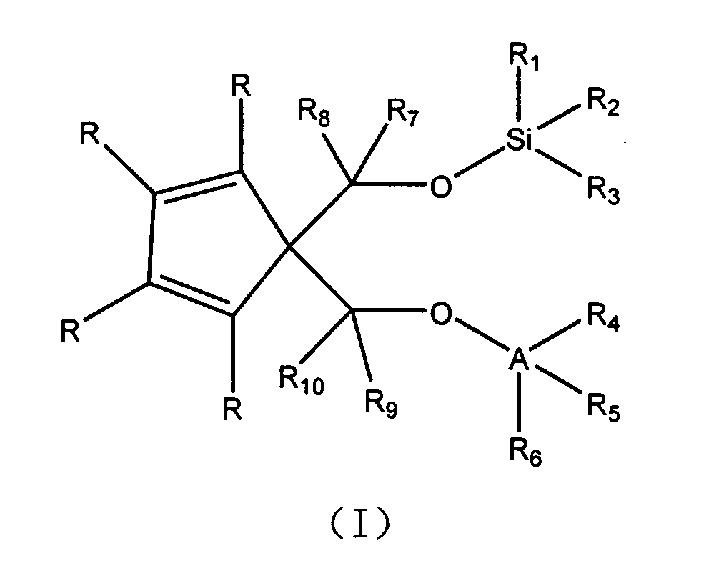

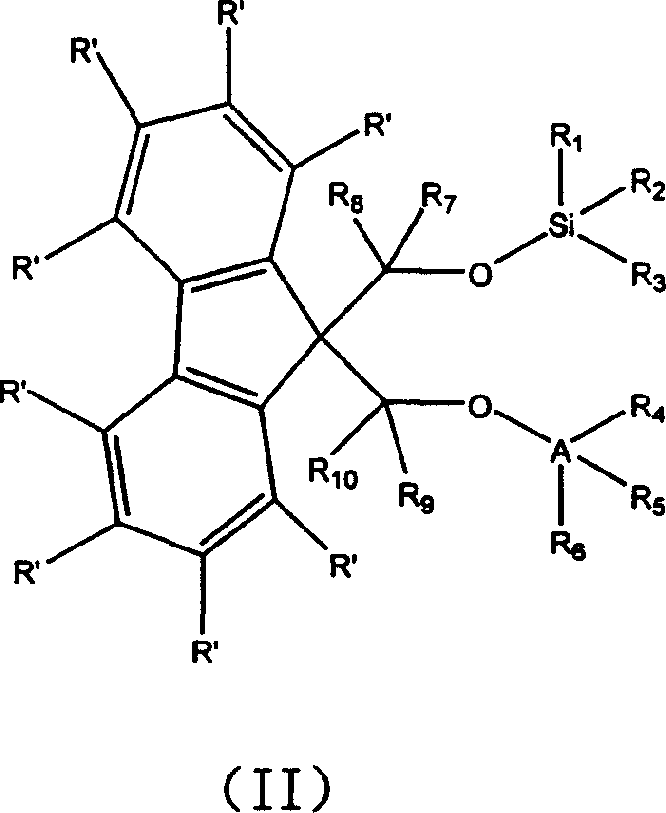

Silicon ether compound and preparation method and application thereof

A kind of technology of compound and silyl ether, applied in the application field of preparing olefin polymerization catalyst, can solve problems such as synthesis method not reported in literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of 9-(methoxymethyl)-9-(hydroxymethyl)fluorene

[0074] Under nitrogen protection and anhydrous conditions, 80ml of tetrahydrofuran, 22.6g of 9,9-bis(hydroxymethyl)fluorene and 57g of methyl iodide were sequentially added, stirred and the reactants were completely mixed evenly. At room temperature, within 2 hours, 4.6 g of sodium hydride with a content of 52% was added in batches, and stirring was continued for 2 hours after the addition was completed.

[0075] Unreacted methyl iodide was recovered by distillation, and the remaining material was diluted with 100 ml of water and extracted twice with 100 ml of ether. The ether extracts were combined and dried by adding anhydrous sodium sulfate. After the dried ether solution was evaporated to dryness, 22.8 g of crude product were obtained. After separation and purification by column chromatography, 14.9 g of 9-(methoxymethyl)-9-(hydroxymethyl)fluorene was obtained (yield 62%).

[0076] 1 H-NMR (CDCl 3 / TM...

Embodiment 2

[0078] Preparation of 9-(methoxymethyl)-9-[(trimethylsilyl)oxymethyl]fluorene

[0079] 1g of 9-(methoxymethyl)-9-(hydroxymethyl)fluorene was dissolved in 20ml of dichloromethane. The solution was cooled below 5°C, 0.7ml of triethylamine was added, stirred for 5 minutes, then 0.6ml of trimethylchlorosilane was added dropwise, and stirred for 2 hours. Stir for an additional 1 hour at room temperature. The reaction solution was washed with water, and the separated organic layer was dried over anhydrous sodium sulfate, filtered, and concentrated to obtain 1.41 g of a concentrate (yield 86%). Mass spectrometry (EI) m / e: 312 (M+).

[0080] 1H-NMR (CDCl3 / TMS) δ (ppm): 0.15 (s, 9H, 3CH3), 3.42 (s, 3H, -OCH3), 3.74 (s, 2H, -CH2O-), 3.82 (s, 2H, - CH2O-), 7.36(t, 2H, ArH), 7.44(t, 2H, ArH), 7.70(d, 2H, ArH), 7.80(d, 2H, ArH).

Embodiment 3

[0082] Preparation of 9,9-bis[(trimethylsilyl)oxymethyl]fluorene

[0083] Mix 1 g of 9,9-bis(hydroxymethyl)fluorene and 20 ml of dichloromethane, and cool the mixture with an ice bath. 1.9 ml of triethylamine was added to the mixture, and 1.4 ml of trimethylsilyl chloride was added dropwise. Stir under ice bath for 2 hours. The reaction solution was washed with water, and the organic layer was separated, dried over anhydrous sodium sulfate, filtered, and concentrated to obtain 1.14 g of a concentrate (yield 88%). Mass spectrometry (EI) m / e: 370 (M+).

[0084] 1 H-NMR (CDCl 3 / TMS) δ (ppm): 0.08 (s, 18H, 6CH 3 ), 3.77 (s, 4H, 2-CH 2 O-), 7.26(t, 2H, ArH), 7.38(t, 2H, ArH), 7.62(d, 2H, ArH), 7.72(d, 2H, ArH).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com