Low voltage related semi-conductive polymer composite material and preparation method thereof

A composite material and correlation technology, applied in the field of semi-conductive composite material preparation, can solve the problems of volume resistivity change, small resistance change, complex conduction mechanism, etc., to achieve the effect of stable resistance and reducing volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

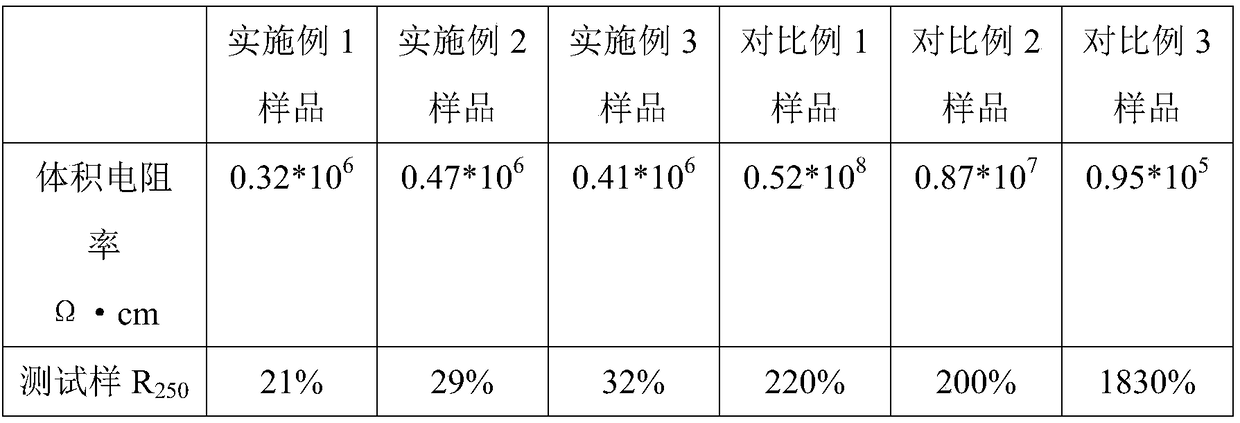

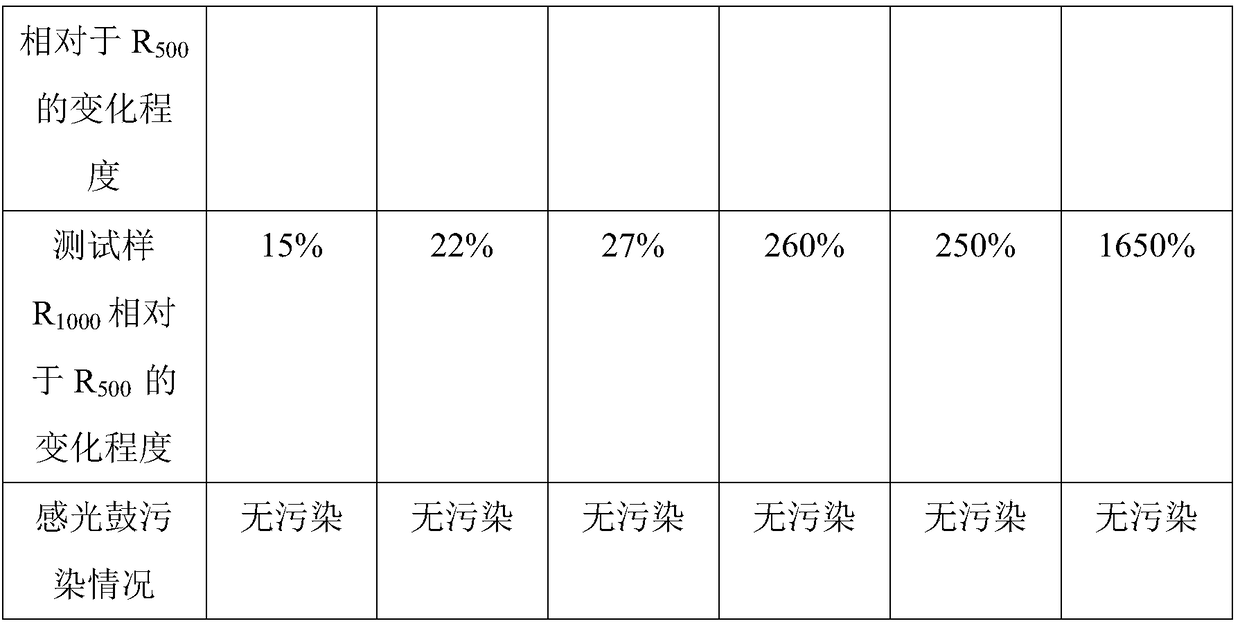

Examples

Embodiment 1

[0030] Example 1 Preparation of semi-conductive polymer composite material with low voltage dependence

[0031] Raw material parts by weight: 70 parts of methyl vinyl silicone rubber; 30 parts of EPDM rubber; 15 parts of conductive masterbatch; 3 parts of crosslinking agent DCP;

[0032] The conductive masterbatch is prepared by the following methods: (1) Preparation of modified carbon black: the carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, refluxed at 80°C for 6 hours, washed and dried Then the acidified carbon black is obtained; then the acidified carbon black is mixed with nano-titanium dioxide and then placed in absolute ethanol for ball milling for 5 hours, the ethanol is removed and dried to obtain the modified carbon black; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain conductive masterbatch; wherein, in step (1), the amount ra...

Embodiment 2

[0034] Example 2 Preparation of semi-conductive polymer composite material with low voltage dependence

[0035] Raw material parts by weight: 60 parts of methyl vinyl silicone rubber; 40 parts of EPDM rubber; 10 parts of conductive masterbatch; 2 parts of cross-linking agent DCP;

[0036] The conductive master particles are prepared by the following methods: (1) Preparation of modified carbon black: the carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, refluxed at 70°C for 8 hours, washed and dried Then the acidified carbon black is obtained; then the acidified carbon black is mixed with nano-titanium dioxide and then placed in absolute ethanol for ball milling for 6 hours, the ethanol is removed and dried to obtain the modified carbon black; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain conductive masterbatch; wherein, the amount ratio of...

Embodiment 3

[0038] Example 3 Preparation of low-voltage-dependent semi-conductive polymer composite material

[0039] Ingredients in parts by weight of raw materials: 50 parts of methyl vinyl silicone rubber; 50 parts of EPDM rubber; 20 parts of conductive masterbatch; 5 parts of crosslinking agent DCP;

[0040] The conductive masterbatch is prepared by the following methods: (1) Preparation of modified carbon black: the carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, refluxed at 90°C for 5 hours, washed and dried Then the acidified carbon black is obtained; then the acidified carbon black is mixed with nano-titanium dioxide and then placed in absolute ethanol for ball milling for 5 hours, the ethanol is removed and dried to obtain the modified carbon black; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain conductive masterbatch; wherein, the amount ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com