A kind of semiconductive polymer composite material with low voltage dependence and its preparation method

A composite material and correlation technology, which is applied in the field of semi-conductive composite material preparation, can solve the problems of volume resistivity change, small resistance change degree, and not easy to solve, and achieve the effect of reducing volume resistivity and stabilizing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

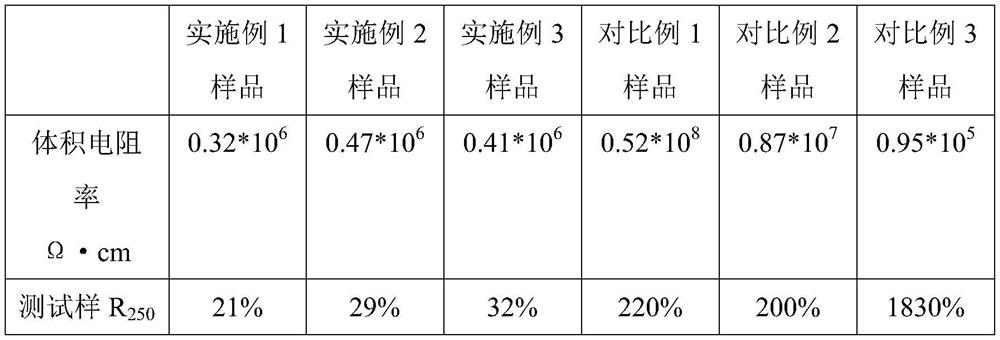

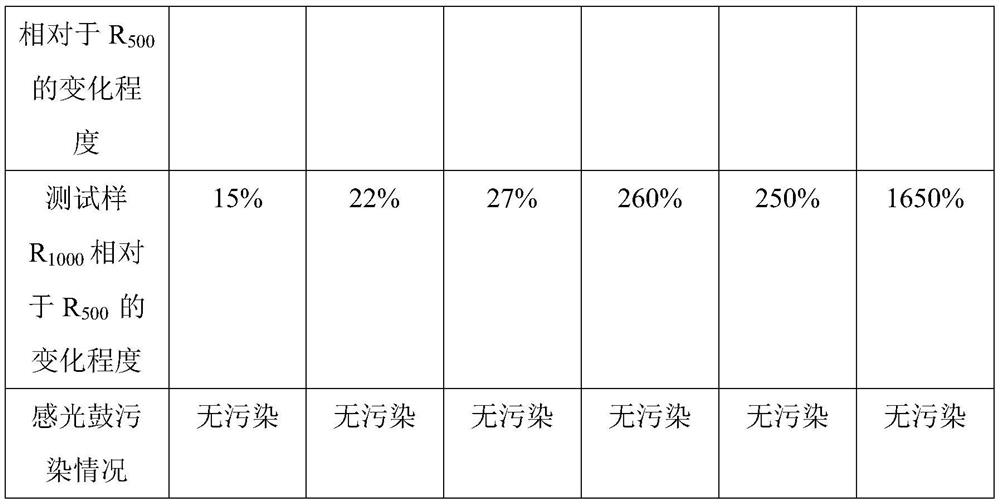

Examples

Embodiment 1

[0030] The preparation of the semiconductive polymer composite material of embodiment 1 low voltage dependence

[0031] Composition of raw materials by weight: 70 parts of methyl vinyl silicone rubber; 30 parts of EPDM rubber; 15 parts of conductive masterbatch; 3 parts of crosslinking agent DCP;

[0032]The conductive masterbatch is prepared by the following method: (1) Preparation of modified carbon black: carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, reflux reaction is carried out at 80°C for 6h, washed and dried Afterwards, acidified carbon black is obtained; then acidified carbon black is mixed with nano-titanium dioxide and then placed in absolute ethanol for ball milling for 5 hours, and the modified carbon black is obtained after removing ethanol and drying; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain the conductive mast...

Embodiment 2

[0034] The preparation of the semiconductive polymer composite material of embodiment 2 low voltage dependence

[0035] Composition by weight of raw materials: 60 parts of methyl vinyl silicone rubber; 40 parts of EPDM rubber; 10 parts of conductive masterbatch; 2 parts of crosslinking agent DCP;

[0036] The conductive masterbatch is prepared by the following method: (1) Preparation of modified carbon black: carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, reflux reaction is carried out at 70 °C for 8 hours, washed and dried Afterwards, acidified carbon black is obtained; then acidified carbon black is mixed with nano-titanium dioxide and placed in absolute ethanol for ball milling for 6 hours, and the modified carbon black is obtained after removing ethanol and drying; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain the conductive ma...

Embodiment 3

[0038] The preparation of the semiconductive polymer composite material of embodiment 3 low voltage dependence

[0039] Composition by weight of raw materials: 50 parts of methyl vinyl silicone rubber; 50 parts of EPDM rubber; 20 parts of conductive masterbatch; 5 parts of crosslinking agent DCP;

[0040] The conductive masterbatch is prepared by the following method: (1) Preparation of modified carbon black: carbon black is placed in a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid, reflux reaction is carried out at 90°C for 5h, washed and dried Afterwards, acidified carbon black is obtained; then acidified carbon black is mixed with nano-titanium dioxide and then placed in absolute ethanol for ball milling for 5 hours, and the modified carbon black is obtained after removing ethanol and drying; (2) the modified carbon black prepared in step (1) Carbon black and methyl vinyl silicone rubber are melt-blended to obtain the conductive mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com