Patents

Literature

50results about How to "Effective technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Question-answering system and method based on semantic labeling of text documents and user questions

ActiveUS20100235164A1Effective technologyDigital data information retrievalNatural language data processingBasic knowledgeQuestion answer

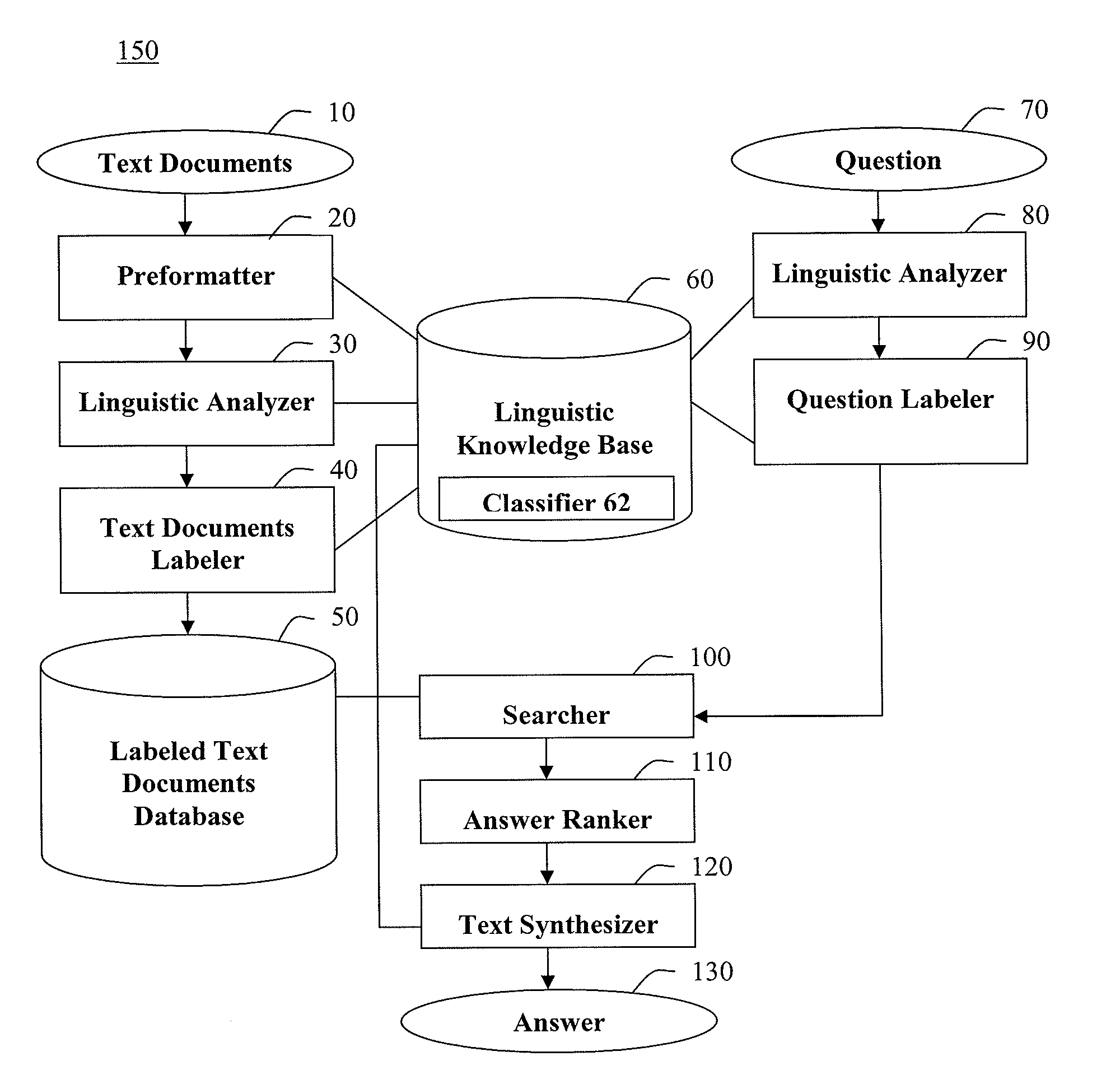

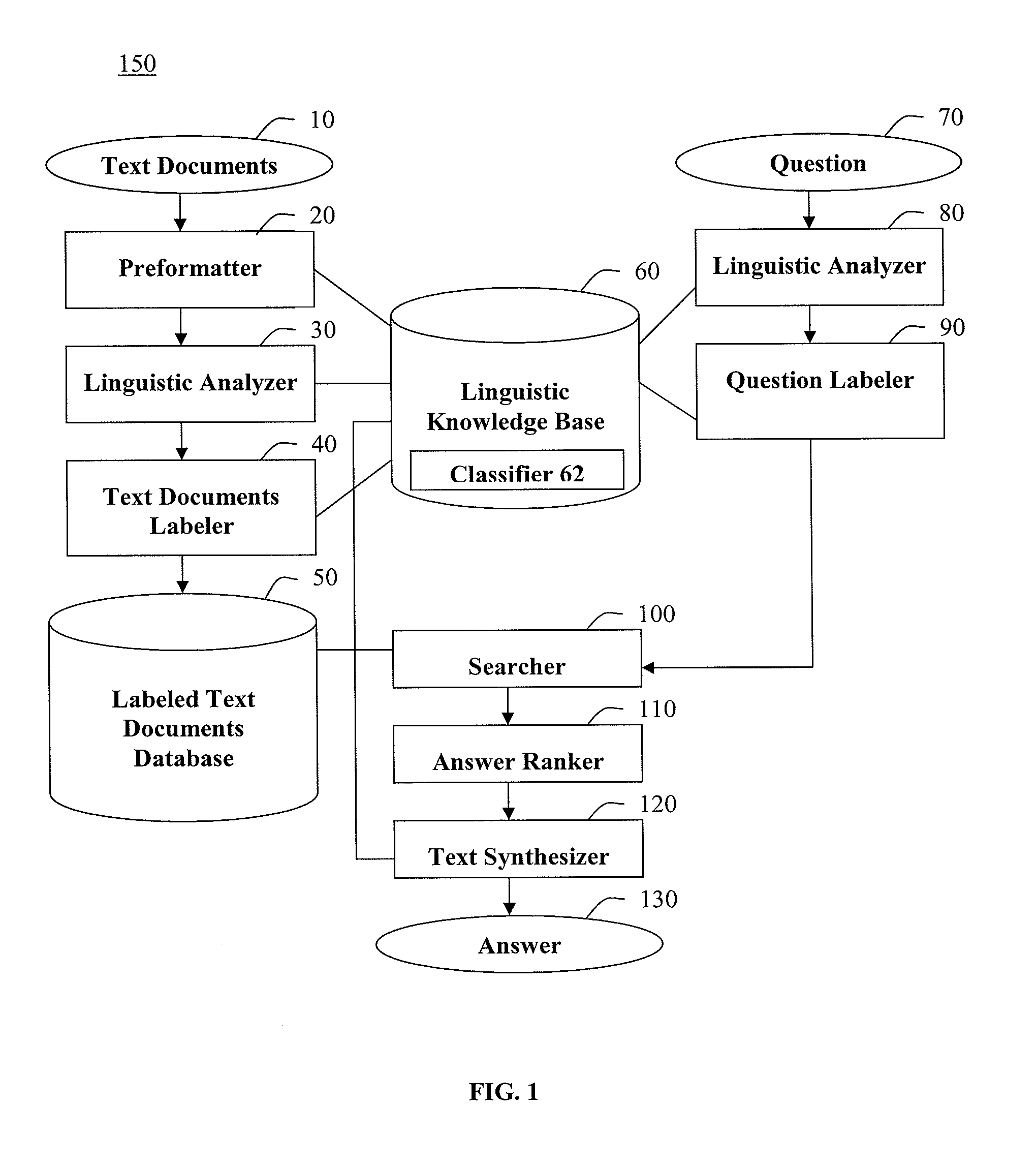

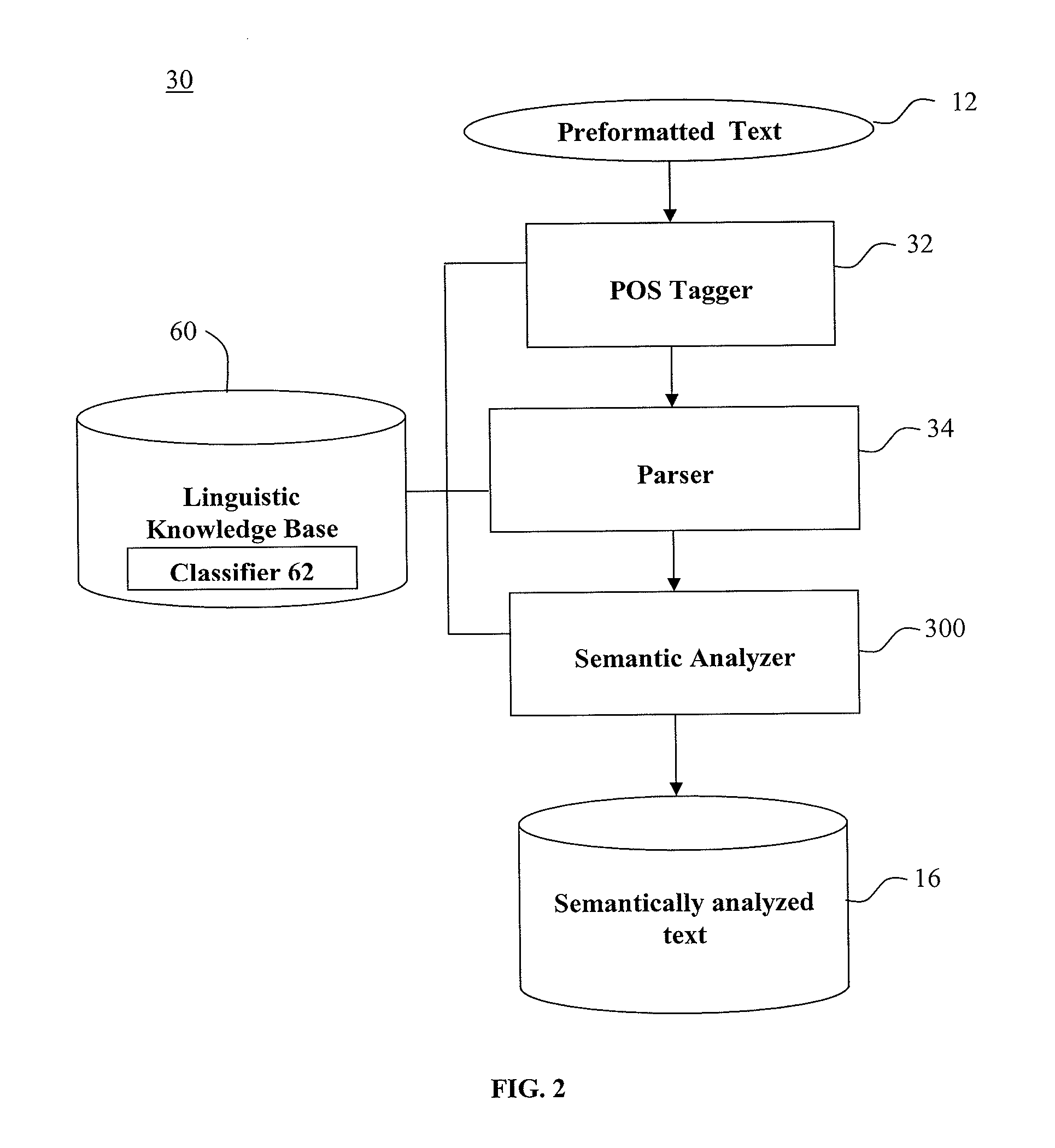

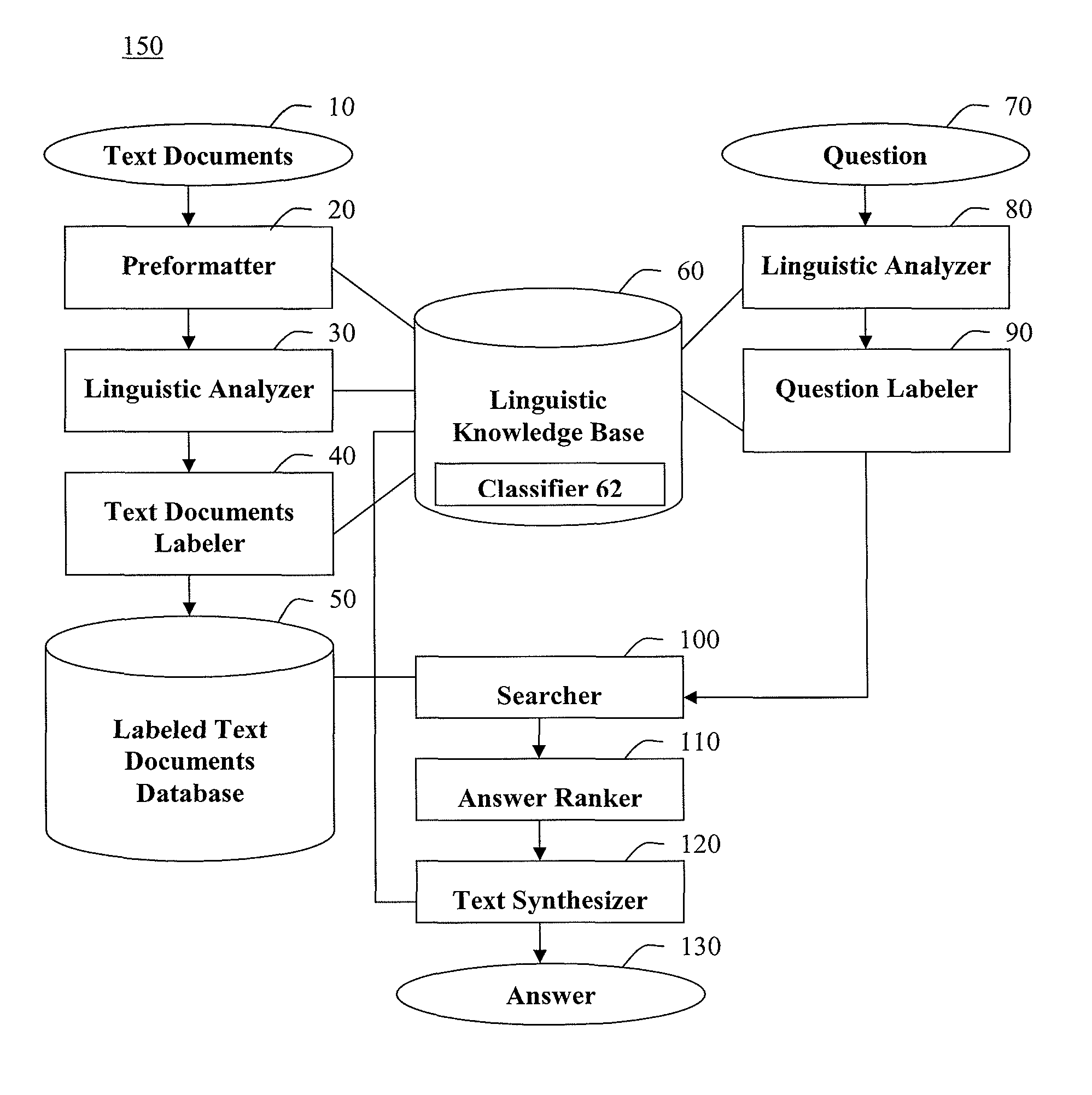

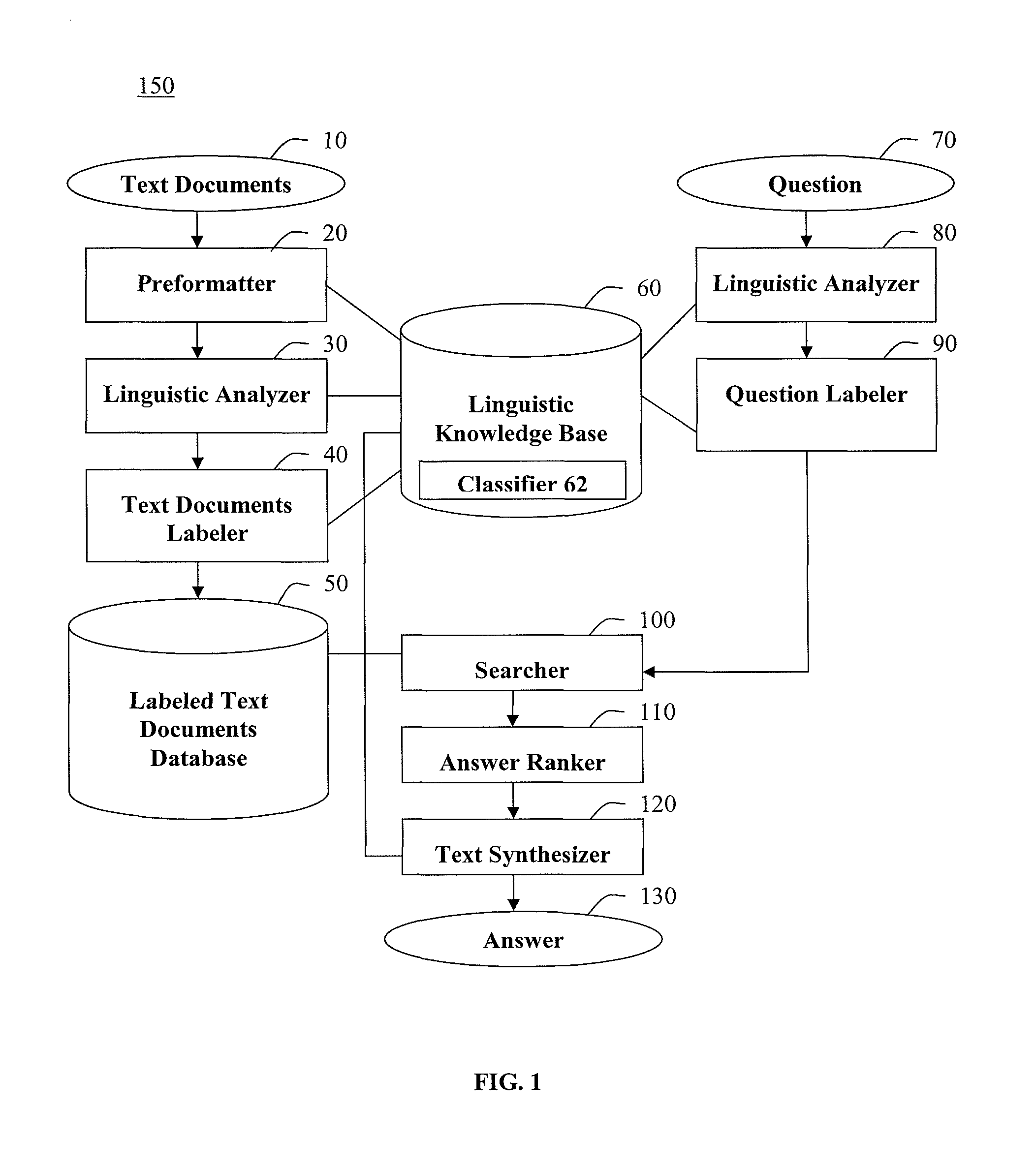

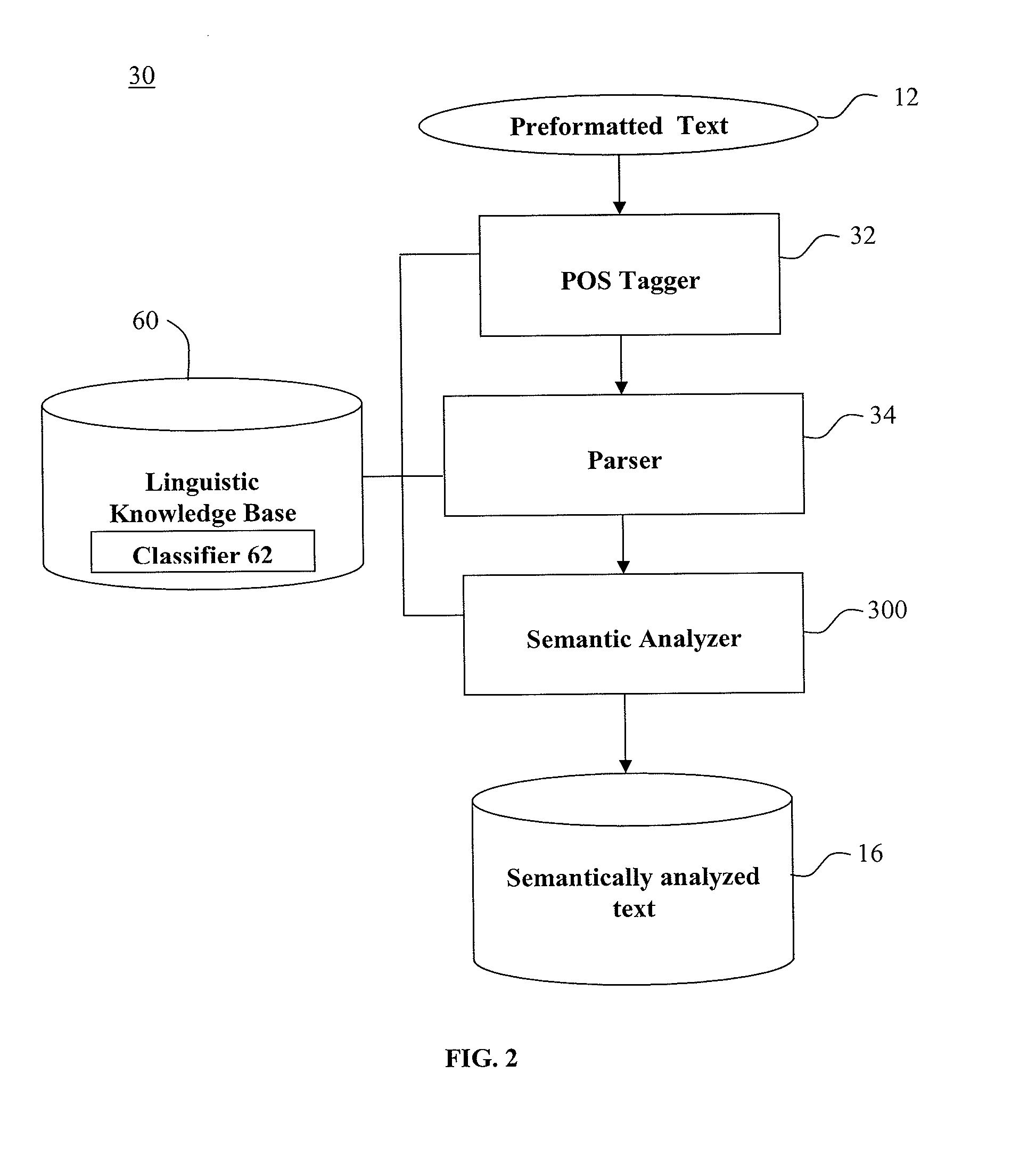

A question-answering system for searching exact answers in text documents provided in the electronic or digital form to questions formulated by user in the natural language is based on automatic semantic labeling of text documents and user questions. The system performs semantic labeling with the help of markers in terms of basic knowledge types, their components and attributes, in terms of question types from the predefined classifier for target words, and in terms of components of possible answers. A matching procedure makes use of mentioned types of semantic labels to determine exact answers to questions and present them to the user in the form of fragments of sentences or a newly synthesized phrase in the natural language. Users can independently add new types of questions to the system classifier and develop required linguistic patterns for the system linguistic knowledge base.

Owner:IHS GLOBAL

Question-answering system and method based on semantic labeling of text documents and user questions

ActiveUS8666730B2Effective technologyDigital data information retrievalNatural language data processingDocumentation procedureHuman language

A question-answering system for searching exact answers in text documents provided in the electronic or digital form to questions formulated by user in the natural language is based on automatic semantic labeling of text documents and user questions. The system performs semantic labeling with the help of markers in terms of basic knowledge types, their components and attributes, in terms of question types from the predefined classifier for target words, and in terms of components of possible answers. A matching procedure makes use of mentioned types of semantic labels to determine exact answers to questions and present them to the user in the form of fragments of sentences or a newly synthesized phrase in the natural language. Users can independently add new types of questions to the system classifier and develop required linguistic patterns for the system linguistic knowledge base.

