Food drying system

A drying system and food technology, applied in the field of drying system, can solve the problems of slow drying speed, long drying time, low degree of automation, etc., and achieve the effect of balanced ambient temperature, clean air and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

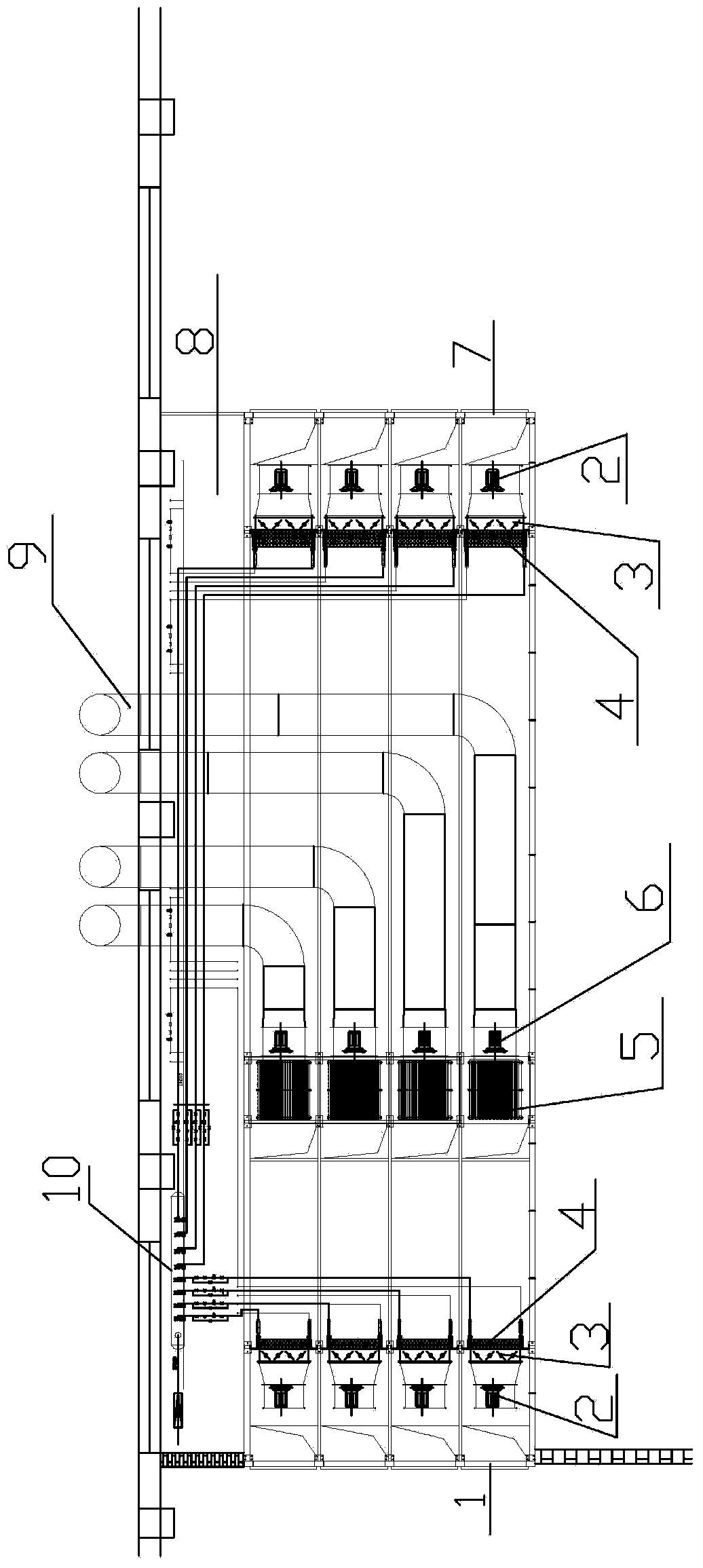

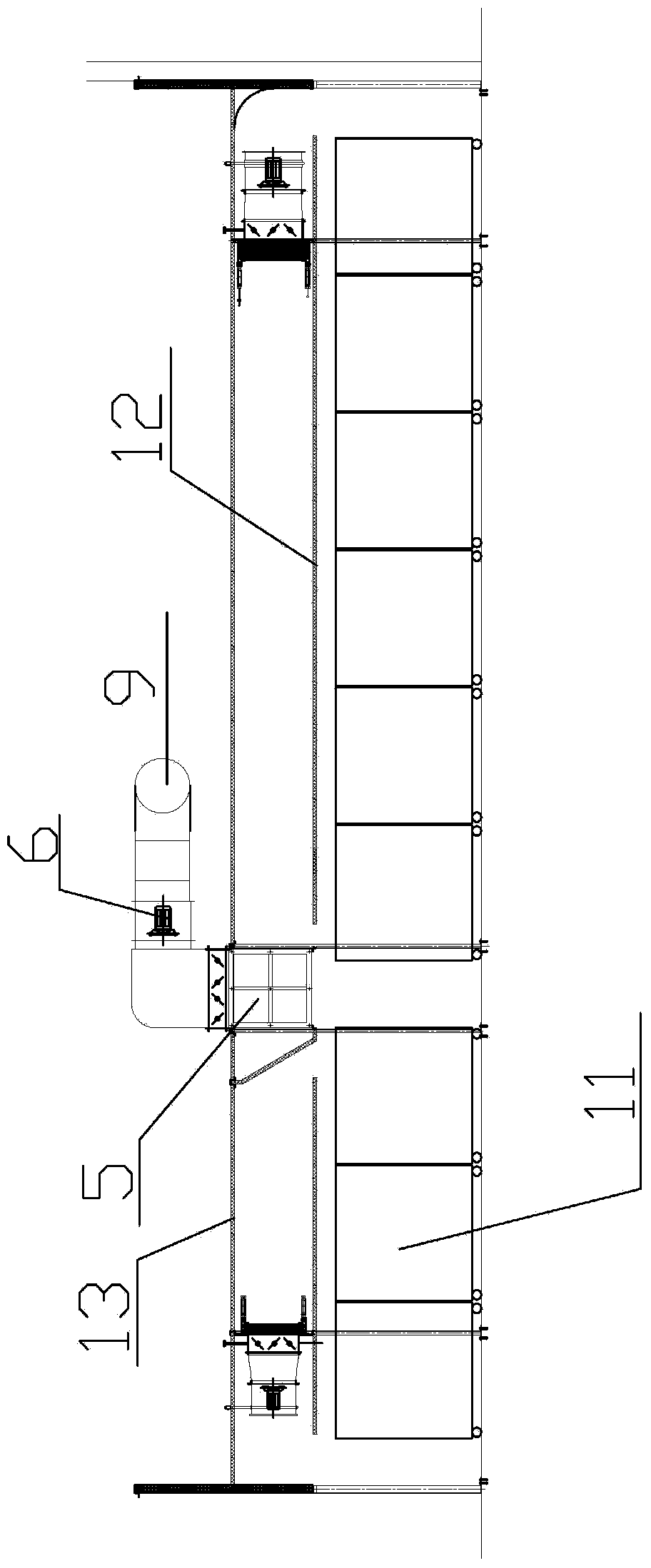

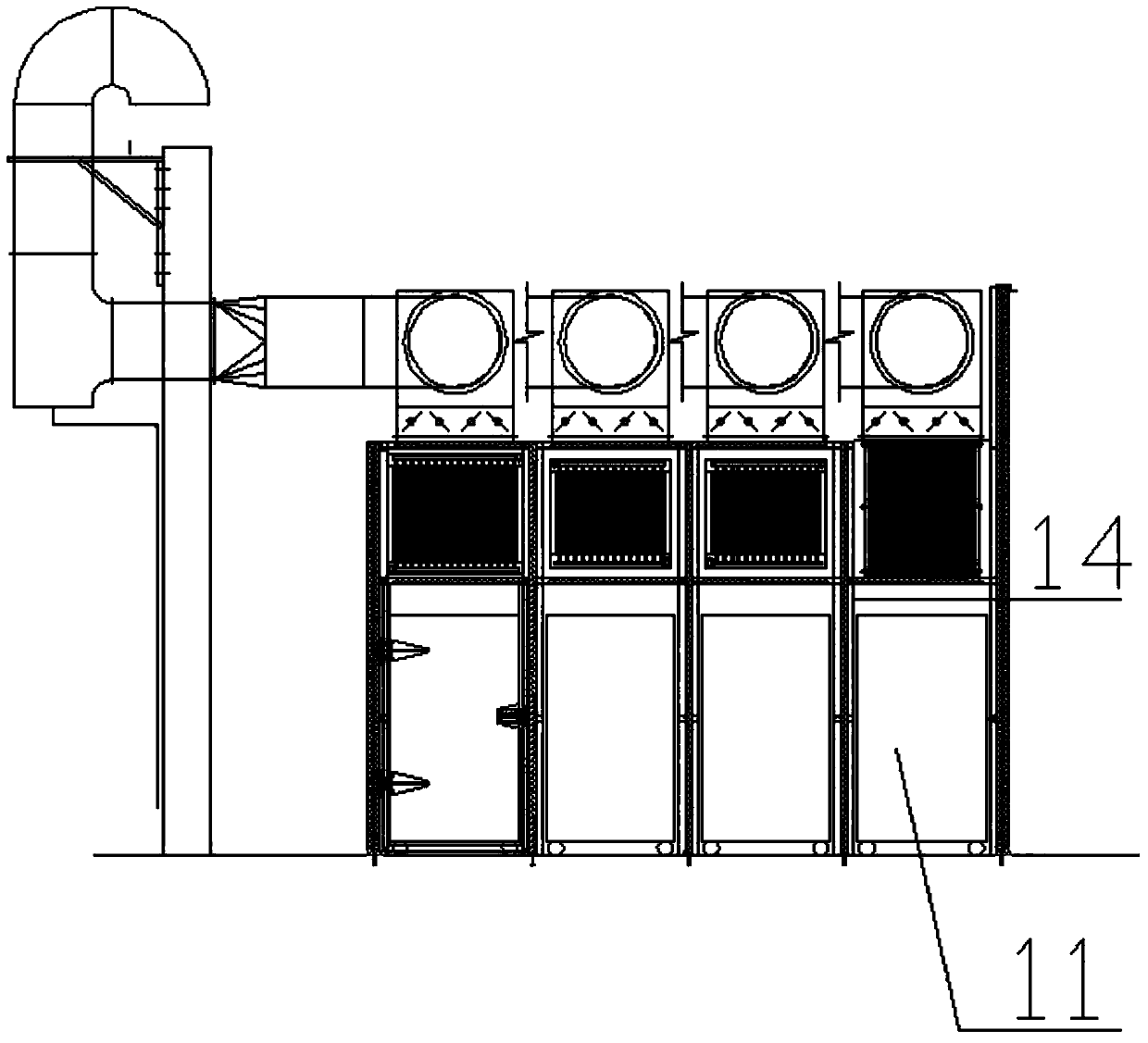

[0028] A food drying system, comprising: a plurality of drying boxes, a steam system, a front box door 1, a rear box door 7, a control panel and a plurality of trolleys; the drying box includes: an exhaust system and two circulation systems, the exhaust system is placed in the middle of the two circulation systems; the exhaust system includes: fresh air heat exchanger 5, exhaust fan 6, air valve and exhaust duct 9, and the fresh air heat exchange A damper and an exhaust fan 6 are sequentially arranged between the device 5 and the exhaust duct 9; the circulation system includes: a circulation fan 2, a manual damper 3 and a heat exchanger 4, and the manual damper 3 is placed in the circulation Between the fan 2 and the heat exchanger 4; the steam system includes: a pressure reducing valve group 20, a sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com