Method for preparing biodiesel

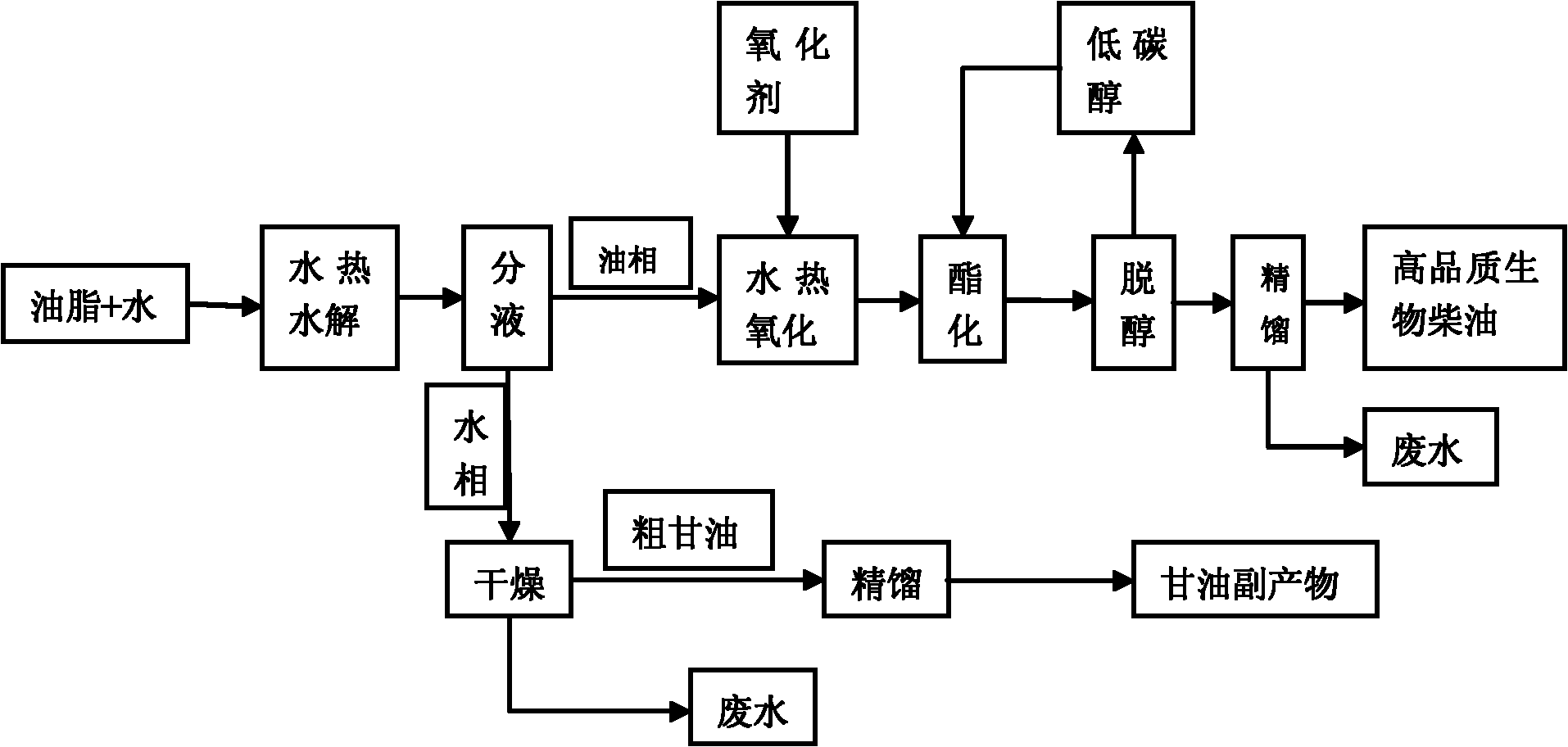

A biodiesel and oil technology, which is applied in the fields of biofuel, fatty acid preparation/refining, petroleum industry, etc., can solve the problems such as low temperature fluidity and antioxidant properties of biodiesel, loss of effective components of biodiesel, and increased refrigeration cost, etc. Achieve the effect of alleviating the global energy crisis, avoiding catalyst removal, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the small-scale experiment, the main product after oil hydrolysis-oleic acid was used as the model substance of the unsaturated polymer fatty acid generated after the raw oil hydrolysis; using commercially available 30% H 2 o 2 As the oxidant raw material required in the incomplete oxidation, the reactor adopts a tubular hydrothermal reactor made of SUS316 for a small test experiment.

[0032] This embodiment adopts the following steps:

[0033] 1. Mix 0.7g oleic acid with 1.7ml H 2 o 2 The solution was added to the tubular hydrothermal reactor with a filling rate of 30%. H in the reactor 2 o 2 The concentration is kept at about 3%, so that the amount of oxidizing agent is about oleic acid is completely oxidized to CO 2 and H 2 1% (by molar ratio) of oxygen demand of O, under the conditions of 300° C. and pressure 25-30 MPa, react for 10 minutes to carry out partial selective oxidation reaction.

[0034] 2. After the oxidation reaction is completed, methanol ...

Embodiment 2

[0037] 1. Mix 0.7g oleic acid with 1.7ml H 2 o 2 The solution was added to the tubular hydrothermal reactor with a filling rate of 30%. H in the reactor 2 o 2 The concentration is kept at about 15%, so that the amount of oxidizing agent is completely oxidized to CO 2 and H 25% of O oxygen demand, at 300°C, 5-10MPa, under the condition of 5min for partial selective oxidation.

[0038] 2. After the oxidation reaction is completed, the amount of methanol added is 30 times that of oleic acid (in molar ratio). The hydrothermal esterification reaction is carried out under the condition that the reaction temperature is 350° C., the pressure is 25-30 MPa, and the reaction time is 15 minutes. After the reaction is complete, the product is dealcoholized, the excess low-carbon alcohol is recovered for recycling, and high-quality biodiesel is obtained after rectification dealcoholization. Finally, 0.687g of biodiesel A was obtained.

[0039] The method biodiesel conversion rate re...

Embodiment 3

[0041] 1. Mix 0.7g oleic acid with 1.7ml H 2 o 2 The solution was added to the tubular hydrothermal reactor with a filling rate of 50%. H in the reactor 2 o 2 The concentration is kept at about 20%, so that the amount of oxidizing agent is completely oxidized to CO 2 and H 2 10% of O oxygen demand, at 350 ° C, 20 MPa, under the conditions of reaction 0.5 min for partial selective oxidation.

[0042] 2. After the oxidation reaction is completed, the amount of methanol added is 40 times that of oleic acid (in molar ratio). The reaction temperature is 300° C., 15-20 MPa, and the hydrothermal esterification reaction is carried out under the conditions of reaction for 10 minutes. After the reaction is complete, the product is dealcoholized, the excess low-carbon alcohol is recovered for recycling, and high-quality biodiesel is obtained after rectification dealcoholization. Finally, 0.6866g of biodiesel A was obtained.

[0043] A represents the above-mentioned esterification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com