Catalyst for decreasing cloud point of lube base oil and preparation method thereof

A lubricating oil base oil and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited conversion capacity of macromolecules and high cloud point of lubricating base oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation method and experimental operation steps of catalyst a are as follows:

[0016] Step ①: Based on the total weight of the mixed substance obtained in step ③, 5% of the ZSM-5 molecular sieve sample with a Si / Al molar ratio of 25.0 is used for 100% of the equivalent volume of adsorption with 0.2mol / L NaOH solution Stirring treatment at 80°C for 0.5h to obtain ZSM-5 microporous molecular sieve treated with alkali;

[0017] Step 2.: Based on the total weight of the mixed substance obtained in step 3., 15% cetyltrimethylammonium bromide template, 0.5% sodium aluminate and 30% sodium silicate and the rest water, stir evenly to obtain a gel;

[0018] Step ③: Add the alkali-treated microporous molecular sieve obtained in step ① into the gel obtained in step ②, stir evenly, and then use dilute H 2 SO 4 The solution adjusts the pH value of the synthesis system to 10.5;

[0019] Step ④: transfer the homogeneous colloid obtained in step ③ into a synthesis kettle, ...

Embodiment 2~4

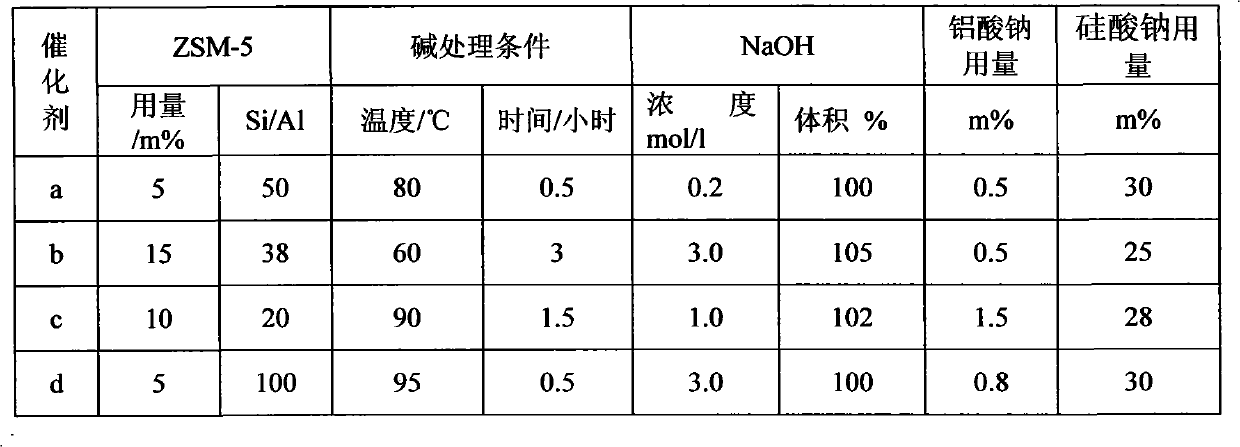

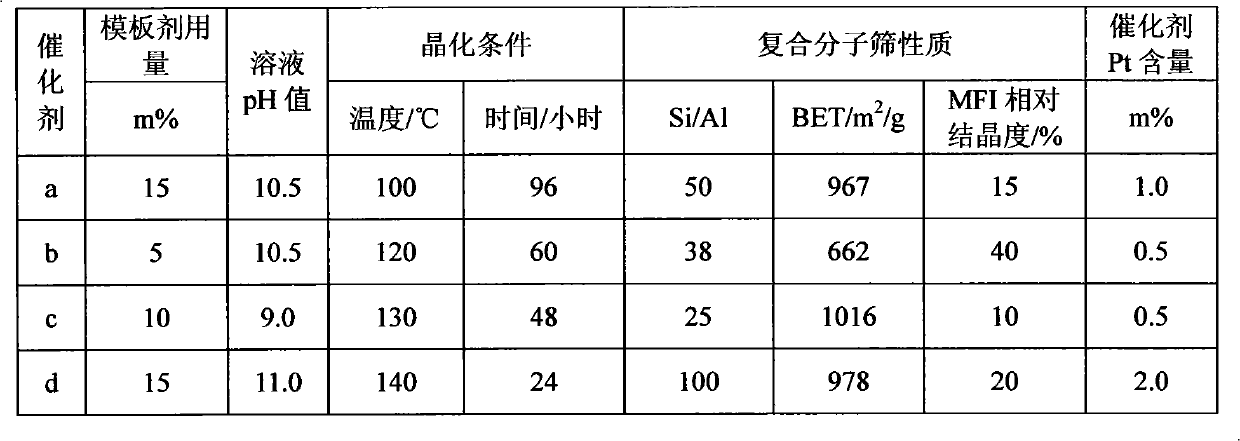

[0023] According to the experimental procedure of Example 1 and the raw materials and operating conditions shown in Table 1, catalysts a, b, c, and d can be obtained.

[0024] Table 1 The parameters related to the preparation of catalysts a~d

[0025]

[0026]

Embodiment 5

[0028]The hydrogen-type composite molecular sieve obtained by ion exchange in Example 1 was prepared catalyst e according to the same aftertreatment method in Example 1 (by weight percentage of the catalyst, the content of alumina was 49%, and the content of Pt was 0.05%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com