Self-adaption sleeve and spanner

A self-adaptive and sleeve technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of reducing work efficiency, tidying troubles, increasing costs, etc., and achieve the effect of improving production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

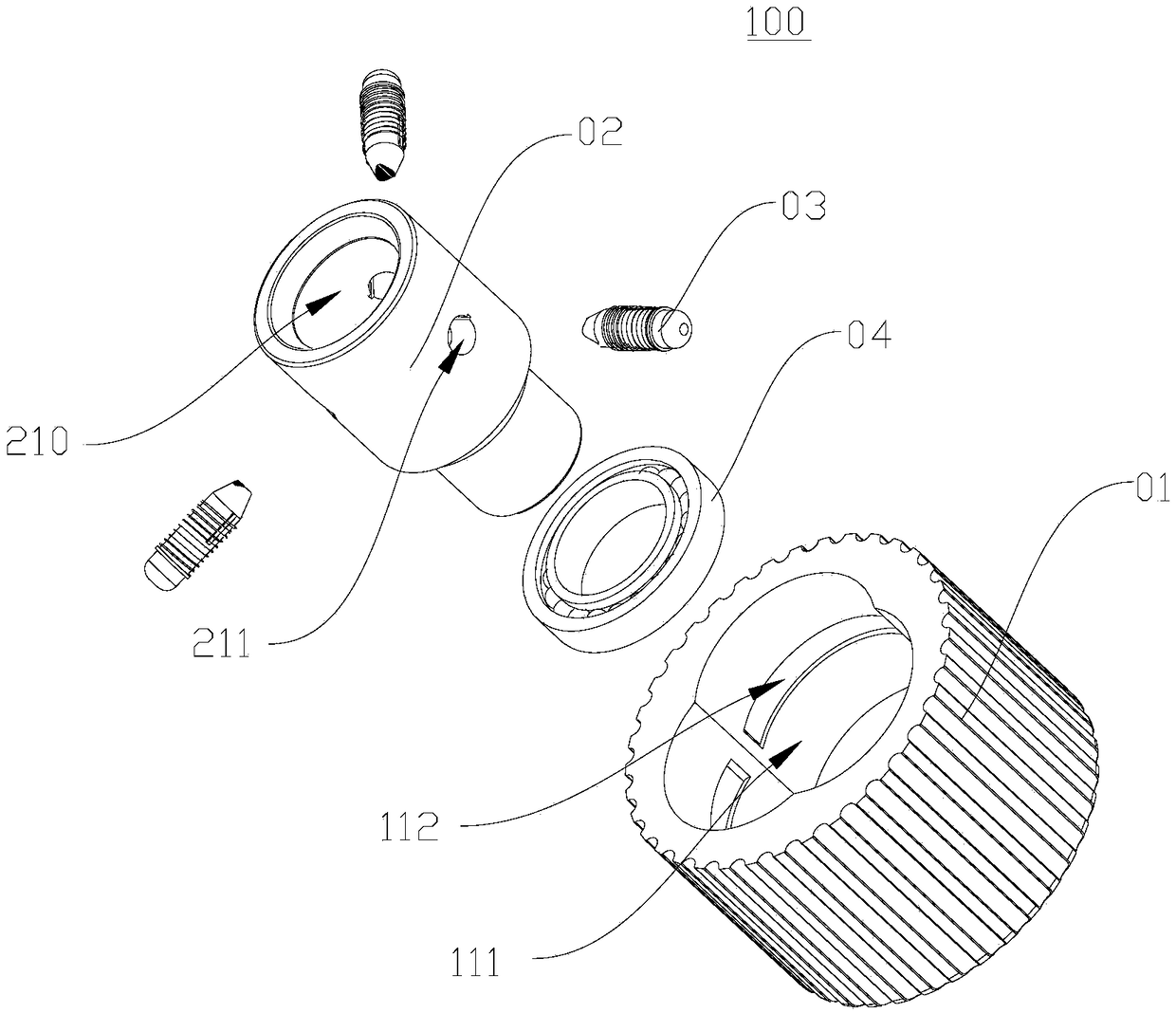

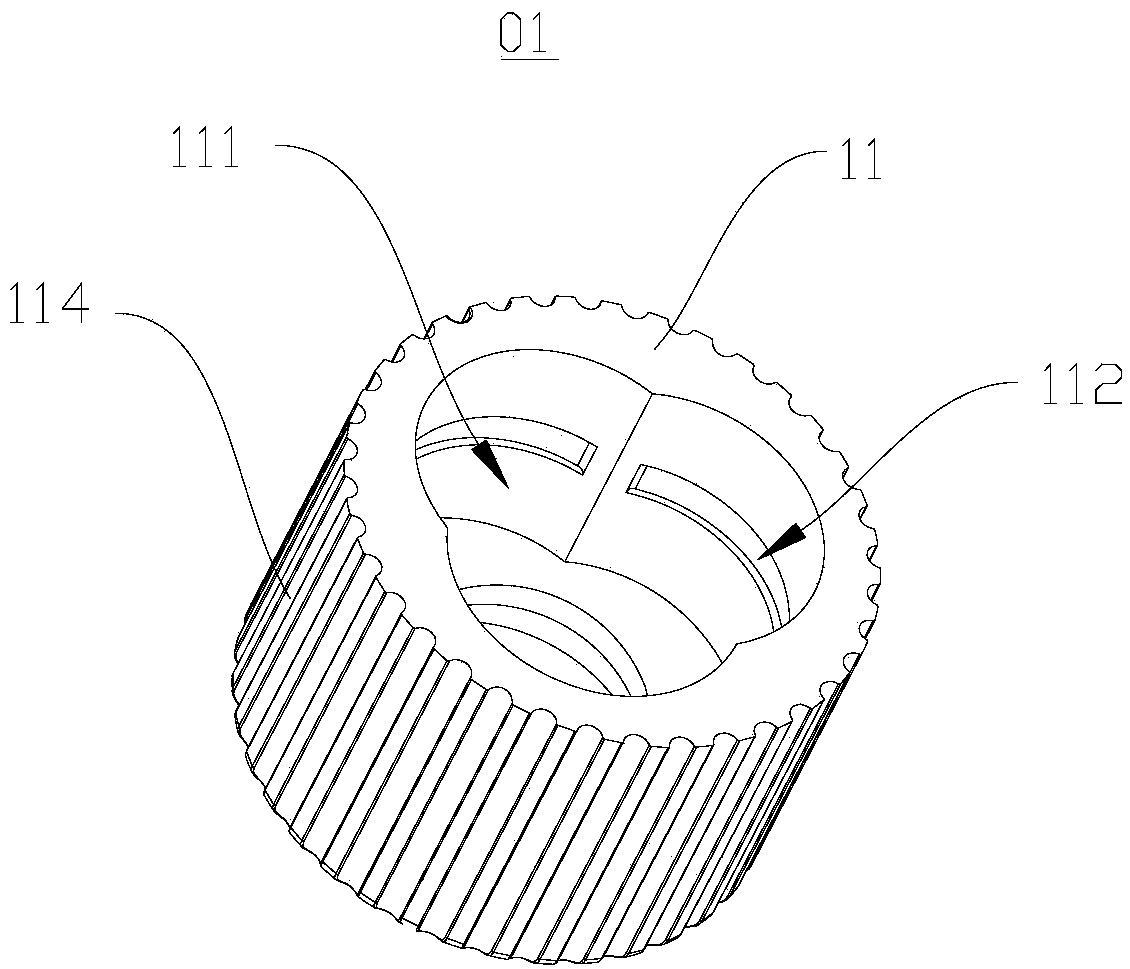

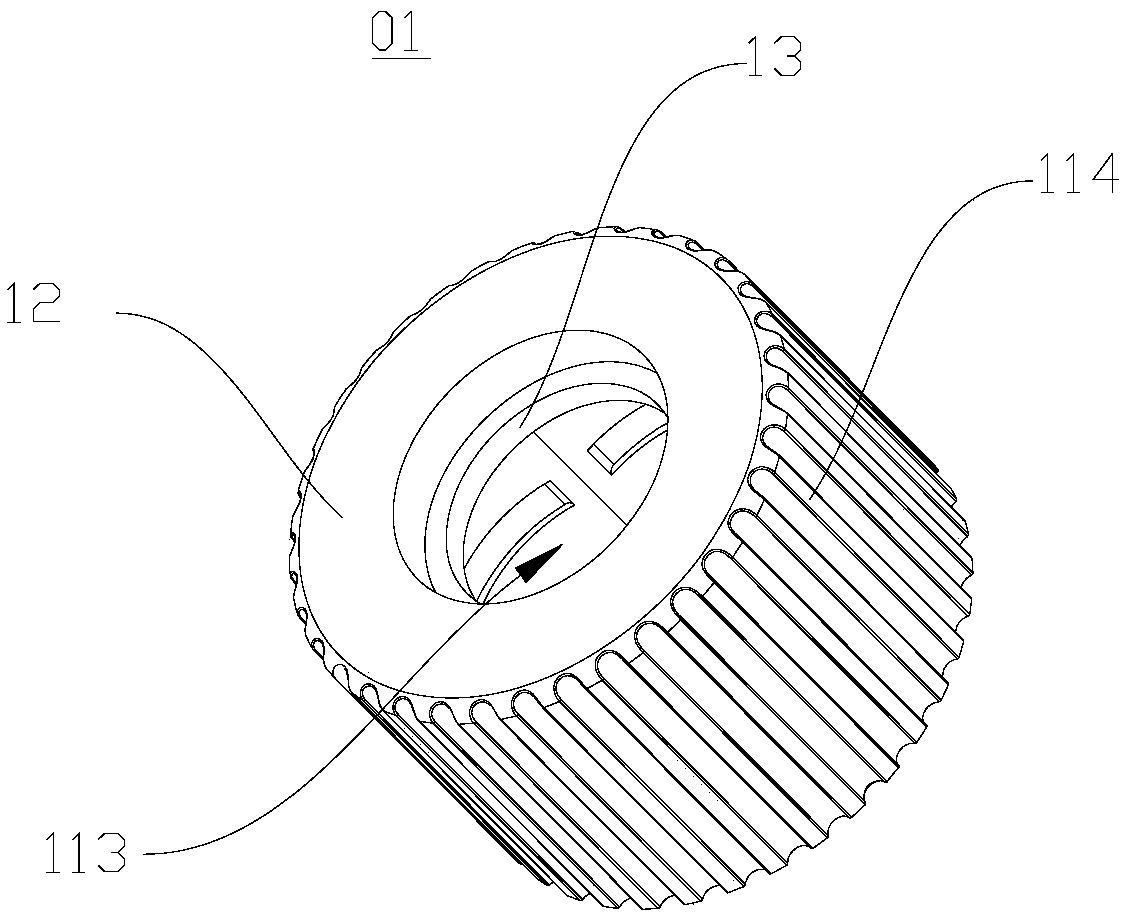

[0038] see figure 1 , this embodiment provides an adaptive sleeve 100 . The adaptive sleeve 100 includes a sleeve 01 , a mandrel 02 , a resisting piece 03 and a bearing 04 . The shaft sleeve 01 is provided with a fixing hole 111 . The mandrel 02 is disposed in the fixing hole 111 , and a sliding groove 112 is defined on a side wall of the fixing hole 111 .

[0039] A mounting hole 210 is formed on the mandrel 02 along the axis, and a positioning hole 211 is formed on the side wall of the mandrel 02 along the radial direction of the mounting hole 210 , and the positioning hole 211 communicates with the mounting hole 210 . The resisting member 03 is disposed in the positioning hole 211 , and one end of the resisting member 03 is resisted in the sliding groove 112 , and the other end is located in the installation hole 210 .

[0040] The supporting part 03 can slide along the sliding groove 112, so that the length of the supporting part 03 extending into the installation hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com