Preparation method of silicon-aluminum composite aerogel powder

A composite airgel and silica-alumina technology, which is applied in the direction of airgel preparation, silicon compounds, chemical instruments and methods, etc., can solve the problem that the pH value of strong alkali sodium hydroxide is not easy to control, affects the quality of airgel, and cannot be salted Ion removal and other issues, to achieve the effect of shortening the reaction process time, high porosity and specific surface area, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

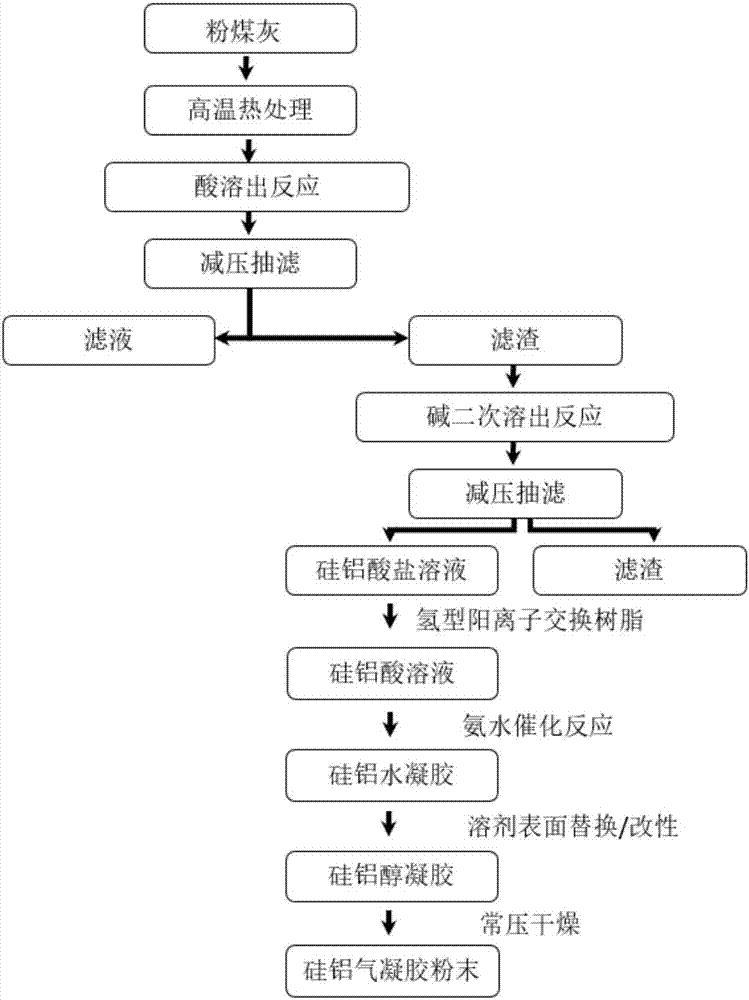

[0035] A method for preparing silicon-aluminum composite airgel powder by drying under normal pressure with fly ash as raw material, such as figure 1 As shown, the following steps are included: the solid waste fly ash of the coal-fired power plant is pretreated in a high-temperature box-type resistance furnace at 750 ° C for 3 hours. Weigh 10 g of activated fly ash, add 100 mL of 5 mol / L hydrochloric acid solution, and react for 2 hours in a boiling water bath. After the reaction, the solution was subjected to suction filtration, and the filtrate was a yellow transparent liquid, which was recovered for processing, and the filter residue was retained. According to the mass ratio of sodium hydroxide and the first acid stripping filter residue of 0.4, 15wt.% sodium hydroxide solution and the filter residue were subjected to alkali dissolution reaction for 3 hours, and the above reaction was followed by secondary suction filtration, and the filtrate was retained. The filtrate was ...

Embodiment 2

[0037] A method for preparing silicon-aluminum composite airgel powder by drying under normal pressure with fly ash as raw material, such as figure 1 As shown, the following steps are included: the solid waste fly ash of a coal-fired power plant is pretreated in a high-temperature box-type resistance furnace at 700 ° C for 2 hours. Weigh 10 g of activated fly ash, add 100 mL of 4 mol / L hydrochloric acid solution, and react for 3 hours in a boiling water bath. After the reaction, the solution was subjected to suction filtration, and the filtrate was a yellow transparent liquid, which was recovered for processing, and the filter residue was retained. According to the mass ratio of sodium hydroxide and the first acid stripping filter residue of 0.2, 20wt.% sodium hydroxide solution and the filter residue were subjected to alkali dissolution reaction for 3 hours, and the above reaction was followed by secondary suction filtration, and the filtrate was retained. The filtrate was a ...

Embodiment 3

[0039] A method for preparing silicon-aluminum composite airgel powder by drying under normal pressure with fly ash as raw material, such as figure 1 As shown, the following steps are included: the solid waste fly ash of the coal-fired power plant is pretreated in a high-temperature box-type resistance furnace at 750 ° C for 3 hours. Weigh 10 g of activated fly ash, add 100 mL of 6 mol / L hydrochloric acid solution, and react for 3 hours under boiling water bath conditions. After the reaction, the solution was subjected to suction filtration, and the filtrate was a yellow transparent liquid, which was recovered for processing, and the filter residue was retained. According to the mass ratio of sodium hydroxide and the first acid stripping filter residue of 0.6, 10wt.% sodium hydroxide solution and the filter residue were subjected to alkali dissolution reaction for 2 hours, and the above reaction was followed by secondary suction filtration, and the filtrate was retained. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com