Marine noise reduction structure

A noise-reducing, marine-used technology, applied to hulls, hull decks, hull panels, etc., can solve the problems of poor vibration and noise absorption, noise pollution, and weak effects, and achieve enhanced water vapor barrier effects and corrosion resistance Effects of performance improvement, vibration and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

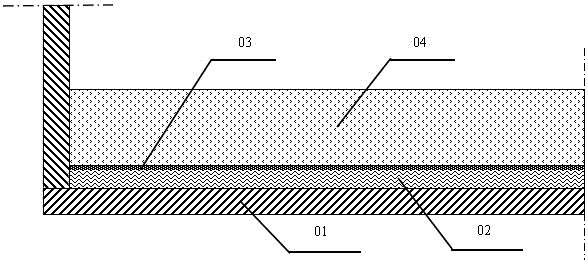

[0015] Such as figure 1 As shown, a marine noise-reduction structure, on a horizontal steel deck 01, hollow special-shaped glass fiber cloth 02, aluminum foil 03 and dressing layer 04 are sequentially laid.

[0016] In this marine noise reduction structure, the steel deck 01 has high hardness and strength. The hollow special-shaped glass fiber cloth 02 laid on the steel deck 01 is a triangular or pentagonal hollow fiber cloth, and the thickness after multi-layer composite is 10mm. Then heat-press composite it with the hollow special-shaped glass fiber cloth 02 by polyethylene hot-air bonding method, and the thickness of the aluminum foil 03 is 8 μm. Then brush a layer of inorganic adhesive on the aluminum foil 03, and finally lay the dressing main body, wherein the inorganic adhesive layer is 0.5mm, and the main dressing layer is 40mm. The main body of the dressing is the ultra-light dressing produced by Taicang Lanyan Deck Dressing Coating Co., Ltd.

[0017] Referring to t...

Embodiment 2

[0019] The marine noise reduction structure is the same as that of Example 1, except that the hollow special-shaped glass fiber cloth 02 laid on the steel deck 01 is a triangular or pentagonal hollow fiber cloth, and the thickness after multilayer composite is 9mm. Then heat-press composite it with the hollow special-shaped glass fiber cloth 02 by polyethylene hot-air bonding method, and the thickness of the aluminum foil 03 is 8 μm. Then brush a layer of inorganic adhesive on the aluminum foil 03, and finally lay the dressing main body, wherein the inorganic adhesive layer is 0.5mm, and the dressing main body layer is 45mm.

[0020] Referring to the GB / T19889.10-2006 standard, the prepared marine noise reduction structure was tested, and the sound insulation weighted index was 46dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com