Brick hearth type hot blast stove

A technology for hot blast stoves and hearths, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of short life, high temperature, easy burnout, etc., and achieve the effect of long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

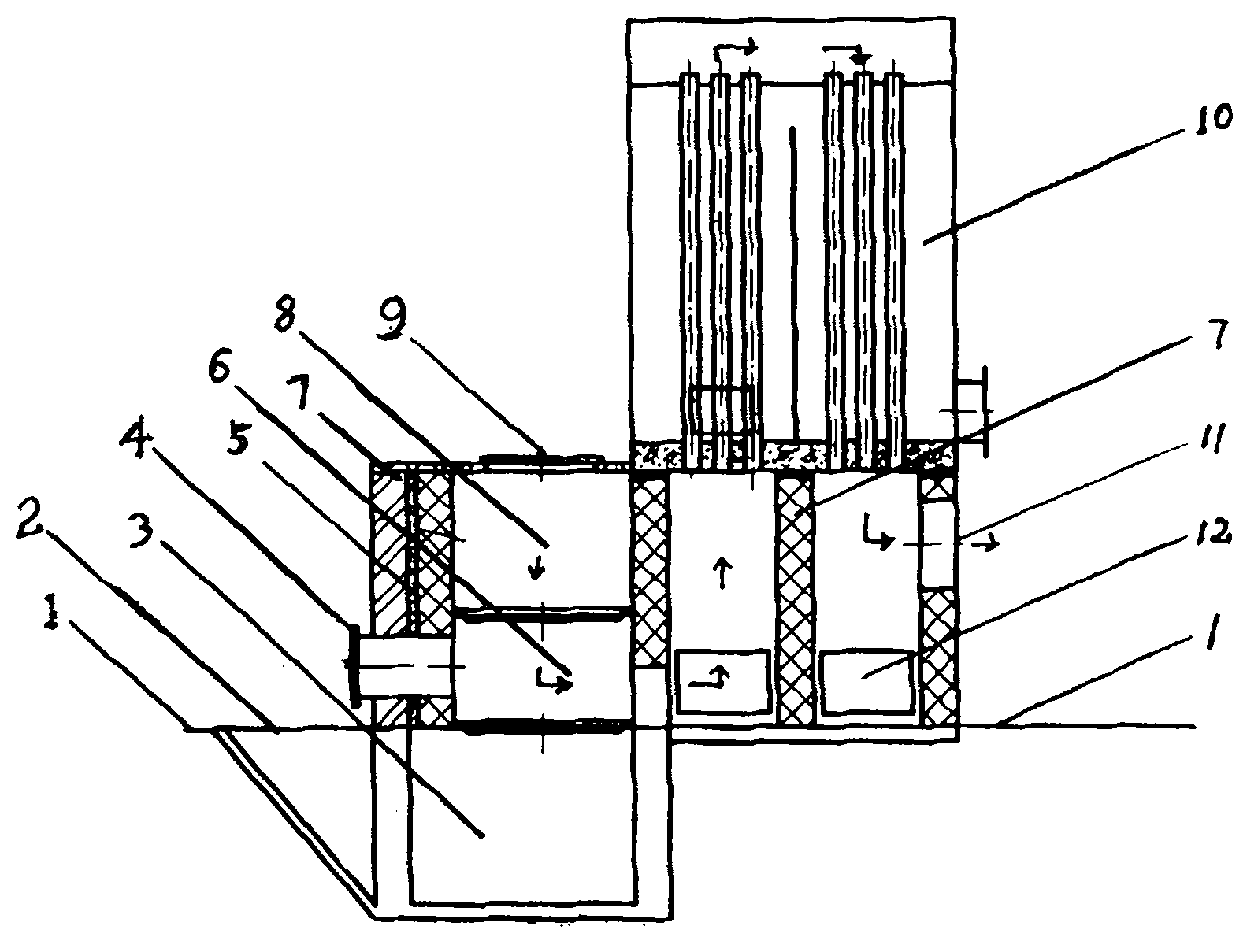

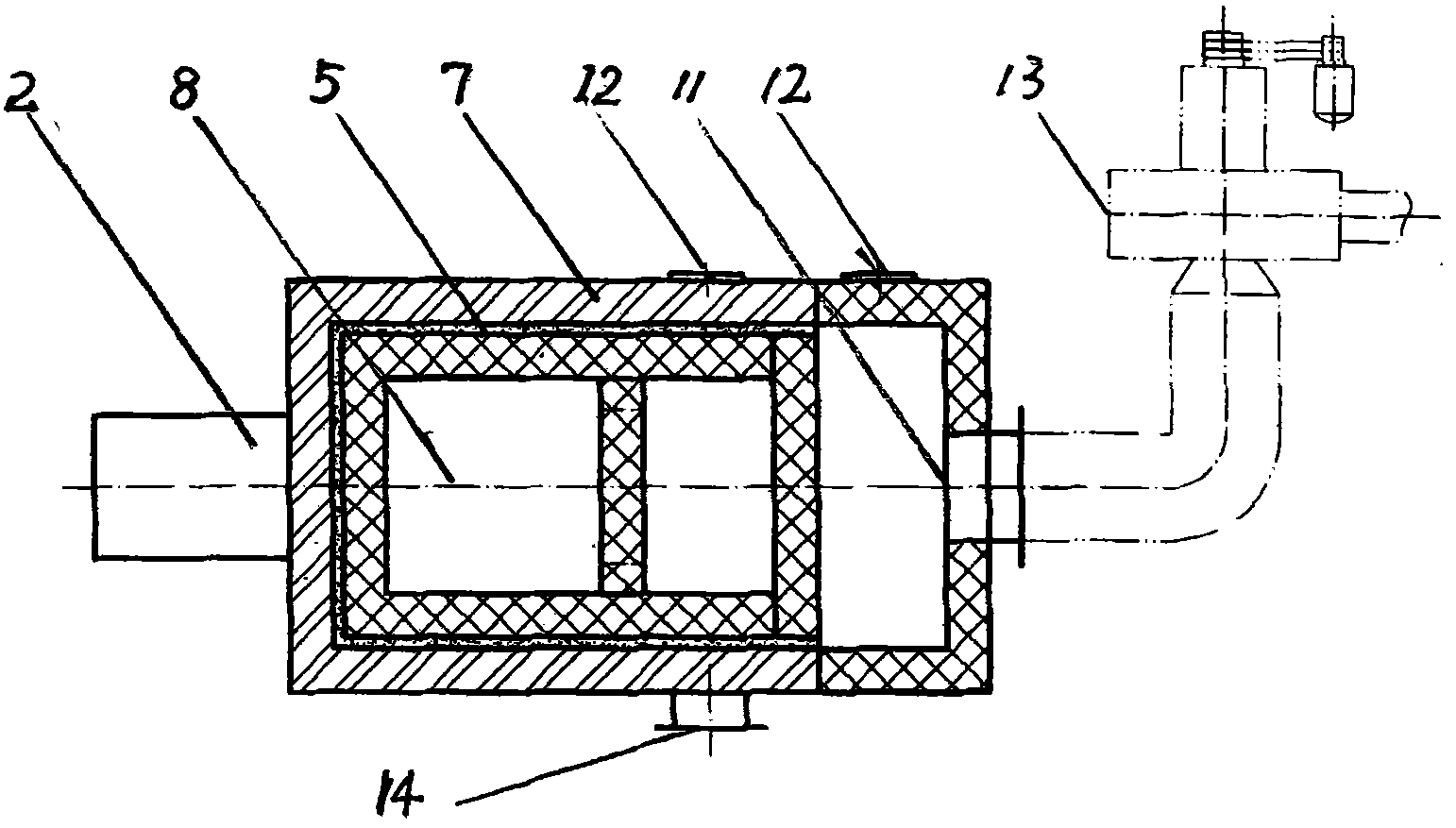

Embodiment 1

[0009] A brick hearth type hot blast stove, comprising: a ground plane (1), an ash removal cover (2), an underground ash pit (3), a furnace door (4), a silicon aluminum hydrochloride plate (5), a second combustion chamber (6 ), refractory bricks (7), first combustion chamber (8), feeding port (9), heat exchange device (10), smoke outlet (11), inspection port (12), induced draft fan (13), secondary tuyere (14). The hearth of the hot blast stove is all built with refractory bricks or refractory bricks combined with ordinary bricks (7), with a layer of silicon aluminum hydrochloride plate (5) sandwiched in the middle, which plays the role of heat preservation and heat insulation, and a heat exchange device (10) is arranged on it. The material used in the present invention is refractory brick.

