Water soluble antirusting fluid, and preparation method and using method thereof

A kind of antirust liquid and water-soluble technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of inconspicuous saving of petroleum resources, failure of oil and water, small amount of water, etc., and achieves simple and convenient preparation and use methods, The cost of use is environmentally friendly and pollution-free, and the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

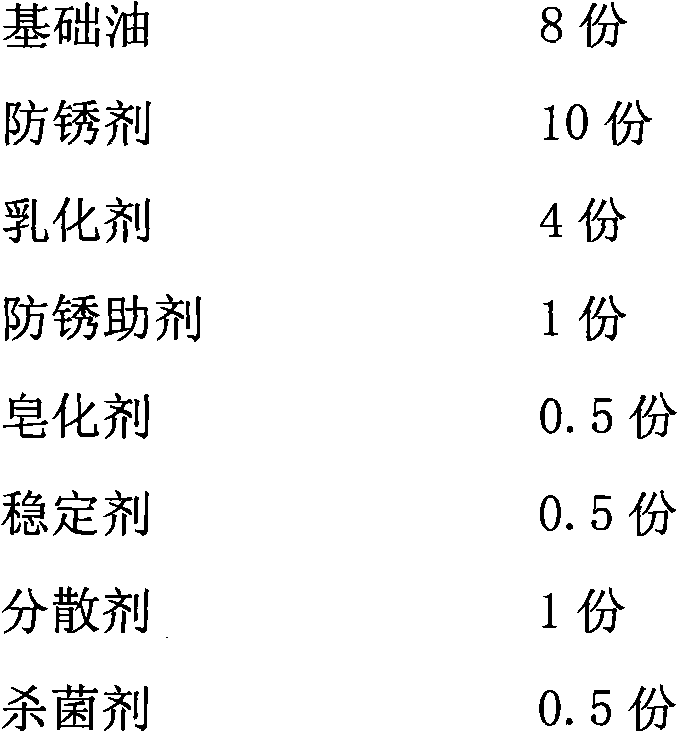

[0029]

[0030] Wherein said base oil is 10# light machine oil, and described antirust agent is the compound of various antirust agents (rust inhibitor is barium petroleum sulfonate, lanolin magnesium soap, triethanolamine oleate and benzene The compound of triazole, its mass ratio is 3:2:1:0.1), the described emulsifier is OP-10, the compound of Pingping plus O and 6501 (the emulsifying agent is OP-10, Pingping Add the compound of O and 6501, its mass ratio is 5:2:2), the described anti-rust additive is the compound of polyoxysilane and light paraffin, its mass ratio is 1:1, Described saponification agent is general soap, and described stabilizer is triethanolamine, and described dispersant is glycerin, and described bactericide is sodium benzoate.

[0031] Add barium petroleum sulfonate and magnesium lanolin soap to the container in sequence according to the mass components, heat to melt, add triethanolamine oleate and benzotriazole under continuous stirring, and make the...