Owner:ALLIUM US HLDG LLC

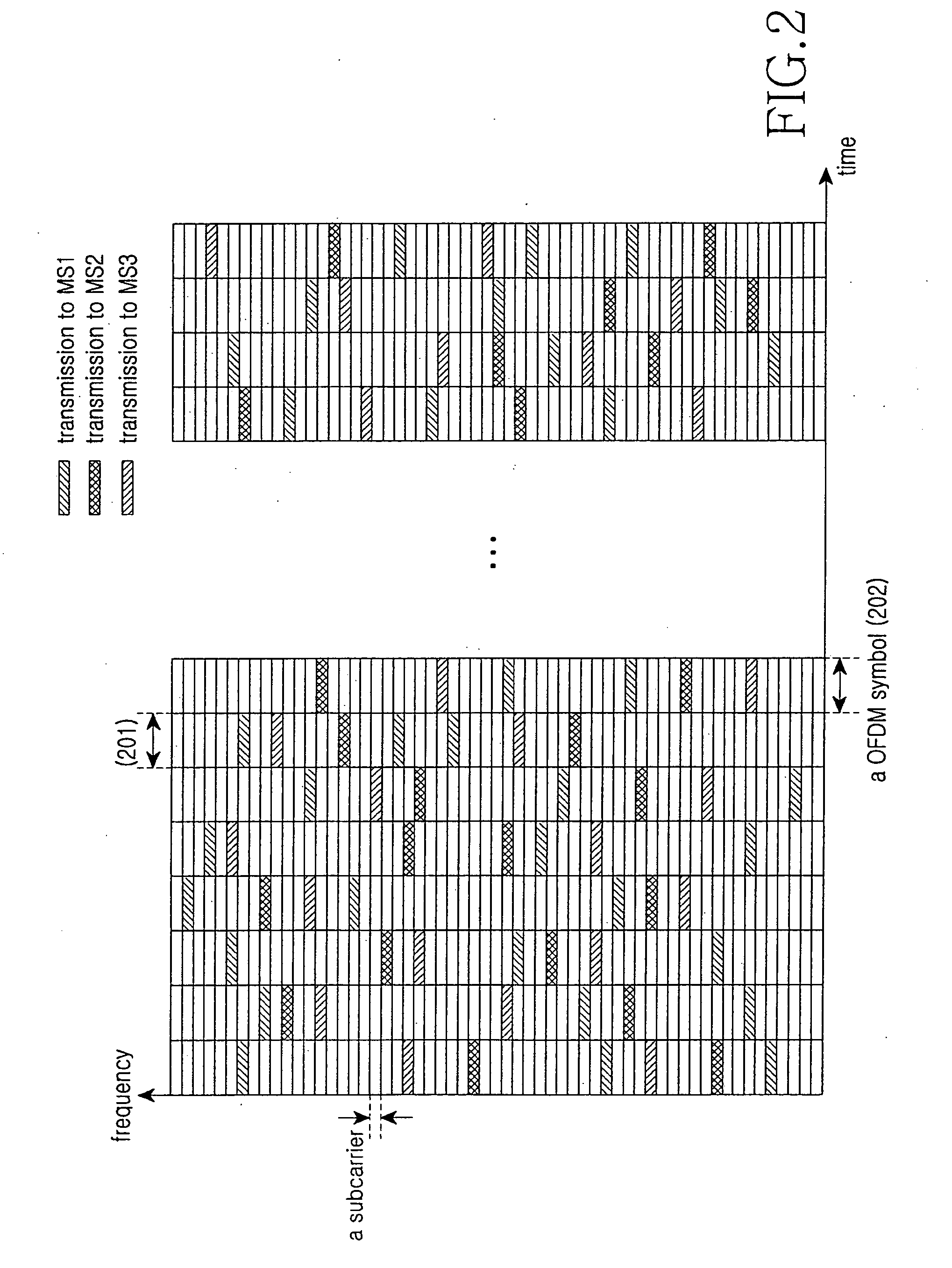

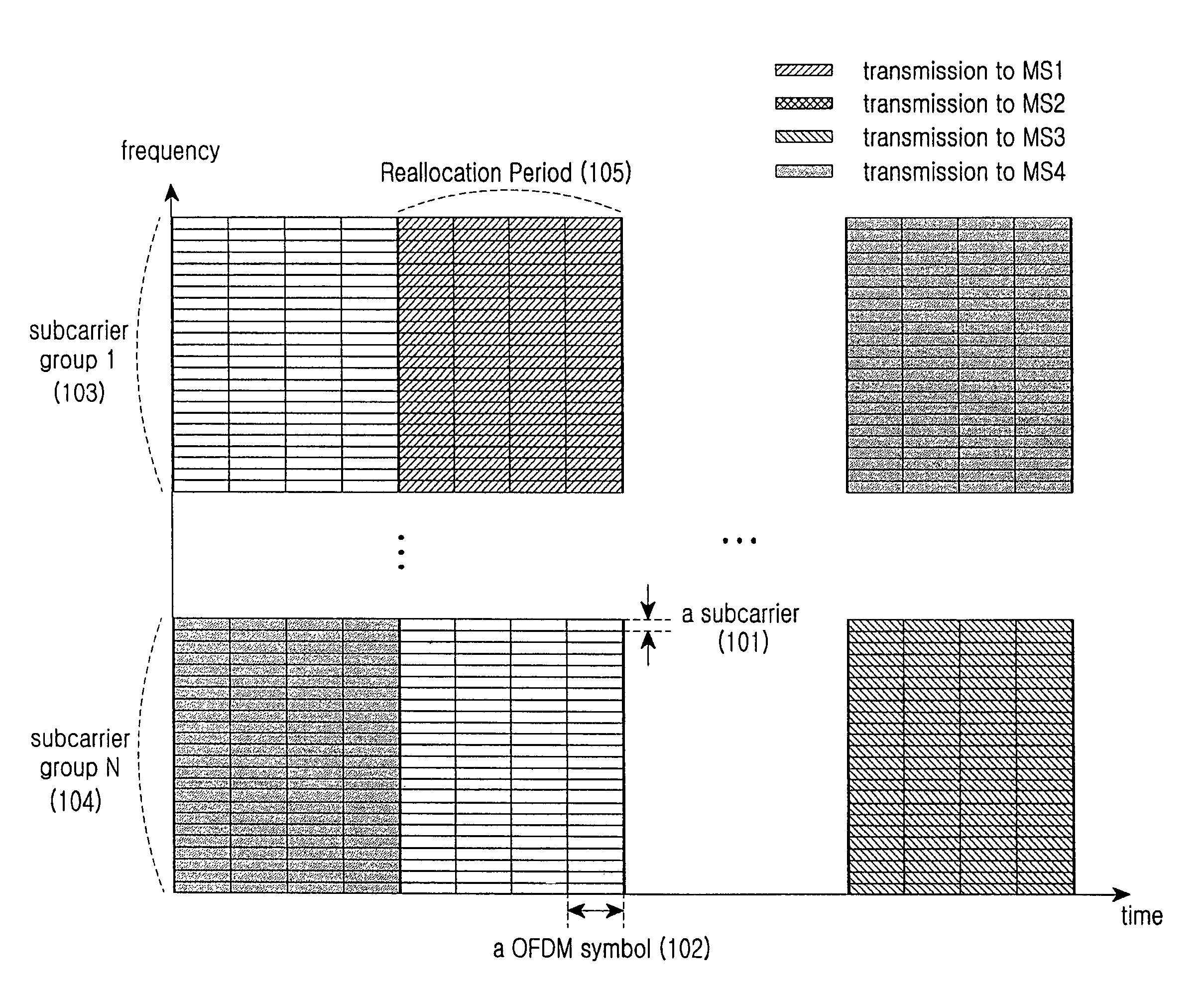

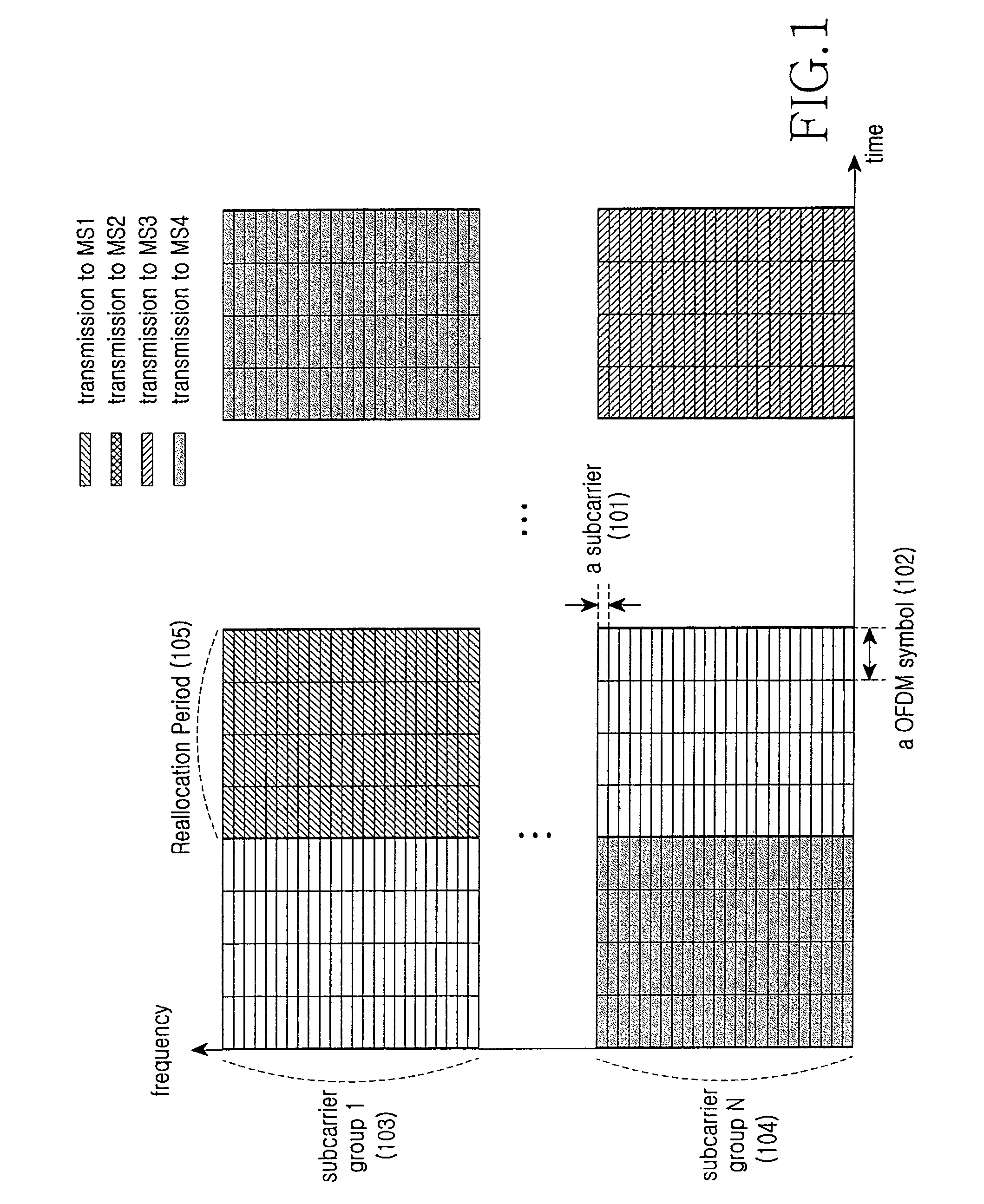

Method for configuring and managing channels in a wireless communication system using AMC channels and diversity channels, transmission/reception apparatus thereof, and system thereof

InactiveUS20060268983A1Effective technologyError preventionModulated-carrier systemsCommunications systemDiversity scheme

