyl ether, cyclohexane, dichloromethane, benzene and methylbenzene. The method is completed by dissolving star-shaped branched butyl rubber in aliphatic hydrocarbon, adding a certain amount of a branching agent capturing agent, adding an oxidant, and carrying out subsequent bromination, neutralization and product recovery; therefore, the residual branching agent in the star-branched butyl rubber can be dissolved before bromination, and isprevented from being combined with an HBr by-product generated in the bromination process, so that the neutralization efficiency is improved, and isomerization conversion from a Type II secondary structure to a Type III primary structure is inhibited.

Owner:山东京博中聚新材料有限公司

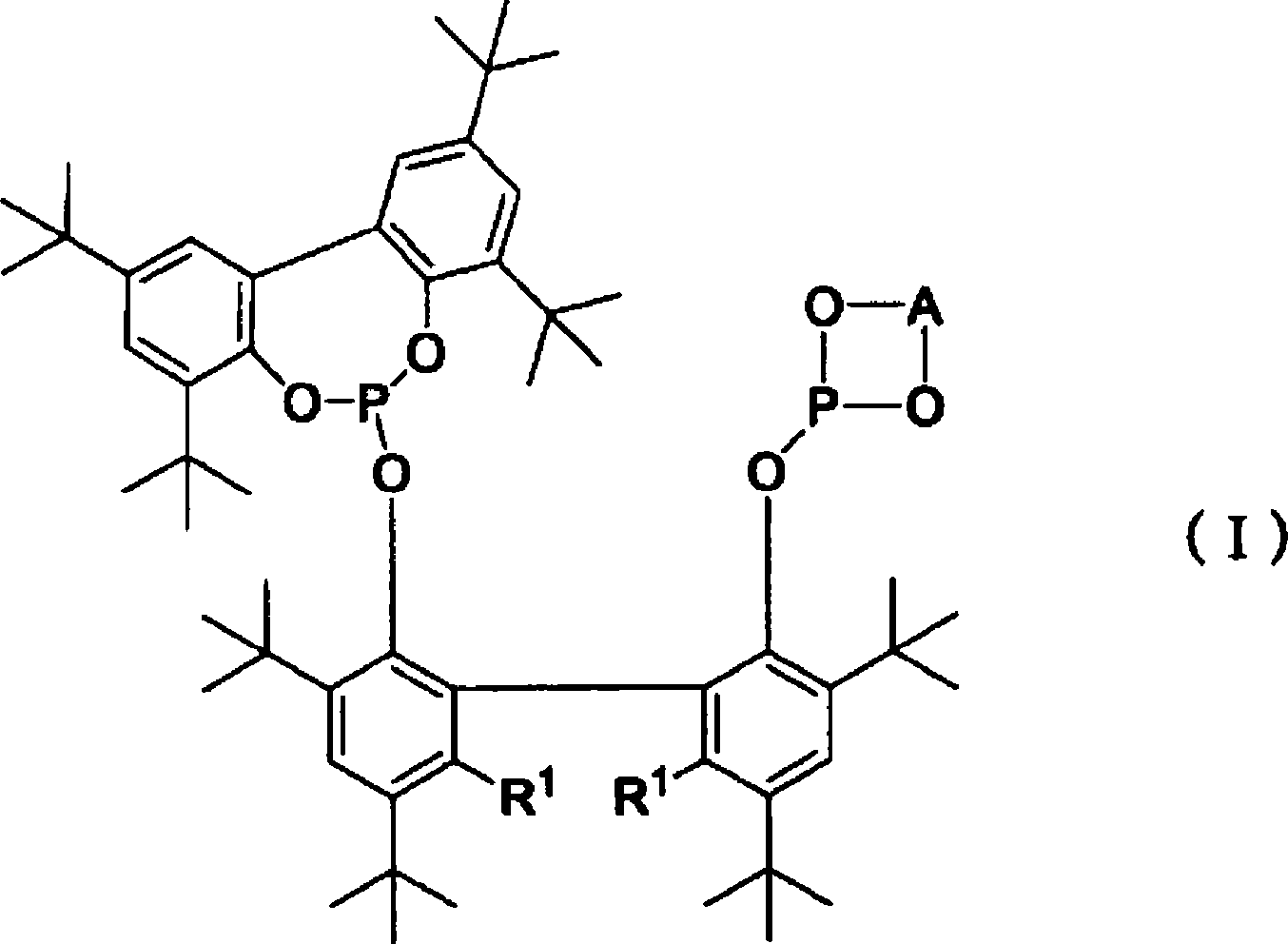

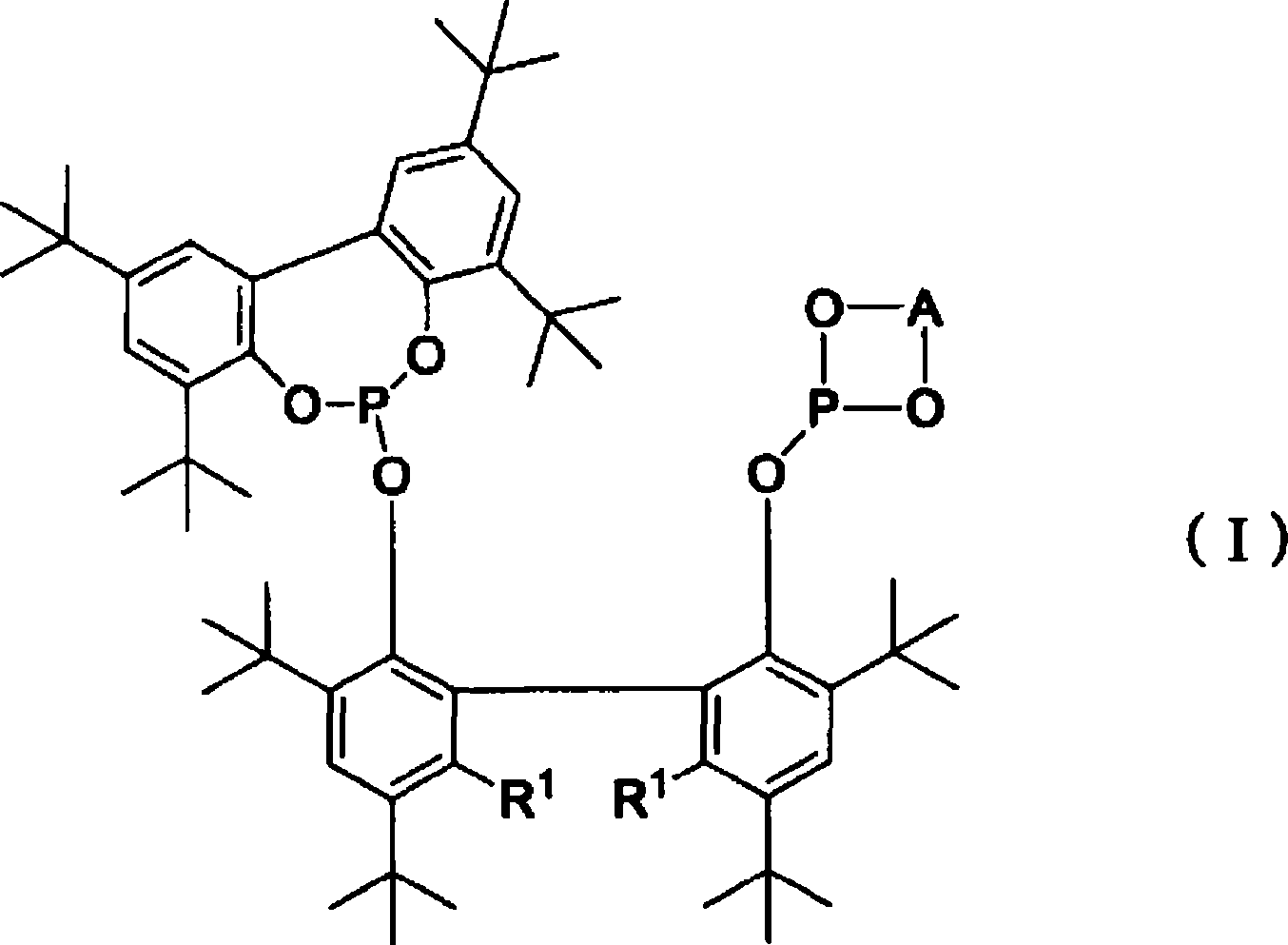

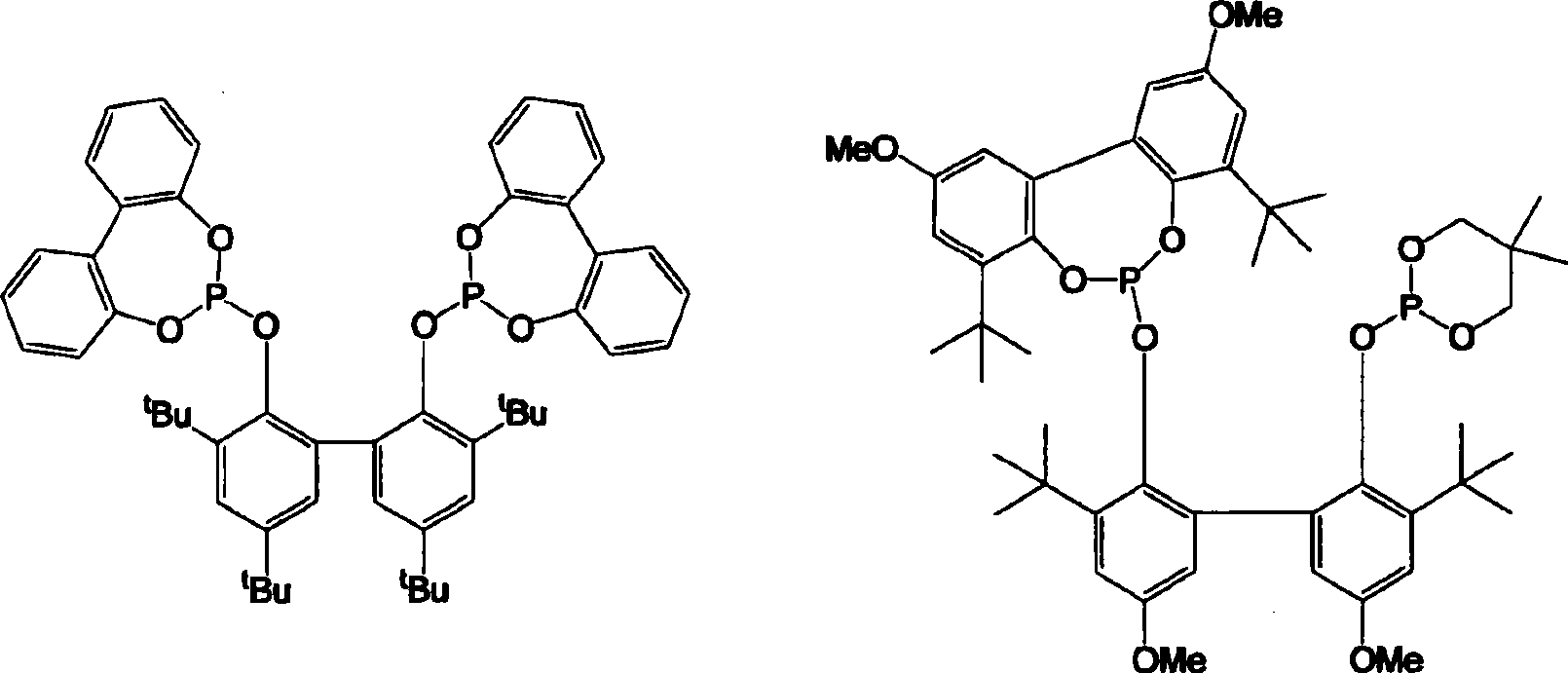

Method for producing aldehyde using bisphosphite and group 8-10 metal compound, and such bisphosphite

ActiveCN101415717AInhibition of isomerizationImprove water resistanceGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenHydrogen atom

Disclosed is a bisphosphite represented by the following general formula (I). Also disclosed is a method for producing an aldehyde, which is characterized in that a nonconjugated diene with 6-20 carbon atoms which has a carbon-carbon double bond at an end of the molecule is reacted with carbon monoxide and hydrogen in the presence of the bisphosphite and a group 8-10 metal compound. In the formula, A represents an optionally substituted alkylene group, an optionally substituted cycloalkylene group, an optionally substituted phenylene group or an optionally substituted naphthylene group; and R<1> represents a hydrogen atom or an alkyl group.

