Composite adhesive for molding coal powder and method for preparing molded coal

A binder and cohesive coal technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of high content of harmful impurities, unsuitable for industrial application, complex preparation process, etc., and achieve low price, low cost, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

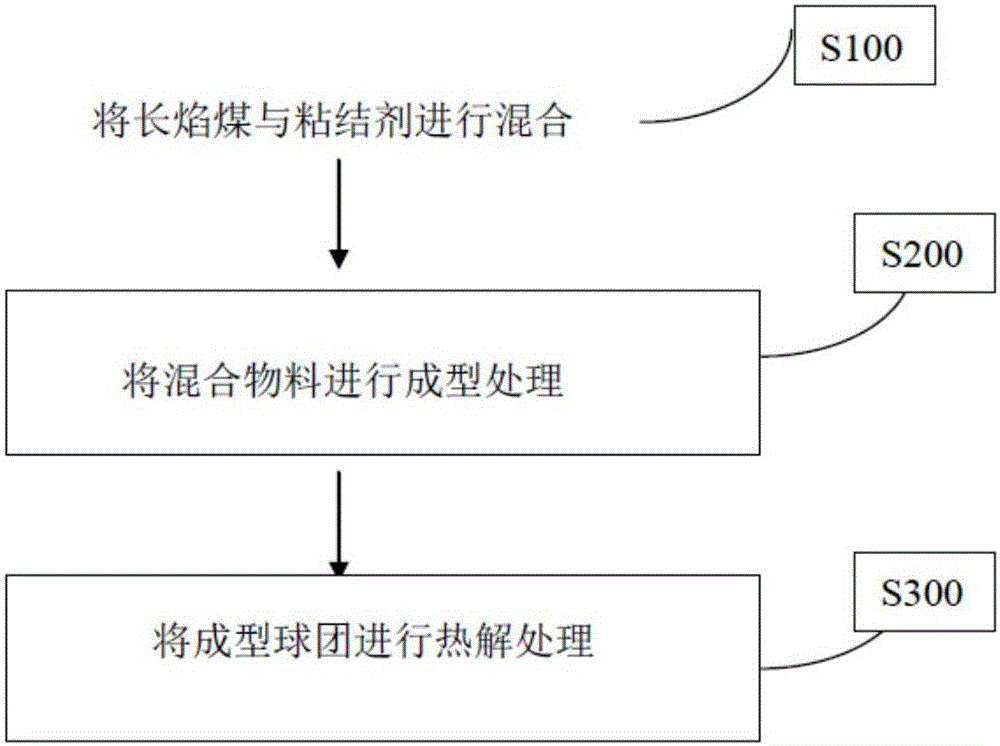

Method used

Image

Examples

Embodiment 1

[0040] Raw materials: long-flame coal powder, coke powder, boron oxide or boron powder, quicklime, caking coal.

[0041] The long-flame coal powder with a particle size distribution of less than 100 mesh accounts for 63.5% of its total mass.

[0042] Form coke preparation steps:

[0043] Step 1, mix 1000g of long-flame coal, 30g of coke powder, 1100g of quicklime, 10g of boron oxide, and 300g of Datong coal for 15 minutes to obtain a mixture;

[0044] Step 2, put the mixture into the molding equipment and press it under the pressure of 13Mpa;

[0045] Step 3, heating the compressed mixture in a preheating furnace at 650° C. for 60 minutes to perform pyrolysis treatment.

[0046] The average compressive strength of the raw briquettes obtained above before pyrolysis is 392N / ball, the average drop strength is 41 times / ball, and the 2-meter steel plate drop M5 reaches 87.54%; the average compressive strength after pyrolysis is 710N / ball, and the average drop strength is more tha...

Embodiment 2

[0049] Raw materials: long-flame coal powder, coke powder, boron oxide or boron powder, quicklime, caking coal.

[0050] The long-flame coal pulverized coal particle size distribution below 100 mesh accounts for 74.9% of its total mass.

[0051] Form coke preparation steps:

[0052] Step 1, mix 1000g of long-flame coal, 50g of coal tar, 1100g of quicklime, 15g of boron powder, and 400g of Datong coal for 15 minutes to obtain a mixture;

[0053] Step 2, put the mixture into the molding equipment and press it under the pressure of 13Mpa;

[0054] Step 3, heating the compressed mixture in a preheating furnace at 650° C. for 60 minutes to perform pyrolysis treatment.

[0055] The average compressive strength of the raw briquettes obtained above before pyrolysis is 644N / ball, the average drop strength is 42 times / ball, and 90.12% of the 2-meter steel plate falls M5; the average compressive strength after pyrolysis is 1053N / ball, and the average drop strength is more than 45 times...

Embodiment 3

[0058] Raw materials: long-flame coal powder, coke powder, boron oxide or boron powder, quicklime, caking coal.

[0059] Its particle size distribution below 100 mesh accounts for 34.9% of its total mass.

[0060] Form coke preparation steps:

[0061] Step 1, mix 1000g of long-flame coal, 100g of coal tar, 1100g of quicklime, 20g of boron powder, and 400g of Datong coal for 15 minutes to obtain a mixture;

[0062] Step 2, put the mixture into the molding equipment and press it under the pressure of 13Mpa;

[0063] Step 3, heating the compressed mixture in a preheating furnace at 650° C. for 60 minutes to perform pyrolysis treatment.

[0064] The average compressive strength of the raw briquettes obtained above before pyrolysis is 534N / ball, the average drop strength is 41 times / ball, and the 2-meter steel plate drop M5 reaches 88.75%; the average compressive strength after pyrolysis is 896N / ball, and the average drop strength is more than 45 times / ball 97.22% of the 2-meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com