High-efficiency hydrate inhibitive environment-friendly drilling fluid

A hydrate and inhibitory technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of weak inhibitory effect, and achieve the effect of less inhibitor addition, significant bactericidal effect, and good generation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

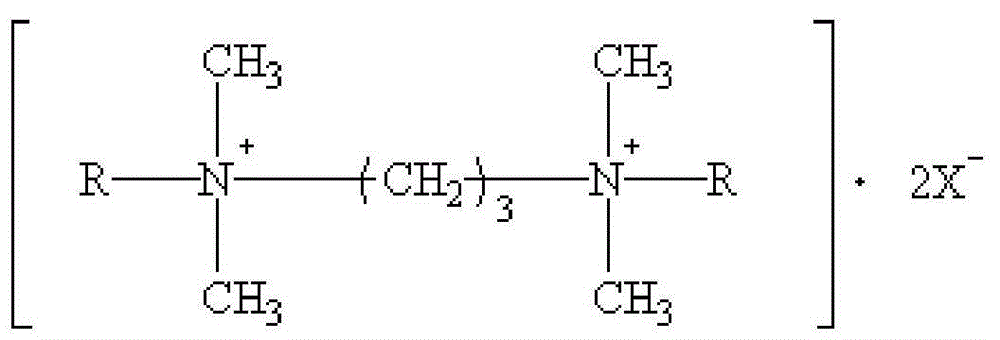

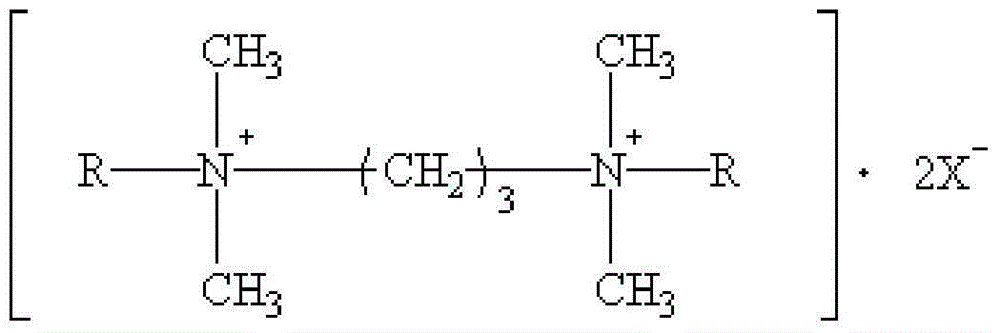

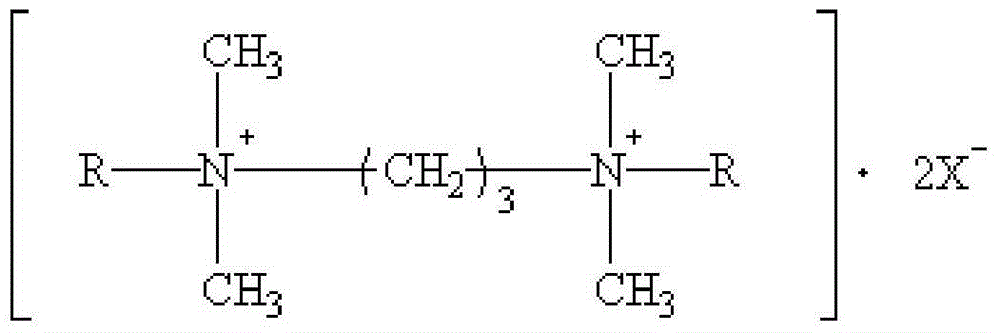

[0022] Drilling fluid comprises the following components by weight percentage: bentonite 4%, quaternary ammonium salt type gemini surfactant (X — = Cl — ) 0.1%, sodium chloride 5.0%, sodium carboxymethyl starch 2.0%, cationic polyacrylamide CPAM (molecular weight 4 million) 0.2%, solid anti-slump lubricant GFRH 1%. The experimental pressure was 15.0MPa, the controlled temperature was 0°C, and the experimental gas was methane with a purity of 99.9%. Under the experimental conditions, no hydrate was formed for 120 hours.

Embodiment 2

[0024] Drilling fluid comprises the following components by weight percentage: bentonite 6%, quaternary ammonium salt type gemini surfactant (X — = Cl — ) 0.4%, sodium chloride 8.0%, sodium carboxymethyl starch at 2.0%, cationic polyacrylamide CPAM (molecular weight 8 million) 0.5%, solid anti-slump lubricant GFRH at 2.0%. The experimental pressure was 15.1 MPa, the controlled temperature was -2.5°C, and the experimental gas was methane with a purity of 99.9%. Under the experimental conditions, no hydrate was formed for 120 hours.

Embodiment 3

[0026] Drilling fluid comprises the following components by weight percentage: bentonite 8.0%, quaternary ammonium salt type gemini surfactant (X — =Br — ) 0.7%, potassium chloride 8.0%, sodium carboxymethyl starch 3.0%, cationic polyacrylamide CPAM (molecular weight 12 million) 1.0%, solid anti-slump lubricant GFRH at 2.0%, test pressure 15.0MPa, control temperature -4.0 ℃, the experimental gas is methane with a purity of 99.9%, and no hydrate has been formed for 120 hours under the experimental conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com