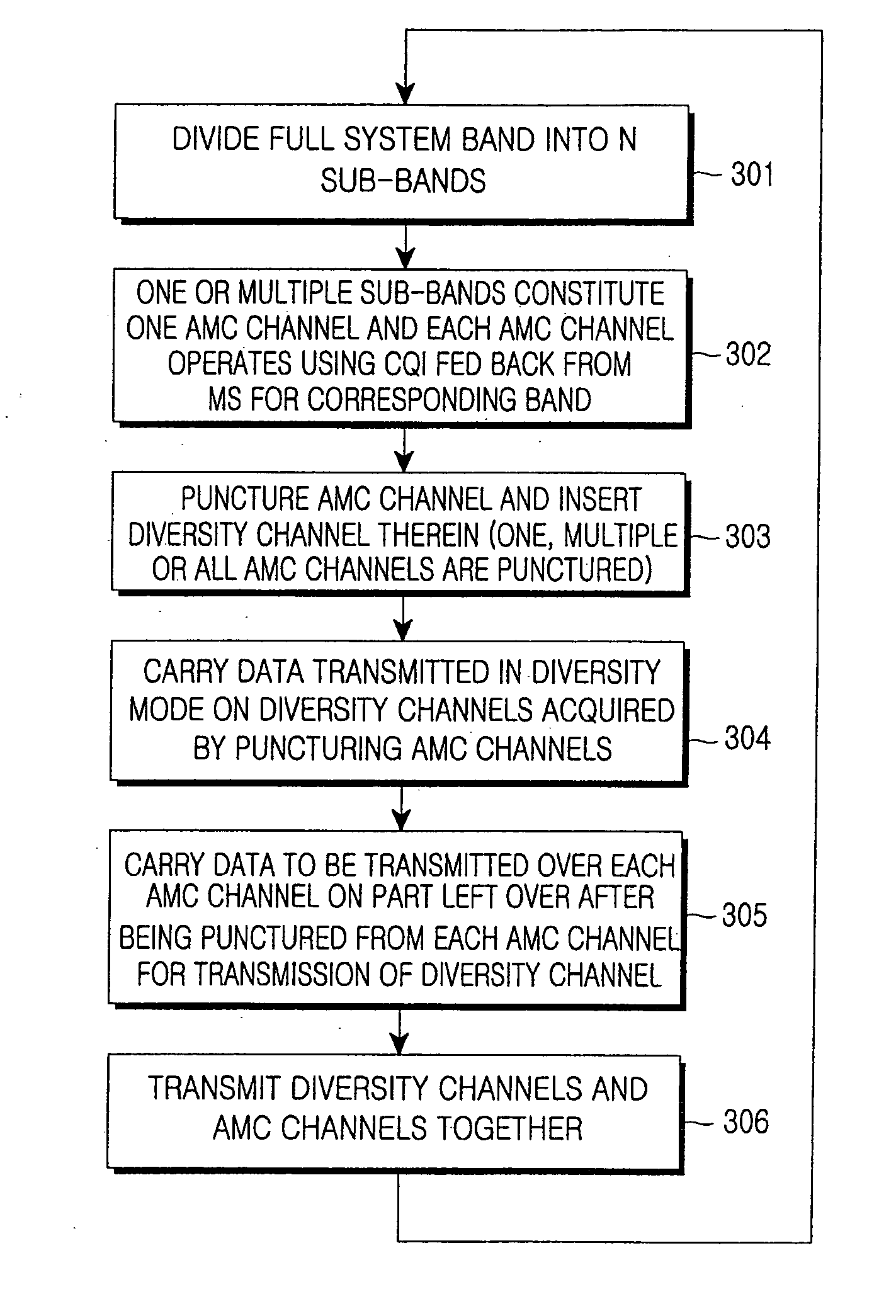

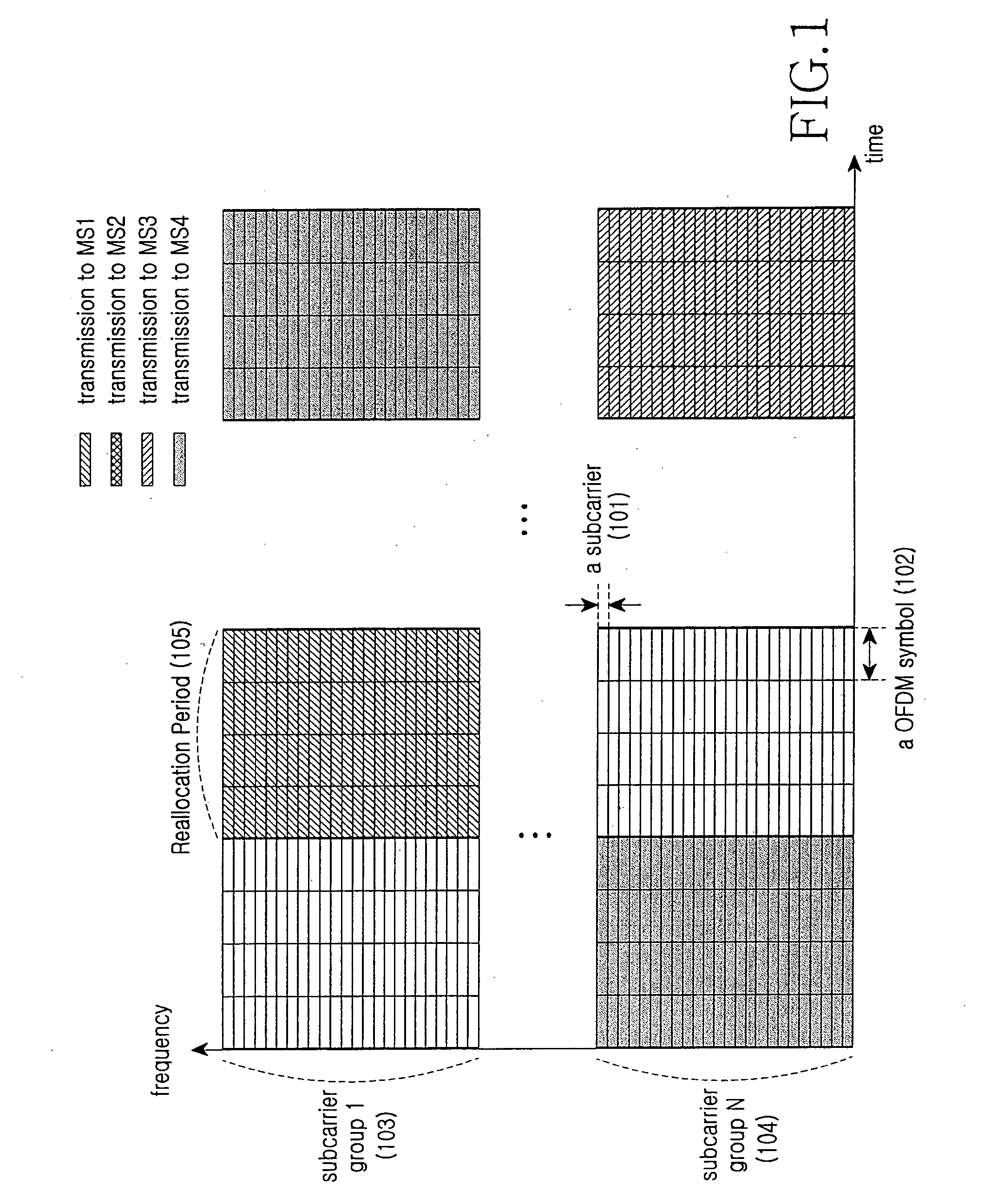

Provided is a method for configuring and managing a channel in a wireless communication system that divides a full frequency band into a plurality of sub-bands. The method comprises selecting at least one sub-band from the plurality of sub-bands and allocating each of a plurality of Adaptive Modulation and Coding (AMC) channels using the selected at least one sub-band; puncturing sub-carriers of at least one of the plurality of AMC channels according to a predetermined pattern; and allocating a diversity channel using the punctured sub-carriers.