Owner:KURARAY CO LTD

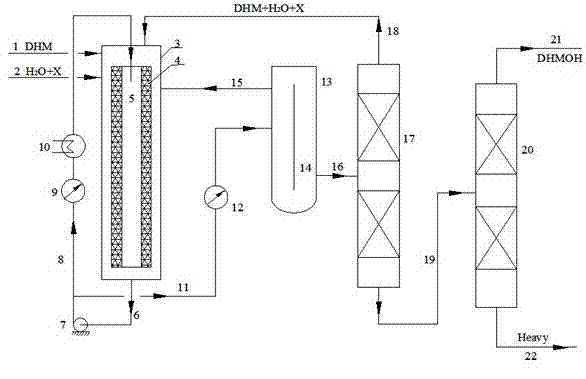

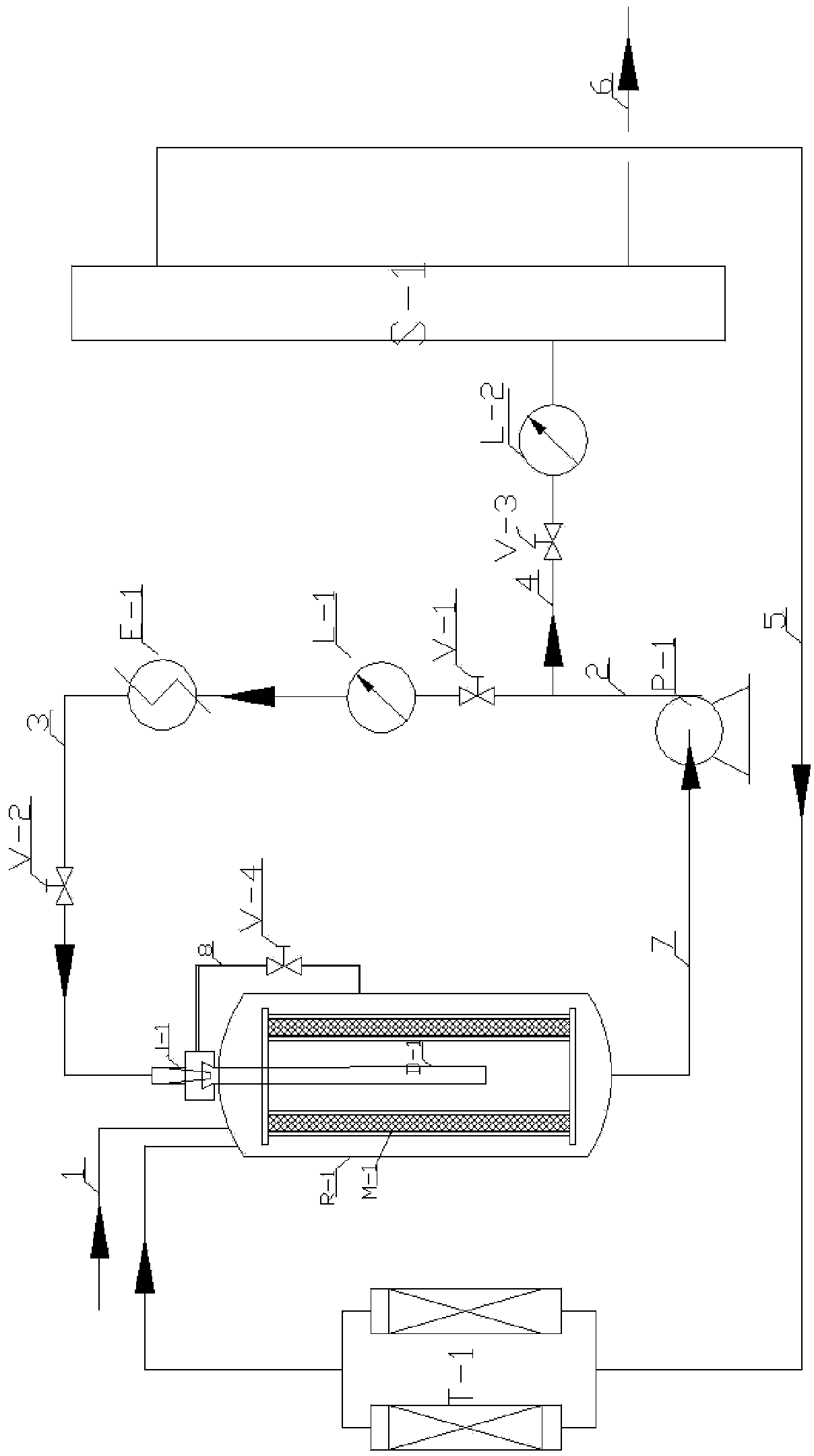

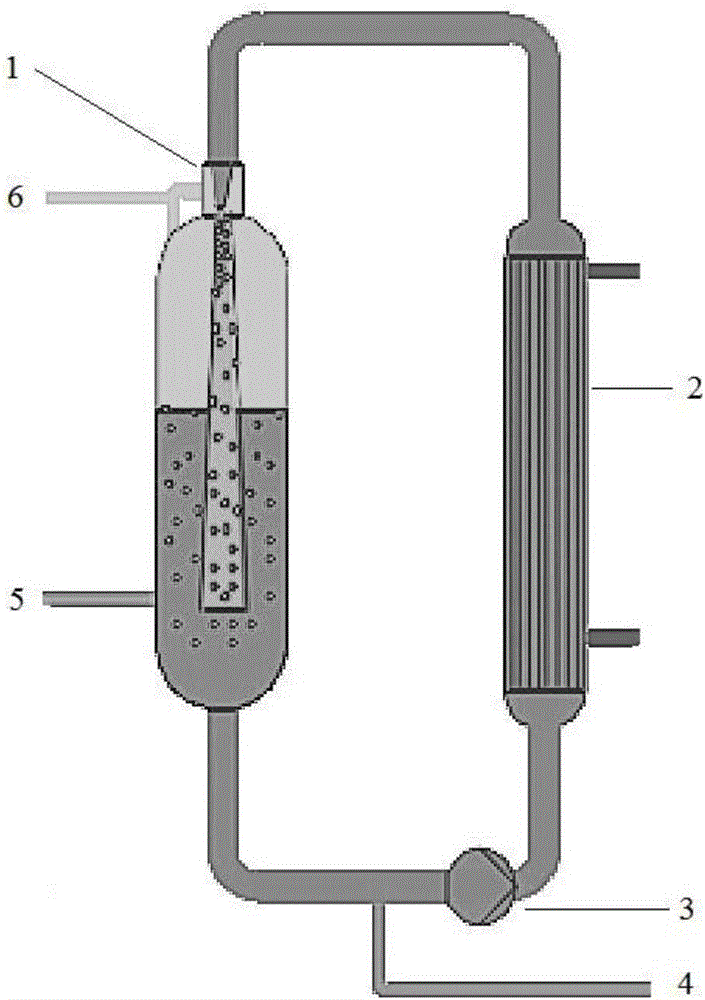

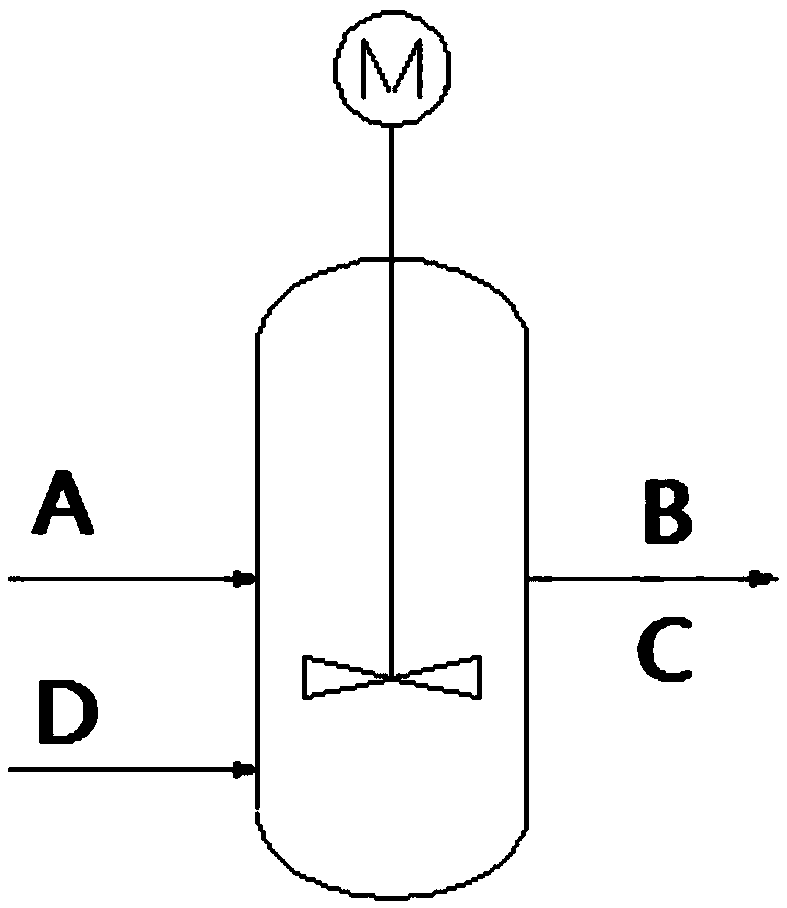

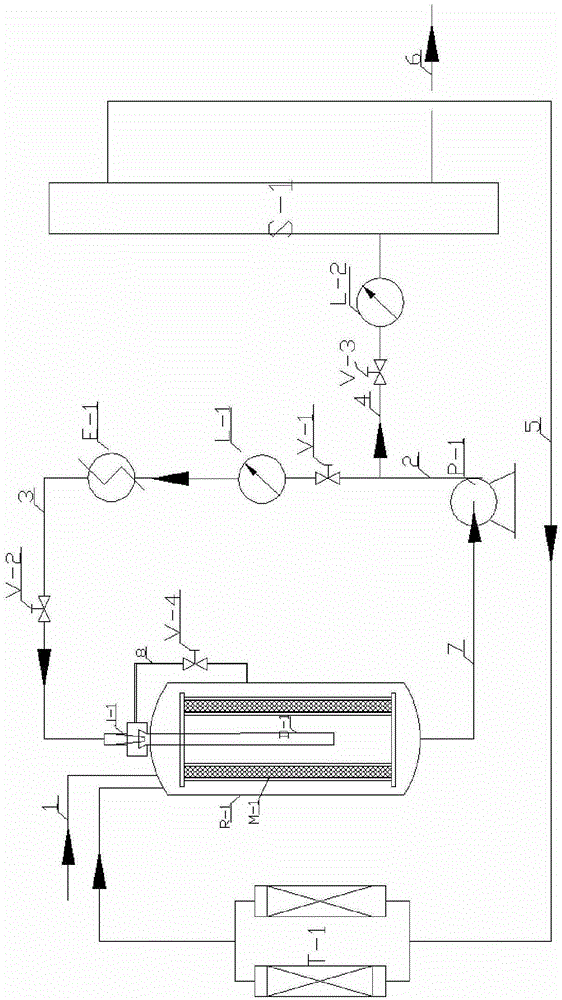

Production method of dihydromyrcenol

ActiveCN102964215AMild reaction conditionsLower operating temperaturePreparation by hydroxy group additionChemical/physical processesPtru catalystPhysical chemistry

The invention provides a production method of a dihydromyrcenol. The technological processes are shown as the figure and carried out through the following step of: introducing dihydromyrcenol (hereafter referred to as DHM), water and a low-viscosity organic solvent X via a DHM feed pipe 1 and a water and solvent input pipe2 into a forced circulation radiation flow fixed bed (hereafter referred to as IRRFB) reactor 3. The pressure in the reactor is 0.12-0.28MPa; the IRRFB reactor 3 is provided with a barrel-shaped housing; a centre pipe 5 with two sealed ends and apertures covered on a side wall is arranged in the housing; and a catalyst fixed bed layer 4 made of metal nets and filled with catalysts is arranged outside the centre pipe 5. A reaction solution is pumped into the centre pipe 5, is introduced into the catalyst fixed bed layer 4 at a high speed in a radiation manner via the apertures on the side wall, penetrates through the catalyst fixed bed layer 4 to enter the housing of the reactor 3 and carries out a next round of circulation via a first pipeline 6 at the bottom. Firstly, oil and water are separated in a reacted liquid and a product is rectified twice, so that a product with a purity of 99.61% is obtained; and the once conversion rate is 10.6%, and the selectivity is 98.1%.

Owner:NANJING ENETEKS

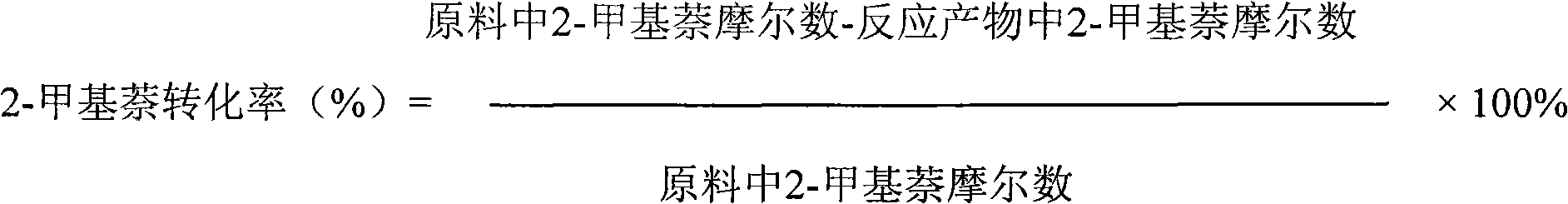

Catalyst used for alkylation of methanol, C10 aromatic hydrocarbons and 2-methylnaphthalene for synthesizing 2,6-dimethylnaphthalene

InactiveCN101972667AHigh catalytic activity for alkylationInhibition of isomerizationMolecular sieve catalystsHydrocarbons2-methylnaphthaleneOxide

The invention relates to a catalyst used for alkylation of methanol, C10 aromatic hydrocarbons and 2-methylnaphthalene for synthesizing 2,6-dimethylnaphthalene, and mainly solves the problems of low conversion rate of the 2-methylnaphthalene, low selectivity of the 2,6-dimethylnaphthalene and low stability of the catalyst in the conventional synthesis process technology. In the technical scheme of the invention, the catalyst comprises the following components in part by weight: 50 to 95 parts of one or a mixture of any two of hydrogen-type silicon-aluminum zeolites, 5 to 50 parts of binder and 1.0 to 15 parts of metal oxide of at least one of transition metal, rare-earth metal and alkaline-earth metal; and the reaction conditions for synthesizing the 2,6-dimethylnaphthalene are that: temperature is between 360 and 500 DEG C, pressure is between 0 and 7.5MPa, the molar ratio of the methanol to the 2-methylnaphthalene is between 1.0 and 3.0, the weight ratio of the C10 aromatic hydrocarbons to the 2-methylnaphthalene is between 1.0 and 6.0, and air speed is between 0.1 and 3.5 hour<-1>. The catalytic reaction ensures relatively high synthesis yield of the 2,6-dimethylnaphthalene, and the problems in the prior art are well solved.

Owner:TONGJI UNIV

Fat producing method

InactiveUS20050145475A1Inhibition of isomerizationFatty oils/acids recovery from wasteFatty acid esterificationIsomerizationDistillation

A method for producing a fat by distillation and purification while preventing isomerization. The distillation and purification is conducted under an acidic condition to prevent isomerization.

Owner:FUJI OIL CO LTD

Azo pigment composition, process for producing azo pigment composition, dispersion containing azo pigment composition, coloring composition and ink for inkjet recording

ActiveUS20110023753A1High tinting strengthGood dispersibilityMonoazo dyesDisazo dyesPhotopigmentLightfastness

To provide an azo pigment composition having extremely good hue and extremely good light fastness and showing excellent tinctorial strength (color density) and, preferably, to provide an azo pigment composition further containing an azo pigment having characteristic X-ray diffraction peaks at different positions or a tautomer thereof.An azo pigment composition which contains at least one azo pigment represented by the following formula (1) and having characteristic peaks at Bragg angles (2θ±0.2°) of 7.2° and 25.9° in X-ray diffraction with the characteristic Cu Kα line, or a tautomer thereof:

Owner:FUJIFILM CORP

Production method for preparing high-purity lutein crystal from marigold extract

InactiveCN108191730AReduce the impactAvoid complexityOrganic chemistry methodsBulk chemical productionChemistrySoftened water

The invention relates to the field of production technology researches of natural pigments and in particular relates to a production method for preparing a high-purity lutein crystal from marigold extract. The production method comprises the following steps: adding the marigold extract into a super-critical CO2 extraction tank; carrying out extraction and separation to obtain a raw solution I; adding the raw solution I into a saponification tank containing a saponification solution and stirring until saponification is completely finished, so as to obtain a saponified product I; adding the saponified product I into a stainless steel tank; firstly, adding softened water for washing; then leading a mixed solution into a centrifugal machine and carrying out various times of separation until noliquid is spun out; collecting to obtain a material II; putting the material II into the stainless steel tank and adding a certain amount of absolute ethyl alcohol; stirring until the material and the absolute ethyl alcohol are uniformly mixed, and stopping stirring; standing and recrystallizing at room temperature; leading a crystallized solution into the centrifugal machine and carrying out solid-liquid separation to obtain the lutein crystal; scrapping the lutein crystal into a stainless steel disc; after uniformly dispersing, putting the lutein crystal into a vacuum drying box and dryingto obtain a lutein crystal finished product. According to the production method provided by the invention, the conversion rate from lutein ester to free-state lutein can be effectively improved, and oxidization and isomerization of the free-state lutein are inhibited.

Owner:邯郸市美康生物科技有限公司

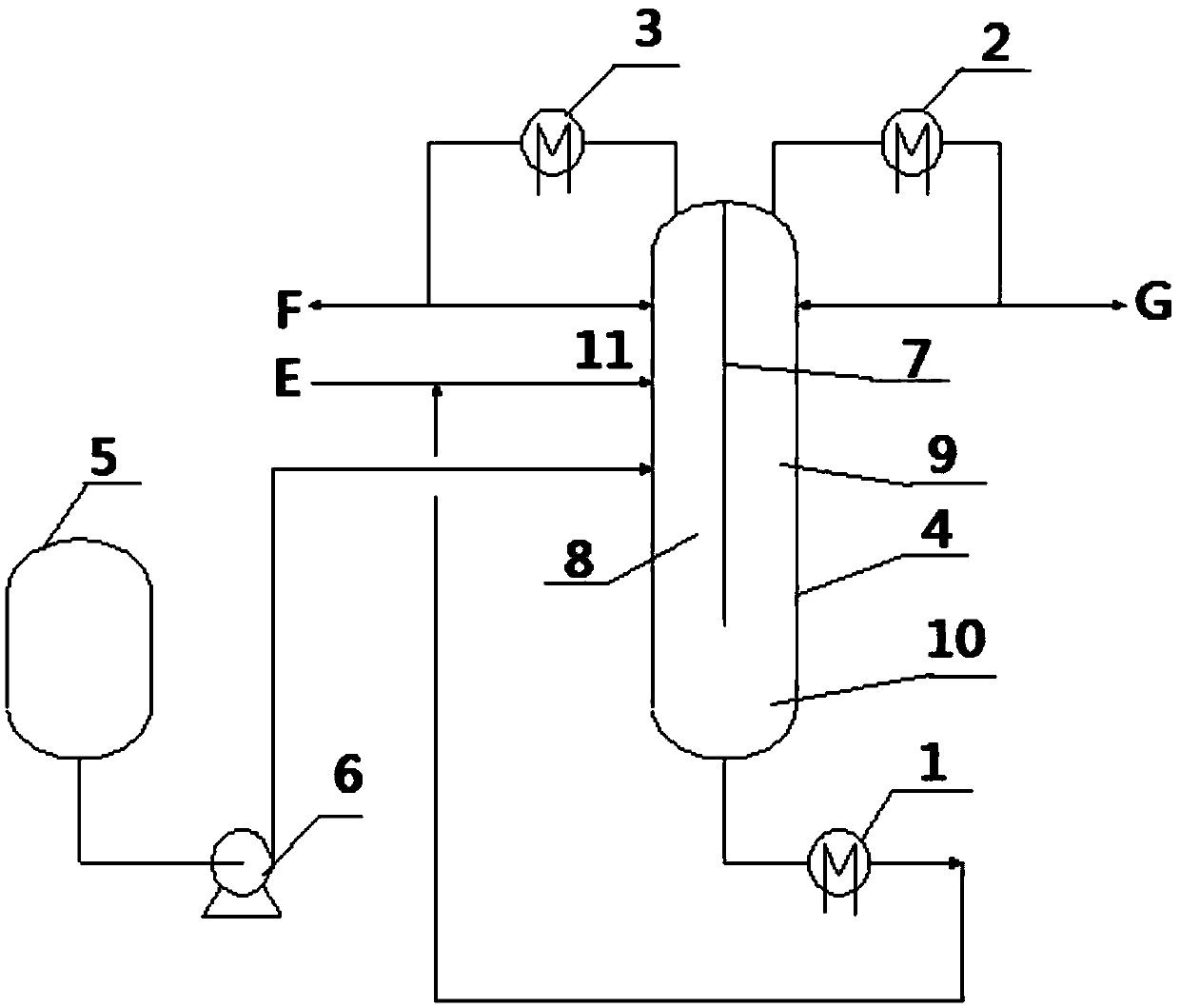

Isoborneol production method

ActiveCN103739447AHydration reaction conditions are mildHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionHydration reactionReaction temperature

The invention provides an isoborneol production method which is carried out in a reinforced radial flow reaction system (IRR) composed of a liquid flow reinforced immersed fixed bed reactor. The isoborneol production method comprises the following steps: mixing the raw materials and a composite solvent by adopting a certain quantity of composite solid acid catalyst according to a certain ratio, wherein camphene and water are used as the raw materials; carrying out hydration reaction in an IRR reaction-separation system to obtain an isoborneol product. The reaction temperature is 40-90 DEG C, the mass of the catalyst is 15-50% of the total mass of the firstly-filled liquid material, the ratio of the camphene to the water to the composite solvent is 1:(0.15-2):(0.5-4), the reaction pressure is 0.1-0.3MPa, and the reaction standing time is 40-70min. After the reacted materials are separated and subjected to ion exchange, the solvent and the unreacted materials are returned to the reactor, and the product is stored. The isoborneol production method has the advantages that the industrial reliability is good, the per-pass conversion rate of the camphene is high, the isoborneol is good in selectivity, and the energy consumption per unit product is only about 60% of that of the traditional fixed bed process.