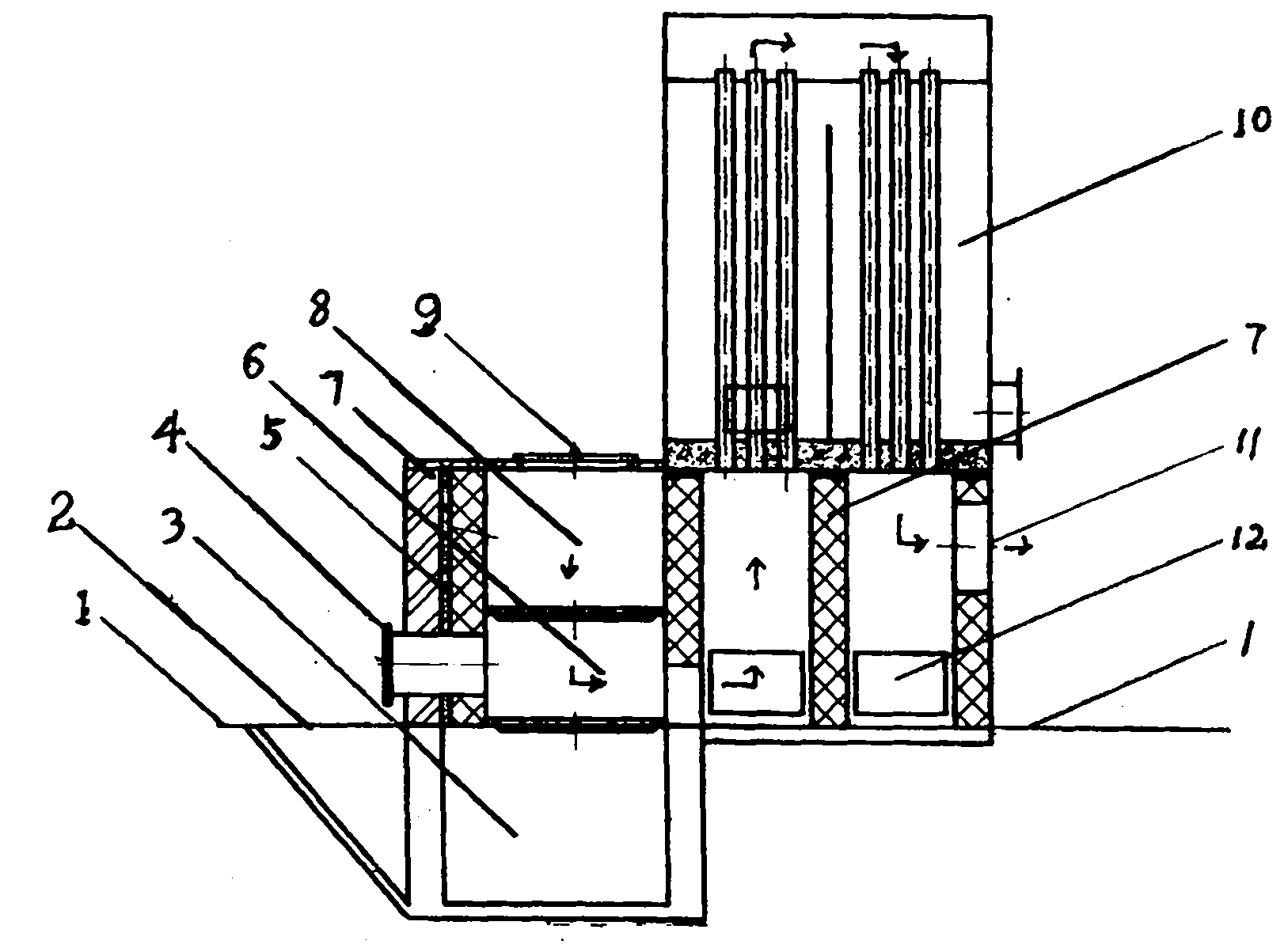

Embodiment 2

[0011] A brick hearth type hot blast stove, comprising: a ground plane (1), an ash removal cover (2), an underground ash pit (3), a furnace door (4), a silicon aluminum hydrochloride plate (5), a second combustion chamber (6 ), refractory bricks (7), first combustion chamber (8), feeding port (9), heat exchange device (10), smoke outlet (11), inspection port (12), induced draft fan (13), secondary tuyere (14). The hearth of the hot blast stove is all built with refractory bricks or refractory bricks combined with ordinary bricks (7), with a layer of silicon aluminum hydrochloride plate (5) sandwiched in the middle, which plays the role of heat preservation and heat insulation, and a heat exchange device (10) is arranged on it. The materials used in the present invention are refractory bricks combined with ordinary bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com