Owner:QUALCOMM INC

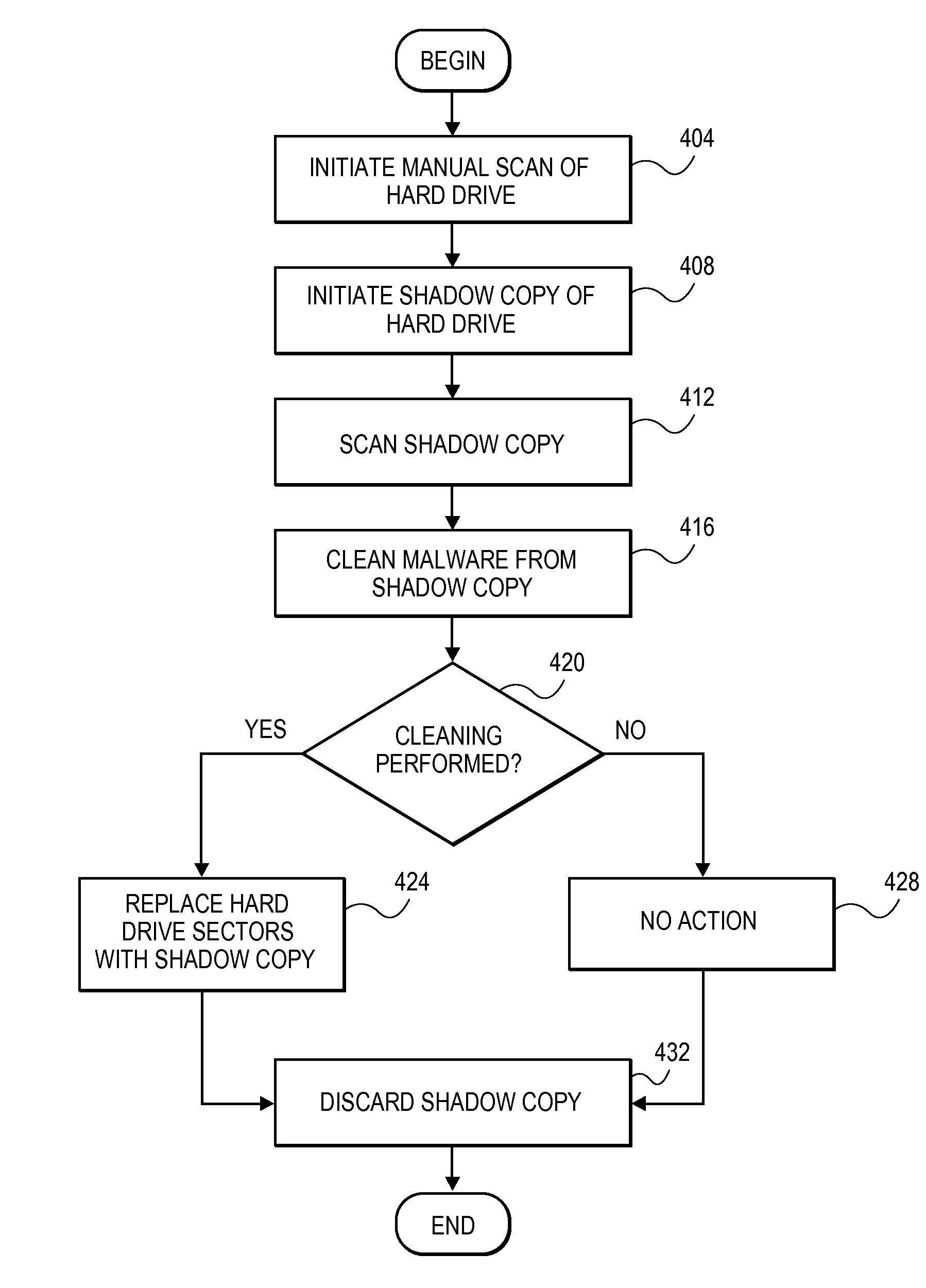

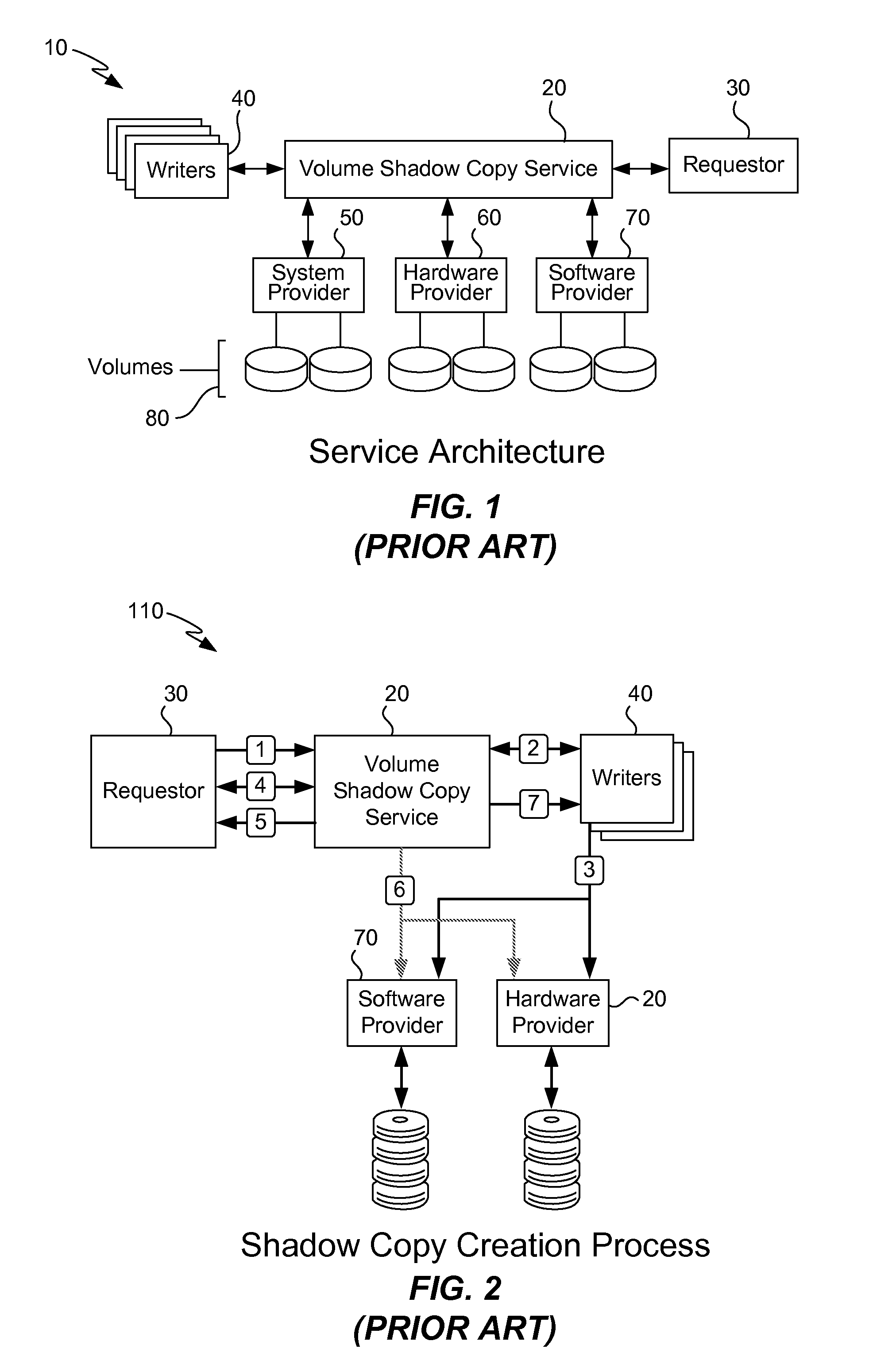

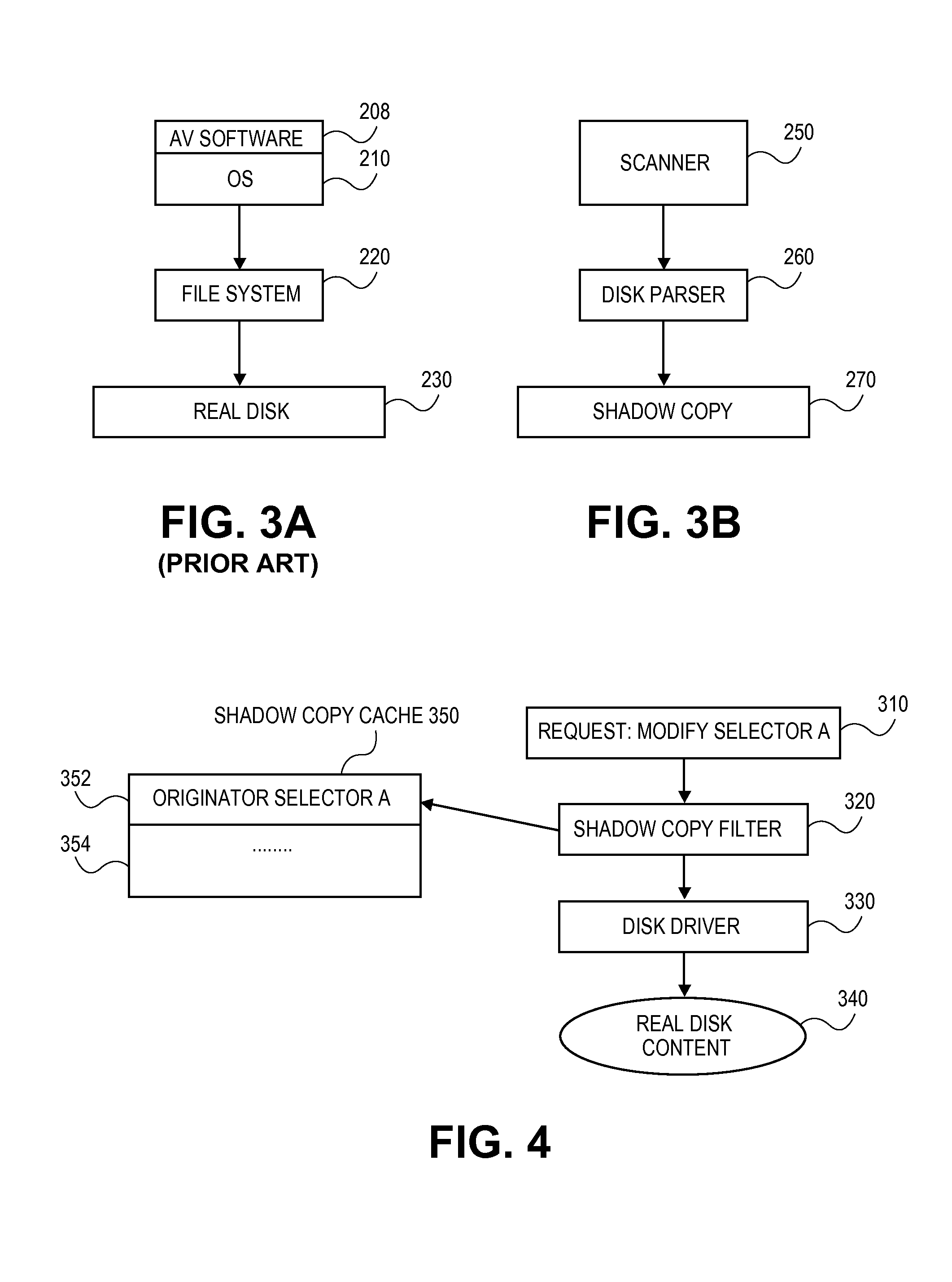

Shadow copy-based malware scanning

ActiveUS8220053B1Easy to handleReduce stepsMemory loss protectionError detection/correctionOperational systemFile system

Scanning of the shadow copy instead of the hard disk of a computer (using an accessing interface instead of the file system interface or an API of the operating system) enables the scanning software to access any files that might have been locked by the malware on the hard disk and avoids root kits. Files cannot be locked because a disk parser is used instead of the operating system or normal file system interface. It is possible for malware to change or reinfect files during the scanning and cleaning process. Files on the hard disk in existence at the time a manual scan is begun are scanned and backed up to the cache if changed during scanning. Dropped malware is removed by reverting the hard disk to the shadow copy once scanning and cleaning has been performed. Even if a watchdog drops a file during the scanning and cleaning process (because it detects that other malware components are being affected) these dropped files will be removed.

