Preparation method of electroconductive polyamide-polyethylene blended alloy material

A technology of alloy materials and polyethylene, which is applied in the field of polymer material preparation, can solve the problems of decreased comprehensive performance and easy moisture absorption, and achieves the effects of less process links, static electricity elimination, and good static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

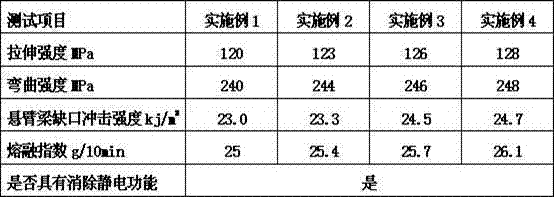

Examples

Embodiment 1

[0017] A) To prepare pellets, first weigh 90 parts of nylon 66 resin, 38 parts of linear low-density polyethylene, namely polyethylene resin, and β-(3, 4 Epoxycyclohexyl) 1 part of ethyltrimethoxysilane, 44 parts of activated talcum powder as a filler and 14 parts of conductive carbon black as a conductive agent were put into the mixer and mixed for 8 minutes. The speed of the mixer was 1000n / min. Then drop into the anti-oxidant that takes by weight and be two (2,4 di-tert-butylphenyl) pentaerythritol diphosphites 0.4 part, length be 45 parts of alkali-free chopped glass fibers and surface modifier That is 0.8 part of bis stearic acid amide, continue to mix 4min, obtain granulated material;

[0018] B) Material making, put the granulated material obtained in step A) into a parallel twin-screw extruder to melt and extrude, after cooling and pelletizing, a conductive polyamide-polyethylene blended alloy material is obtained, wherein the parallel twin-screw extruder The extr...

Embodiment 2

[0020] A) To prepare granulated materials, first weigh 95 parts of nylon 66 resin, 42 parts of linear low-density polyethylene, namely polyethylene resin, and β-(3, 4 Epoxycyclohexyl) 1.5 parts of ethyltrimethoxysilane, 32 parts of activated talcum powder as a filler, and 9 parts of conductive carbon black as a conductive agent were put into the mixer and mixed for 8 minutes. The speed of the mixer was 1000n / min. 0.6 parts of bis(2,4 di-tert-butylphenyl) pentaerythritol diphosphite, 40 parts of alkali-free chopped glass fibers and a surface modifier of 3mm in length are dropped into the anti-oxidant taken in parts by weight. That is, 1 part of bis stearic acid amide, and continue mixing for 4 minutes to obtain granulated material. All the other are the same as the description to embodiment 1.

Embodiment 3

[0022] A) To prepare pellets, first weigh 105 parts of nylon 66 resin, 36 parts of linear low-density polyethylene, namely polyethylene resin, and β-(3, 4 Epoxycyclohexyl) 1.9 parts of ethyltrimethoxysilane, 36 parts of activated talc powder as a filler and 11 parts of conductive carbon black as a conductive agent were put into the mixer and mixed for 8 minutes. The speed of the mixer was 1000n / min. 0.9 parts of bis(2,4 di-tert-butylphenyl) pentaerythritol diphosphite, 48 parts of alkali-free chopped glass fibers and a surface modifier of 3mm in length are dropped into the antioxidant that weighs again That is, 1.2 parts of bis stearic acid amide, and continue mixing for 4 minutes to obtain granulated material. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com