Production method of preserved beancurd

A production method and product technology, applied in the production field of fermented bean curd products, can solve problems such as the traditional production process, achieve the effects of sufficient fermentation, increase aroma and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

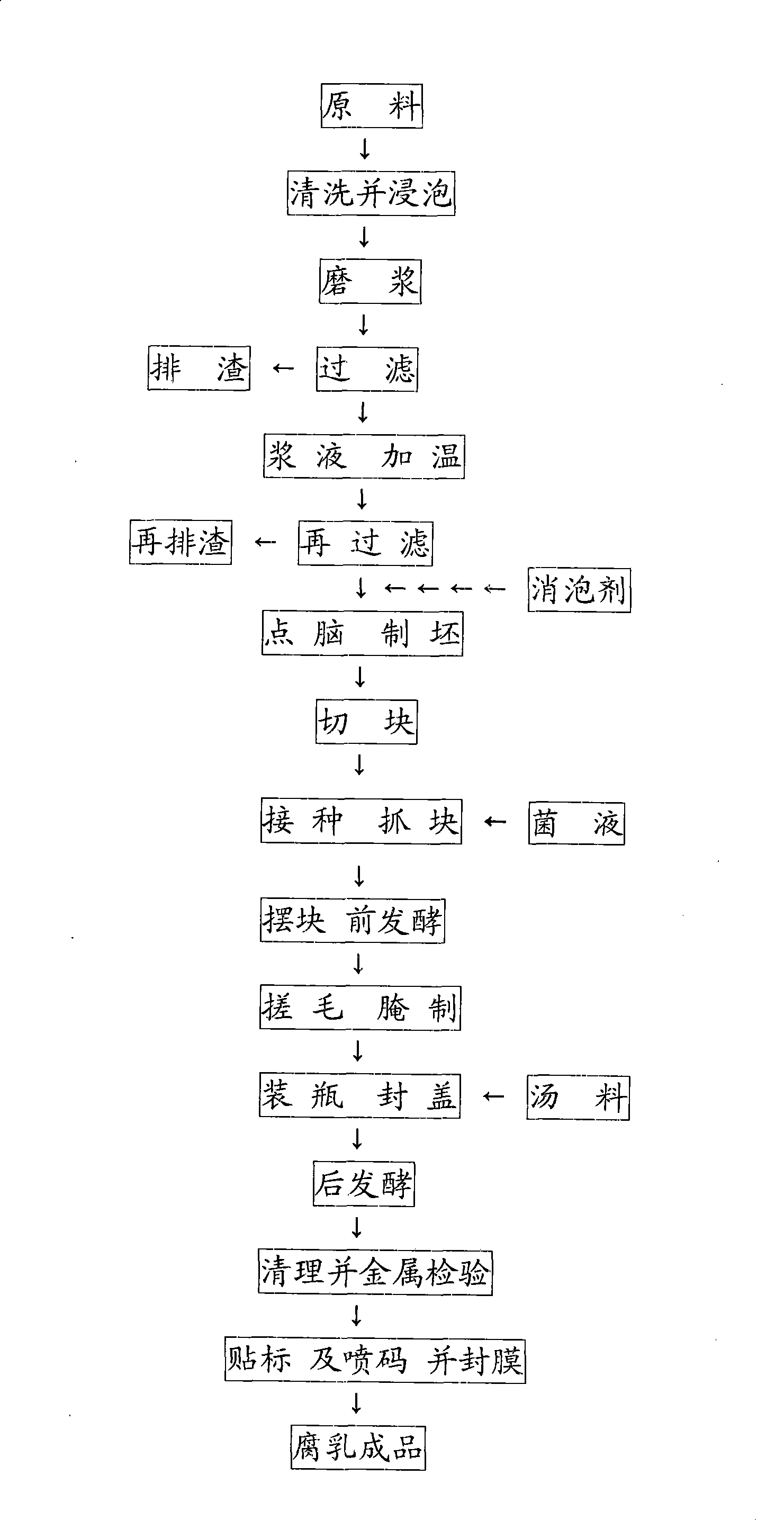

Method used

Image

Examples

specific Embodiment approach 2

[0087] Carry out according to specific embodiment one, just: the salt content of described bean curd finished product is respectively 3.5%, 3.6%, 3.7%, 3.8%, 3.9%, 4%, 5%, 6%, 6.5%, 6.6%, 6.7% and 6.8% have been implemented; thus low-salt fermented bean curd products have been produced; expected good results have been obtained.

specific Embodiment approach 3

[0088] Carry out according to specific embodiment 1, just: the salt content of described fermented bean curd product is carried out with 6.9%, 7%, 8%, 9%, 10%, 11%, 12%, 13% respectively; The light salt fermented bean curd product was obtained; the expected good effect was also obtained.

specific Embodiment approach 4

[0089] Carry out according to specific embodiment 1, just: the salt content of described fermented bean curd product is implemented with 13.1%, 14%, 15%, 16%, 17%, 18% respectively; Thereby produced light salt fermented bean curd product; The expected good effect was also obtained.

[0090] After the test of the present invention was carried out, the fermented bean curd products produced were detected, and all met the standards; through expert evaluation in the industry, it was unanimously believed that the method was scientific and reasonable, had extensive promotion and application value, and the color, fragrance, taste and shape of the product were all good. New varieties of fermented bean curd products have been added, making due contributions to the technological progress of the industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com