Owner:NANJING ENETEKS +1

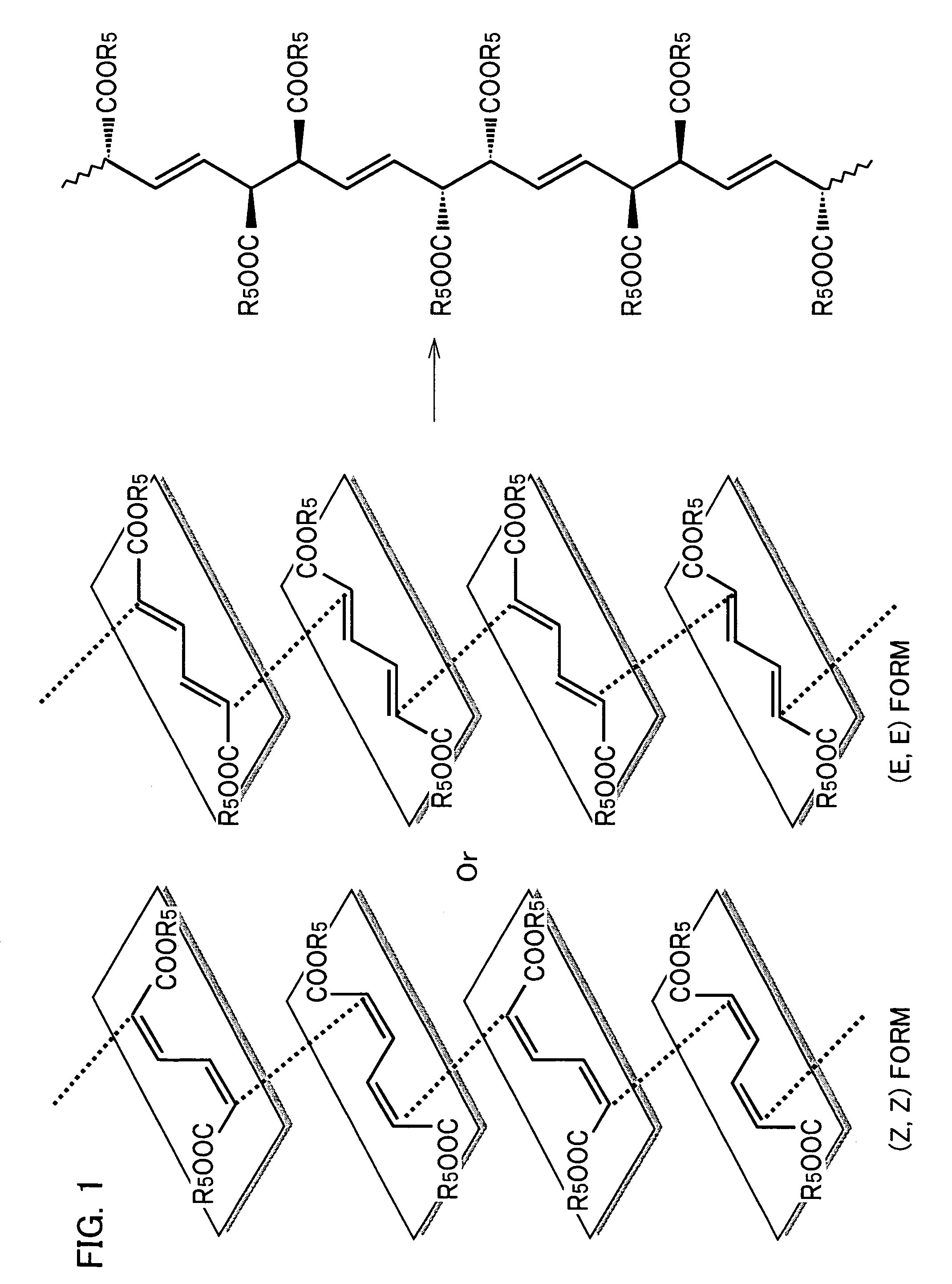

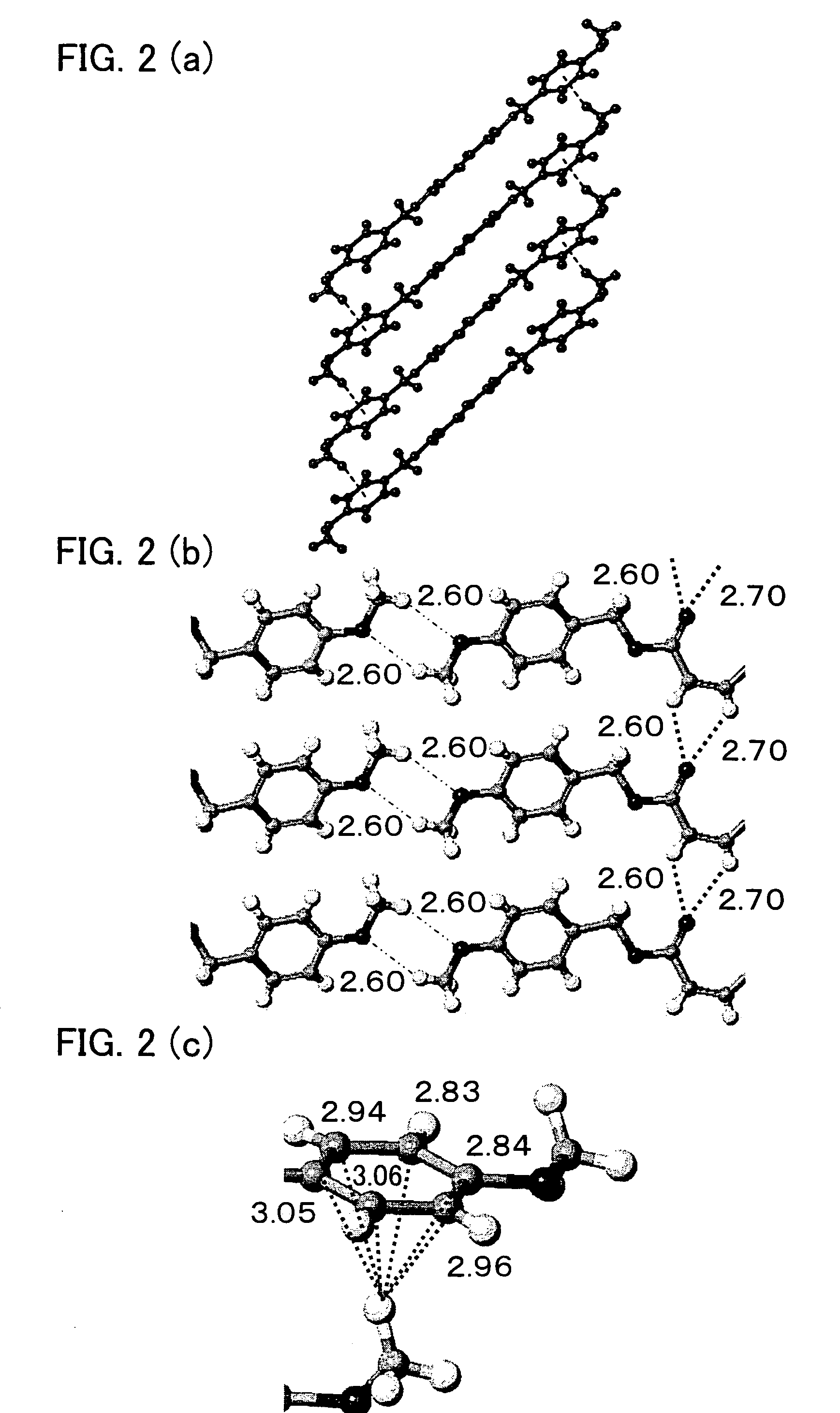

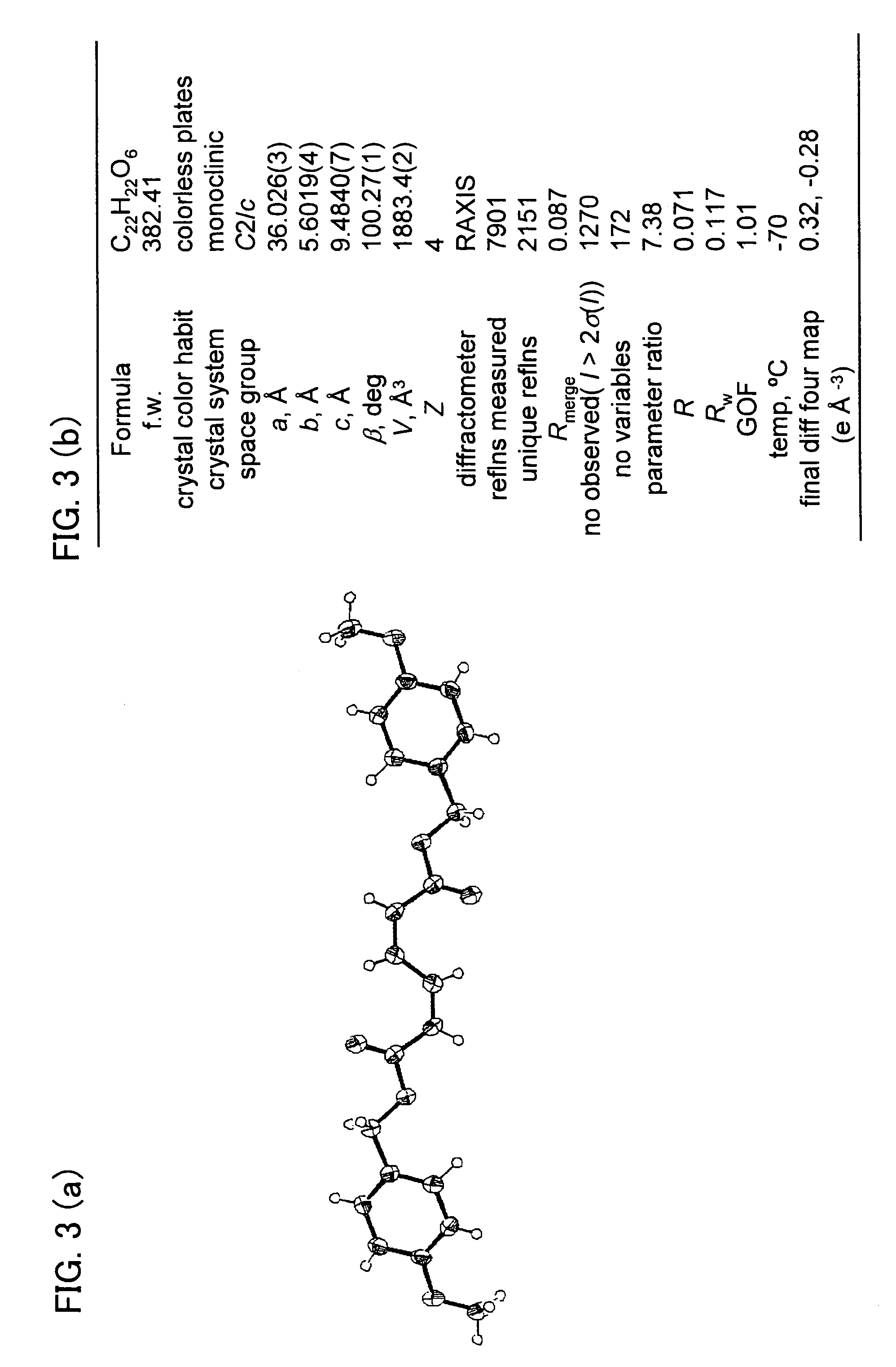

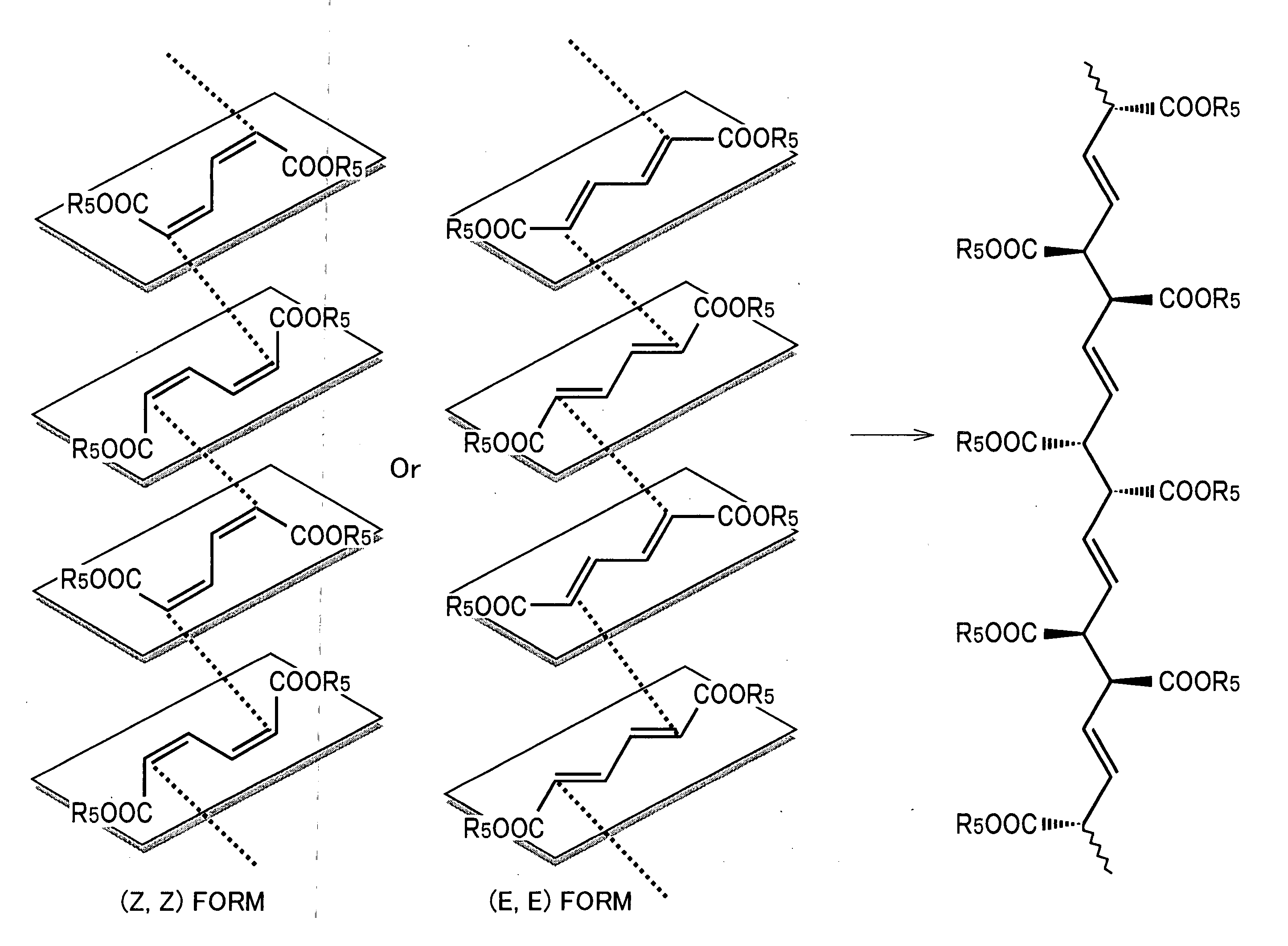

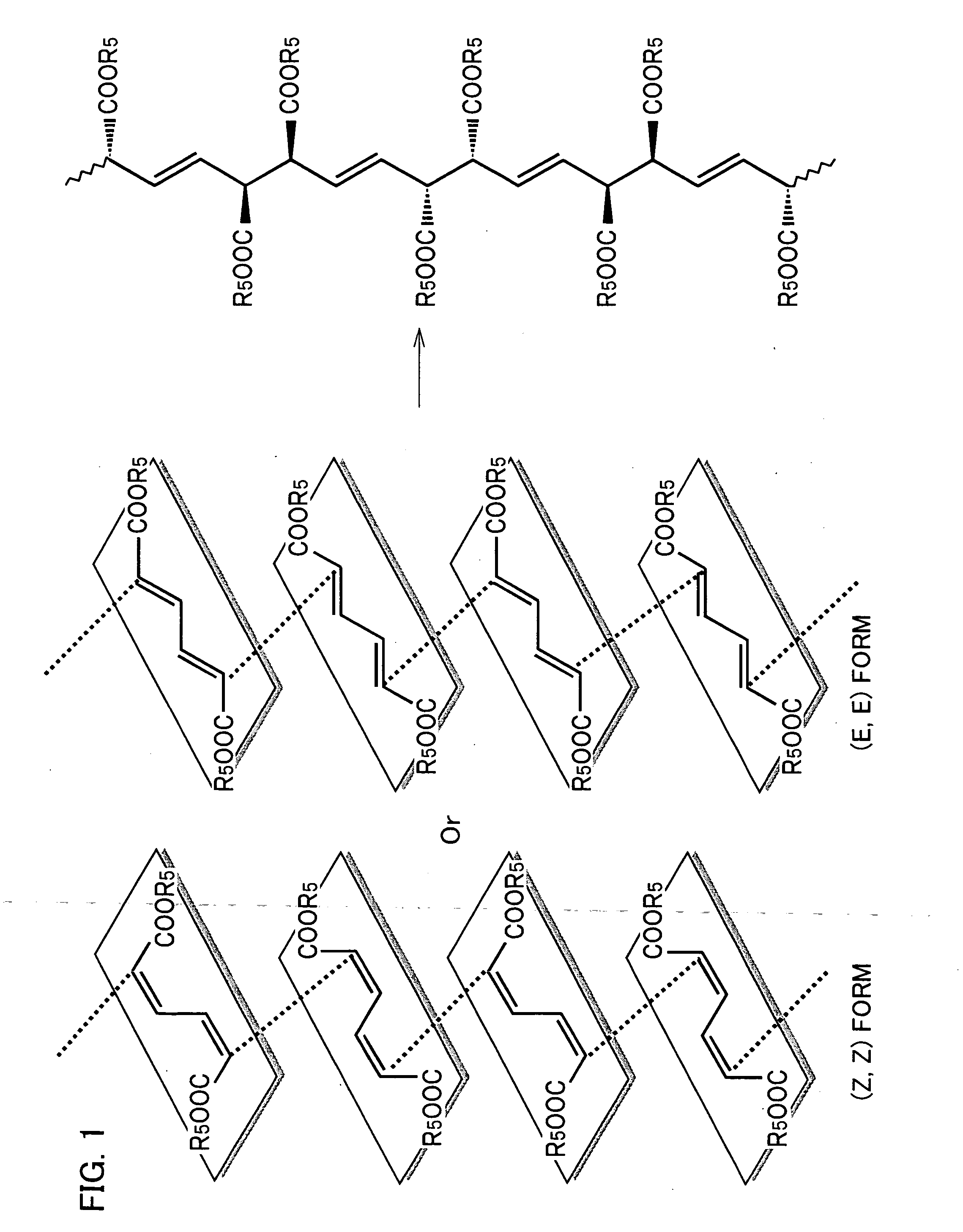

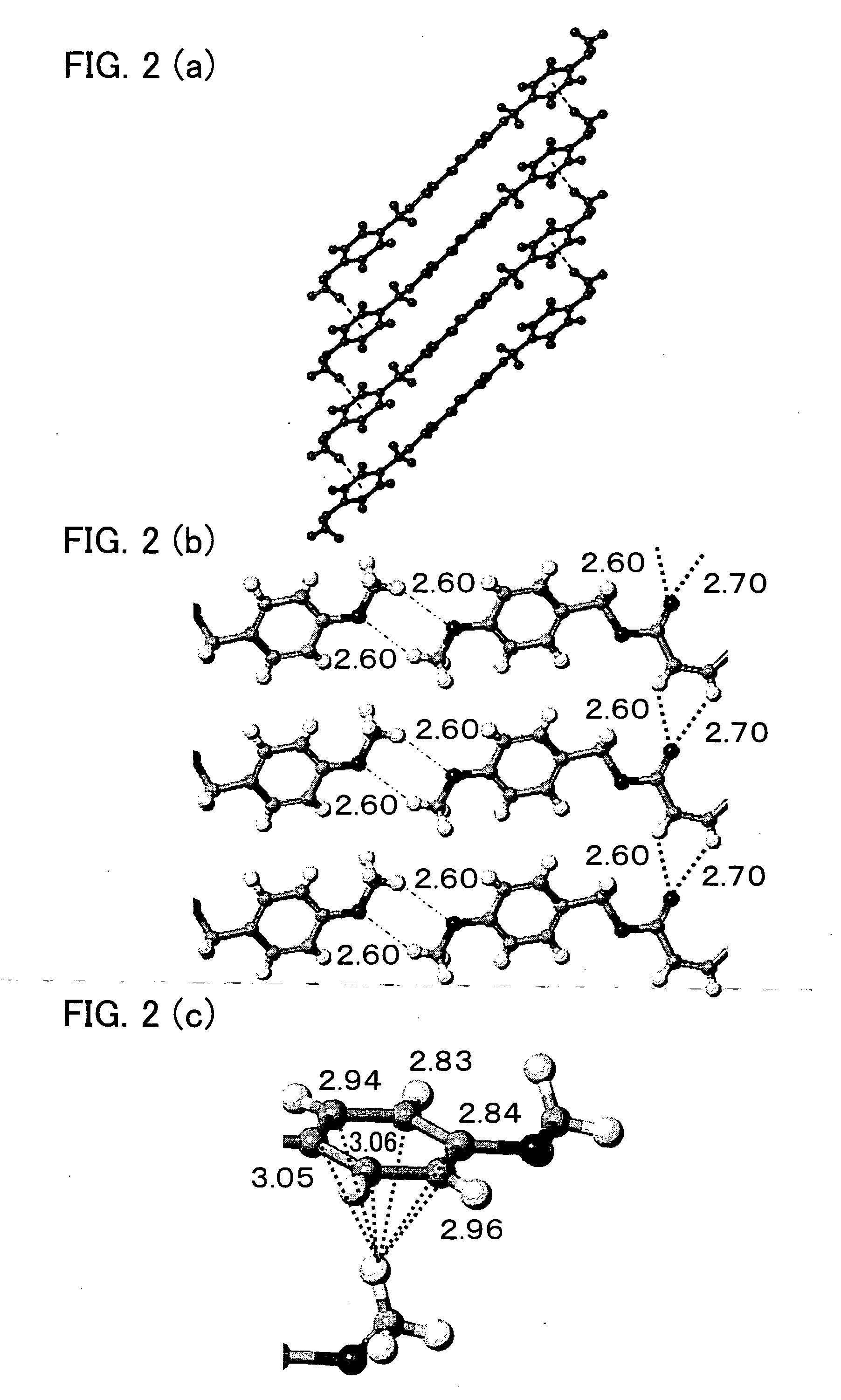

Stereoregular polymer and monomer thereof and process for production of both

InactiveUS7388064B2Increase elasticityIncrease resistanceOrganic compound preparationCarboxylic acid esters preparationLight irradiationCrystal structure

An ester derivant having a crystal structure in which the molecules in two adjacent molecule planes are antiparallel is created from a carboxylic acid having carbon-carbon double bond and a compound having a functional group that can react to a carboxyl group of the carboxylic acid. The crystal of the ester derivant is then subjected to light irradiation or heating.

Owner:JAPAN SCI & TECH CORP

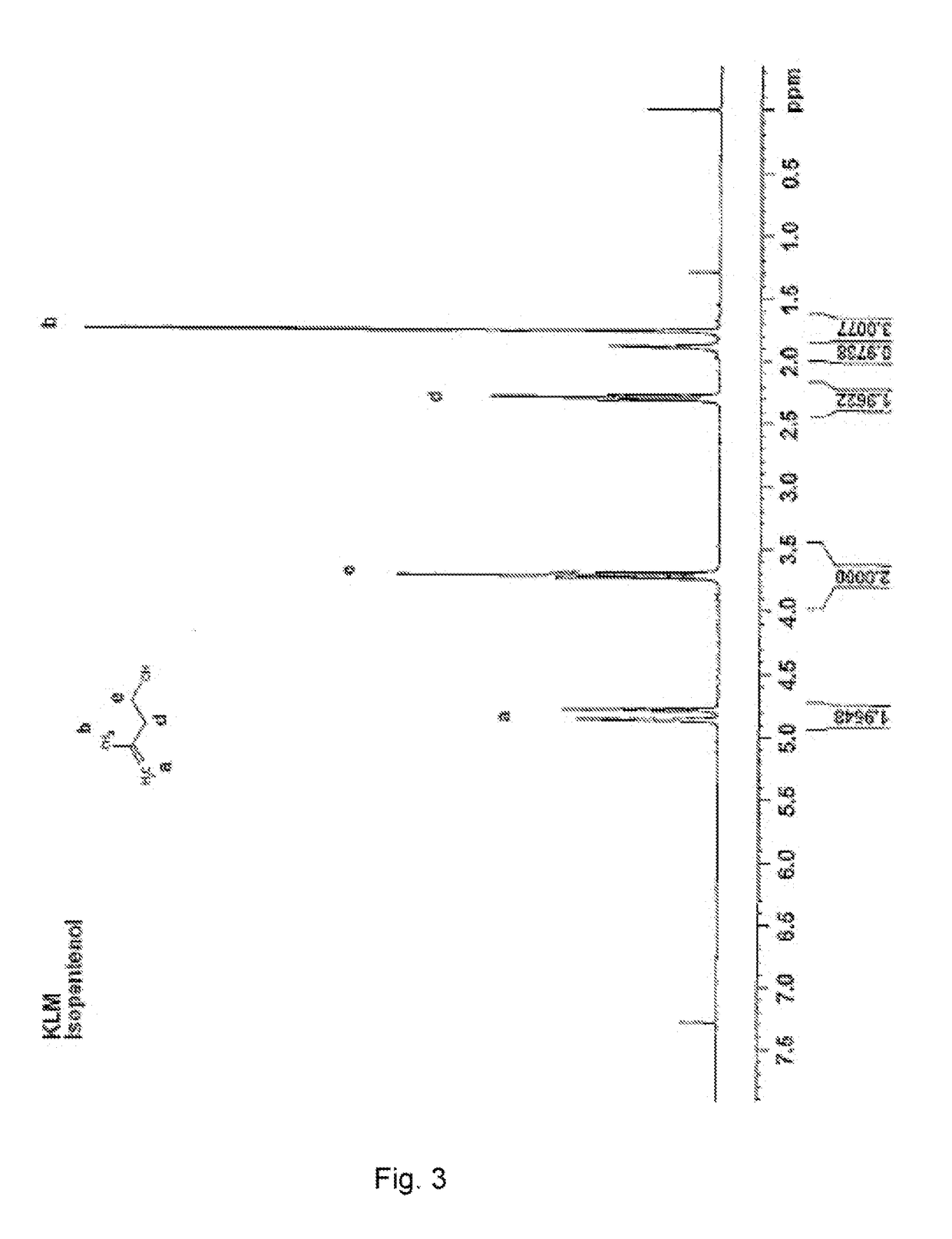

Novel method for terminating allyl alcohol irregular polyether methyl

InactiveCN106565949AIncrease mass transfer rateIncreased mass transfer rates over conventional stirred tank reactorsEther preparation by ester reactionsIsomerizationKinetic control

