Servo-type reverse-pulling pre-stress detector

A prestressed, servo-type technology, applied in the field of servo-type anti-pull prestressed detectors, can solve the problems of long dynamic response time of motor acceleration and deceleration, limited continuous operation time, and inability to guarantee detection accuracy, so as to enhance detection efficiency and service life, shorten detection time, and high-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

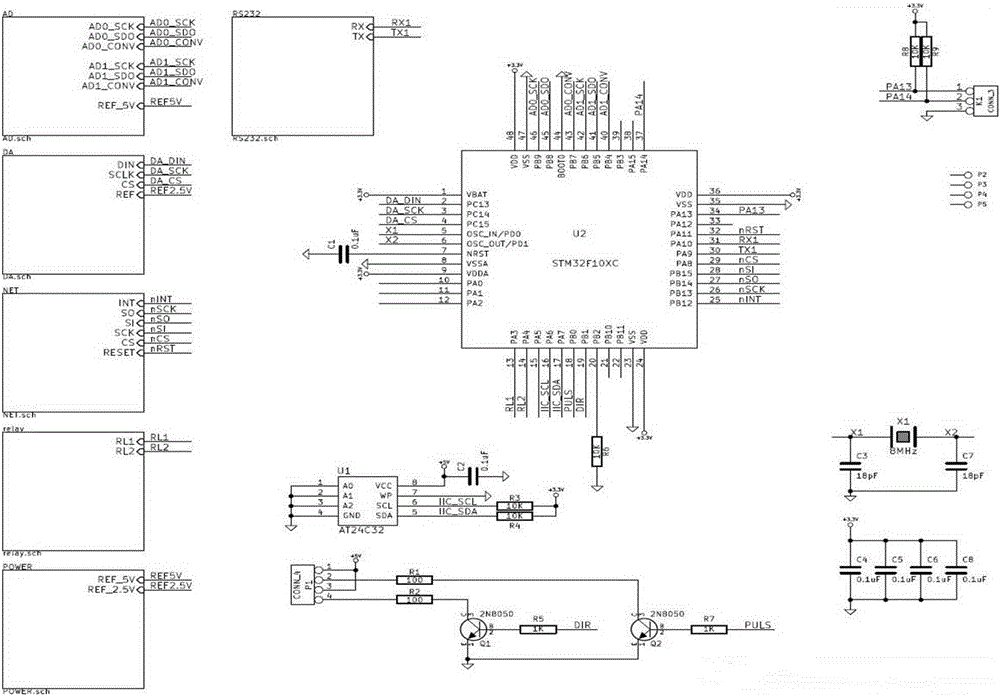

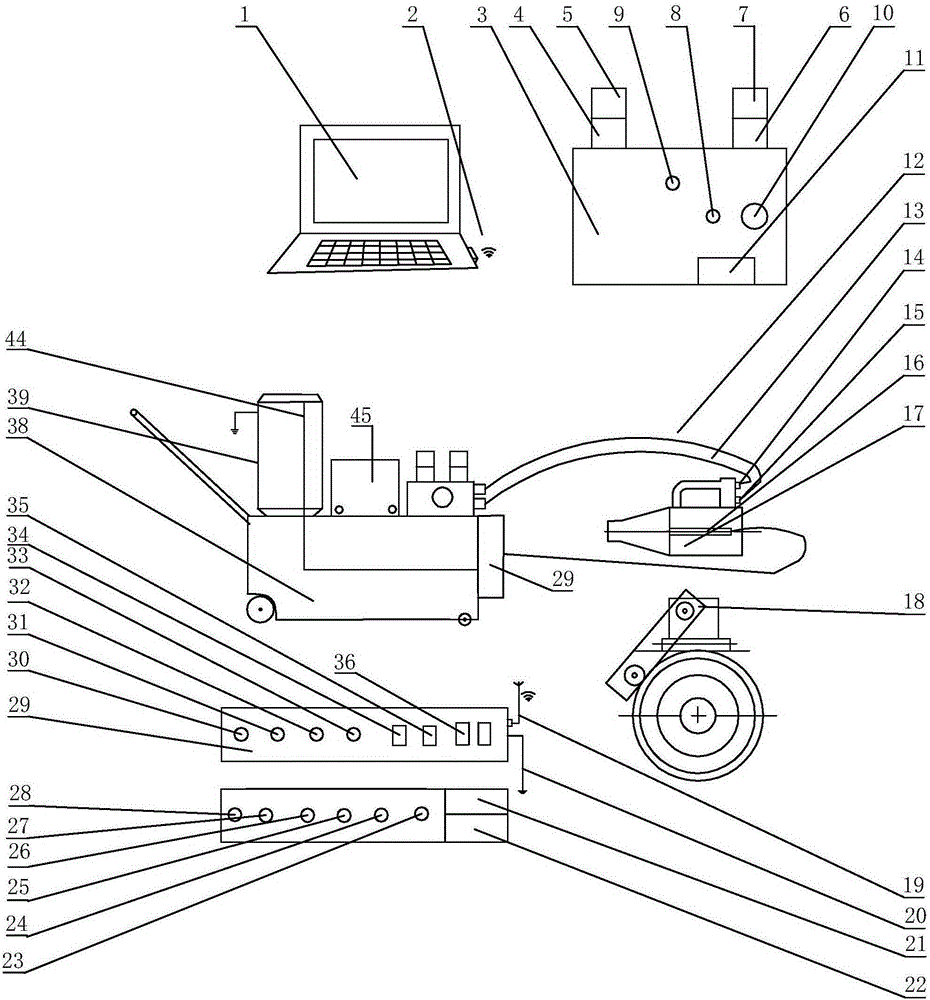

[0034] like figure 1Shown, it is a kind of servo type anti-pull method prestress detector of the present invention, and it comprises intelligent terminal, oil tank 38, displacement sensor 16, through-hole type jack 17, is provided with the control box 29 of control circuit, is installed on the oil tank 38 The combined valve body 3, the servo motor 39 and the servo driver 21 for controlling the servo motor 39. In this embodiment, the smart terminal adopts the computer 1. In addition, the smart terminal can also use a mobile phone or a tablet computer, and the servo driver 21 21 is set in the control box 29, the combined valve body 3 is mainly composed of a block-shaped base with a low-pressure oil circuit and a high-pressure oil circuit inside, a pressure transmitter 10, an electromagnetic reversing valve 6, and a differential overflow valve 7 , low-pressure safety valve 4, high-pressure safety valve 5 and oil filter 11. One end of the low-pressure oil circuit and the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com