Owner:TREND MICRO INC

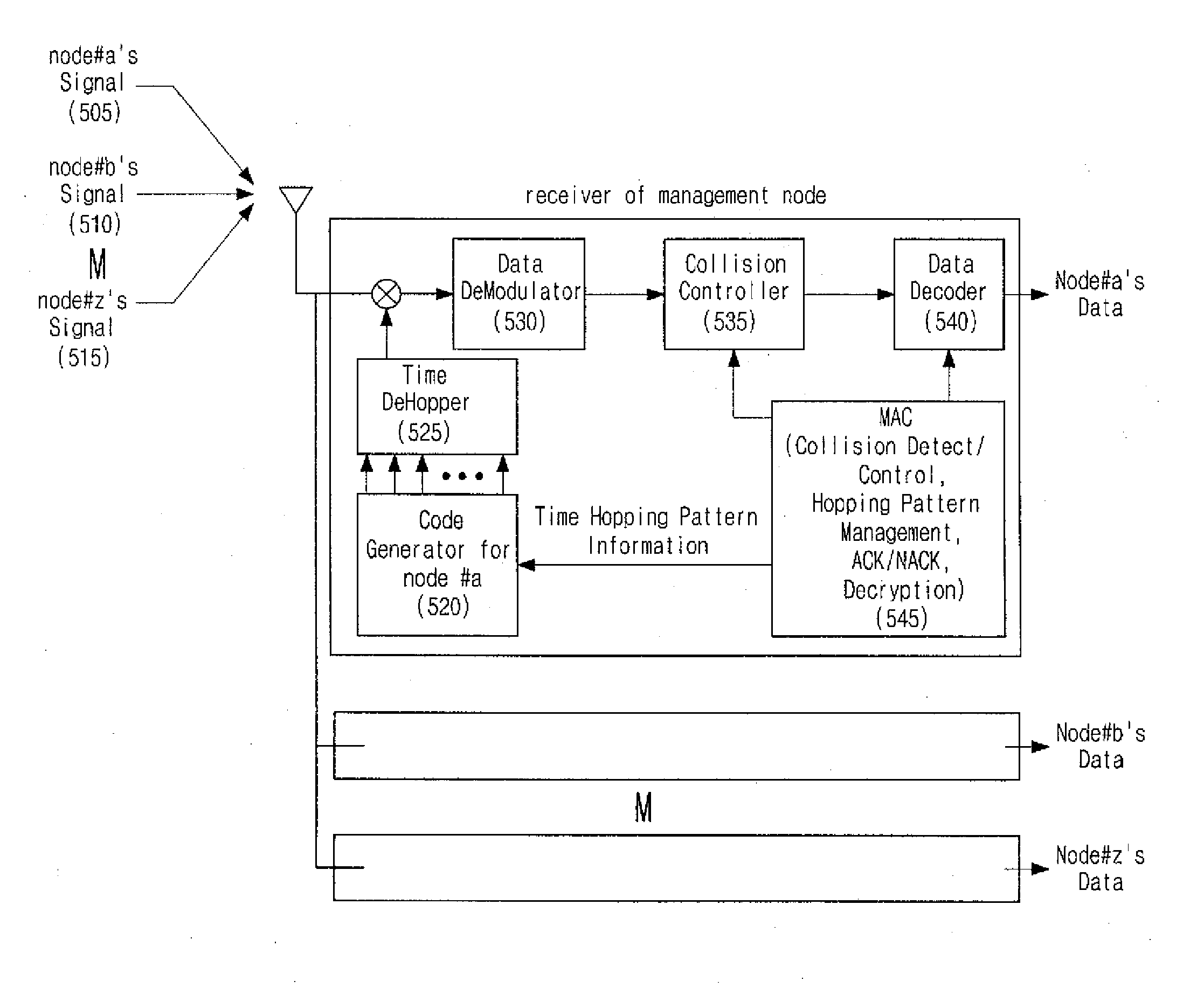

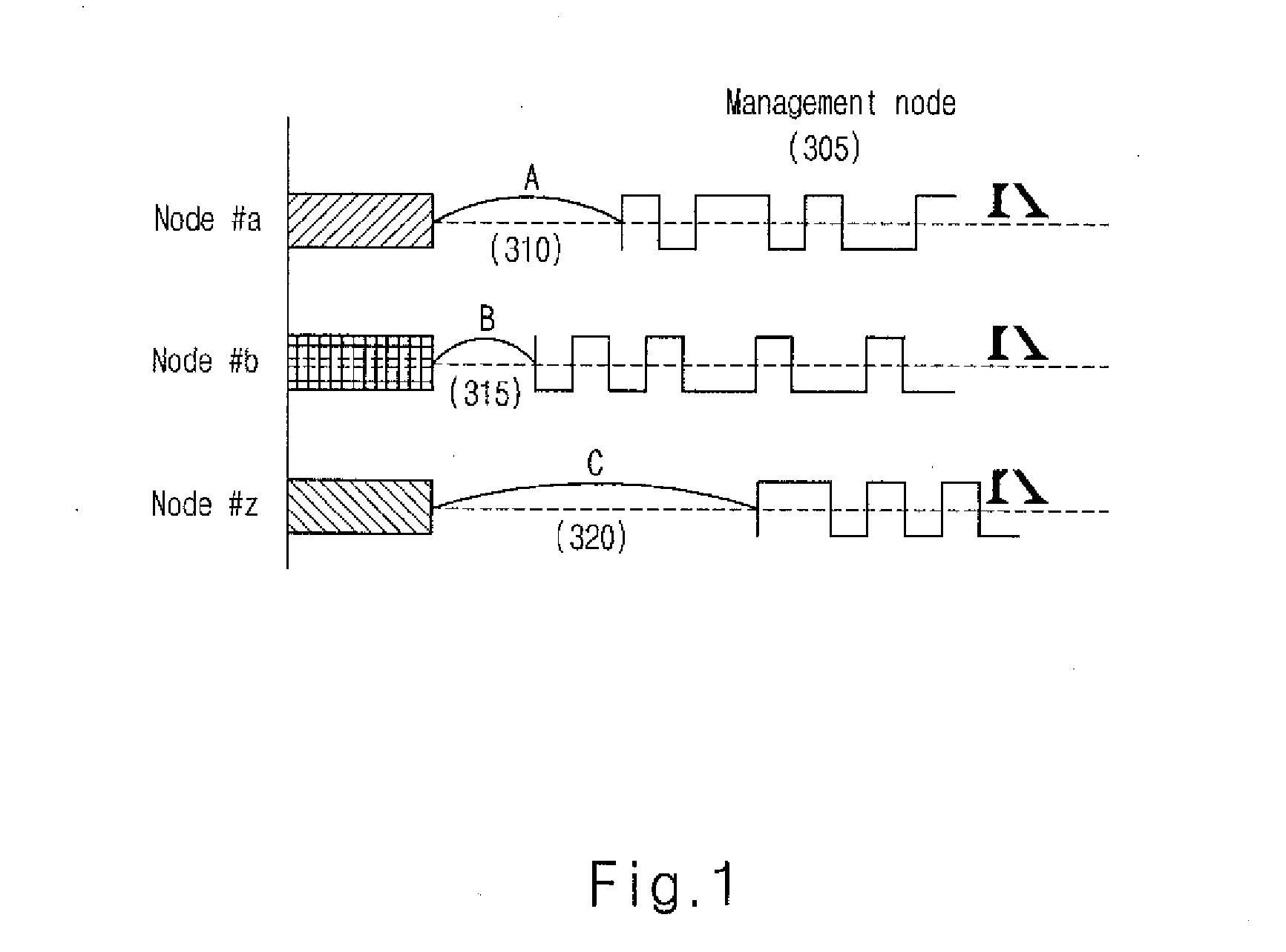

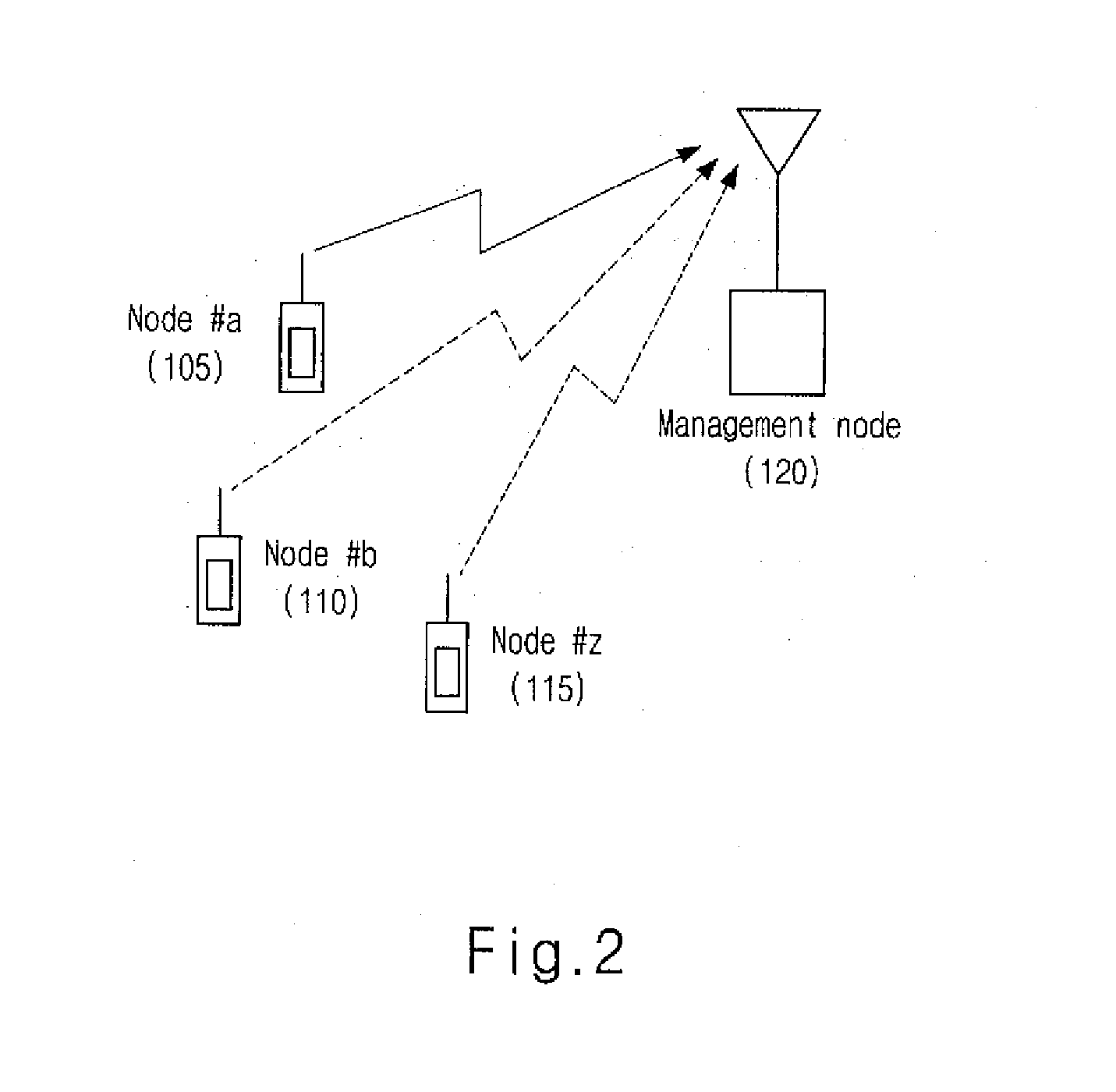

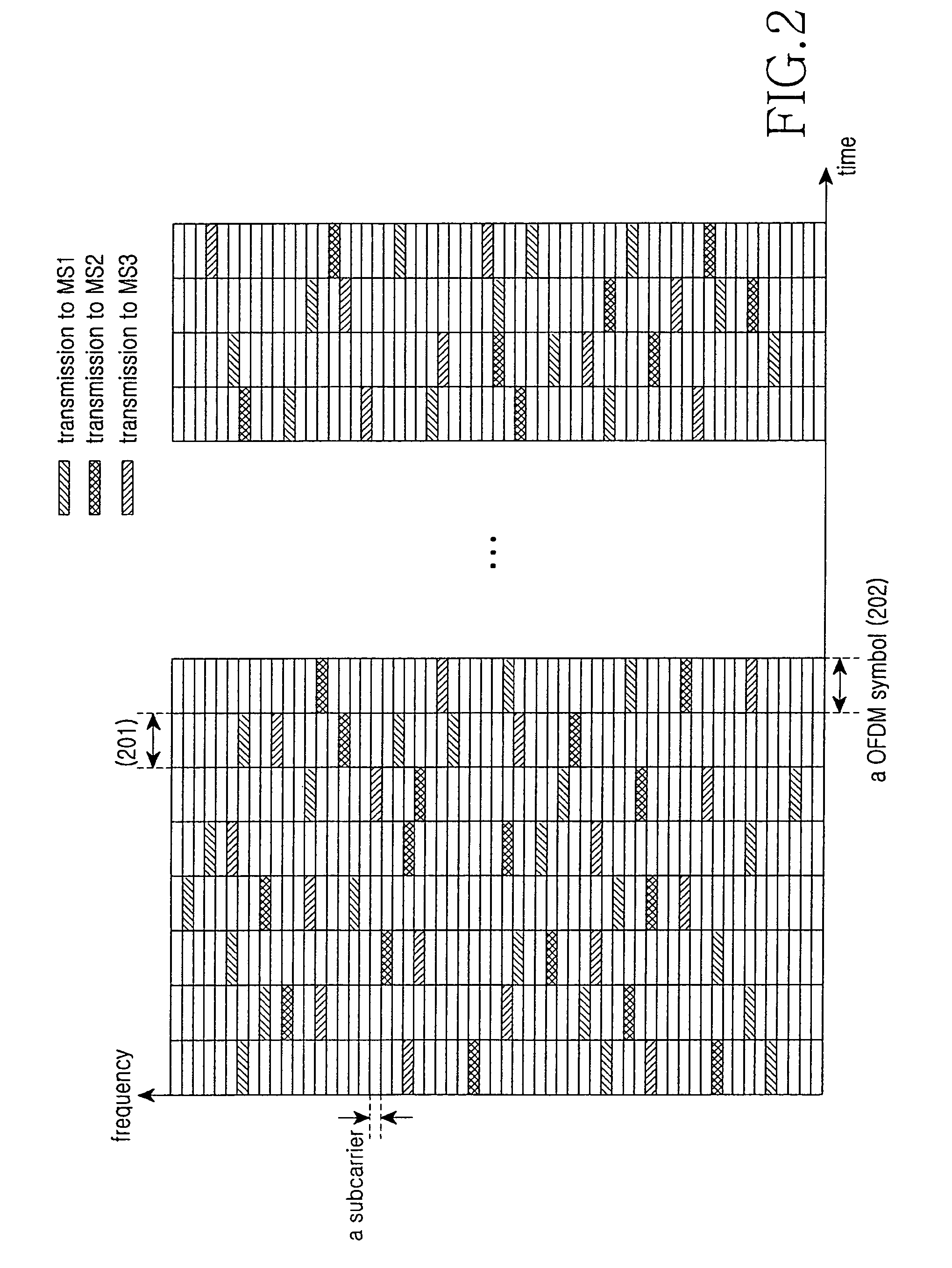

Multiple Access Digital Communicating Method In Ultra-Wideband Radio Access Networks

ActiveUS20080165746A1Effective technologyReduce power consumptionPower managementSynchronisation arrangementUltra-widebandCommunications system

A multiple access digital communication method in ultra-wideband (UWB) radio access network is provided. More specifically, a multiple access technique in UWB communication channels is provided where UWB communication channels can be more efficiently used and collisions between