Water-based Low VOC high-metal texture two-component polyurethane low-temperature curing coating and preparation method thereof

A two-component polyurethane and water-based polyurethane technology, applied in polyurea/polyurethane coatings, chemical instruments and methods, coatings, etc., can solve problems such as high energy consumption, and achieve good alcohol resistance, excellent resistance, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

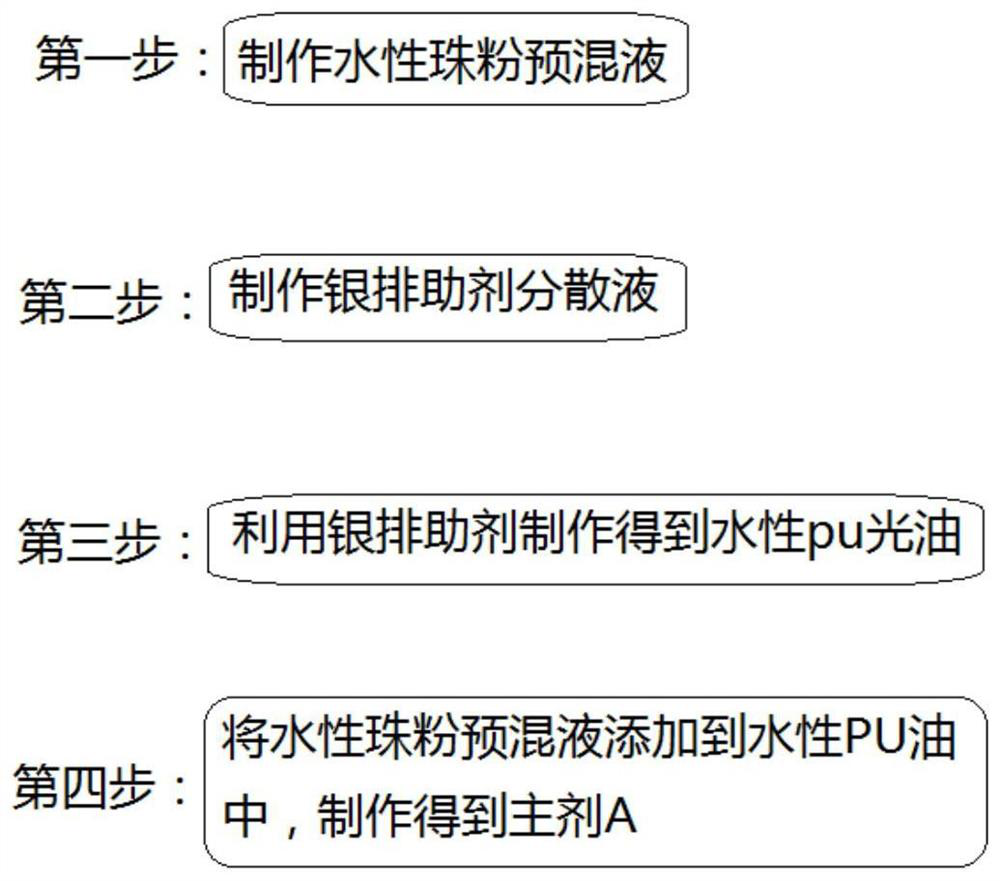

[0043] The preparation of component A of the main agent comprises the following steps: the first step: making water-based silver bubble water containing a water-based dispersant, then adding water-based aluminum silver powder, stirring at 200-400 rpm for 30-60 minutes, and soaking for more than 2 hours to obtain Water-based aluminum-silver paste, or add pearl powder to the silver soaking water at 200-400rpm and stir for 30-60 minutes to obtain a water-based pearl powder premix paste;

[0044] The second step: making the silver row additive dispersion;

[0045] Step 3: Stir water-based polyurethane PU and acrylic dispersion resin, pH regulator, water-based film-forming aid, water-based wetting agent, water-based leveling agent, self-made water-based silver row aid in the second step, deionized water, etc. Mix evenly to get water-based PU varnish;

[0046] Step 4: Add the water-based aluminum silver paste obtained in the first step, or the pearl powder premixed paste to the wat...

Embodiment 1

[0057] The water-based Low VOC high metal texture two-component polyurethane low-temperature curing coating provided in this embodiment includes: 25 parts of water-based hydroxyl acrylic dispersion and water-based polyurethane (PUD) mixed resin, 0.1 part of pH regulator AMP-95, water-based 2 parts of film-forming aids, 0.3 parts of water-based wetting agent, 0.6 parts of water-based leveling agent, 40 parts of self-made water-based silver row additive, 8 parts of self-made silver bubble water, 4 parts of water-based aluminum silver paste, thickening thixotropic agent 5 parts, deionized water 15 parts, the above components are calculated according to mass. Among them, allnex SETAQUA 6530 and DSM NeoRez R-4000 are used for water-based water-based polyurethane (PUD) and acrylic dispersion mixed resin; dipropylene glycol butyl ether (DPnB) is used as water-based coalescent; BYK is used as thickening thixotropic agent -8421.

[0058] The preparation method of the above-mentioned w...

Embodiment 2

[0065] The water-based Low VOC high metal texture two-component polyurethane low-temperature curing coating provided in this embodiment includes: 40 parts of water-based hydroxyl acrylic dispersion and water-based polyurethane (PUD) mixed resin, 0.3 parts of pH regulator AMP-95, water-based 5 parts of film-forming aids, 1.0 parts of water-based wetting agent, 0.7 parts of water-based leveling agent, 25 parts of self-made water-based silver row additives, 8 parts of self-made silver bubble water, 4 parts of water-based aluminum silver paste, thickening thixotropic agent 1 part, 15 parts of deionized water, the above components are calculated according to mass. Among them, the water-based hydroxyl acrylic dispersion and water-based polyurethane (PUD) mixed resin are Tongde Chemical 3AH0562W Di Aisheng (DIC) WKC-593-GZS, DSM (DSM) NeoRez R-4000, and the water-based coalescent is Dipropylene glycol butyl ether (DPnB) and diethylene glycol butyl ether (DBG); the thickening thixotro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com