Purification method of silicon tetrafluoride prepared by using fluoride and silicon source power as raw materials

A technology of silicon tetrafluoride and purification method, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve the problem of high cost of silica gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

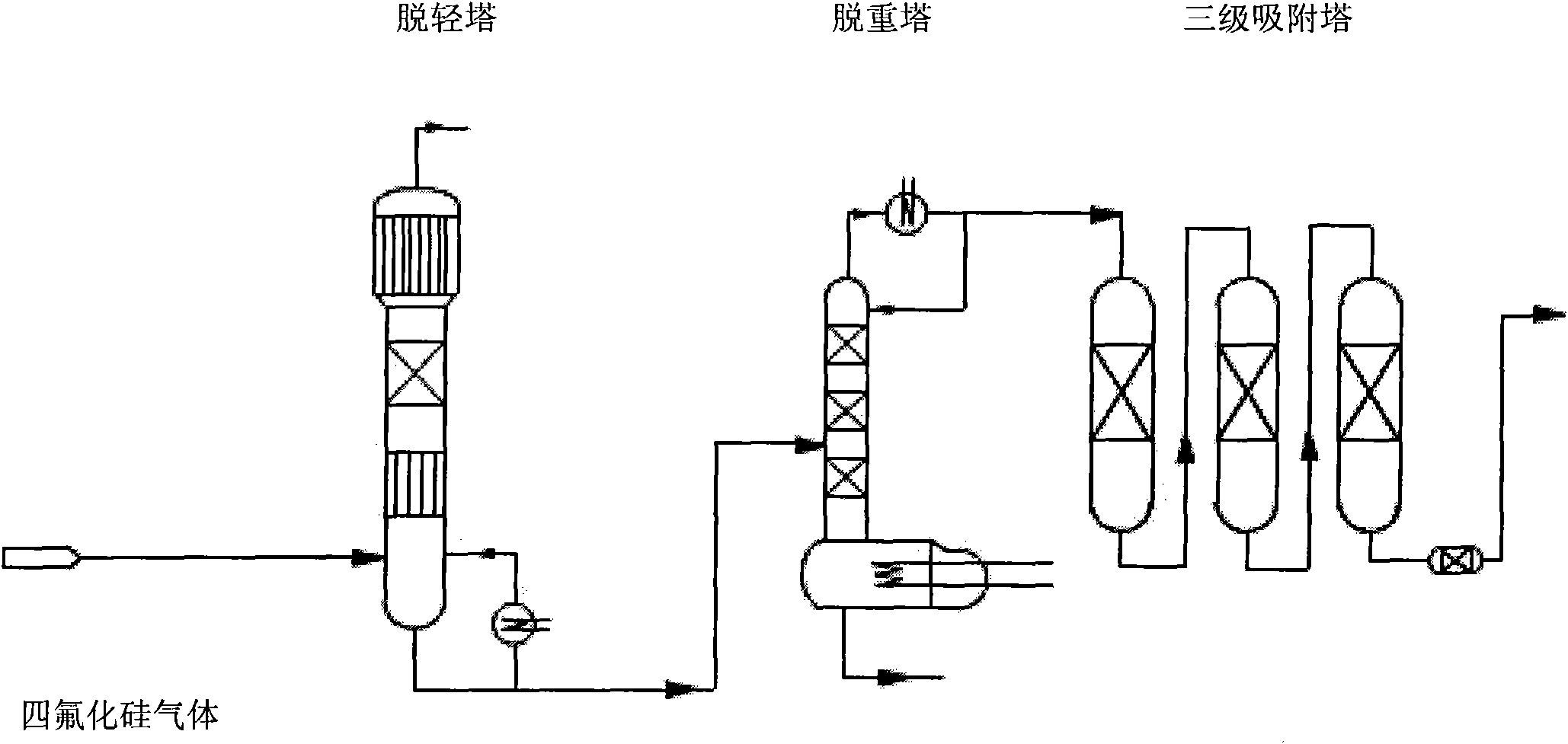

[0028] The crude silicon tetrafluoride produced with fluoride and silicon source powder as raw materials is passed through a light-removing tower to remove nitrogen, oxygen, carbon dioxide and carbon monoxide at -150 ° C. The operating pressure of the light-removing tower is 0.1MPa; The bottom liquid phase material is passed into the weight-removing tower, the moisture and hydrogen fluoride are removed from the bottom of the tower at a temperature of -20 ℃, the silicon tetrafluoride gas is discharged through the top of the tower, and the operating pressure of the weight-removing tower is 0.5MPa; The discharged silicon tetrafluoride gas passes through a three-stage adsorption tower, and the adsorption tower is equipped with activated carbon, and the moisture content of the activated carbon is below 0.8%. The hexafluorodimethylsilyl ether is removed by adsorption; the purified silicon tetrafluoride gas comes out of the adsorption tower and is connected to the compressor pipeline,...

Embodiment 2

[0031] The crude silicon tetrafluoride produced from fluoride and silicon source powder is passed through a light-removing tower to remove nitrogen, oxygen, carbon dioxide and carbon monoxide at -50°C. The operating pressure of the light-removing tower is 3MPa; The bottom liquid phase material is passed into the weight-removing tower, the moisture and hydrogen fluoride are removed from the bottom of the tower at a temperature of 80 ° C, and the silicon tetrafluoride gas is discharged through the top of the tower, and the operating pressure of the weight-removing tower is 5MPa; The silicon fluoride gas passes through the three-stage adsorption tower, and the adsorption tower is equipped with activated carbon, and the quasi-dry humidity of the activated carbon is below 0.8%. The hexafluorodimethylsilyl ether is removed by adsorption; the purified silicon tetrafluoride gas comes out of the adsorption tower and is connected to the compressor pipeline, compressed to 2.5MPa, and then...

Embodiment 3

[0034] The crude silicon tetrafluoride produced with fluoride and silicon source powder as raw materials is passed through a light-removing tower to remove nitrogen, oxygen, carbon monoxide and carbon monoxide at -120 ° C. The operating pressure of the light-removing tower is 1MPa; The liquid material at the bottom is passed into the weight-removing tower, the moisture and hydrogen fluoride are removed from the bottom of the tower at a temperature of -15°C, and the silicon tetrafluoride gas is discharged through the top of the tower, and the operating pressure of the weight-removing tower is 1MPa; The silicon tetrafluoride gas passes through the three-stage adsorption tower, and the adsorption tower is equipped with activated carbon, and the quasi-dry humidity of the activated carbon is below 0.8%. The hexafluorodimethylsilyl ether is removed by adsorption; the purified silicon tetrafluoride gas comes out of the adsorption tower and is connected to the compressor pipeline, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com