Conductive plastic and its processing method and apparatus

A technology of conductive plastics and processing methods, applied in the field of plastics and its processing, to achieve the effects of easy compounding, low cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

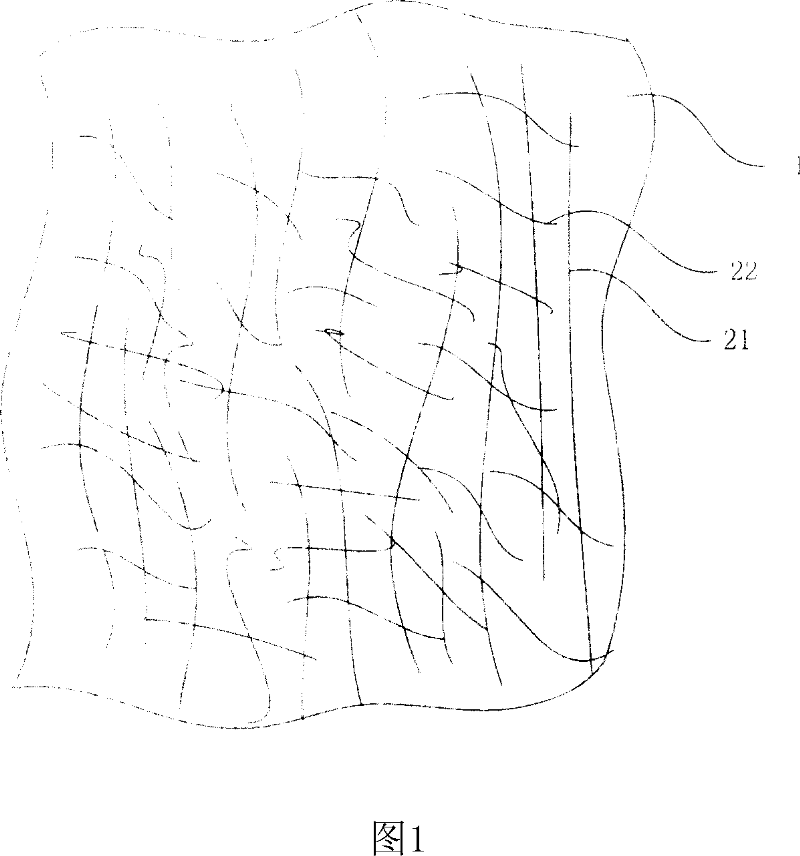

[0049] In the first embodiment, the conductive plastic includes 5v% stainless steel fiber (SS), 93v% thermoplastic PC and 2v% processing aid. The stainless steel fiber (SS) is divided into long and short fibers. The long fiber has a diameter of 12um and a length of 10mm. The short fiber has a diameter of 6um and a length of 1mm. The mixed volume ratio of long fiber and short fiber is 10:1. , Long and short fibers present a three-dimensional network in the thermoplastic PC. The processing aid includes 1.0v% diisodecyl phthalate, 0.3v% aluminate, 0.2v% N,N-diphenyl-p-phenylenediamine, 0.4v% antimony trioxide, 0.1v% benzophenone.

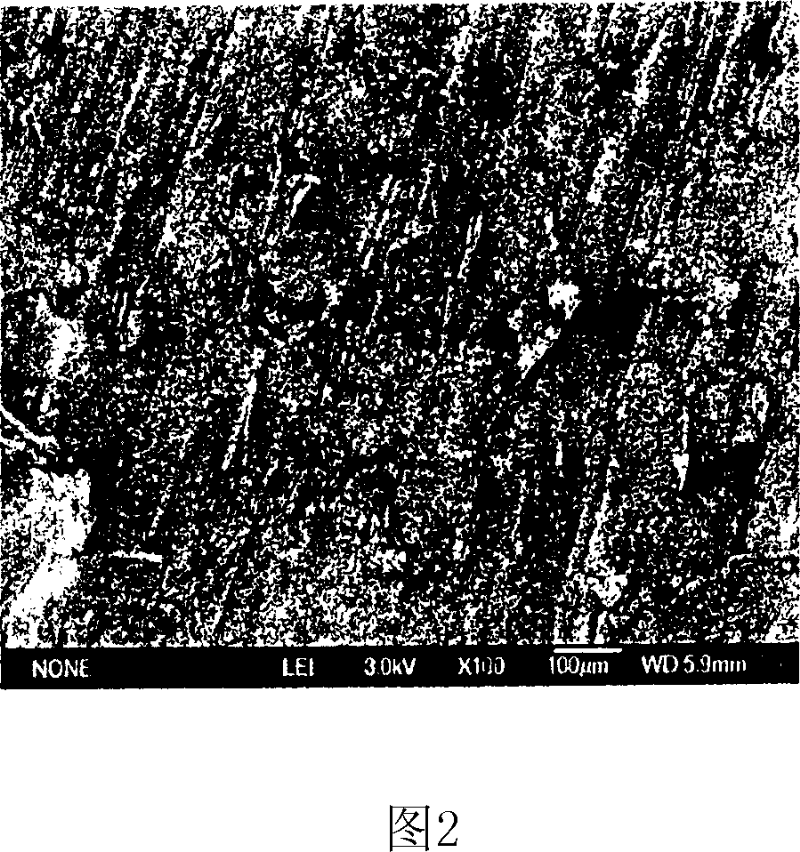

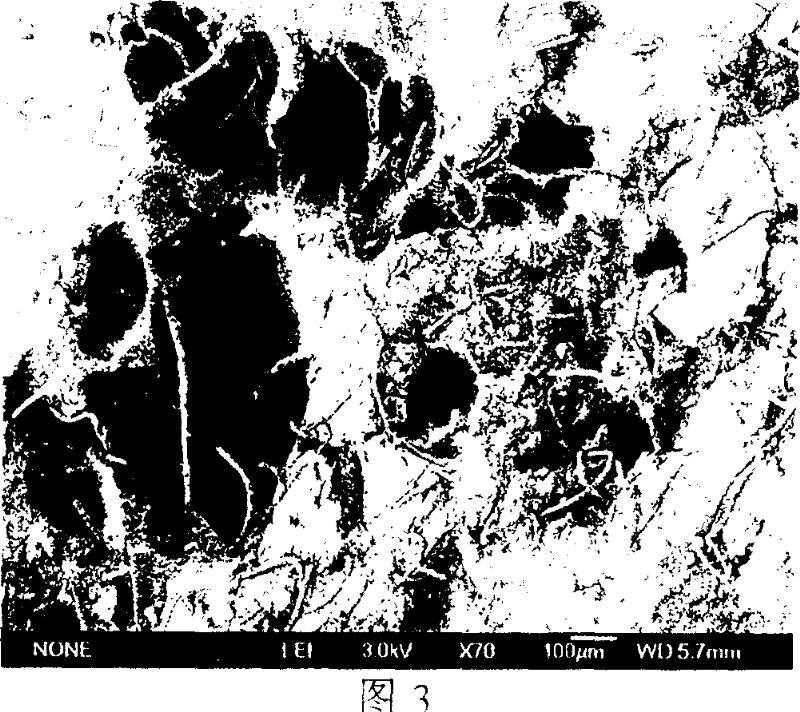

[0050] The plane scanning electron microscope of the conductive plastic particles of this embodiment is shown in Figure 2, and the cross-sectional scanning electron microscope of the conductive plastic particles of this embodiment is shown in Figure 3. It can be seen from the above two figures that the long and short stainless steel fibers ( SS) Staggered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com