Preparation method of condensation point reducer with dual functions of reducing condensation point and turbidity point

A dual-function, pour point depressant technology, applied in lubricating compositions and other directions, can solve the problems of prone to poisoning accidents, cannot change the cloud point, pollute the environment, etc. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

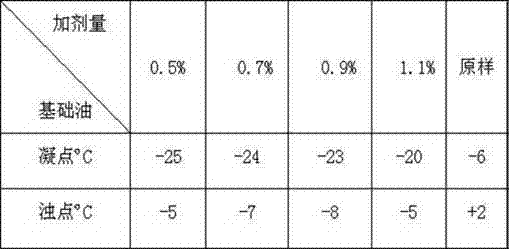

Image

Examples

Embodiment 1

[0026] Example 1: A method for preparing a pour point depressant with dual functions of reducing pour point and turbidity, combining 275 g of C8-C18 fatty alcohol, 86 g of methacrylic acid, 2 g of polymerization inhibitor hydroquinone, and catalyst p-toluene sulfonic acid 4g, 250g of diluted oil, heated, the esterification reaction was carried out at 120oC, after about 5 hours of reaction, a crude product of octadecyl methacrylate was obtained. After the crude product was neutralized with an aqueous alkali solution to pH=7, the organic layer was separated and the organic The layer is washed with water, the vacuum pump is turned on and dehydrated under reduced pressure. The higher alcohol methacrylate is obtained by dehydrating at 115oC for 5 hours. The esterification rate is 96.5%. The prepared higher alcohol methacrylate is added under the protection of nitrogen with acid anhydride or The ratio of ester, initiator benzoyl peroxide, higher alcohol methacrylate to initiator to ac...

Embodiment 2

[0027] Example 2: A method for preparing a pour point depressant with dual functions of reducing pour point and turbidity, combining 248 g of C8-C18 fatty alcohol, 86 g of methacrylic acid, 2 g of polymerization inhibitor hydroquinone, and catalyst p-toluene sulfonic acid 4g, 250g of diluted oil, heated, the esterification reaction was carried out at 120oC, after about 5 hours of reaction, a crude product of octadecyl methacrylate was obtained. After the crude product was neutralized with an aqueous alkali solution to pH=7, the organic layer was separated and the organic The layer was washed with water, the vacuum pump was turned on and dehydrated under reduced pressure, and dehydrated at 115oC for 5 hours to obtain higher alcohol methacrylate with an esterification rate of 95.2.5%. The prepared higher alcohol methacrylate was added under the protection of nitrogen The ratio of acid anhydride or ester, initiator benzoyl peroxide, higher alcohol methacrylate to initiator to acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com