Reverse burning multi-return-stroke biomass low-carbon energy-saving steam boiler

A steam boiler and biomass technology, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of high fuel consumption, polluted air, low utilization rate of heat energy, etc., and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

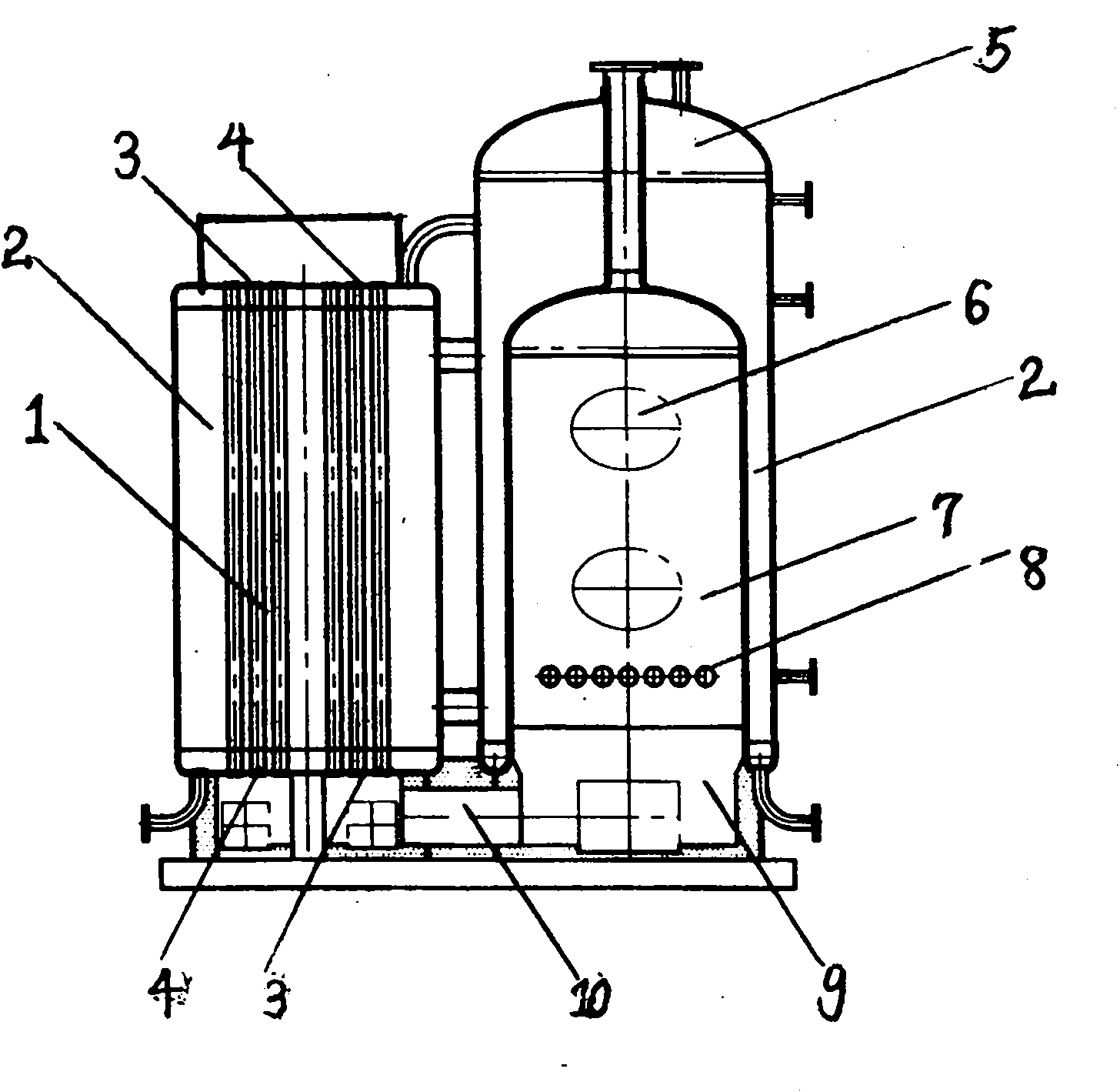

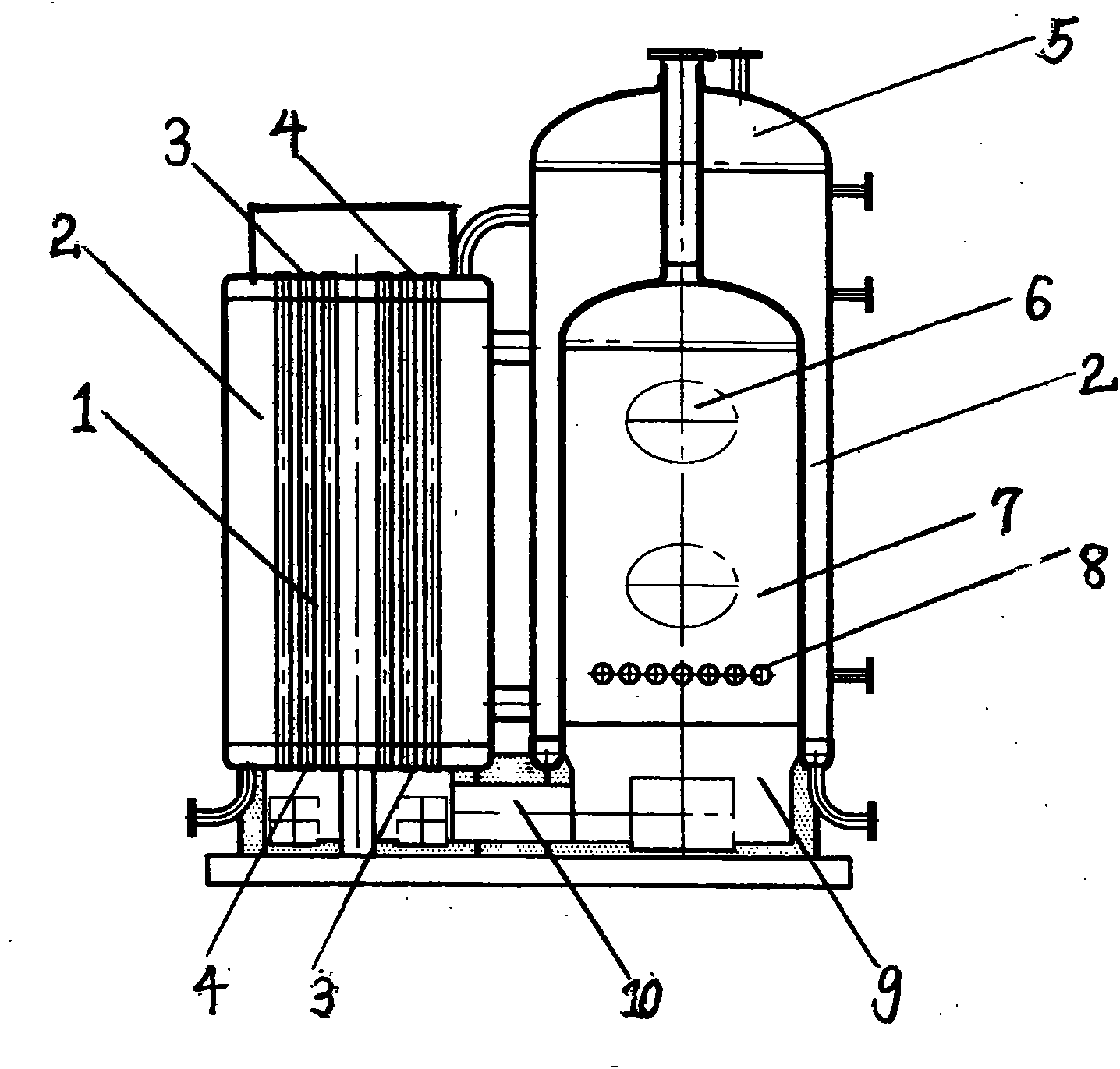

[0008] A low-carbon energy-saving steam boiler with reverse combustion and multi-pass biomass, including a multi-pass fire tube (1), a water jacket (2), a return fire outlet (3), a return fire inlet (4), and an oval head (5) , a biomass feed port (6), a biomass semi-gasification furnace (7), a fire grate (8), a secondary combustion chamber (9), and an anti-burning channel (10). Under the action of the induced draft fan in the reverse-burning multi-pass biomass low-carbon energy-saving steam boiler, the fuel is first gasified in the biomass semi-gasification furnace, and a large amount of volatile matter is precipitated during this process. Under the action of the secondary air, the fuel is fully burned, and the flame then enters the fire tube from bottom to top to the return fire outlet, and then returns from the return fire inlet to top to bottom, thus forming a multi-return process of back-burning. It can use thermal energy more effectively to increase water temperature and ...

Embodiment 2

[0010] A low-carbon energy-saving steam boiler with reverse combustion and multi-pass biomass, including a multi-pass fire tube (1), a water jacket (2), a return fire outlet (3), a return fire inlet (4), and an oval head (5) , a biomass feed port (6), a biomass semi-gasification furnace (7), a fire grate (8), a secondary combustion chamber (9), and an anti-burning channel (10). Under the action of the induced draft fan in the reverse-burning multi-pass biomass low-carbon energy-saving steam boiler, the fuel is first gasified in the biomass semi-gasification furnace, and a large amount of volatile matter is precipitated during this process. Under the action of the secondary air, the fuel is fully burned, and the flame then enters the fire tube from bottom to top to the return fire outlet, and then returns from the return fire inlet to top to bottom, thus forming a multi-return process of back-burning. It can use thermal energy more effectively to increase water temperature and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com