Production method of sea-buckthorn transparency liquid facial soap

A technology of transparent liquid and production method, which is applied in the field of daily chemicals to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

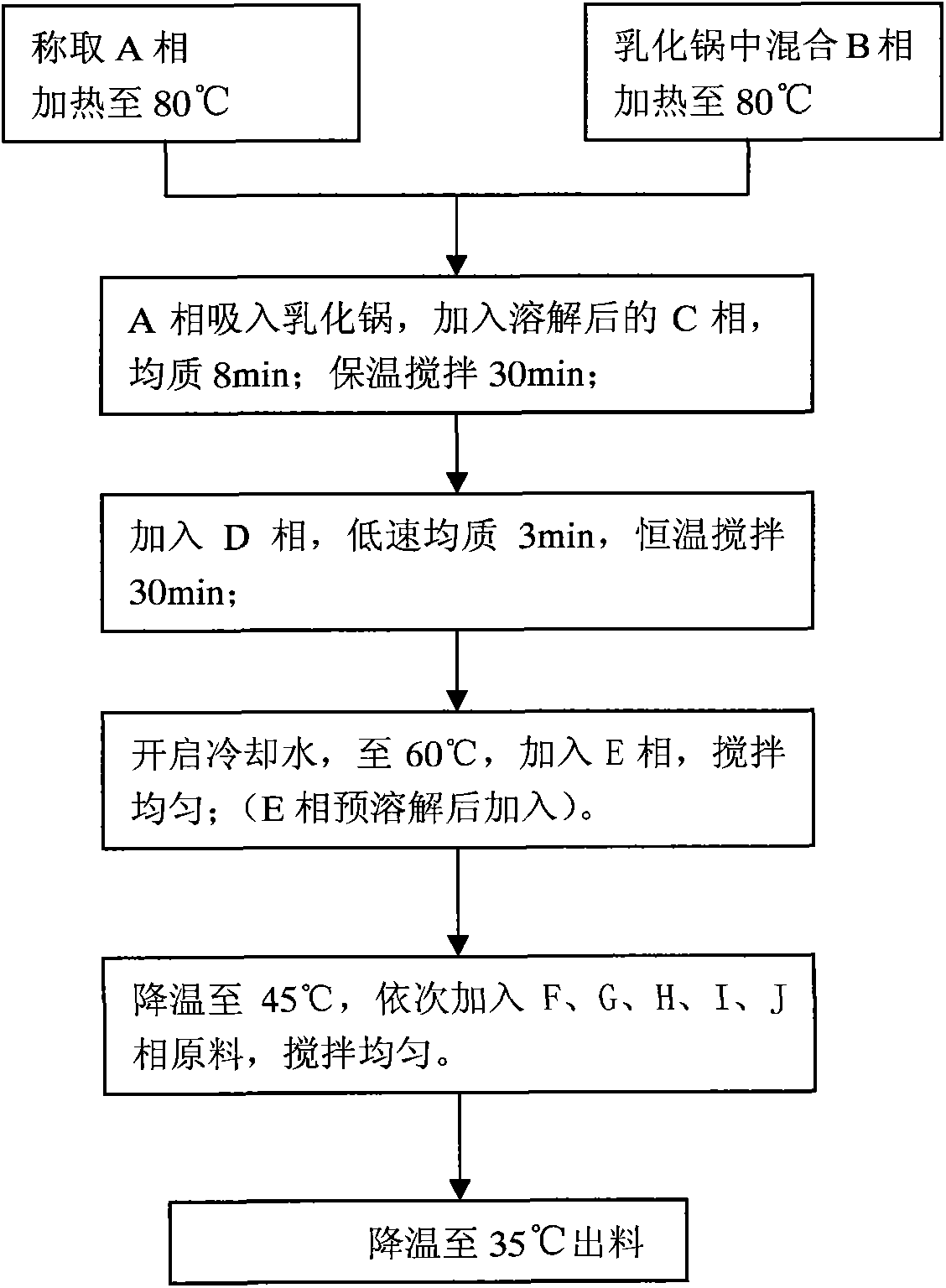

Image

Examples

Embodiment 1

[0028] (1) Mix phase A: weigh 6 parts by weight of lauric acid and 1.5 parts by weight of myristic acid, mix them in a water pot until uniform, and heat to 80°C;

[0029] (2) Mix phase B: add 10 parts by weight of glycerin to a vacuum emulsification stirring pot and then copolymerize with 5 parts by weight of acrylic esters, or 5 parts by weight of stearyl ether-20 methacrylate Mix the material, add water and heat to 80°C, stir until the material is evenly dispersed;

[0030] (3) Mixing Phase A, Phase B and Phase C: Inhale the final mixture obtained in step (1) into a vacuum emulsification stirring pot and mix it with the mixture obtained in step (2), then add 2.86 parts by weight and the purity is 91.5 % potassium hydroxide, 10 parts by weight of water, homogenized for 8 minutes, and incubated for 30 minutes;

[0031] (4) Mix phase A, phase B, phase C, and phase D: add 0.2 parts by weight of cocamide MEA and sodium laureth sulfate of 4 parts by weight to the mixture finally ...

Embodiment 2

[0041] (1) Mix phase A: weigh 6 parts by weight of lauric acid and 1.5 parts by weight of myristic acid, mix them in a water pot until uniform, and heat to 80°C;

[0042] (2) Mix phase B: add 15 parts by weight of glycerin to a vacuum emulsification stirring pot and then copolymerize with 5 parts by weight of acrylic acid esters, or 5 parts by weight of steareth-20 methacrylate Mix the material, add water and heat to 80°C, stir until the material is evenly dispersed;

[0043] (3) Mix phase A, phase B and phase c: suck the mixture finally obtained in step (1) into a vacuum emulsification stirring pot and mix it with the mixture finally obtained in step (2), then add 2.86 parts by weight and the purity is 91.5 % potassium hydroxide, 10 parts by weight of water, homogenized for 8 minutes, and incubated for 30 minutes;

[0044] (4) Mix phases A, B, C and D: add 0.2 parts by weight of cocamide MEA and 6 parts by weight of sodium laureth sulfate to the final mixture obtained in ste...

Embodiment 3

[0054] (1) Mix phase A: weigh 8 parts by weight of lauric acid and 2 parts by weight of myristic acid, mix them in a water pot until uniform, and heat to 80°C;

[0055] (2) Mix phase B: add 10 parts by weight of glycerin to a vacuum emulsification stirring pot and then copolymerize with 5 parts by weight of acrylic esters, or 5 parts by weight of stearyl ether-20 methacrylate Mix the material, add water and heat to 80°C, stir until the material is evenly dispersed;

[0056] (3) Mix phase A, phase B and phase C: suck the mixture finally obtained in step (1) into a vacuum emulsification stirring pot and mix it with the mixture finally obtained in step (2), then add 3.81 parts by weight and the purity is 91.5 % potassium hydroxide, 10 parts by weight of water, homogenized for 8 minutes, and incubated for 30 minutes;

[0057] (4) Mix phase A, phase B, phase C, and phase D: add 0.2 parts by weight of cocamide MEA and sodium laureth sulfate of 4 parts by weight to the mixture final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com