The invention discloses a novel method for terminating allyl alcohol irregular polyether methyl. The novel method comprises the following steps of: adding allyl alcohol irregular polyether raw materials through a material inlet in a jetting loop reactor based on Venturi effect, deoxidizing and introducing inert gases for replacement and protection, and starting an external circulating pump to carry out high-speed jetting mixing; and at a control temperature ranging from 20 DEG C to 70 DEG C, slowly adding a methane chloride raw material and an alkali raw material into the jetting loop reactor through a methane chloride raw material feeding hole and a material feeding hole separately, and the like. According to the novel method disclosed by the invention, this system belongs to a dynamic control system, side reactions are restrained sufficiently, a low-temperature method is further adopted to carry out dynamic reaction control according to the characteristic that activation energy of side reactions is high, hydrolysis reaction of methane chloride is restrained, and isomerization reaction of allyl is further restrained, and therefore, selectivity of a reaction system is higher. Finally obtained allyl alcohol irregular polyether methyl terminated product has color and luster smaller than 30, and has a terminating rate greater than 98%.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

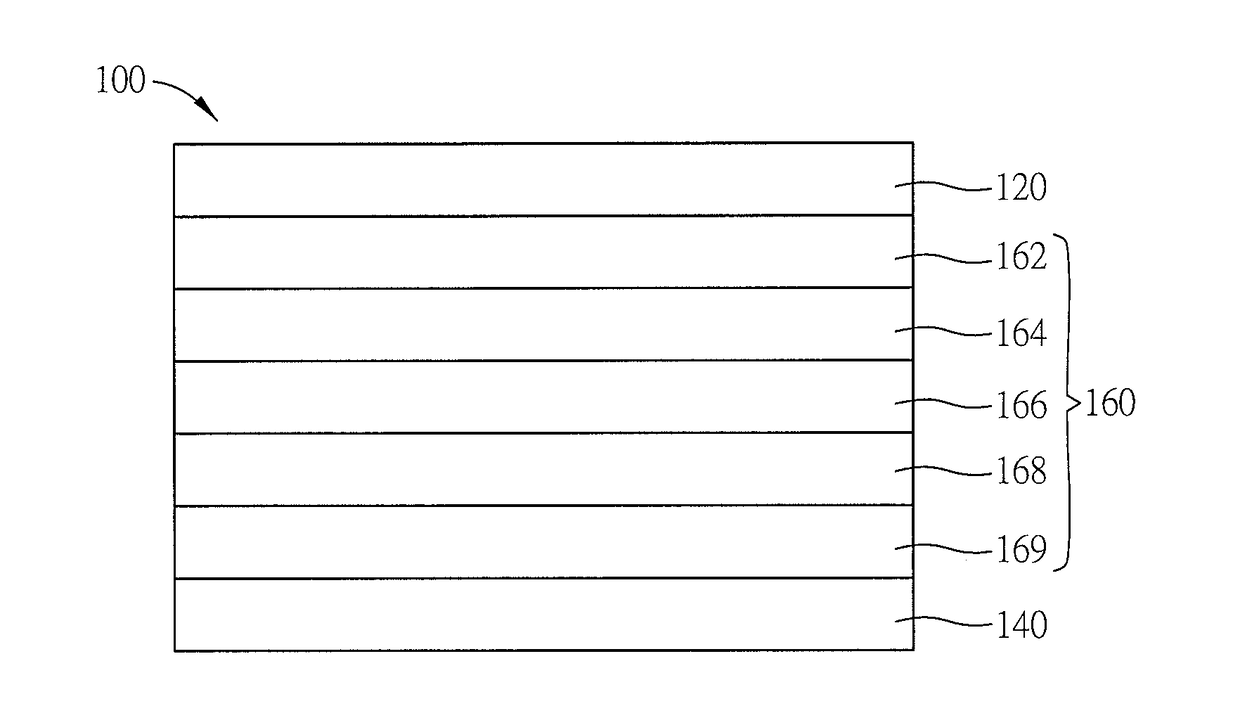

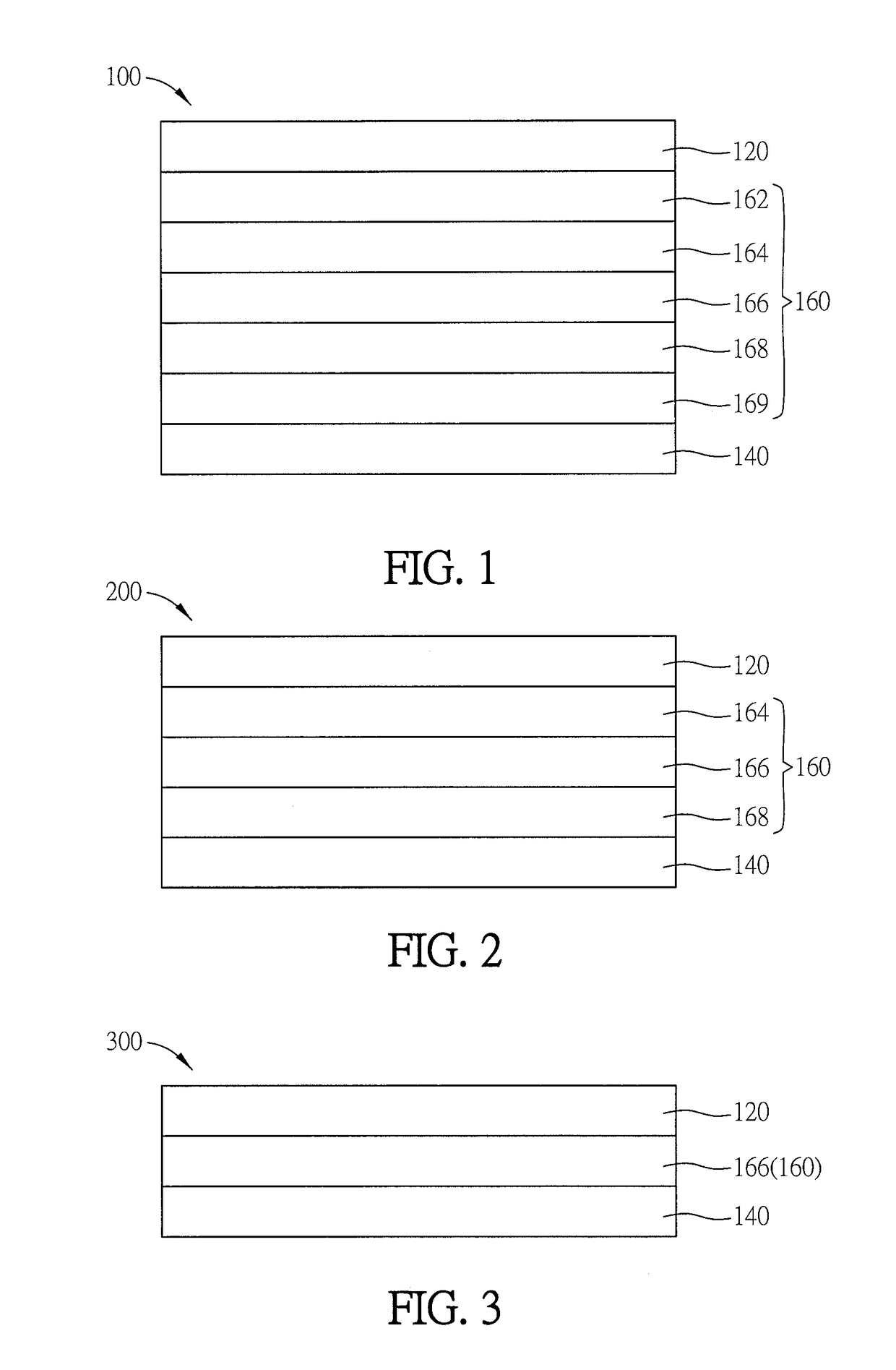

Spirally configured cis-stilbene/fluorene hybrid material and organic electroluminescent device using the same

