Three-dimensional multi-cavity micro-perforated periodical ultra-wideband sound-absorbing structure

An ultra-wideband, micro-perforation technology, applied in the field of acoustics, can solve the problems of large volume, less than 2, narrow sound absorption frequency band, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

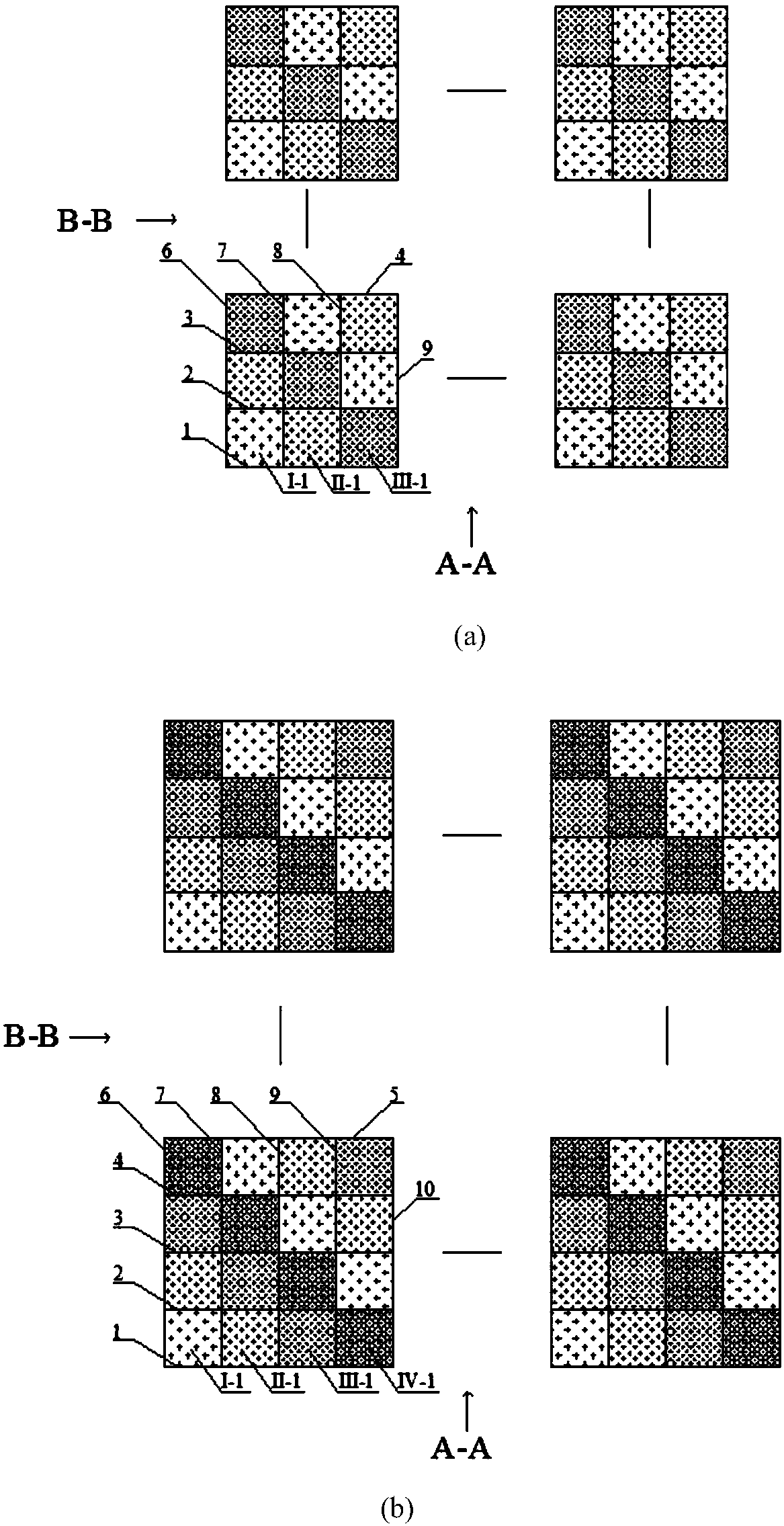

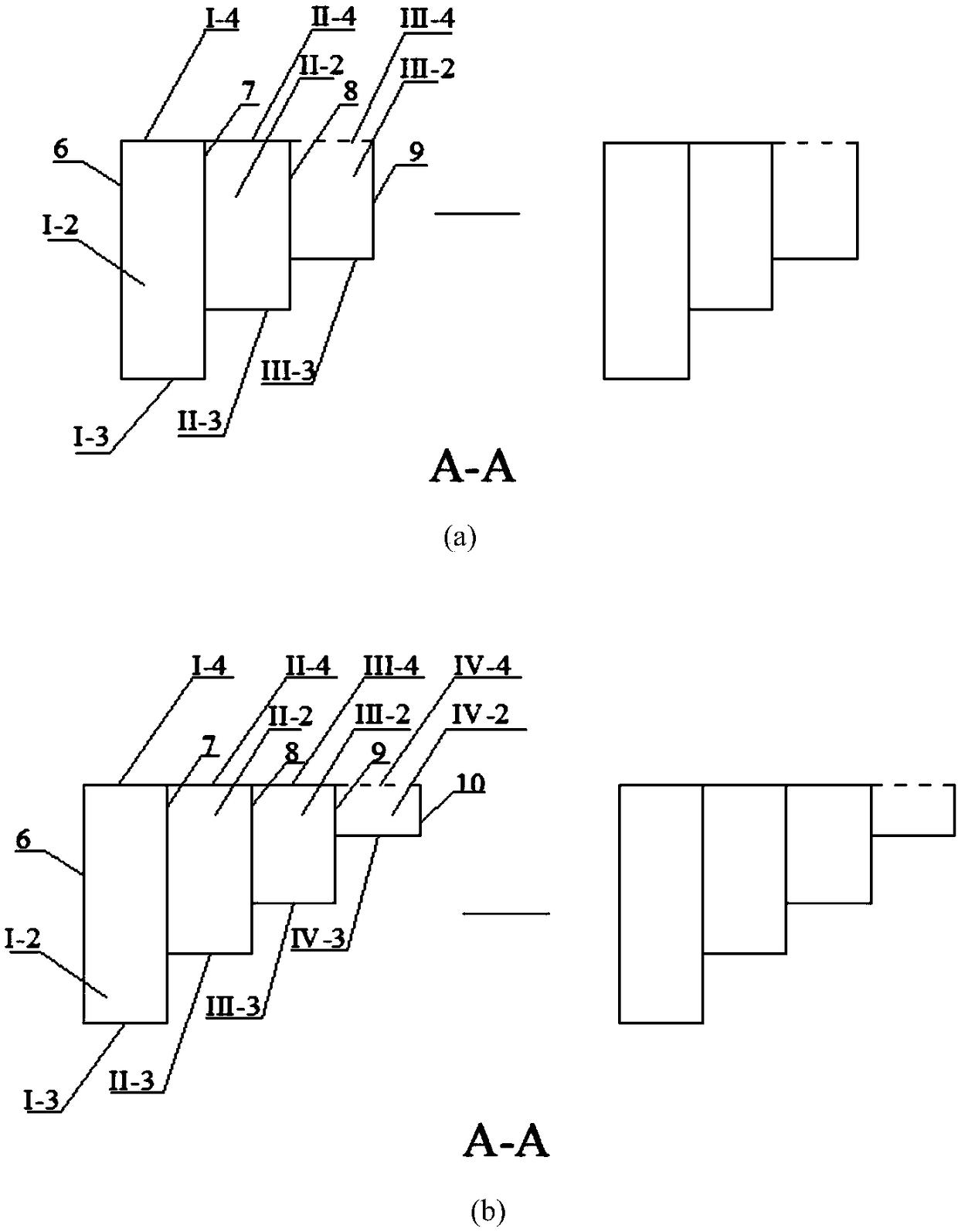

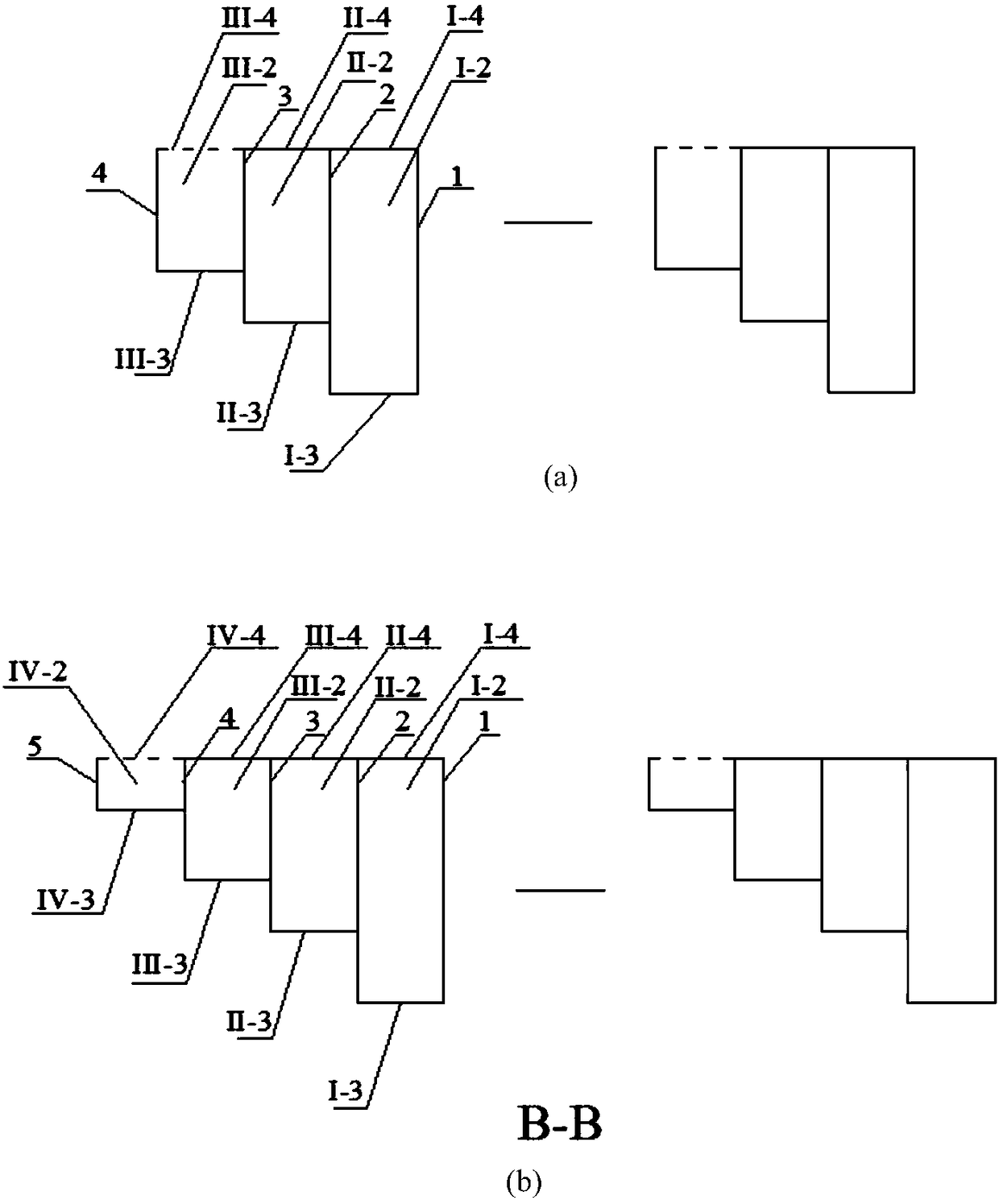

[0038] Example 1: Press the following components Figure 1~Figure 3 It is connected in the manner shown, and those skilled in the art can implement it smoothly. Three-dimensional multi-cavity micro-perforated periodic ultra-broadband sound absorption structure, the number of cavities is more than 2, preferably 3 or 4 cavities, the 3-cavity structure includes the cuboid structure unit A closed cavity I-2, unit B closed cavity II-2 and cell C closed cavity III-2, alternate in two directions adjacent to the cell A closed cavity I-2, cell B closed cavity II-2 and cell C closed cavity III-2 A 3*3 periodic structure is obtained by periodic arrangement, and the arrangement unit of the next row in the cycle is moved from the last unit of the previous row of arrangement units to the first, and the rest are obtained by moving forward. The first row is composed of unit A, unit B, and unit C, the second row is composed of unit B, unit C, and unit A, and the third row is composed of unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com