Preparation method of turbidity reducing agent

A technology of turbidity reducing agent and catalyst, which is used in petroleum industry, lubricating composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

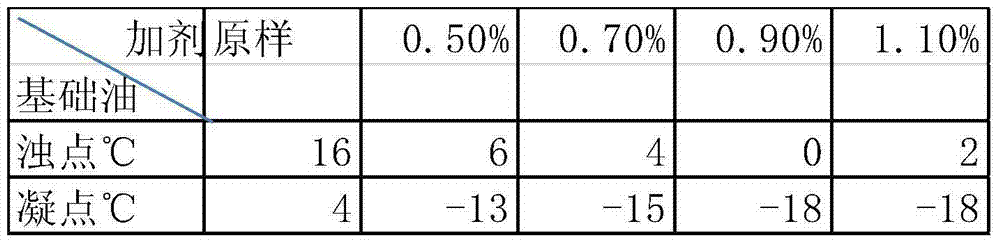

Embodiment 1

[0015] A kind of preparation method of novel turbidity reducer, with the fatty alcohol 210g of C12-14, the fatty alcohol 255g of C14-18 is mixed with 90g methacrylic acid respectively, each reaction adds inhibitor hydroquinone 1.7g, and catalyst is to 4g of toluenesulfonic acid, after all the reactants melted, under the protection of nitrogen, the temperature was raised to 120°C for 5 hours to react, and the crude product of higher alcohol methacrylate was produced. After neutralizing the obtained crude product with aqueous sodium hydroxide solution to pH = 7, the organic layer was separated, washed with water, and dehydrated to obtain higher alcohol methacrylate. Mix the prepared C12-C14, C14-C18 two high-carbon alcohol esters of methacrylate according to the mass ratio of 1:3, under the protection of nitrogen, add acid anhydride, ester or styrene, the initiator azoisobutylene Nitrile was reacted at 120°C for 7 hours to obtain its polymer. Wherein, the mass ratio of higher a...

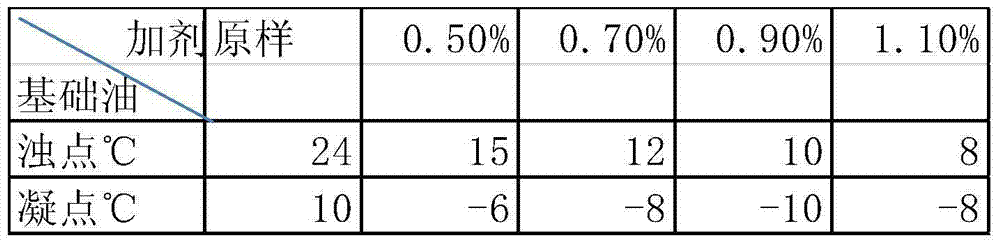

Embodiment 2

[0018] (1), the molar ratio is 1:1.01 C12-14, the linear fatty alcohol of C14-18 is mixed with methacrylic acid respectively, add inhibitor hydroquinone, catalyst p-toluenesulfonic acid, in nitrogen Under protection, the reaction temperature is 100 ° C for 8 hours, and the reaction generates a crude product of higher alcohol methacrylate; its mass ratio is fatty alcohol: polymerization inhibitor: catalyst = 90:1:1;

[0019] (2), the high-carbon alcohol crude product of methacrylic acid obtained in step (1), adding sodium hydroxide solution to neutralize to pH=7, stirring, making its redundant methacrylic acid completely neutralized, and separating the organic layer; Higher alcohol methacrylate;

[0020] (3), mix C12-C14, C14-C18 two kinds of straight-chain higher alcohol methacrylates according to the mass ratio of 1:1, under the protection of nitrogen, add maleic anhydride, initiator azoisobutylene Nitrile was reacted at 80°C for 8 hours to obtain a polymer, namely: the targ...

Embodiment 3

[0023] (1), the molar ratio is 1:1.05 C12-14, C14-18 straight-chain aliphatic alcohol is mixed with methacrylic acid respectively, add inhibitor hydroquinone, catalyst p-toluenesulfonic acid, in nitrogen Under protection, the reaction temperature is 140°C for 2 hours, and the crude product of higher alcohol methacrylate is generated in the reaction; the mass ratio is fatty alcohol:inhibitor:catalyst=95:1.5:1;

[0024] (2), the high-carbon alcohol crude product of methacrylic acid obtained in step (1), adding sodium hydroxide solution to neutralize to pH=7, stirring, making its redundant methacrylic acid completely neutralized, and separating the organic layer; Higher alcohol methacrylate;

[0025] (3), C12-C14, C14-C18 two kinds of linear high-carbon alcohol esters are mixed according to the mass ratio of 1:6, under the protection of nitrogen, add vinyl acetate, initiator azoisobisbutyronitrile, in React at 130°C for 6 hours to obtain a polymer, namely: the target product; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com