Embodiment 2

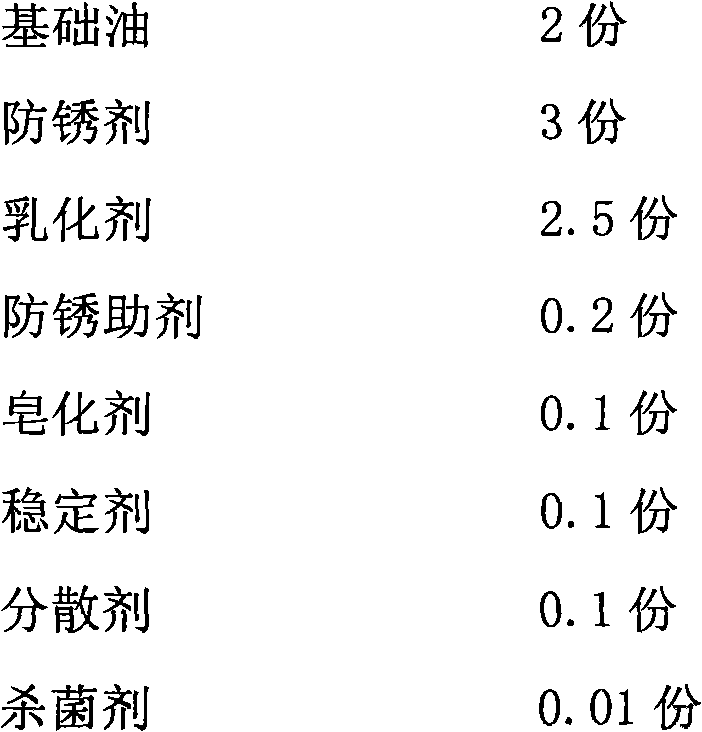

[0034]

[0035] Wherein said base oil is 10# light machine oil, and described antirust agent is the compound of various antirust agents (rust inhibitor is barium petroleum sulfonate, lanolin magnesium soap, triethanolamine oleate and benzene The compound of triazole, its mass ratio is 3:2:1:0.1), the described emulsifier is OP-10, the compound of Pingping plus O and 6501 (the emulsifying agent is OP-10, Pingping Add the compound of O and 6501, its mass ratio is 5:2:2), the described anti-rust additive is the compound of polyoxysilane and light paraffin, its mass ratio is 1:1, Described saponification agent is general soap, and described stabilizer is triethanolamine, and described dispersant is kerosene, and described bactericide is sodium benzoate.

[0036] Add barium petroleum sulfonate and magnesium lanolin soap to the container in sequence according to the mass components, heat to melt, add triethanolamine oleate and benzotriazole under continuous stirring, and make the...

Embodiment 3

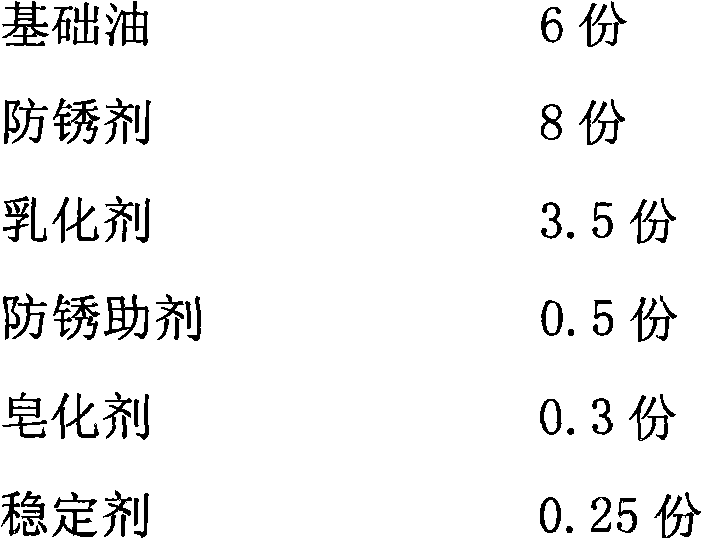

[0039]

[0040]

[0041] Wherein said base oil is 10# light machine oil, and described antirust agent is the compound of various antirust agents (rust inhibitor is barium petroleum sulfonate, lanolin magnesium soap, triethanolamine oleate and benzene The compound of triazole, its mass ratio is 3:2:1:0.1), the described emulsifier is OP-10, the compound of Pingping plus O and 6501 (the emulsifying agent is OP-10, Pingping Add the compound of O and 6501, its mass ratio is 5:2:2), the described anti-rust additive is the compound of polyoxysilane and light paraffin, its mass ratio is 1:1, Described saponification agent is general soap, and described stabilizer is triethanolamine, and described dispersant is alcohol, and described bactericide is sodium benzoate.

[0042] Add barium petroleum sulfonate and magnesium lanolin soap to the container in sequence according to the mass components, heat to melt, add triethanolamine oleate and benzotriazole under continuous stirring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com