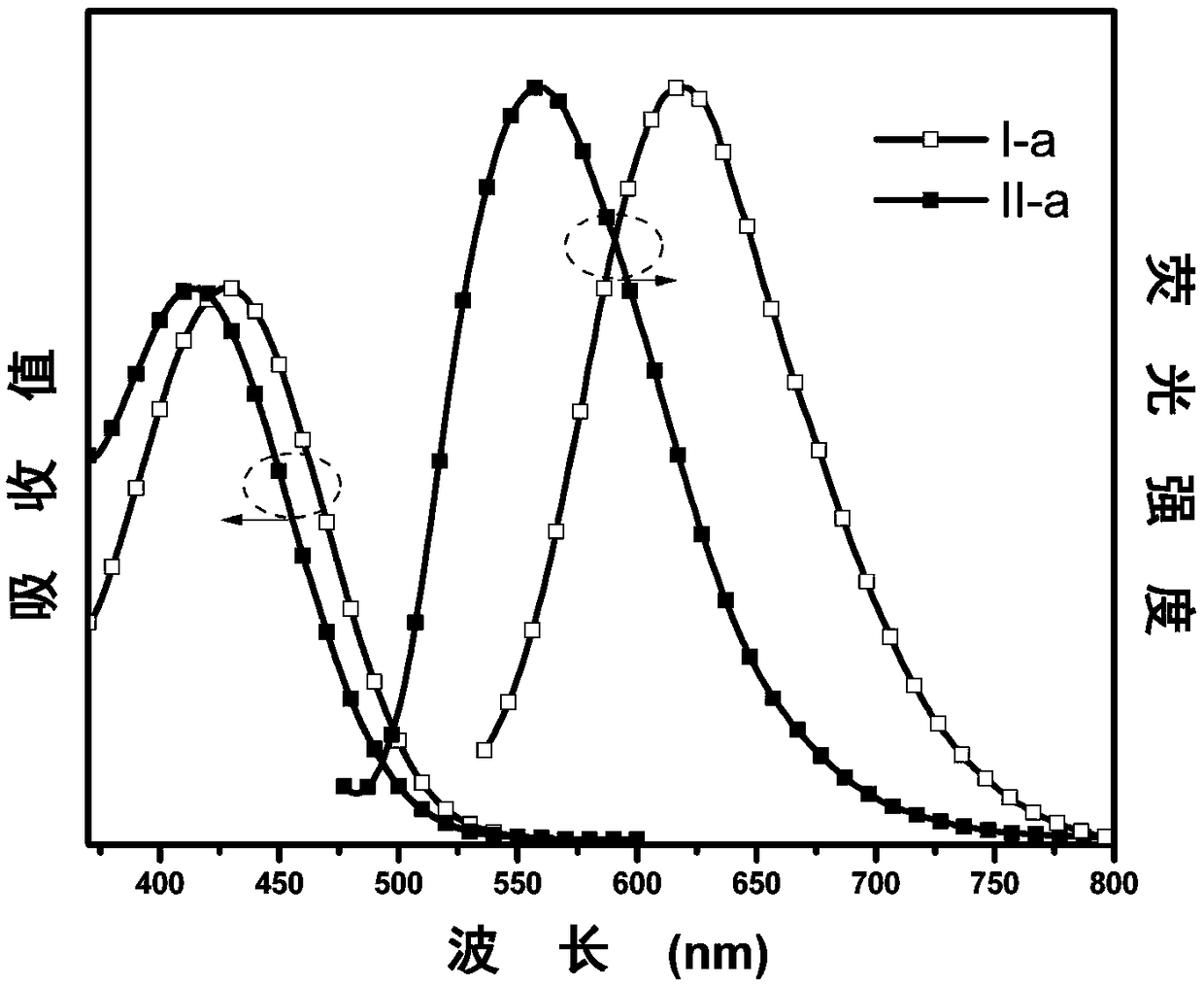

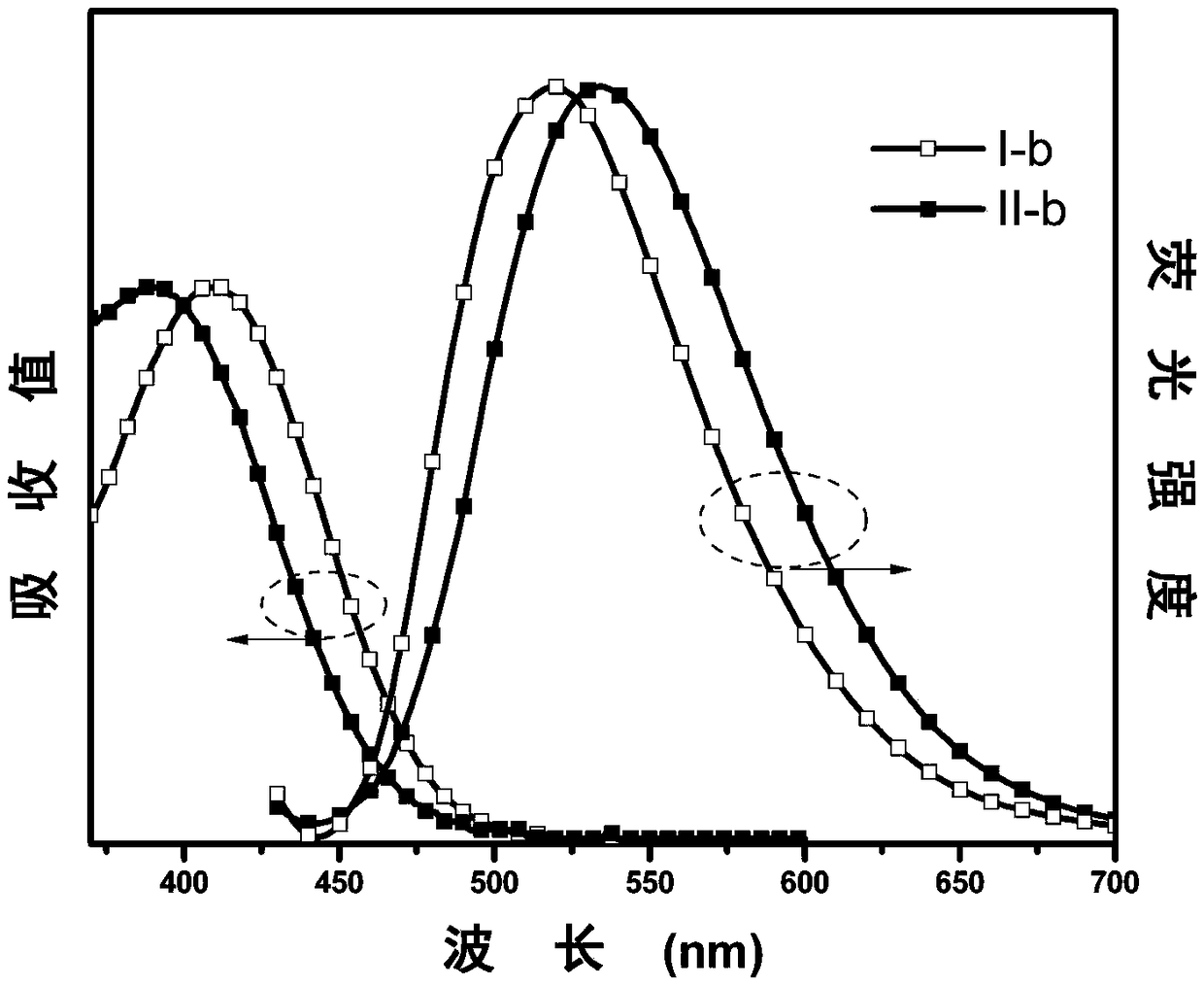

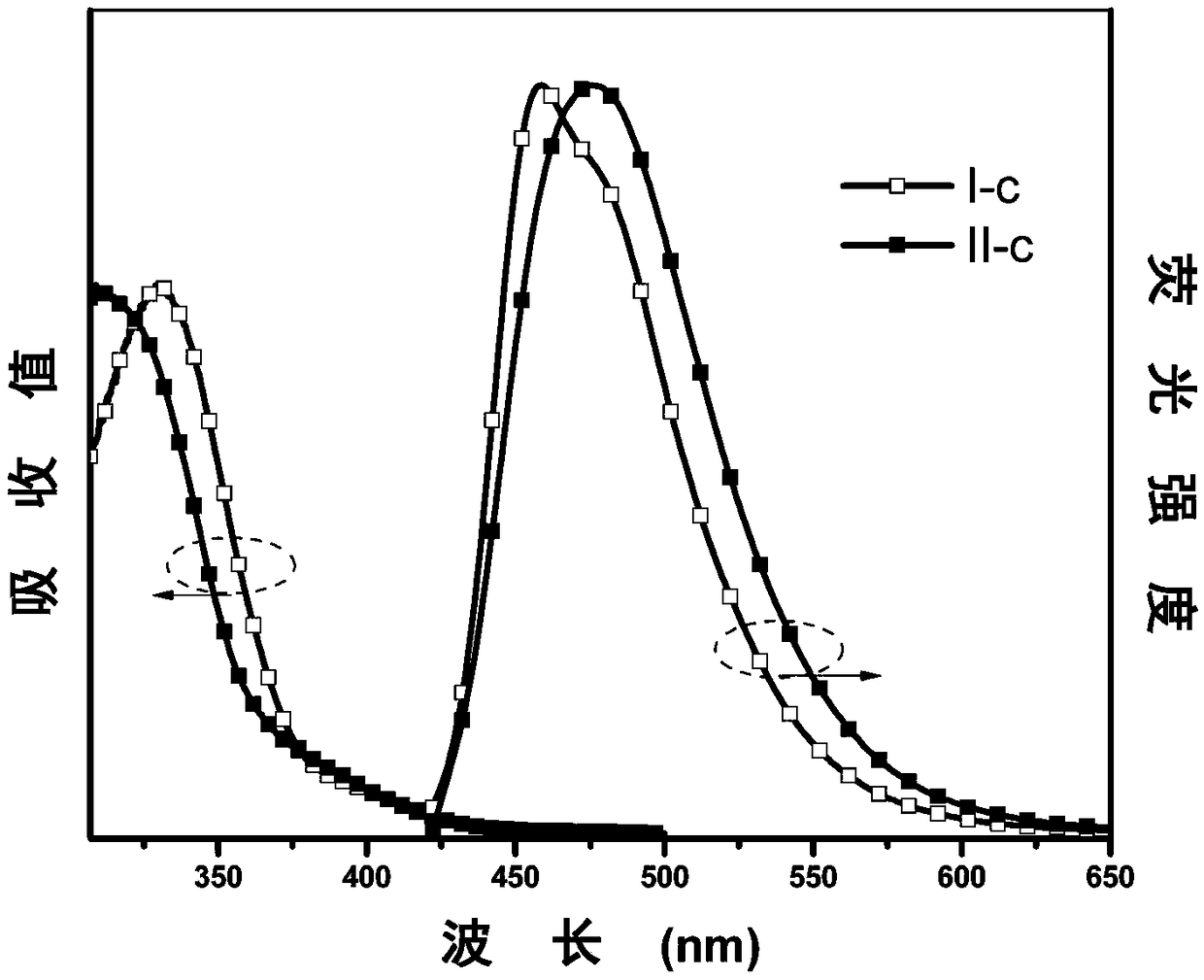

InactiveUS20180301632A1High fluorescence quantum effectPrevent from isomerizationOrganic chemistrySolid-state devicesOrganic electroluminescencePyrimidine

A spirally configured cis-stilbene / fluorene hybrid material is shown in formula (1),R′ is an alkyl group or represented by formula (2),wherein R1 to R4, R6, R8 to R11 and R13 to R18 are independently selected from the group consisting of hydrogen atom, halogen atom, cyano group, alkyl group, cycloalkyl group, alkoxy group, amino group, haloalkyl group, thioalkyl group, silyl group and alkenyl group, R5 is a hydrogen atom, tert-butyl group or aryl group, R7 and R12 are independently selected from the group consisting of hydrogen atom, aryl group, diarylamino group, cyano group, heteroaryl (e.g., pyridine group, or pyrimidine group).

Owner:JUST ABOUT SHOWING CO LTD

Cyanodiphenylethylene compound with stable Z/E configuration in excited state and preparation method and application thereof

InactiveCN109134396ABroad application prospectsConformationally stableOrganic chemistryLuminescent compositionsFluorescenceChemistry

The invention provides cyanodiphenylethylene compound with stable Z / E configuration in excited state and a preparation method and application thereof. The cyanodiphenylethylene compound with stable Z / E configuration in excited state acts as a novel light-emitting isomer; the structure can be controlled by introducing different push-pull electron groups so as to adjust light emission color and efficiency of the isomer; therefore, the cyanodiphenylethylene compound has a very promising application prospect in the fields, such as photoluminescence, piezochromism and fluorescent sensing.

Owner:ZHEJIANG UNIV OF TECH

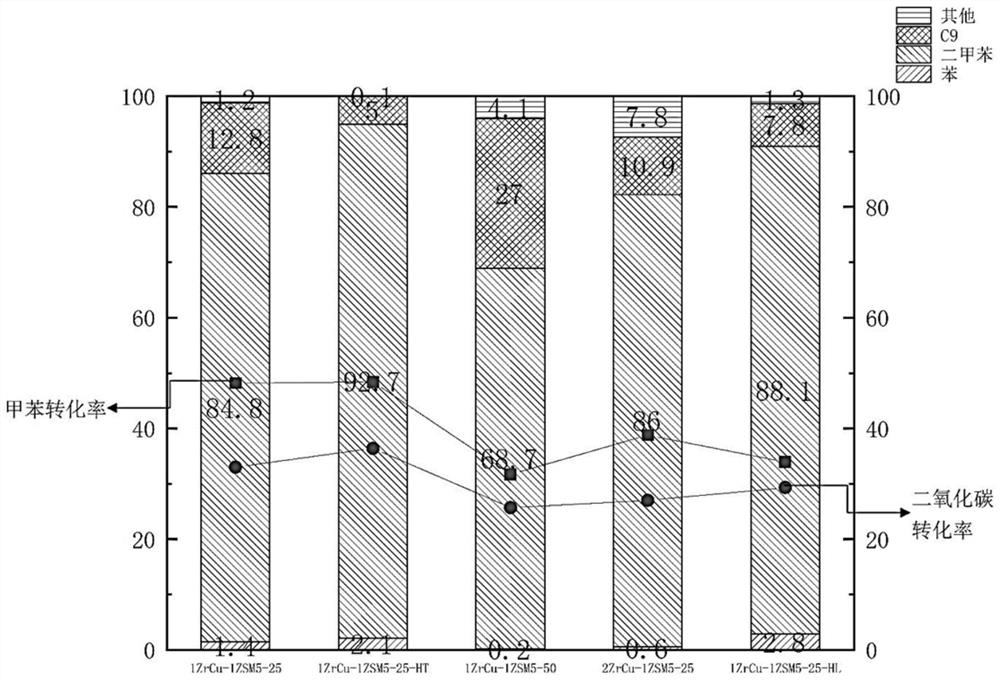

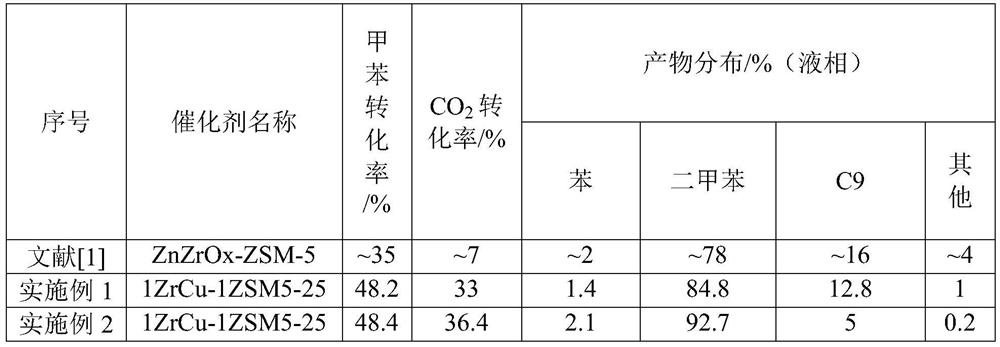

Catalyst for carbon dioxide hydrogenation and toluene aromatic ring alkylation as well as preparation method and application of catalyst

InactiveCN113070094AGood choiceHigh reactivityMolecular sieve catalystsOrganic compound preparationXylyleneMolecular sieve

The invention relates to a catalyst for carbon dioxide hydrogenation and toluene aromatic ring alkylation as well as a preparation method and application of the catalyst. The catalyst is prepared by mixing a Cu-based catalyst and an HZSM-5 molecular sieve. The Cu-based catalyst is a mixed oxide composed of a Cu body and modified metal, and the mass ratio of the Cu-based catalyst to the surface HZSM-5 molecular sieve is 1: 3 to 3: 1. The modified metal is one of Zr, Zn, Ce and Ti, the content of the Cu oxide is 50 wt%-95 wt%, and the content of the modified metal is 5 wt%-50 wt%. Compared with the prior art, the method has the advantages that the methanol-to-olefin side reaction caused by an improper methanol / toluene feeding ratio can be reduced, and the production efficiency of xylene is improved; meanwhile, the isomerization reaction of xylene can be inhibited, and the selectivity of p-xylene in the product is improved; and the catalyst has good stability at a high temperature, provides a new idea for carbon dioxide hydrogenation and toluene aromatic ring alkylation, and has a good industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

