Halogen-free flame-retardant electronic material and preparation method thereof

A technology of electronic materials and particles, applied in the field of halogen-free flame retardant electronic materials and their preparation, can solve the problems of reducing the thermal properties of materials and failing to achieve the flame retardant effect, so as to improve the thermal properties, avoid the decrease of the dielectric properties, and maintain the Effect of toughness and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a halogen-free flame-retardant electronic material, comprising the following steps:

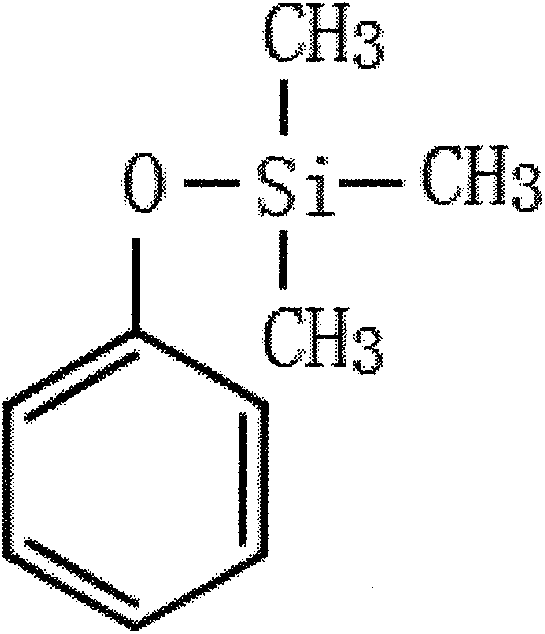

[0022] Add 5g of fullerene derivative PCBM to 4000g of cyanate chlorobenzene solution (25wt%), then add 100g of diethylphenylphosphate and 150g of enol silyl ether, and add 80g of dicarboxyphthalate after 80 minutes of reflux reaction Formimide, reacted for 75 minutes, then rotary evaporated, dried at 135°C to remove the solvent, and obtained a cyanate ester prepolymer; the cyanate ester prepolymer was mixed with 100g N-4-hydroxyphenyl maleic anhydride imide, 450g naphthalene Phenolic phenolic resin, 400g tetraglycidyl diaminodimethylbenzene mixed, stirred at 120°C for 45 minutes, then added 5g silicon carbide short fiber and 100g 1,8-octanedithiol, continued to stir for 20 minutes, cooled naturally to obtain cyanide Ester modified product; then crush the cyanate modified product, add 150g polyphenylene sulfide and 60g hollow alumina into the extruder, and extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com