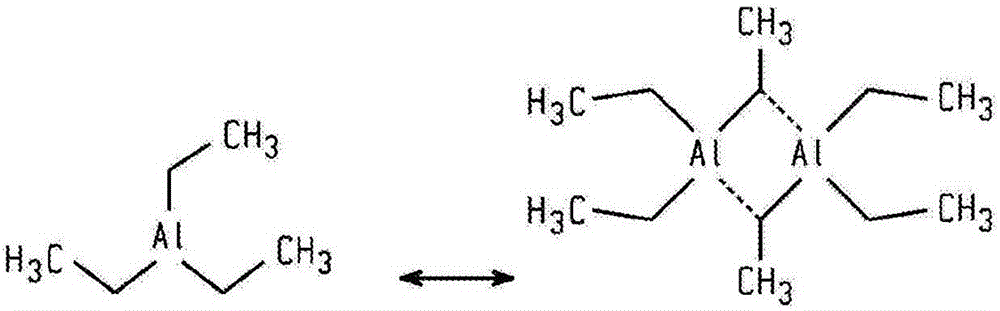

Modifying organoaluminum co-catalysts for improved performance

A modifier and catalyst technology, applied in catalysts, organic chemistry, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of too long initial induction period of polymer formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

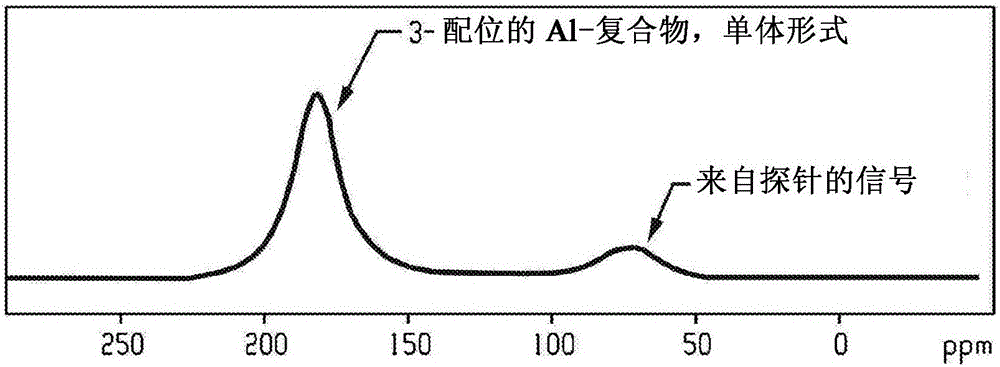

Method used

Image

Examples

Embodiment

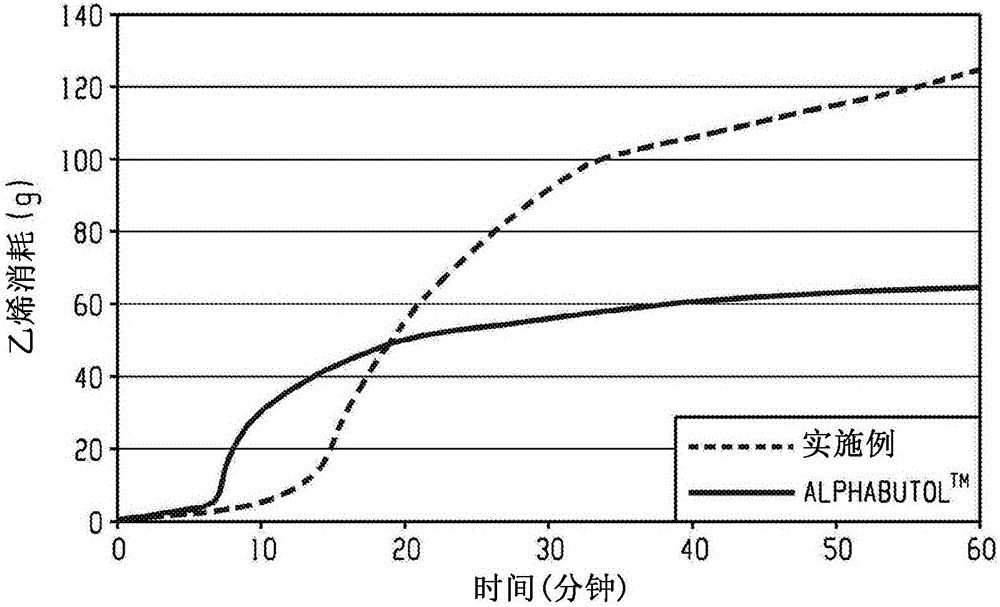

[0069] The following examples are merely illustrative of the subject matter of the present disclosure and they should not be considered as limiting the scope of the subject matter of the present disclosure in any way.

[0070] The following experiments were performed in a 300 mL jacketed Parr autoclave reactor (Parr Modell 4566). Standard conditions are 23 bar ethylene pressure and 60°C for 1 hour.

[0071] Commercial Alphabutol TM system

[0072] To use commercial Alphabutol TM The experiment was systematically performed by dissolving 1 mL of a catalytic solution containing 45 vol.% THF and 55 vol% of TNBT in 50 mL of n-hexane prepared in a glove box under a nitrogen atmosphere. Before use, add 3.6 mL of 1M TEAL solution to activate TNBT. The activated catalyst composition was introduced into the reactor by vacuum suction. The reactor was then pressurized with ethylene from a 2-liter aluminum cylinder (ethylene supply) to achieve the desired pressure (23 bar in most expe...

Embodiment approach 1

[0079] Embodiment 1. A method of preparing a catalyst composition comprising: treating an organoaluminum compound with a modifier that reduces the initial reduction strength of the organoaluminum compound, wherein the modifier is selected from the group consisting of ethers , anhydrides, amines, amides, silicates, silyl ethers, siloxanes, esters, carbonates, carbamates, ureas, sulfoxides, sulfones, phosphoramides, silanes and acetals; transition metal complexes adding to a mixture of an organoaluminum compound and a modifier; and obtaining a catalyst composition comprising an organoaluminum compound and a transition metal complex.

Embodiment approach 2

[0080] Embodiment 2. The method of embodiment 1, wherein the transition metal complex comprises at least one metal of Groups IV-B, V-B, VI-B and VIII of the Periodic Table of the Elements, preferably wherein the metal is titanium, zirconium , hafnium, vanadium, niobium, tantalum, chromium, molybdenum, tungsten, iron, cobalt, nickel or combinations thereof, more preferably, wherein the transition metal complex is tetra-n-butoxytitanium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com