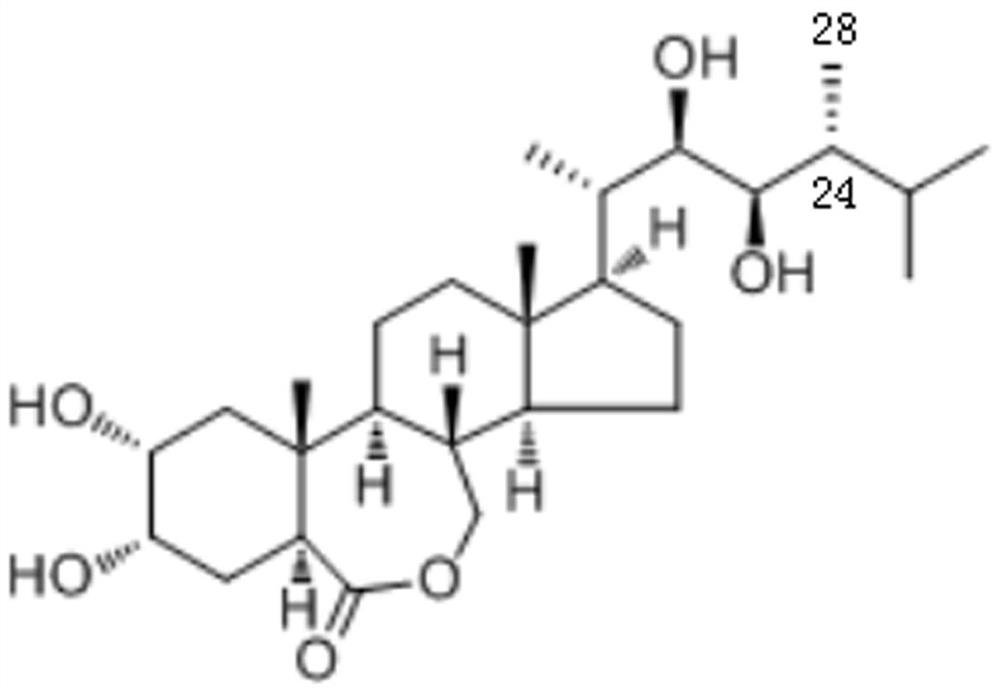

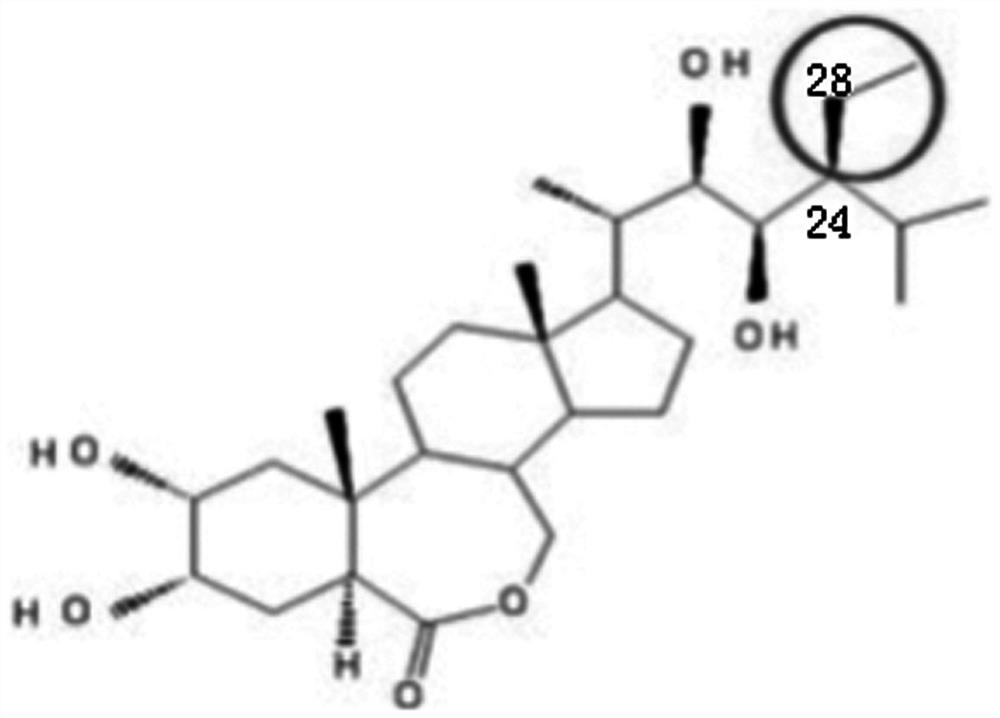

Compound water dispersible granules and preparation method thereof

InactiveCN111937882AImprove growth performanceStrong synergismPlant growth regulatorsBiocideWater dispersibleSODIUM NAPHTHALENESULFONATE

The invention relates to compound water dispersible granules and a preparation method thereof. The compound water dispersible granules at least comprise gibberellic acid GA<4+7>, 28-epihomobrassinolide and an auxiliary agent, wherein under the condition that the mass of the gibberellic acid GA<4+7> is smaller than that of the 28-epihomobrassinolide, the mass ratio of the gibberellic acid GA<4+7> to the 28-epihomobrassinolide is 1: 12.5 to 1:50; the auxiliary agent comprises at least one of a sodium methylnaphthalene sulfonate-formaldehyde condensate, sodium methylene dinaphthalenesulfonate andsodium lignin sulfonate; the ratio of the mass of the gibberellic acid GA<4+7> and the 28-epihomobrassinolide to the mass of the auxiliary agent is 1: 2 to 1: 10; the ratio of the auxiliary agent inthe ratio of the mass of the gibberellic acid GA<4+7< and the 28-epihomobrassinolide to that of the auxiliary agent increases along with increase of the ratio of the gibberellic acid GA<4+7> to the 28-epihomobrassinolide.

Owner:ZHENGZHOU NONGDA BIOCHEM PROD

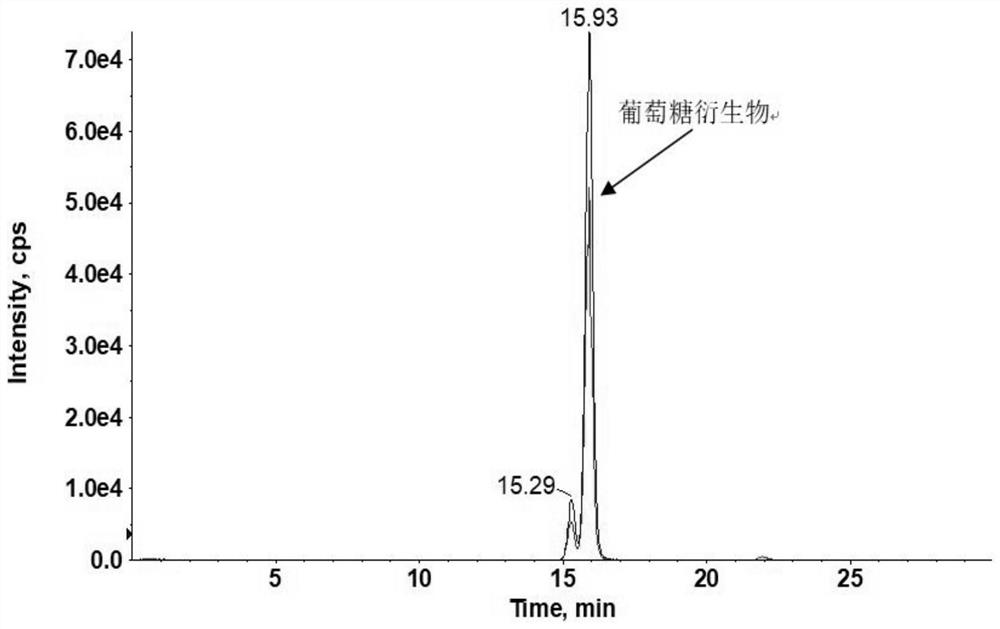

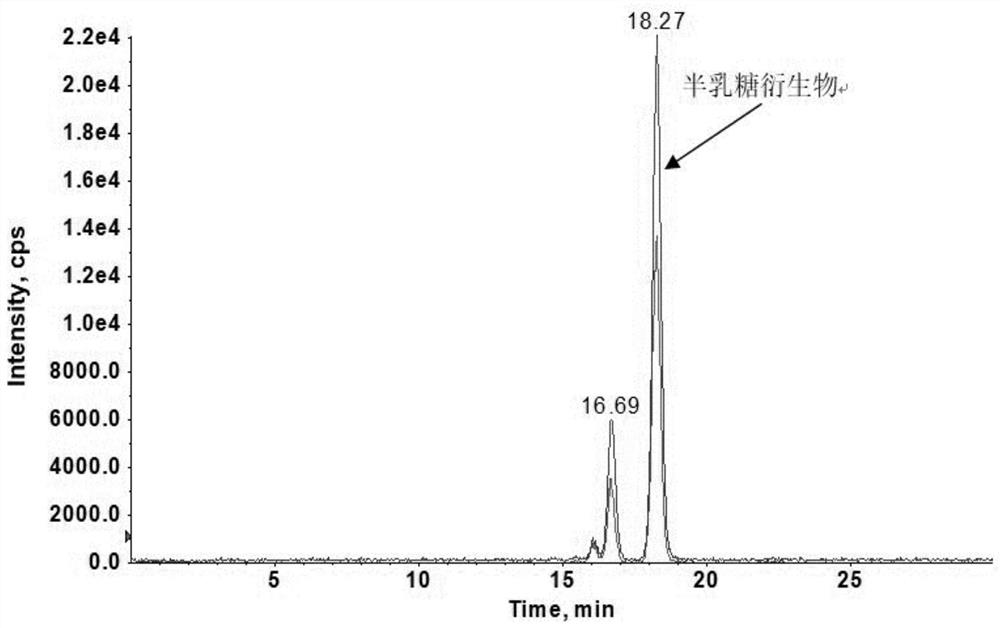

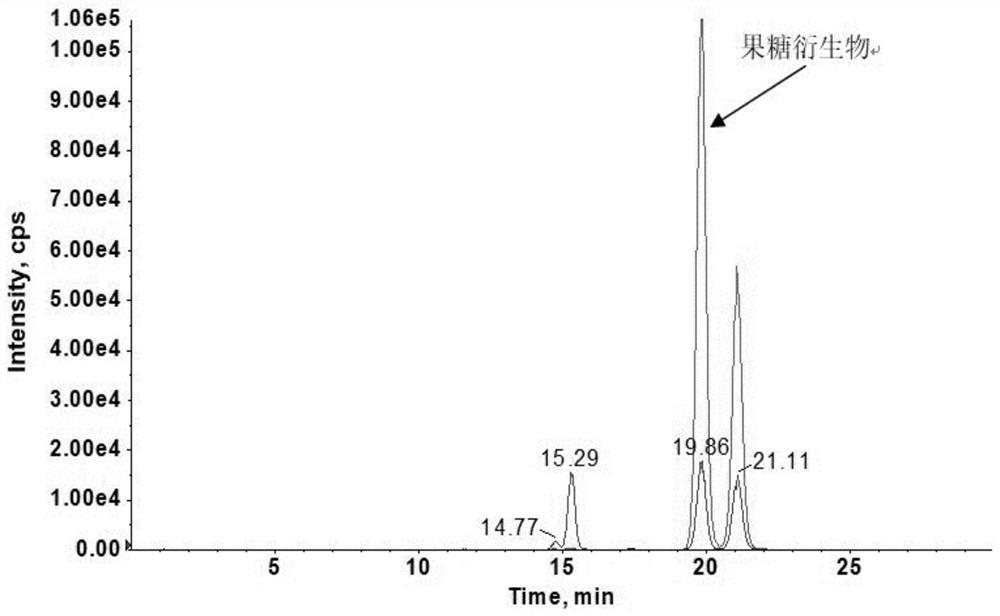

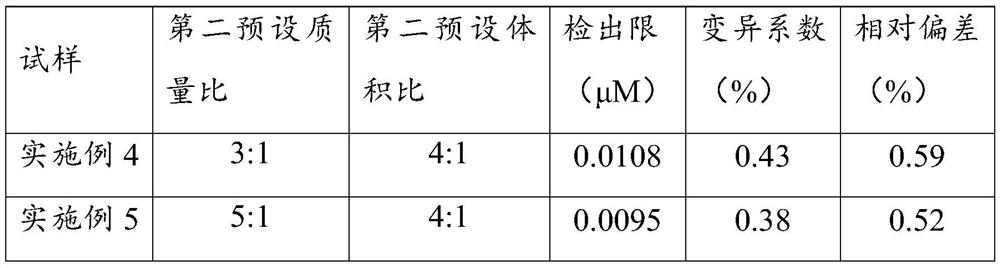

Method for detecting lactulose in dairy product

ActiveCN111855829ADoes not change the properties of the aqueous phaseEfficient separationComponent separationBiotechnologyPasteurization

The invention provides a method for detecting lactulose in a dairy product. The method comprises the steps of adding beta-D-galactosidase into a dairy product sample, carrying out an enzymatic hydrolysis reaction on lactose and lactulose to generate galactose, fructose and glucose, respectively carrying out an oximation reaction on galactose, glucose and fructose and methoxylamine, and carrying out a derivatization reaction on the generated reactants and N-methyl-N-trimethylsilane trifluoroacetamide to finally obtain a test solution. The test sample solution is analyzed by adopting an ultra-high performance liquid chromatography tandem mass spectrometer to obtain the content of lactulose. The method can accurately and sensitively determine the content of lactulose in pasteurized milk.

Owner:唐山市食品药品综合检验检测中心

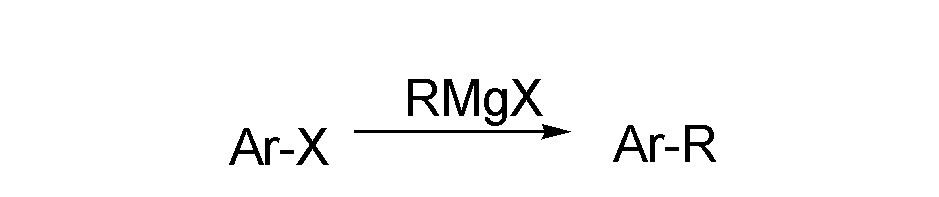

Grignard reagent and aryl halide coupled alkyl introduction method by metal catalysis

InactiveCN102516001ALow costInhibition of isomerizationOrganic grignard reactionsAryl halideMedicinal chemistry

Disclosed is a Grignard reagent and aryl halide coupled alkyl introduction method by metal catalysis. According to the invention, commercialized or easily prepared aryl halide Ar-X is selected as a main raw material, wherein Ar is phenyl ring or C4-C8 heterocyclic benzenoid and X is I or Br or Cl. A final product Ar-R is obtained by coupling of the Grignard reagent RMgX with the aryl halide, wherein Ar is phenyl ring or C4-C8 heterocyclic benzenoid, X is I or Br or Cl, and R is C1-C5 alkyl or C3-C6 cycloalkyl. The raw materials used in the synthetic method are all cheap and easily available. The chemical conditions are mild. During the whole production process, the method is simple to operate, is a feasible synthetic technology with low pollution, and provides a novel thinking and method for the preparation of alkyl aromatics.

Owner:ASYMCHEM LAB TIANJIN +4

Stereoregular polymer and monomer thereof and process for production of both

InactiveUS20060009601A1Improve bindingReduce deformationOrganic compound preparationCarboxylic acid esters preparationLight irradiationCrystal structure

An ester derivant having a crystal structure in which the molecules in two adjacent molecule planes are antiparallel is created from a carboxylic acid having carbon-carbon double bond and a compound having a functional group that can react to a carboxyl group of the carboxylic acid. The crystal of the ester derivant is then subjected to light irradiation or heating.

