Reprocessing method and device of EVA foamed product and board made through reprocessing method and device of EVA foamed product

A technology for foaming products and reprocessing, which is applied to flat products, other household appliances, applications, etc., can solve the problems of polluting the environment, EVA foam products and waste materials cannot be effectively treated, and achieves convenient processing, wide use value, and solution The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

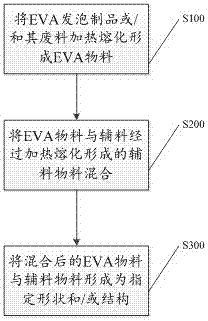

[0078] image 3 It is a schematic flow chart of the reprocessing method of the EVA foamed product; see image 3 , the application provides a method for reprocessing EVA foamed products, comprising:

[0079] S100, heating and melting EVA foamed products or / and waste materials thereof to form EVA materials;

[0080] S200, mixing the EVA material and the auxiliary material formed by heating and melting the auxiliary material;

[0081] S300, forming the mixed EVA material and auxiliary material into a specified shape and / or structure;

[0082] Wherein, the auxiliary material is polyethylene or / and polyester fiber or / and polypropylene fiber.

[0083] In the case not shown in the accompanying drawings, further, the auxiliary materials include polyethylene or / and polyester fibers or / and polypropylene fiber products and waste materials thereof; and / or, EVA foam products or / and waste materials thereof include car floor mats, Crawling mats, insoles or / and mats for sports equipment; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com