Method for detecting lactulose in dairy product

A detection method and technology for dairy products, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to accurately quantify lactulose content, low lactulose sensitivity, and high detection limit, and achieve inhibition of isomerization, The effect of increasing sensitivity and increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

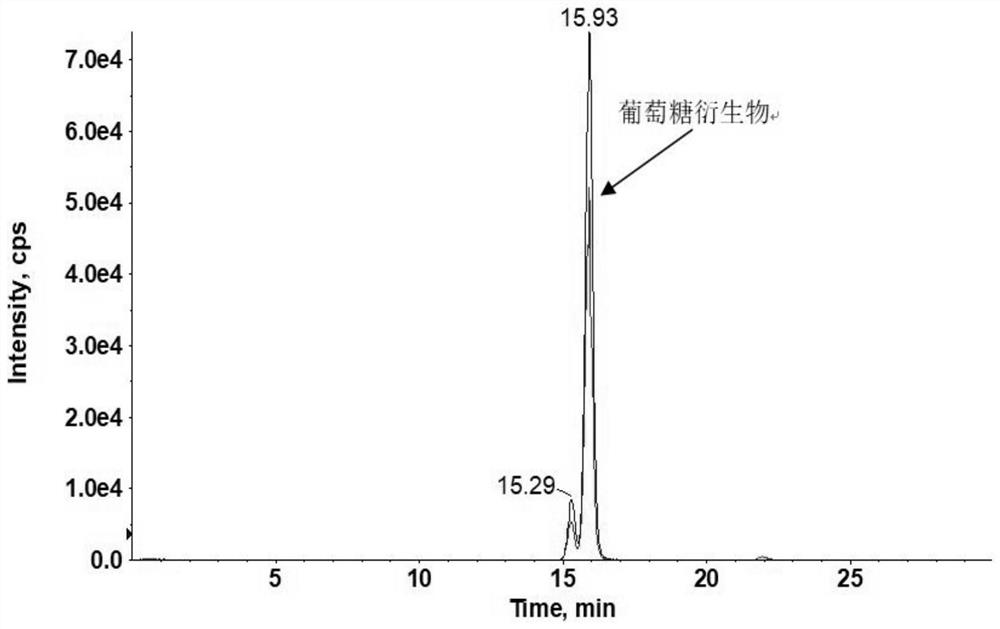

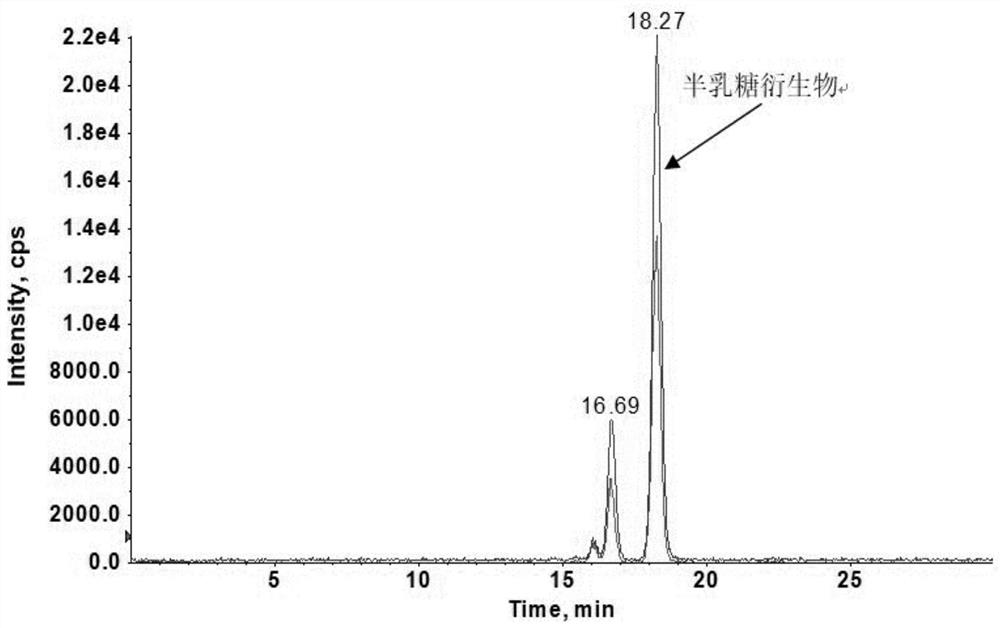

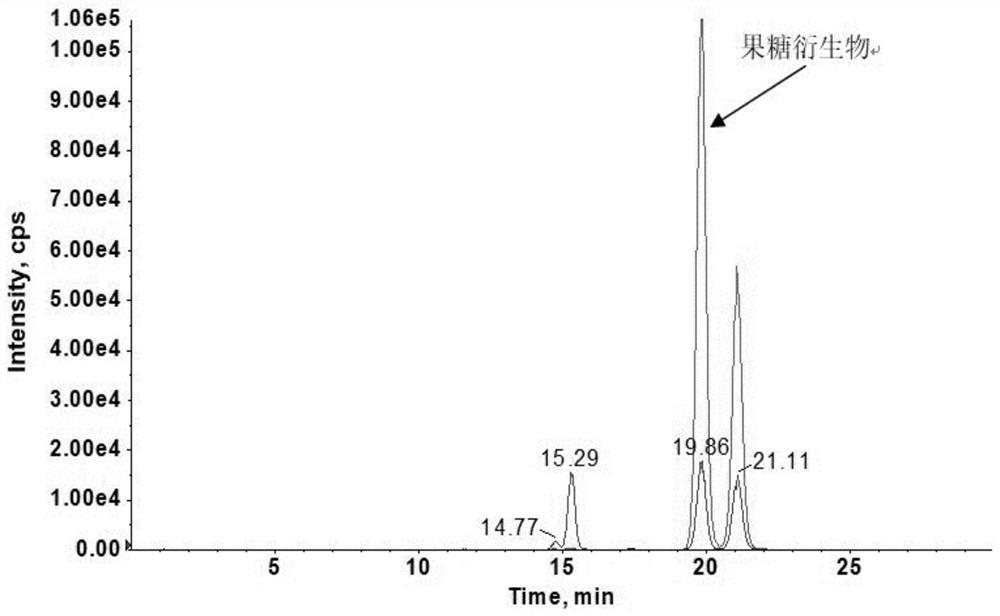

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Add the lactulose standard solution into the fresh milk sample that has been measured, and mix well to obtain the lactulose spiked sample of this embodiment.

[0045] (1) Sample pretreatment

[0046] Draw 5.00mL lactulose spiked sample into a 50mL centrifuge tube, add 5.0mL water, 2.0mL potassium ferrocyanide solution with a concentration of 130g / L, 2.0mL zinc sulfate solution with a concentration of 168g / L and 6.0mL phosphate For salt buffer (48 g / L disodium hydrogen phosphate, 8.6 g / L sodium dihydrogen phosphate, 1 g / L magnesium sulfate, adjust the pH to 7.5), every time a reagent is added, it needs to be vortexed and mixed thoroughly. After mixing well, centrifuge at 8000r / min at 4°C for 5min, take 1.0mL supernatant, add 