Owner:JAPAN SCI & TECH CORP

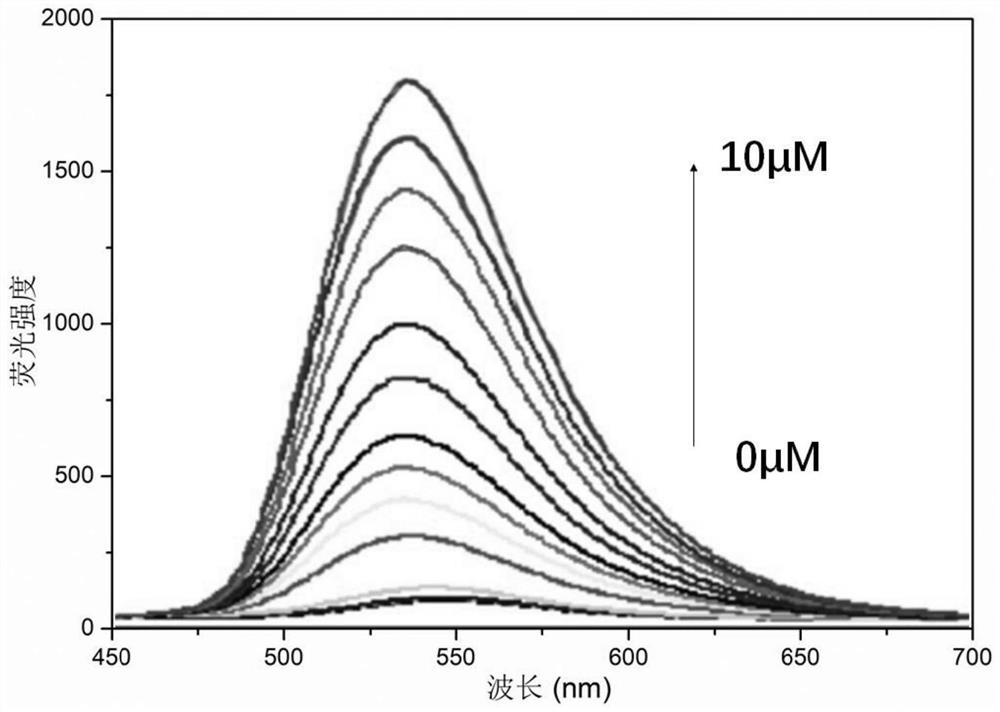

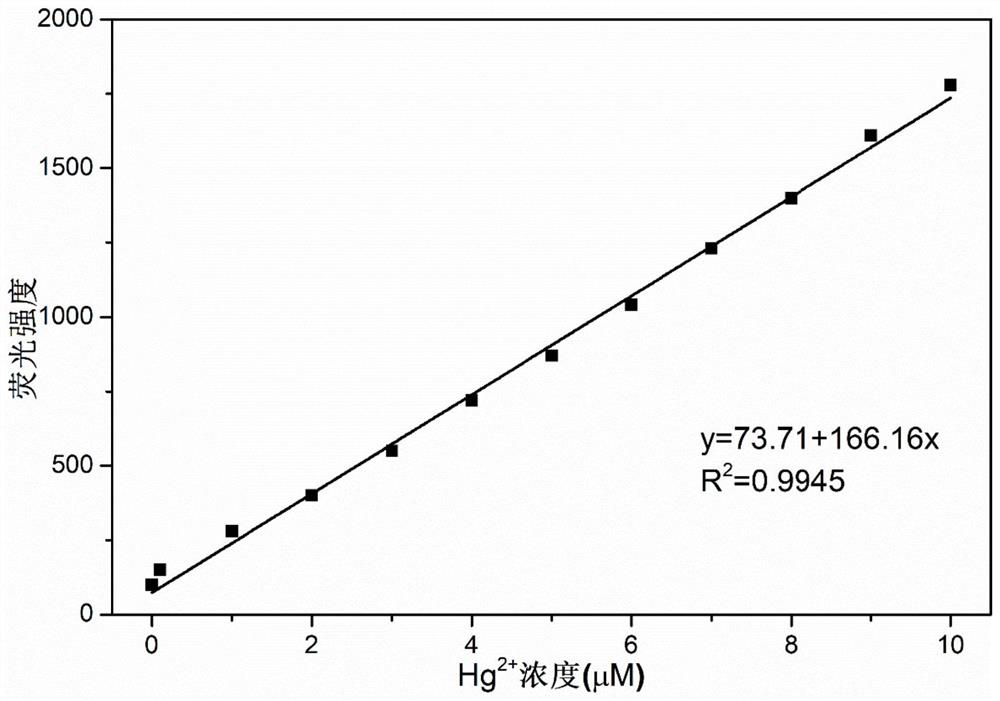

Outdoor water source heavy metal detection polymer preparation and preparation method thereof

ActiveCN112500602AHigh fluorescence intensityInhibition of isomerizationFluorescence/phosphorescenceLuminescent compositionsPolyvinyl alcoholThiourea

The invention provides an outdoor water source heavy metal detection polymer preparation and a preparation method thereof. The preparation method comprises steps: introducing borax and agar with specific contents into polyvinyl alcohol to prepare a composite hydrogel; preparing a fluorescent product containing a naphthalimide fluorophore, and performing carboxylation on the fluorescent product toobtain a carboxylated fluorescent product; grafting the fluorophore onto the composite hydrogel by utilizing an esterification reaction between the composite hydrogel and the carboxylated fluorescentproduct to obtain an esterification product; carrying out hydroformylation on the esterification product, and introducing thiosemicarbazide to carry out a Schiff base reaction, so as to obtain the heavy metal detection polymer preparation containing the fluorophore and the thiourea group at the same time. Through the mode, the heavy metal detection polymer preparation prepared by the invention notonly can be used for efficiently, accurately and sensitively detecting heavy metal mercury ions in an outdoor water source, but also can be repeatedly used, so that the detection cost is effectivelyreduced, and the heavy metal detection polymer preparation has a relatively high application value.

Owner:江西月池天然矿泉水有限公司

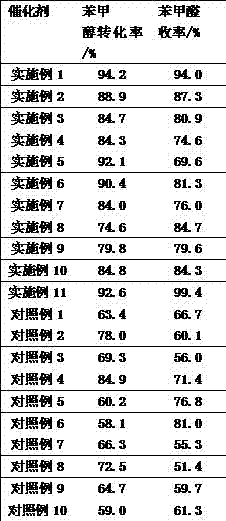

Method for preparing benzaldehyde catalyst through catalytic oxidation of benzyl alcohol

InactiveCN107983412AUniform porosityLarge specific surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSupercritical dryingPolymer science

The invention discloses a method for preparing a benzaldehyde catalyst through catalytic oxidation of benzyl alcohol. The method comprises the following steps: taking La2O3@COF, epoxypropane, hydrochloric acid, deionized water, absolute ethyl alcohol, La2O3, benzidine and anhydrous THFA as main raw materials, preparing La2O3@COF aerogel particles by adopting a supercritical CO2 drying technology,preparing wet gel by adopting a simple sol-gel method, and preparing the aerogel particles with uniform pores and high specific surface area by adopting the supercritical drying technology. Accordingto the method disclosed by the invention, the preparation process is novel, raw material cost is low, application range is wide, a normal pressure drying method can be used, a supercritical drying process can also be used, and the obtained catalyst has excellent catalytic performance on the oxidation reaction of benzyl alcohol.

Owner:XUZHOU NORMAL UNIVERSITY

Separation method and system for byproduct 2M2BN in course of producing 3PN by 2M3BN isomerization

ActiveCN105367448AReduce equipment cost and operational difficultyIncrease relative volatilityCarboxylic acid nitrile purification/separationChemistryRelative volatility

A separation method and system for a byproduct 2M2BN in a course of producing 3PN by 2M3BN isomerization. The present invention proposes that in the course of producing 3PN by 2M3BN isomerization, a byproduct 2M2BN is produced, and 2M2BN will continuously accumulate in the system to suppress the isomerization reaction. The relative volatility of 2M2BN and 2M3BN is increased by using an extractant of the present invention, and separation of 2M2BN and 2M3BN and recycle of the extractant are completed in one distillation column with a partition plate, so that the equipment cost and difficulty are greatly reduced, and 2M2BN and 2M3BN products with high purity can be obtained.

Owner:CHINA TIANCHEN ENG +1

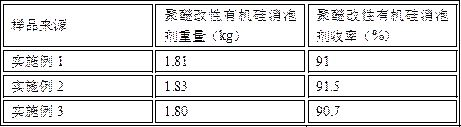

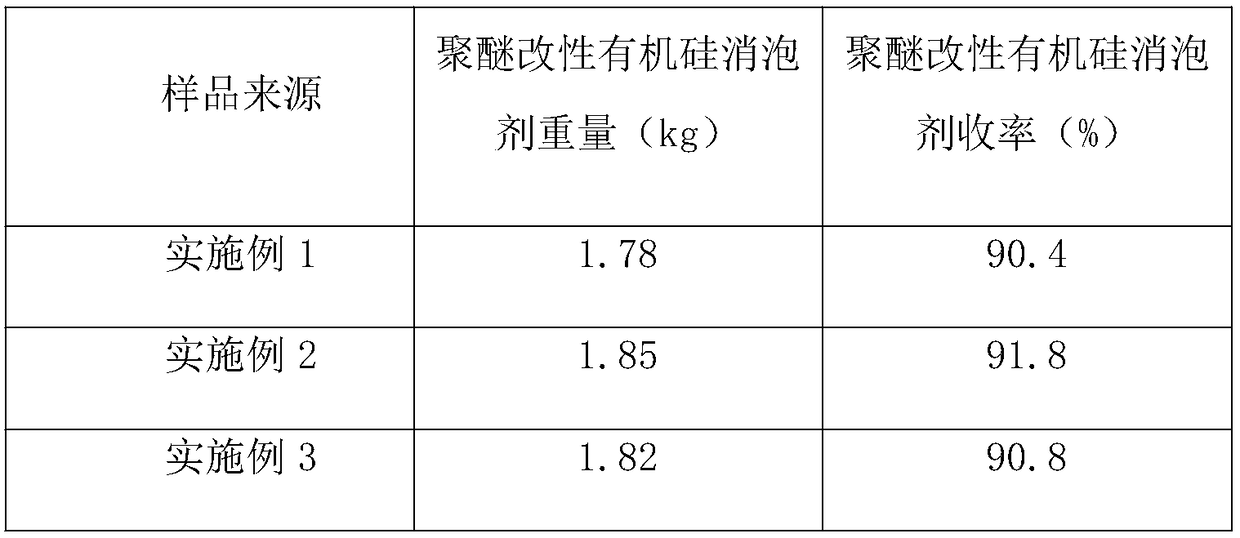

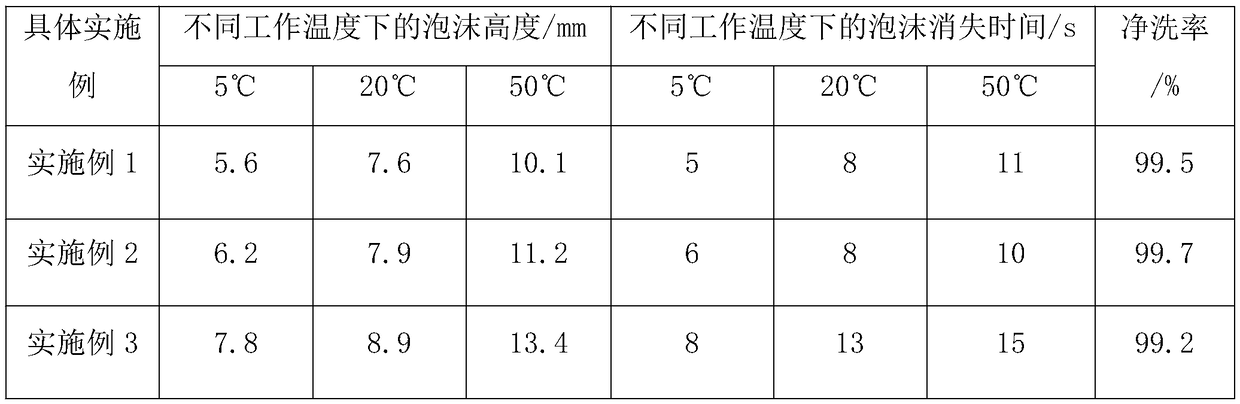

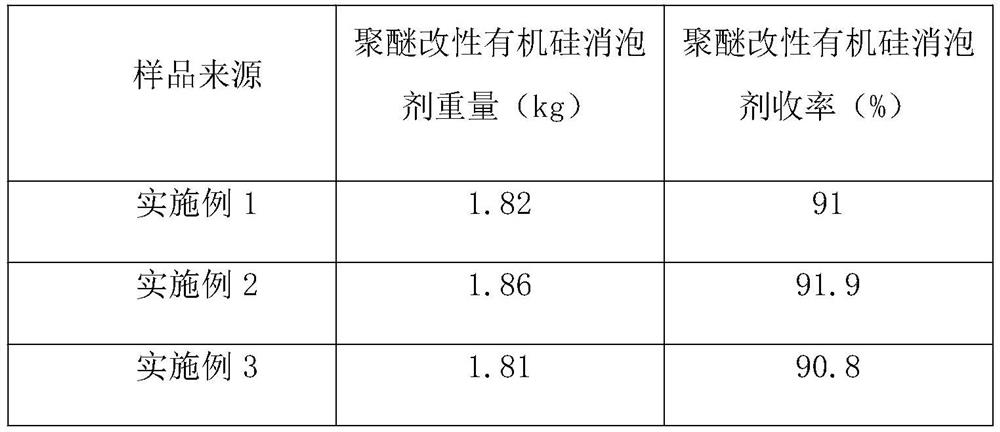

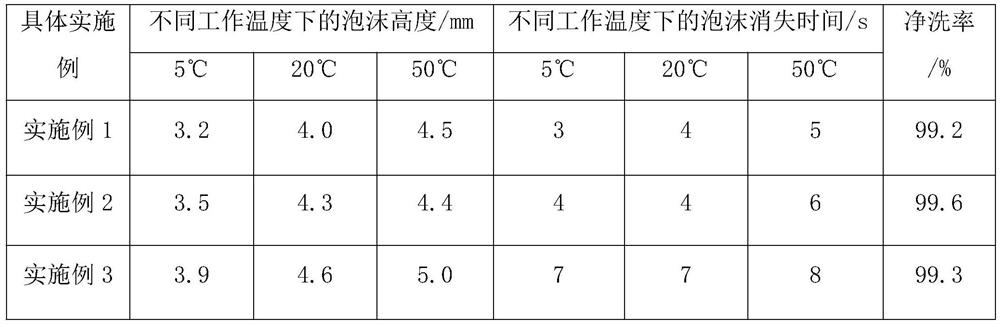

A kind of preparation method of polyether modified silicone type defoamer

ActiveCN109370794BIncrease electrophilicityHigh reaction conversion rateOrganic detergent compounding agentsNon-ionic surface-active compoundsPolymer scienceDioxyethylene Ether

The invention provides a preparation method of a novel high-efficiency cleaning agent, wherein the formula of the cleaning agent is: 8-15% of alkyl glycoside, 2-8% of fatty alcohol polyoxyethylene ether, 10-15% of nonylphenol polyoxyethylene ether %, coconut oil fatty acid diethanolamide 10‑15%, antifoam agent 2‑5%, polyether modified silicone type defoamer 5%‑8%, water balance; of which polyether modified silicone type defoamer The preparation method of the foaming agent is as follows: preparing hydrogen-containing silicone oil; preparing mixed solution A; synthetic reaction; obtaining viscous solid B which is the polyether modified silicone type defoamer. The object of the present invention is to provide a preparation method of a cleaning agent with low foam height and good cleaning effect.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

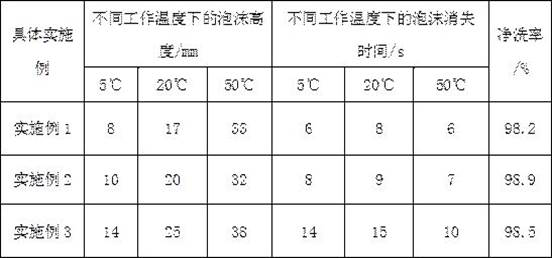

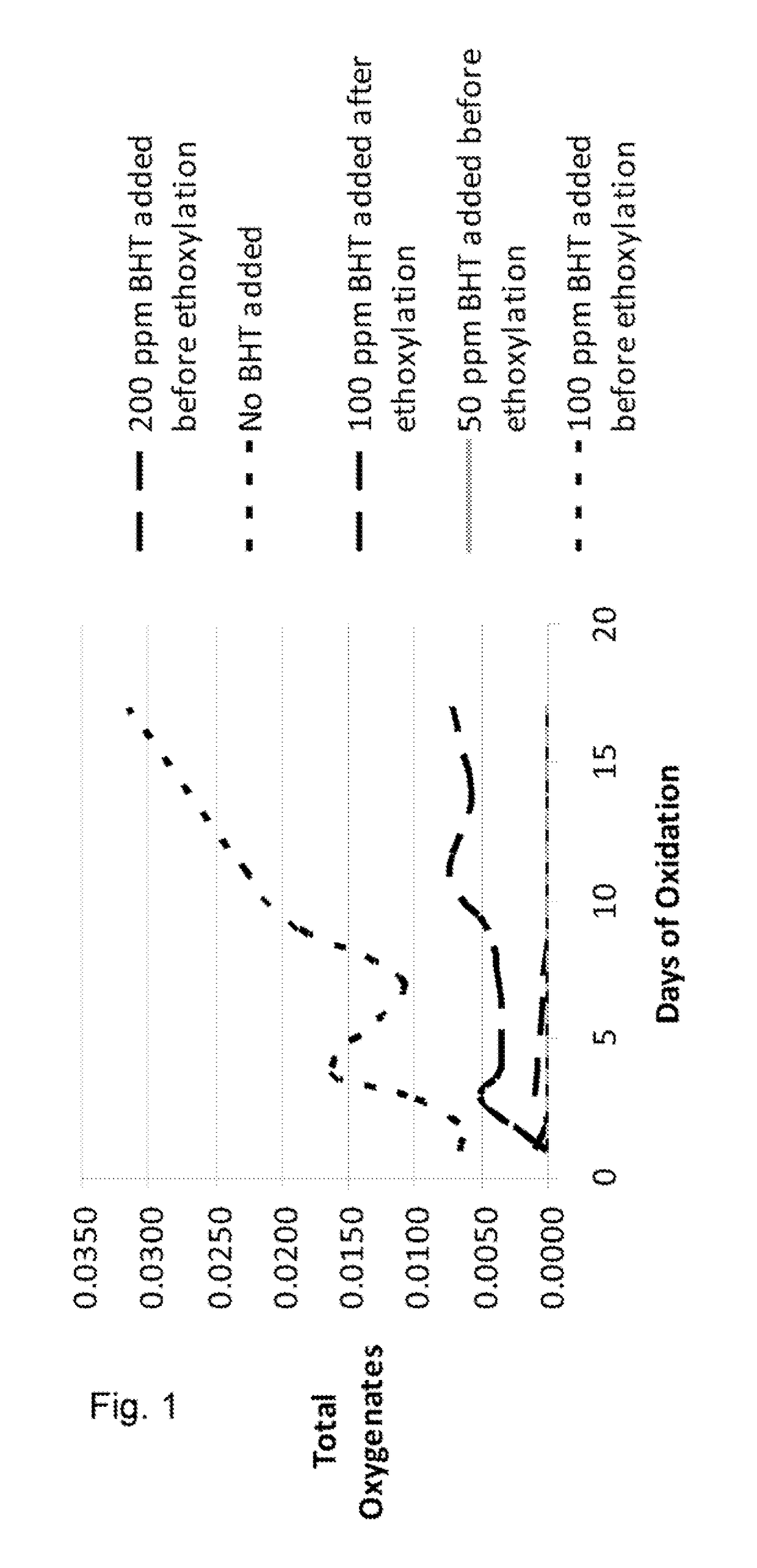

Catalyst Compositions, Methods of Preparation Thereof, and Processes for Alkoxylating Alcohols Using Such Catalysts

ActiveUS20170137356A1Inhibition of isomerizationOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesCalcium hydroxideAlcohol

A process of preparing an alkoxylation catalyst wherein a catalyst precursor which is formed from an alkoxylated alcohol, calcium hydroxide, carboxylic acid, inorganic acid, and propylene oxide, is mixed with an antioxidant, preferably butylated hydroxyl toluene. A process of alkoxylation using the catalyst of the present invention.

