Biomass back-burning multi-return low-carbon energy-saving blast stove

A biomass, multi-return technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high cost, short life, environmental pollution, etc., to achieve fuel saving, increase temperature, and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

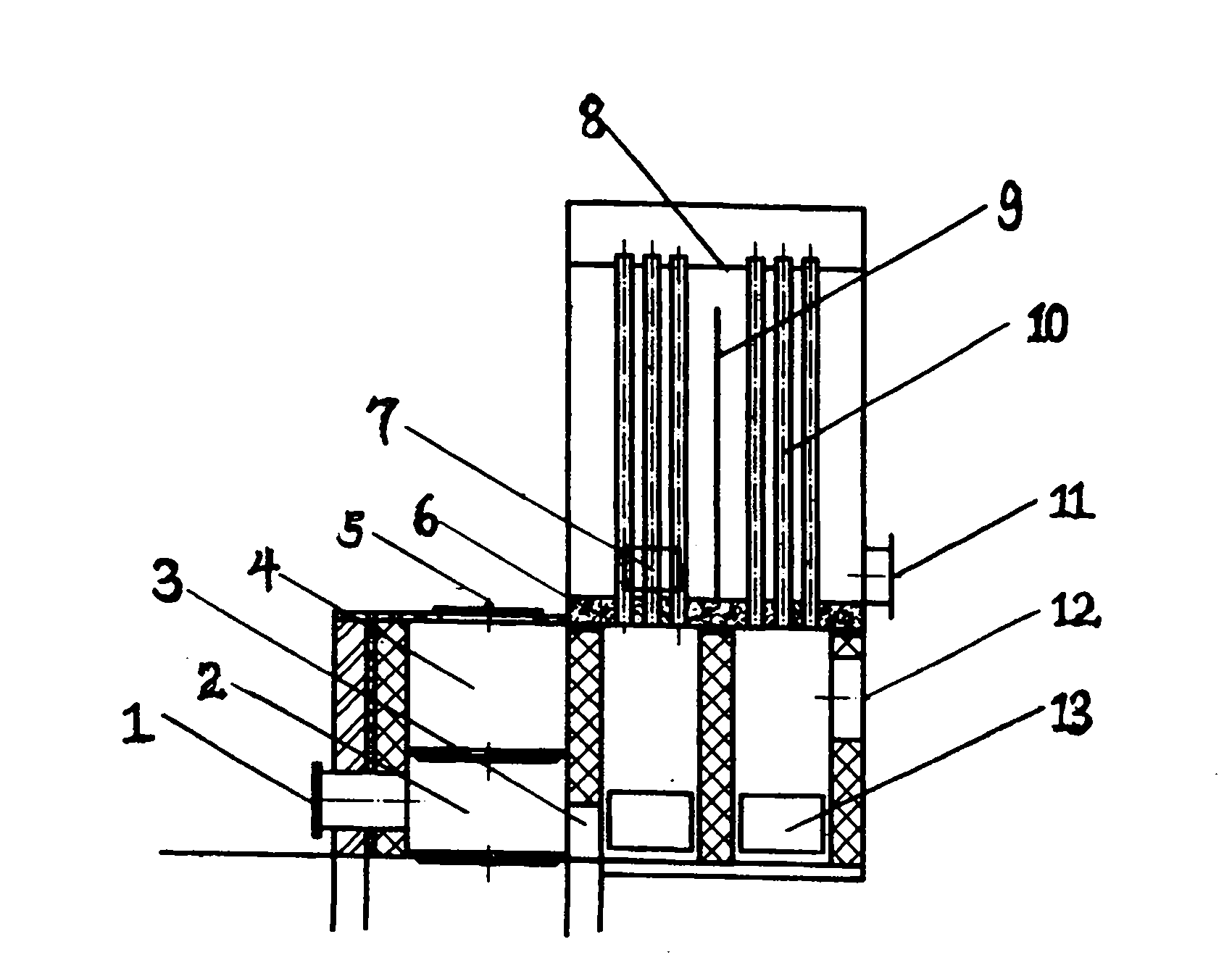

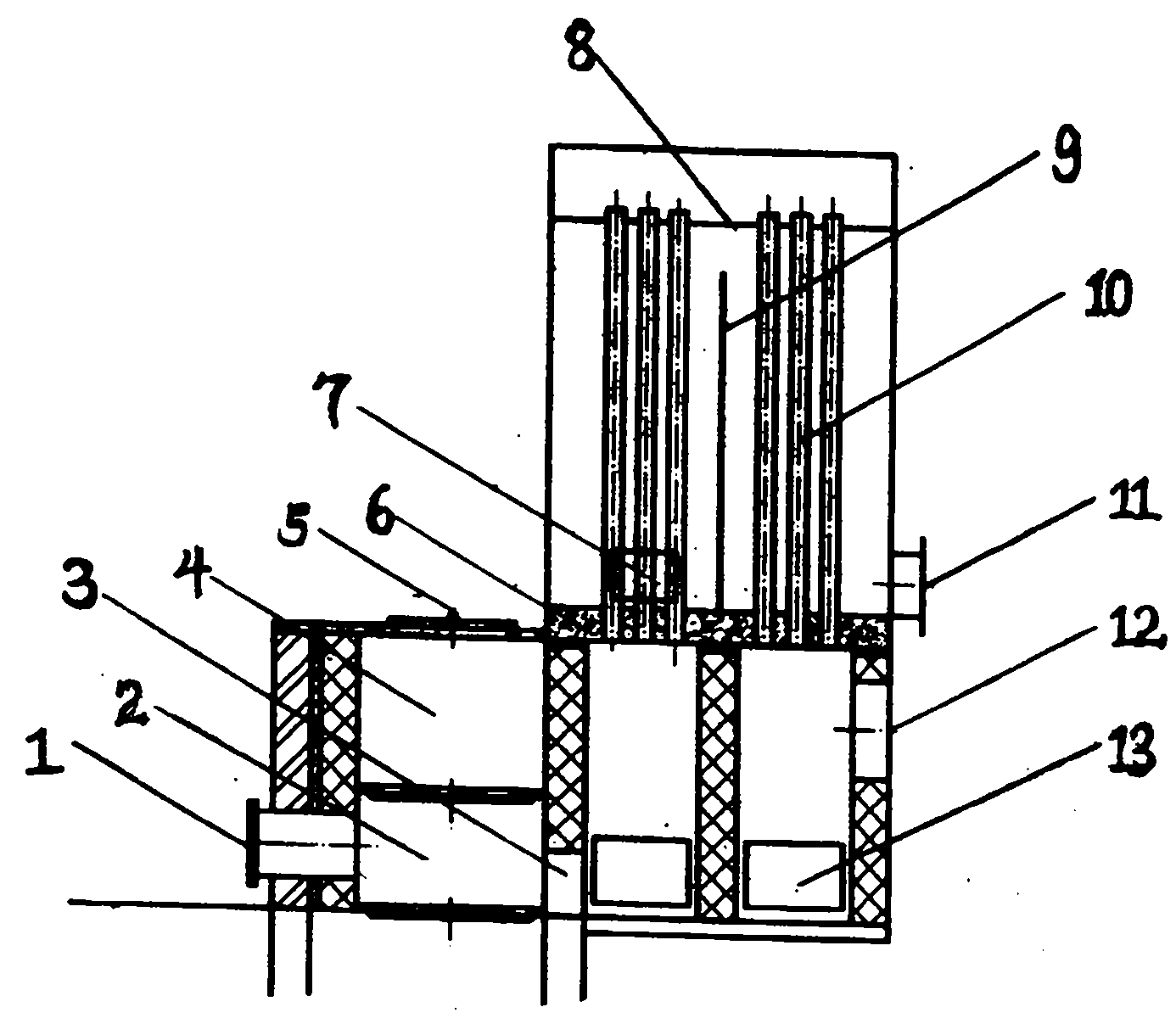

[0007] A biomass back-burning multi-pass low-carbon energy-saving hot air stove, comprising a furnace door (1), a biomass back-burning hearth (2), a biomass back-burning burner (3), a biomass hearth (4), and a biomass feeding port (5), refractory material (6), cold air inlet (7), sealing plate (8), air isolation plate (9), biomass multi-return fire pipe (10), hot air outlet (11), chimney mouth (12), inspection door (13). Attached figure 1 As shown, a biomass back-burning furnace (2) is provided under the biomass furnace (4), and a biomass back-burning burner (3) is provided on the bottom side, and the biomass multi-return fire tube (10) is welded upright on the top, and the fire A layer of refractory material (6) is filled under the pipe, and a chimney opening (12) is provided at the lower part of one side of the hot blast stove, so that automatic flame biomass back-burning and multiple return directions are naturally formed, which not only saves fuel, but also is low-carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com