PVC material for extra-high voltage cable outer sheath and preparation method thereof

A PVC material and ultra-high voltage technology, applied in the field of PVC material and its preparation for the outer sheath of ultra-high voltage cables, can solve the problems of workshop environmental pollution, volume resistivity instability, etc., to solve workshop environmental pollution and solve volume resistivity unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the conductive black paste is as follows: After starting the three-roll mill, adjust the gap between the middle and rear rolls to 0.2 mm, press the baffle plate, add the second plasticizer, and wait until the second plasticizer is evenly covered with the rolls. Then add conductive carbon black, adjust the handwheel of the front roller, so that the front roller slowly touches the middle roller, when the surface of the front roller is completely covered with slurry, lock the fixing nut, and then adjust the angle of the discharge plate, the slurry can be discharged evenly, use Fineness scraper to control the fineness of conductive black paste.

[0028] The conductive carbon black is one or more selected from Czech CHEZACARB AC 80, CABOT VXC72 and Degussa PRINTEX XE2-B.

[0029] The first plasticizer and the second plasticizer are one or more independently selected from DIDP, DPHP and DINP.

[0030] The polyvinyl chloride resin is one or more sele...

Embodiment 1

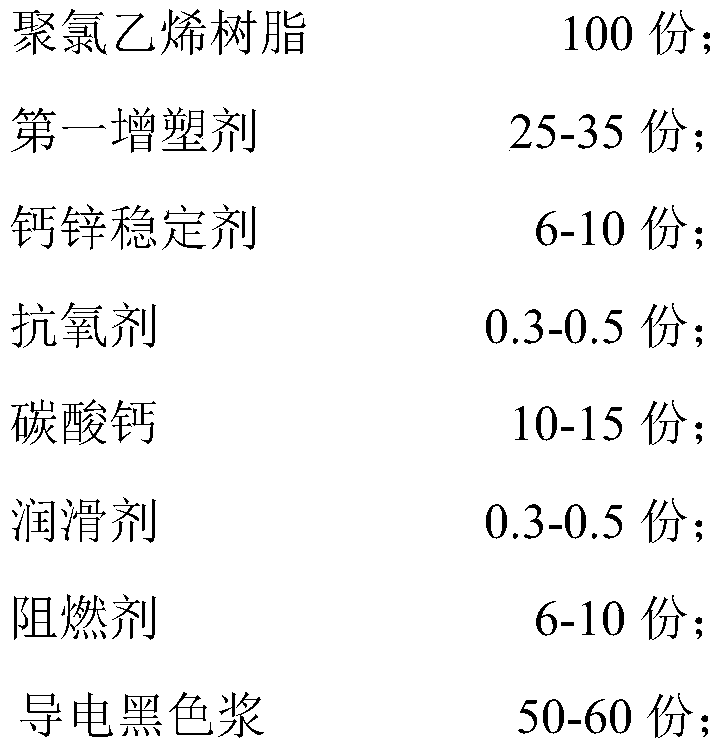

[0040] Embodiment 1 provides a kind of PVC material for extra-high voltage cable outer sheath, and it comprises the component of following parts by weight:

[0041] 100 parts of polyvinyl chloride resin; (HG-1300)

[0042] 30 parts of the first plasticizer; (DPHP)

[0043] 8 parts of calcium zinc stabilizer; (Bear brand MC92539)

[0044] 0.4 part of antioxidant; (antioxidant 1010)

[0045] 12 parts of calcium carbonate; (Rieter LD-1000C)

[0046] 0.4 parts of lubricant; (calcium stearate)

[0047] 8 parts of flame retardant; (antimony trioxide)

[0048] 55 parts of conductive black paste. (the ratio of parts by weight of the second plasticizer and conductive carbon black is 1.5:1, wherein the second plasticizer (DPHP) is 33 parts, conductive carbon black (Czech CHEZACARB AC 80) is 22 parts)

[0049] First prepare the conductive black paste: After starting the three-roll mill, adjust the gap between the middle and rear rolls to 0.2mm, press the baffle plate, add the secon...

Embodiment 2

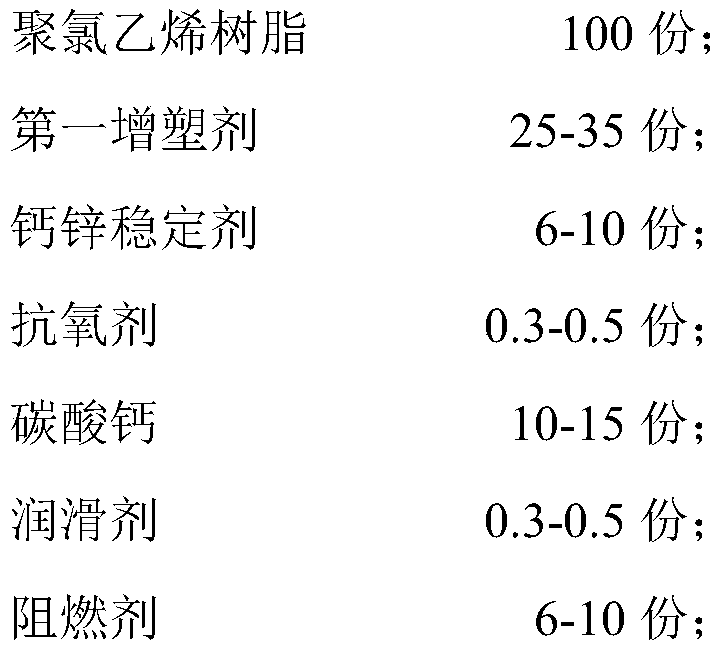

[0054] Embodiment 2 provides a PVC material for an extra-high voltage cable outer sheath. Its preparation method is exactly the same as in Embodiment 1, except that its raw material components are different, and it includes the following components in parts by weight:

[0055] 100 parts of polyvinyl chloride resin; (HG-1300)

[0056] 25 parts of the first plasticizer; (DPHP)

[0057] 6 parts of calcium zinc stabilizer; (Bear brand MC92539)

[0058] 0.5 part of antioxidant; (antioxidant 1010)

[0059] 10 parts of calcium carbonate; (Rieter LD-1000C)

[0060] 0.5 parts of lubricant; (calcium stearate)

[0061] 10 parts of flame retardant; (antimony trioxide)

[0062] 50 parts of conductive black paste. (wherein the second plasticizer (DPHP) is 30 parts, conductive carbon black (Czech CHEZACARB AC80) is 20 parts)

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com