Variable-damping mechanical impedance combined sound absorption structure

A mechanical impedance and damping technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of narrow sound absorption frequency band and difficult control of sound absorption coefficient, and achieve the effect of good sound absorption bandwidth, small thickness and high sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below according to the drawings and specific embodiments of the specification.

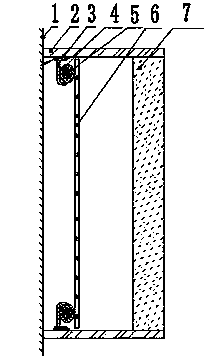

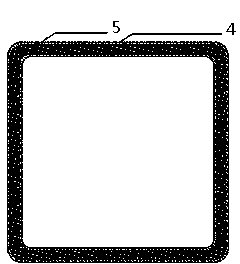

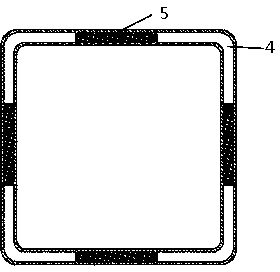

[0012] Such as figure 1 As shown, a variable damping mechanical impedance composite sound-absorbing structure includes a wall surface 1 and a sound-absorbing material 7. A bracket 2 is horizontally installed on the wall surface 1, and the bracket 2 is made of a metal plate; the bracket 2 A bracket 3 is welded on the inner side, and the whole circle of gas welding ensures that the bracket 3 and the bracket 2 are tightly bonded. The bracket 3 is pasted on one side of the viscoelastic hose 4, and the viscoelastic hose 4 is A variable damping mechanical impedance plate 6 is pasted on the other side to keep pasting tightly without gaps. The front end of the composite sound-absorbing structure is provided with sound-absorbing material 7, and the variable damping mechanical impedance plate 6 is placed in the cavity at the rear of the composite struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com