4.0mL phosphate buffer (disodium hydrogen phosphate 48g / L, sodium dihydrogen phosphate 8.6g / L, magnesium sulfate 1g / L, adjust the pH to 7.5), mix well to obtain a diluent. Aspirate 1.00 mL of the diluent, add 200 μL of β-D-galactosid...

Embodiment 2

[0060] Prepare pasteurized milk samples.

[0061] (1) Sample pretreatment

[0062] Draw 5.00mL pasteurized milk sample into a 50mL centrifuge tube, add 5.0mL water, 2.0mL potassium ferrocyanide solution with a concentration of 130g / L, 2.0mL zinc sulfate solution with a concentration of 168g / L and 6.0mL phosphate For salt buffer (48 g / L disodium hydrogen phosphate, 8.6 g / L sodium dihydrogen phosphate, 1 g / L magnesium sulfate, adjust the pH to 7.5), every time a reagent is added, it needs to be vortexed and mixed thoroughly. After mixing, centrifuge at 8000r / min at 4°C for 5min, take 1.0mL supernatant, add 4.0mL phosphate buffer (disodium hydrogen phosphate 48g / L, sodium dihydrogen phosphate 8.6g / L, magnesium sulfate 1g / L L, adjust the pH to 7.5), and mix well. Aspirate 1.0 mL of the diluent, add 0.2 mL of β-D-galactosidase suspension (enzyme concentration: 40 mg / mL), shake slightly, and perform enzymatic reaction at 50°C for 1 h.

[0063] Take 0.60 mL of enzymatic hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com