Big shelter board with radar stealth function and preparation method thereof

A radar stealth and functional technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem that the wave-absorbing performance of the large board of the shelter needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

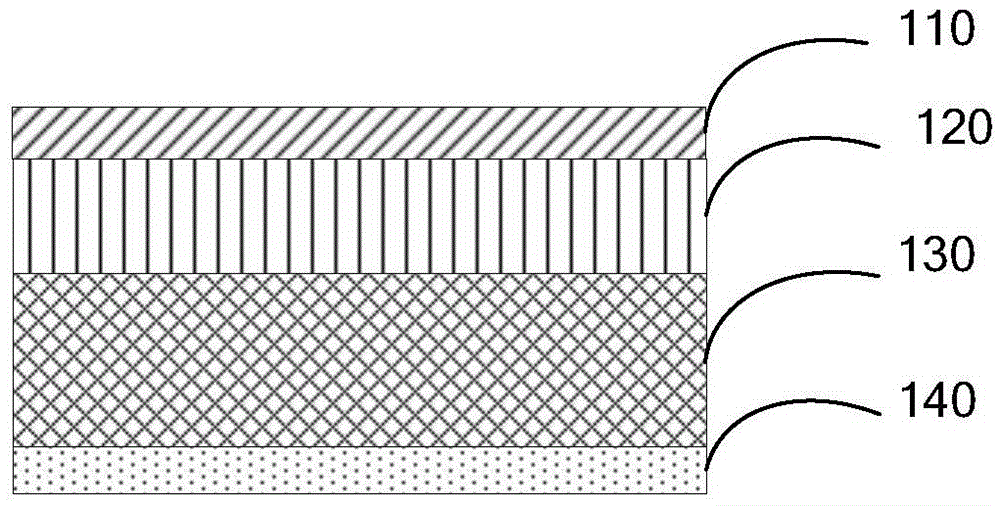

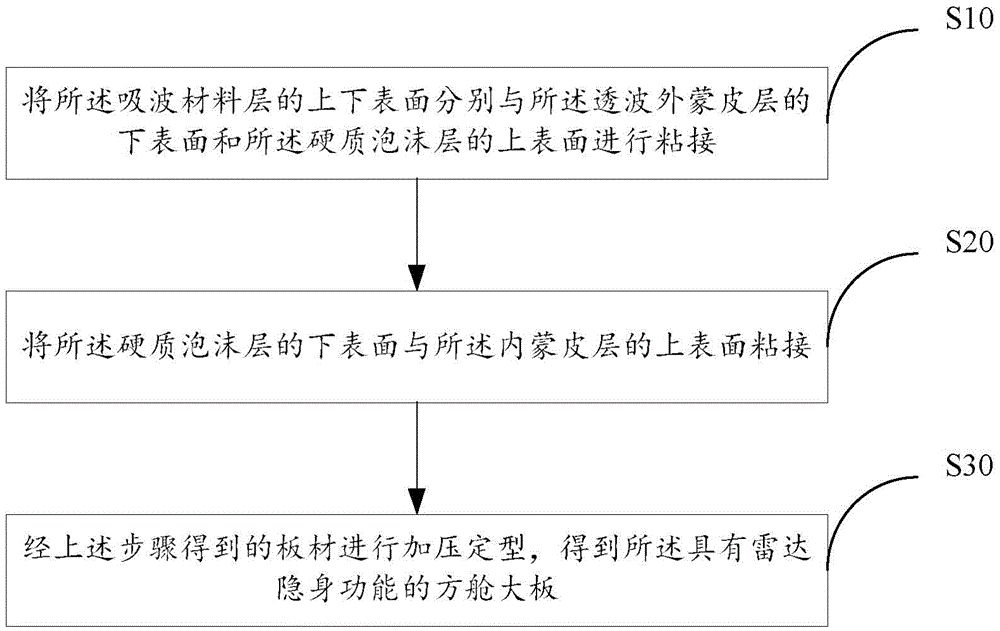

[0037] Such as figure 2 Shown, the preparation method of the shelter slab with radar stealth function of an embodiment, comprises the following steps:

[0038] Step S110: bonding the upper and lower surfaces of the wave-absorbing material layer to the lower surface of the wave-transparent outer skin layer and the upper surface of the rigid foam layer respectively;

[0039] Step S120: bonding the lower surface of the rigid foam layer to the upper surface of the inner skin layer;

[0040] Step S130: pressurize and shape the plates obtained through the above steps to obtain the large shelter plate with radar stealth function.

[0041] Preferably, the absorbing material layer is prepared by the following method:

[0042] The fiber-reinforced resin-based material is prepared into a sheet, and the sheet is prepared into a honeycomb core, and a wave-absorbing material is introduced into the honeycomb core; or prepared by the following method; or the fiber-reinforced resin-based ma...

Embodiment 1

[0046] The preparation process of the shelter slab with radar stealth function of the present embodiment is as follows:

[0047] Prepare the wave-absorbing material layer: prepare a fiber-reinforced resin-based material into a sheet, then prepare the sheet into a honeycomb core, introduce a wave-absorbing material into the honeycomb core, and the wave-absorbing material is carbon fiber;

[0048] The lower surface of the hard foam layer is bonded to the upper surface of the inner skin layer; the hard foam layer includes a hard foam, and the hard foam is a flame-retardant rigid polyurethane foam, and the inner skin layer is aluminum alloy;

[0049] The plates obtained through the above steps are pressurized and shaped to obtain the large shelter plate with radar stealth function.

Embodiment 2

[0051] The preparation process of the shelter slab with radar stealth function of the present embodiment is as follows:

[0052]Prepare the wave-absorbing material layer: prepare a fiber-reinforced resin-based material into a sheet, then prepare the sheet into a honeycomb core, introduce a wave-absorbing material into the honeycomb core, and the wave-absorbing material is graphite;

[0053] The lower surface of the hard foam layer is bonded to the upper surface of the inner skin layer; the hard foam layer includes a hard foam, and the hard foam is a flame-retardant polyimide foam, and the inner skin layer It is a resin-based material, and the resin-based material is a glass fiber reinforced epoxy-based composite material;

[0054] The plates obtained through the above steps are pressurized and shaped to obtain the large shelter plate with radar stealth function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com