Brick hearth type steam boiler

A technology for steam boilers and furnaces, which is applied to steam boilers, steam boiler accessories, and components of steam boilers, etc., can solve problems such as high cost, burning collapse, water leakage, etc., and achieve the effect of low cost and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

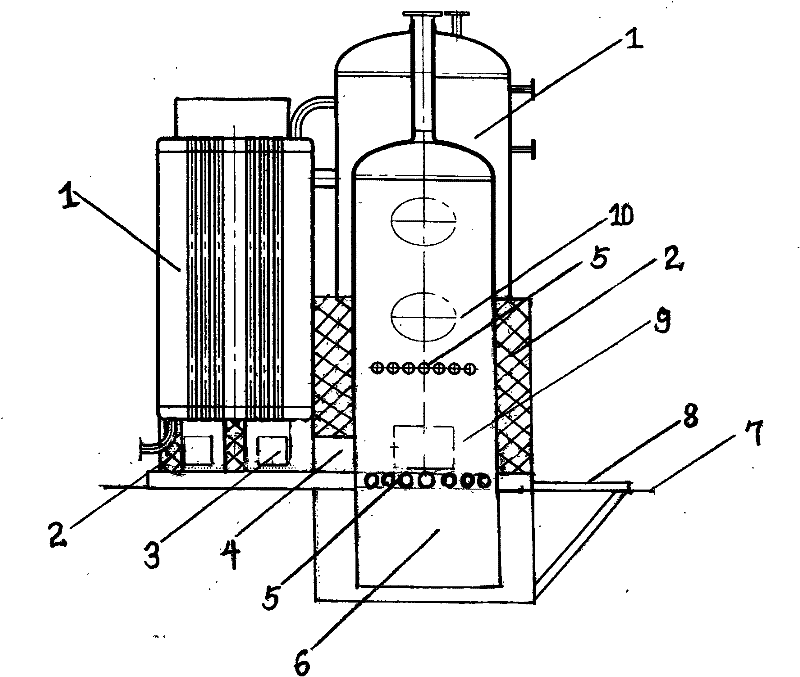

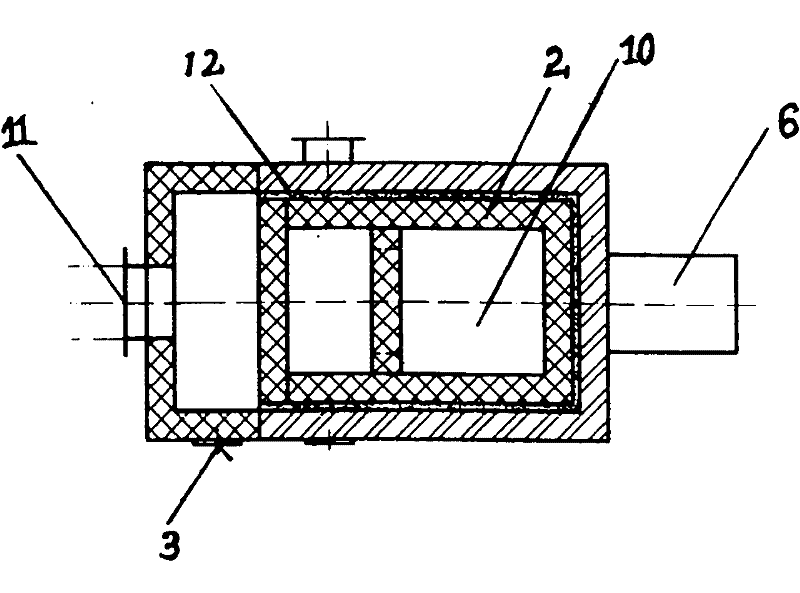

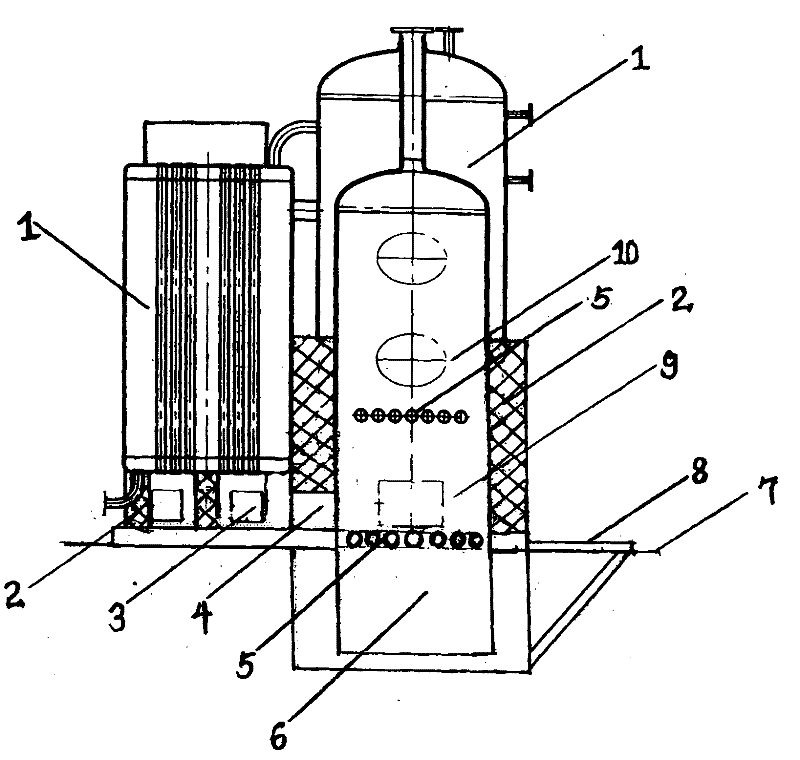

[0009] A brick hearth type steam boiler, comprising a steam boiler (1), refractory bricks (2), ash removal port (3), counter-burning passage (4), fire grate (5), underground ash pit (6), ground Plane (7), ash removal cover (8), brick-laying reverse-burning hearth (9), brick-laying hearth (10), chimney mouth (11), aluminum silicate plate (12). according to figure 1 Requirements, use refractory bricks (2) to build a furnace (10) and a backfired furnace (9), sandwich a layer of aluminum silicate plate (12) in the middle, play the role of thermal insulation, a steam boiler (1) is arranged on it, and the ground plane ( 7) An underground ash pit (6) is provided below. The material used in the present invention is refractory brick.

Embodiment 2

[0011] A brick hearth type steam boiler, comprising a steam boiler (1), refractory bricks (2), ash removal port (3), counter-burning passage (4), fire grate (5), underground ash pit (6), ground Plane (7), ash removal cover (8), brick-laying reverse-burning hearth (9), brick-laying hearth (10), chimney mouth (11), aluminum silicate plate (12). according to figure 1 It is required to use refractory bricks (2) to build the furnace (10) and reflective furnace (9), with a layer of aluminum silicate board (12) sandwiched between them for thermal insulation. There is a steam boiler (1) on it, and a ground plane (7) An underground ash pit (6) is provided above. The materials used in the present invention are refractory bricks combined with ordinary bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com