Silyl ether mixed defoaming agent emulsion and preparation method thereof

A technology of defoamer and composite emulsifier, applied in the direction of foam dispersion/prevention, etc., can solve problems such as poor water solubility, emulsion instability, easy demulsification, etc., achieve stable emulsion stability, benefit mass production, and chemical properties inert effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

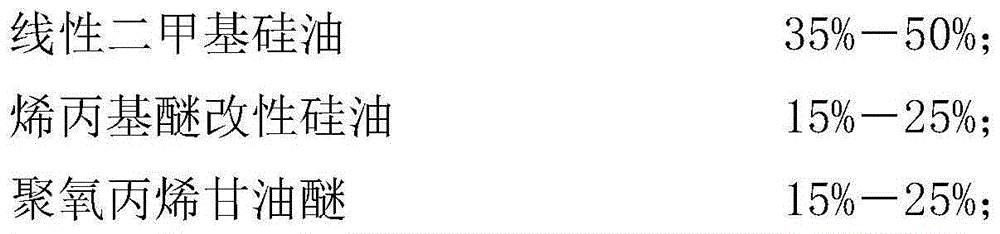

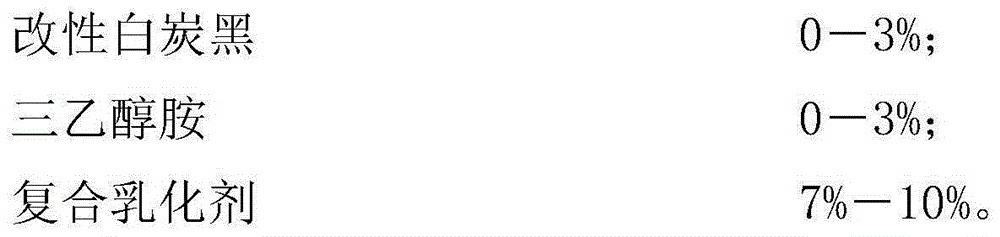

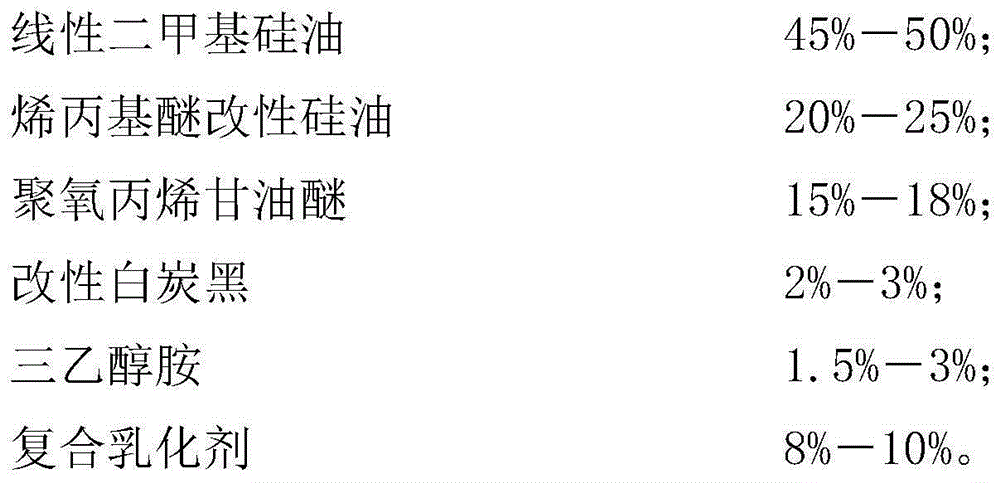

Method used

Image

Examples

Embodiment 1

[0027] Mix 100 parts of linear dimethyl silicone oil with 3 parts of modified white carbon black evenly, heat up to 130°C; add 3 parts of triethanolamine, stir for 3 hours, then cool to 90°; add 40 parts of allyl ether modified silicone oil and 25 parts of polyoxypropylene glyceryl ether, after continuing to stir for one hour; add 10 parts of compound emulsifiers and stir at a high speed to form a coarse emulsion, wherein the compound emulsifiers are mixed by 5 parts of Tween-80 and 5 parts of soybean lecithin; then Add 320mL of 0.5% hydroxymethyl cellulose thickening water to the coarse emulsion to prepare an emulsion with a solid content of 35%; then pour the emulsion into a high-speed homogenizer and stir at 12000r / min for 20min. A fine and stable microemulsion is formed; this microemulsion can be centrifuged in a 5000r / min centrifuge for 5 minutes without stratification.

[0028] Test method: Pour 100mL of bubbling liquid into a 500mL measuring cylinder, insert the glass t...

Embodiment 2

[0033] Mix 100 parts of linear dimethyl silicone oil with 5 parts of modified silica evenly, heat up to 130°C; add 5 parts of triethanolamine, stir for 3 hours, then cool to 80°; add 50 parts of allyl ether to modify Silicone oil and 35 parts of polyoxypropylene glyceryl ethers, continue to stir for 1h; Add 7 parts of compound emulsifiers and stir at high speed to form a coarse emulsion, wherein the compound emulsifiers are mixed by 3.5 parts of Tween-80 and 3.5 parts of soybean lecithin; Add 360mL of 0.5% hydroxymethylcellulose thickening water to the coarse emulsion to prepare an emulsion with a solid content of 35%; then pour the emulsion into a high-speed homogenizer and stir at 12000r / min for 25min to form Delicate and stable microemulsion; this microemulsion can guarantee that it will not be separated when centrifuged in a 5000r / min centrifuge for 5 minutes.

[0034] Test method: 35kg fermentation broth base material, 50L fermentation tank, first add 5g polyether defoame...

Embodiment 3

[0039] Mix 100 parts of linear dimethyl silicone oil with 3 parts of modified silica evenly, heat up to 130°C; add 2 parts of triethanolamine, stir for 3 hours, then cool to 80°C; then add 30 parts of allyl ether modified silicone oil And 30 parts of polyoxypropylene glyceryl ethers, continue to stir for 1h; Add 8 parts of compound emulsifiers and stir at high speed to form a coarse emulsion, wherein the compound emulsifiers are mixed by 4 parts of Tween-80 and 4 parts of soybean lecithin; Add 480mL of hydroxymethyl cellulose thickening water with a mass concentration of 0.3% to the emulsion to prepare an emulsion with a solid content of 25%; then pour the emulsion into a high-speed homogenizer and stir at a high speed of 12000r / min for 20min to form Delicate and stable microemulsion; this microemulsion can guarantee that it will not be separated in a 3000r / min centrifuge for 5 minutes.

[0040] Test method: 35kg fermentation broth base material, 50L fermentation tank, first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com