Owner:SASOL USA

Method for purifying hexafluorobutadiene

PendingCN113227024AInhibition of isomerizationHigh puritySemiconductor/solid-state device manufacturingHalogenated hydrocarbon preparationIsomerizationButadiene Dioxide

The purpose of the present disclosure is to purify hexafluorobutadiene to a high purity while inhibiting the isomerization of hexafluorobutadiene. A method for purifying hexafluorobutadiene, said method comprising a step for contacting a composition containing hexafluorobutadiene with zeolite having an SiO2 / Al2O3 ratio of 4.0-8.0.

Owner:DAIKIN IND LTD

A method for producing isoborneol

ActiveCN103739447BHydration reaction conditions are mildHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionHydration reactionReaction temperature

The invention provides an isoborneol production method which is carried out in a reinforced radial flow reaction system (IRR) composed of a liquid flow reinforced immersed fixed bed reactor. The isoborneol production method comprises the following steps: mixing the raw materials and a composite solvent by adopting a certain quantity of composite solid acid catalyst according to a certain ratio, wherein camphene and water are used as the raw materials; carrying out hydration reaction in an IRR reaction-separation system to obtain an isoborneol product. The reaction temperature is 40-90 DEG C, the mass of the catalyst is 15-50% of the total mass of the firstly-filled liquid material, the ratio of the camphene to the water to the composite solvent is 1:(0.15-2):(0.5-4), the reaction pressure is 0.1-0.3MPa, and the reaction standing time is 40-70min. After the reacted materials are separated and subjected to ion exchange, the solvent and the unreacted materials are returned to the reactor, and the product is stored. The isoborneol production method has the advantages that the industrial reliability is good, the per-pass conversion rate of the camphene is high, the isoborneol is good in selectivity, and the energy consumption per unit product is only about 60% of that of the traditional fixed bed process.

Owner:NANJING ENETEKS +1

Preparation method of polyether modified organic silicon defoamer containing low-foaming cleaner

ActiveCN109486565AIncrease electrophilicityHigh reaction conversion rateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolyethylene glycolSolvent

The invention provides a preparation method of a polyether modified organic silicon defoamer containing low-foaming cleaner. The polyether modified organic silicon defoamer containing low-foaming cleaner is composed of 1.0-1.2% of twin anionic surfactant, 6-10% of nonionic surfactant, 0.5-1.0% of modified sodium disilicate, 0.25-0.5% of sodium carbonate, 0.5-1.1% of triethanolamine, 1.0-1.5% of dipropylene glycol butyl ether, 0.5-1.0% of polyethylene glycol ethyl ether, 0.5-1.0% of solubilizer, 5-8% of polyether modified organic silicon defoamer, 2-4% of foam inhibitor and water as balance, wherein the preparation method of the polyether modified organic silicon defoamer comprises preparing hydrogen silicone oil, preparing a mixed solution A and performing synthesis to obtain a thick solidB, namely, the polyether modified organic silicon defoamer. According to the preparation method of the polyether modified organic silicon defoamer containing low-foaming cleaner, the prepared p polyether modified organic silicon defoamer containing low-foaming cleaner is low in foam height and good in cleaning effects.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

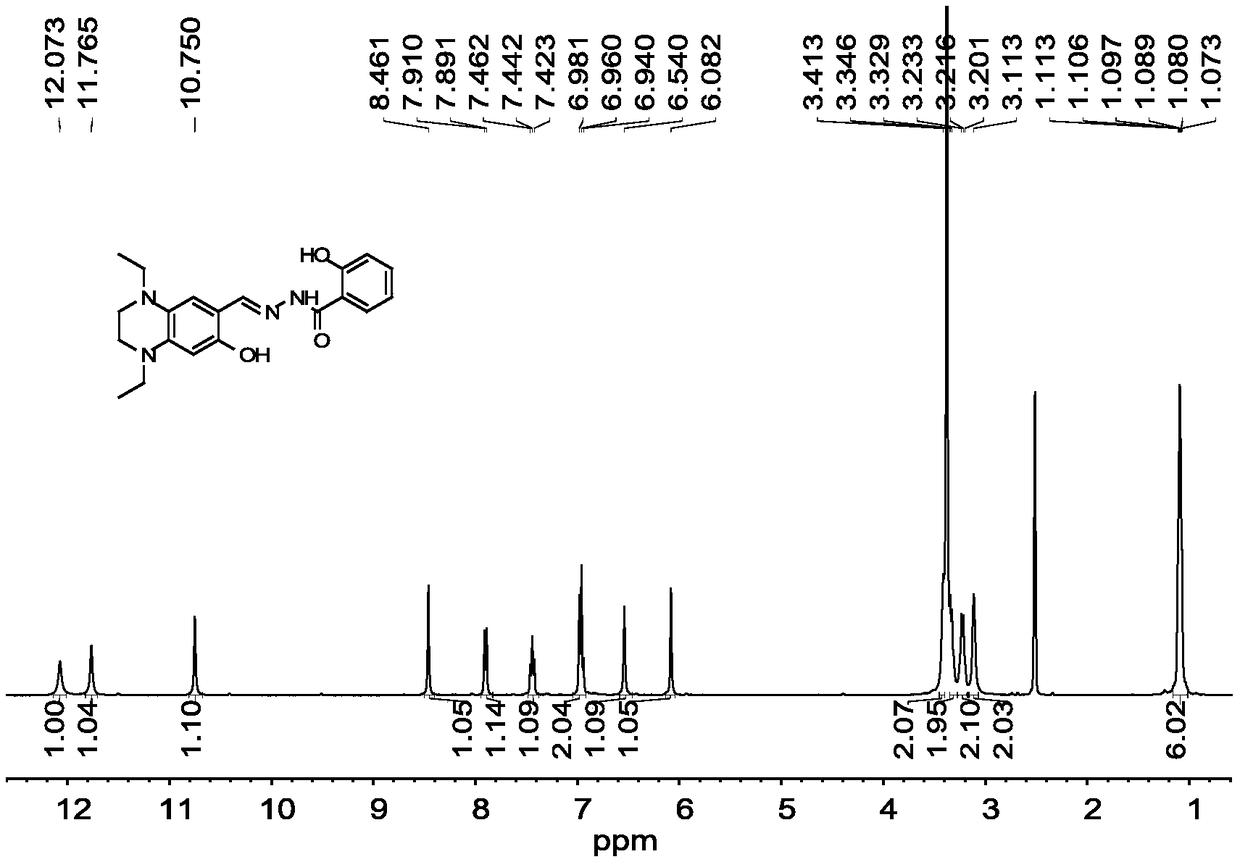

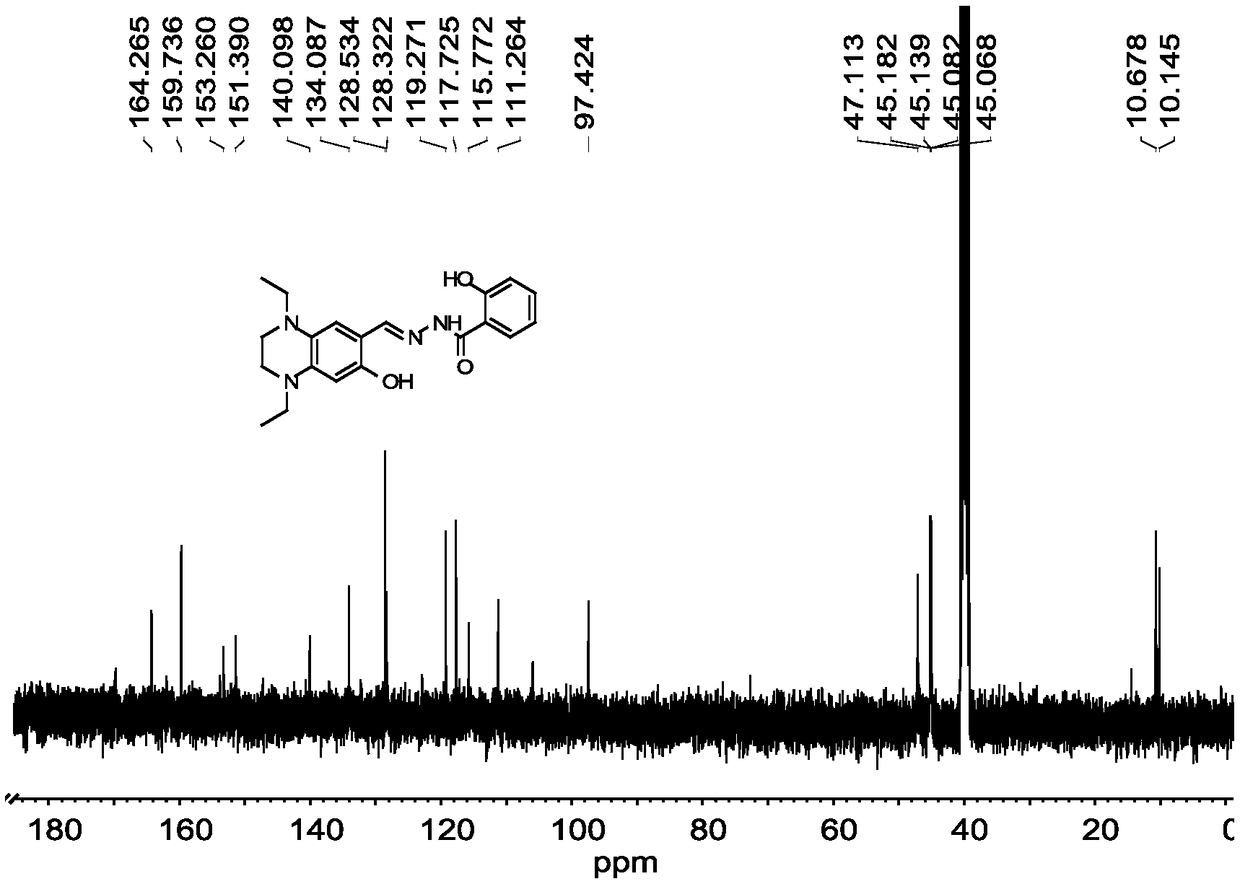

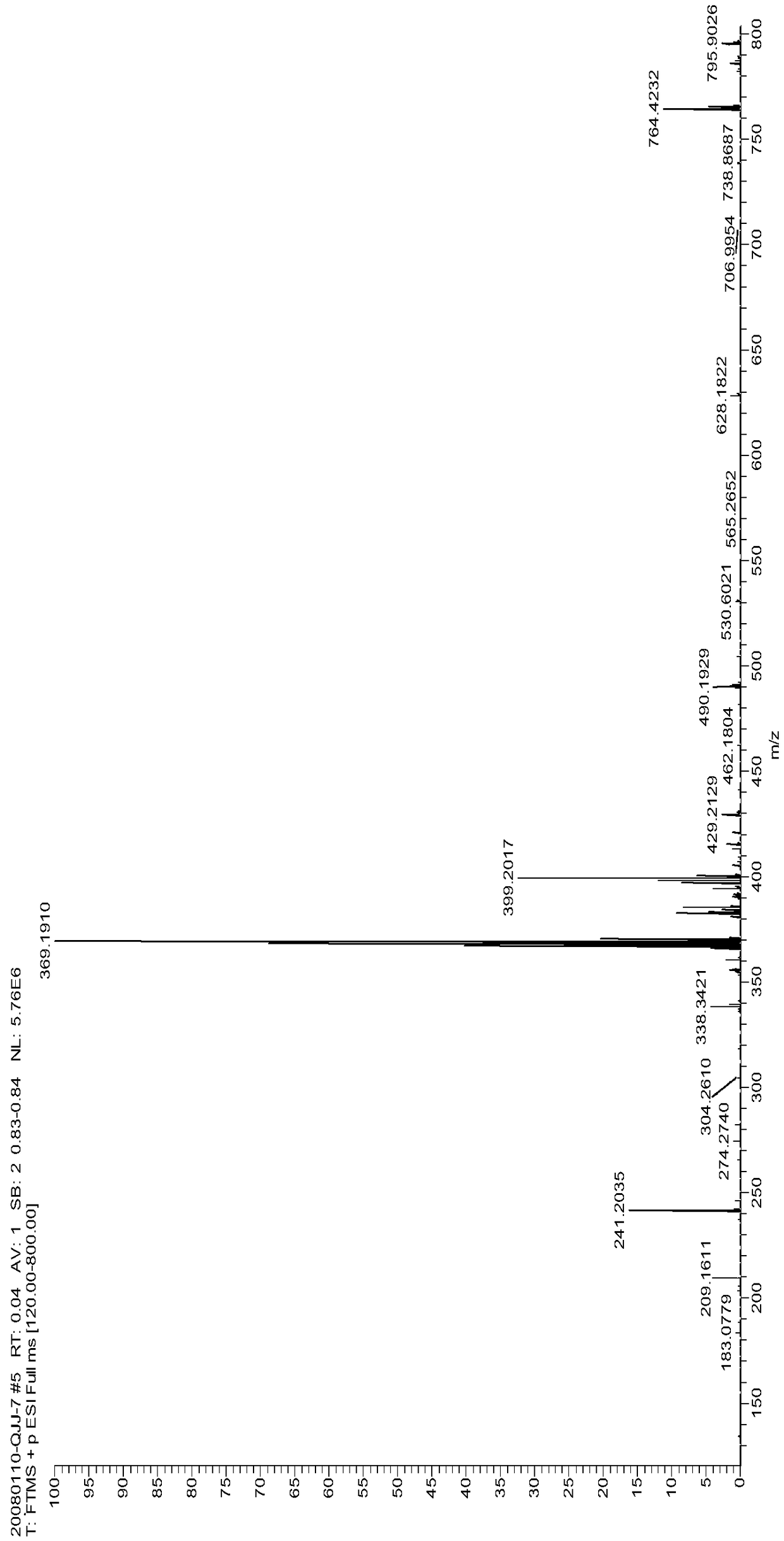

Method for detecting aluminum ions in cells by long wave emission fluorescence imaging

ActiveCN109115743AEasy to separate and purifyGood choiceFluorescence/phosphorescenceSelf interferenceAluminum Ion

The invention relates to a method for detecting aluminum ions in cells by long wave emission fluorescence imaging. A fluorescent probe L is adopted as a fluorescent imaging probe for detecting trace Al<3+> in cells by fluorescent imaging, trace Al<3+> in cells is detected by long wave emission fluorescence imaging, and the chemical structural formula of the fluorescent probe L is shown in the formula. The formula is shown in the description. During detection, a fluorescent probe L solution is first used for culturing cells, so that the fluorescent probe L gets into the active cells, the activecells with the fluorescent probe L are then cultured along with Al<3+>, so that the probe reacts with Al<3+> in the active cells to produce a compound which can emit fluorescence with a characteristic wavelength, realizing the imaging of Al<3+> ions dyed by the probe in the active cells, and a laser confocal fluorescence microscope is used for observing the fluorescence image of the cultured active cells. The method has the advantages that: the method has high selectivity and good sensitivity, trace Al<3+> in cells can be detected by fluorescence imaging under a long emitted wavelength, moreover, the tissue-penetrating capability is high, and light-induced injury and background fluorescence self-interference are prevented.

Owner:BOHAI UNIV

A kind of preparation method of low-foam cleaning agent

ActiveCN109456843BIncrease electrophilicityHigh reaction conversion rateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolymer scienceSodium metasilicate

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

A modified catalyst and its preparation method and application

ActiveCN106902868BStrong acidInhibition of isomerizationMolecular sieve catalystsHydrocarbonsXylylenePtru catalyst

The invention provides a modified catalyst. Aluminum silicate is subjected to ion exchange in ammonium salt solution to obtain an ion exchange product, the ion exchange product and adhesive mixture is formed in acid liquor to obtain a formed product, and the formed product is baked to obtain the modified catalyst. The modified catalyst prepared by the preparation method is high in acidity, isomerization of C9 aromatics can be inhibited when the modified catalyst is used for catalyzing methylbenzene and the C9 aromatics to perform transalkylation reaction to prepare xylene, and finally, the modified catalyst has high selectivity for the xylene. Results indicate that the highest selectivity of the modified catalyst for the xylene can reach 68.61%.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com