multiple access user nodes can be more effectively avoided when the channels have a great multiple path fading. The digital communication method for use in an uplink in a UWB communication system includes the steps of: receiving data symbols from respective nodes, in which the data symbols are transmitted according to respective orthogonal time hopping patterns; checking whether there is a collision of the orthogonal time hopping patterns; and decoding the data symbols depending on whether data symbols of nodes involved in the collision of the orthogonal time hopping patterns are the same.

Owner:PANTECH CORP

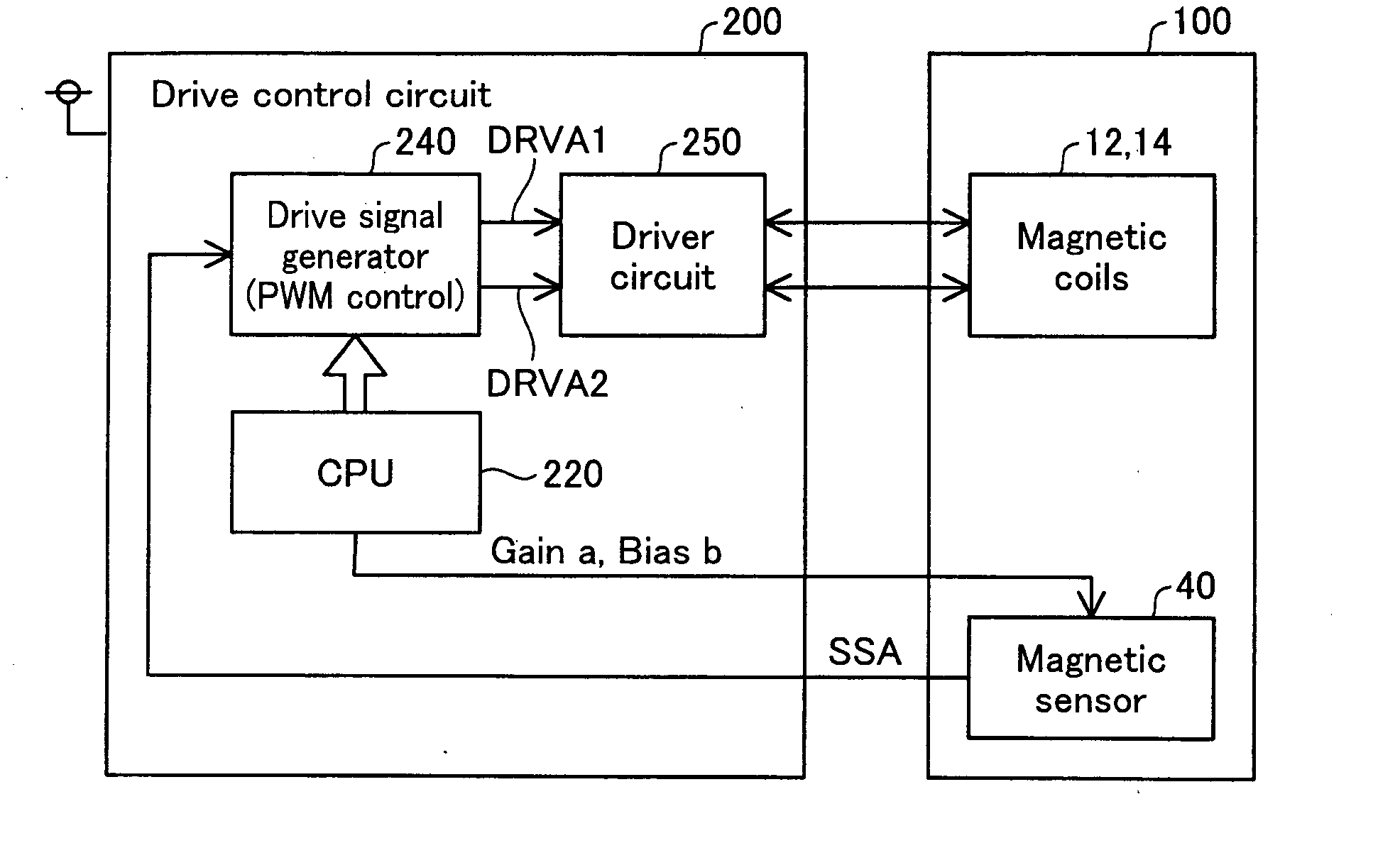

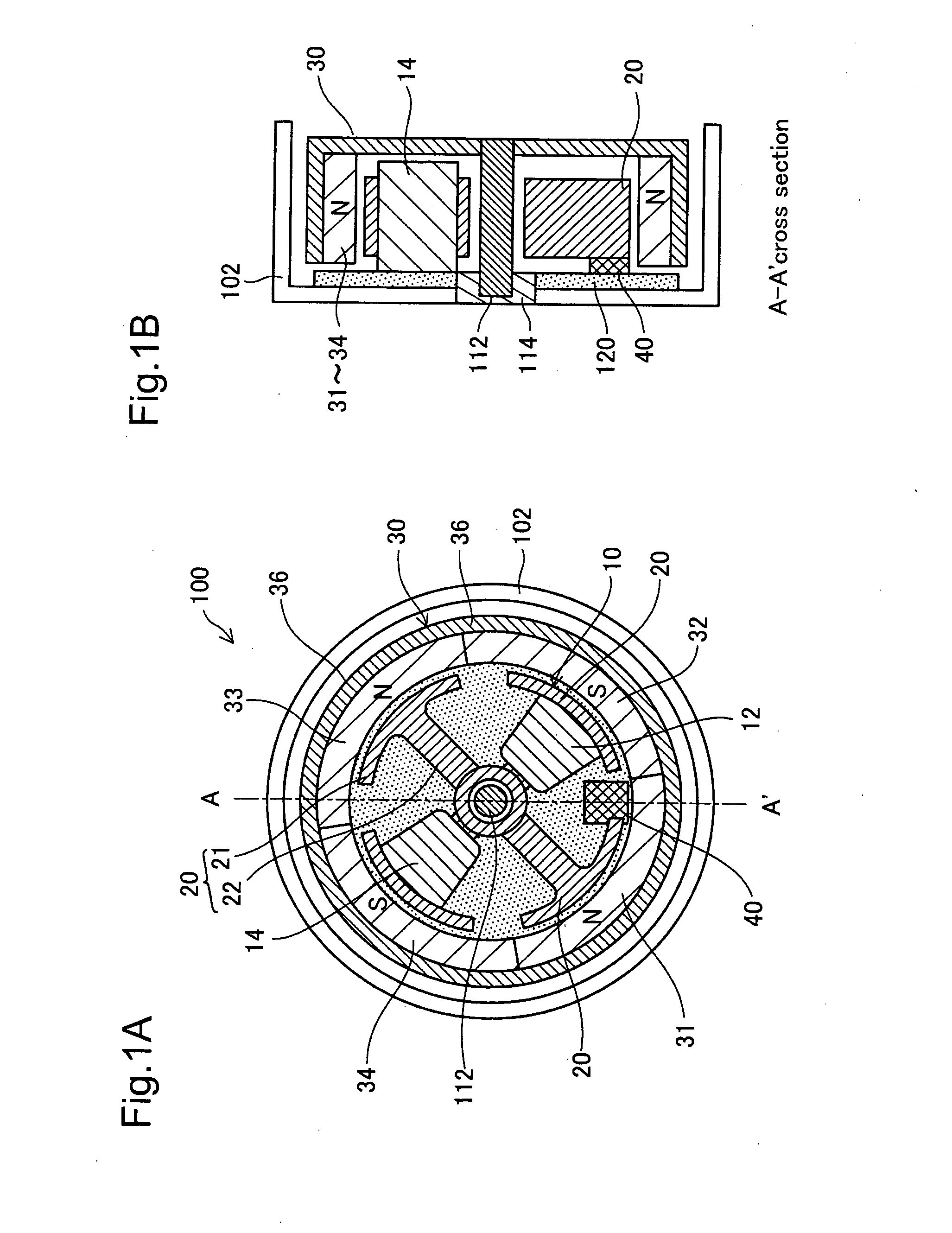

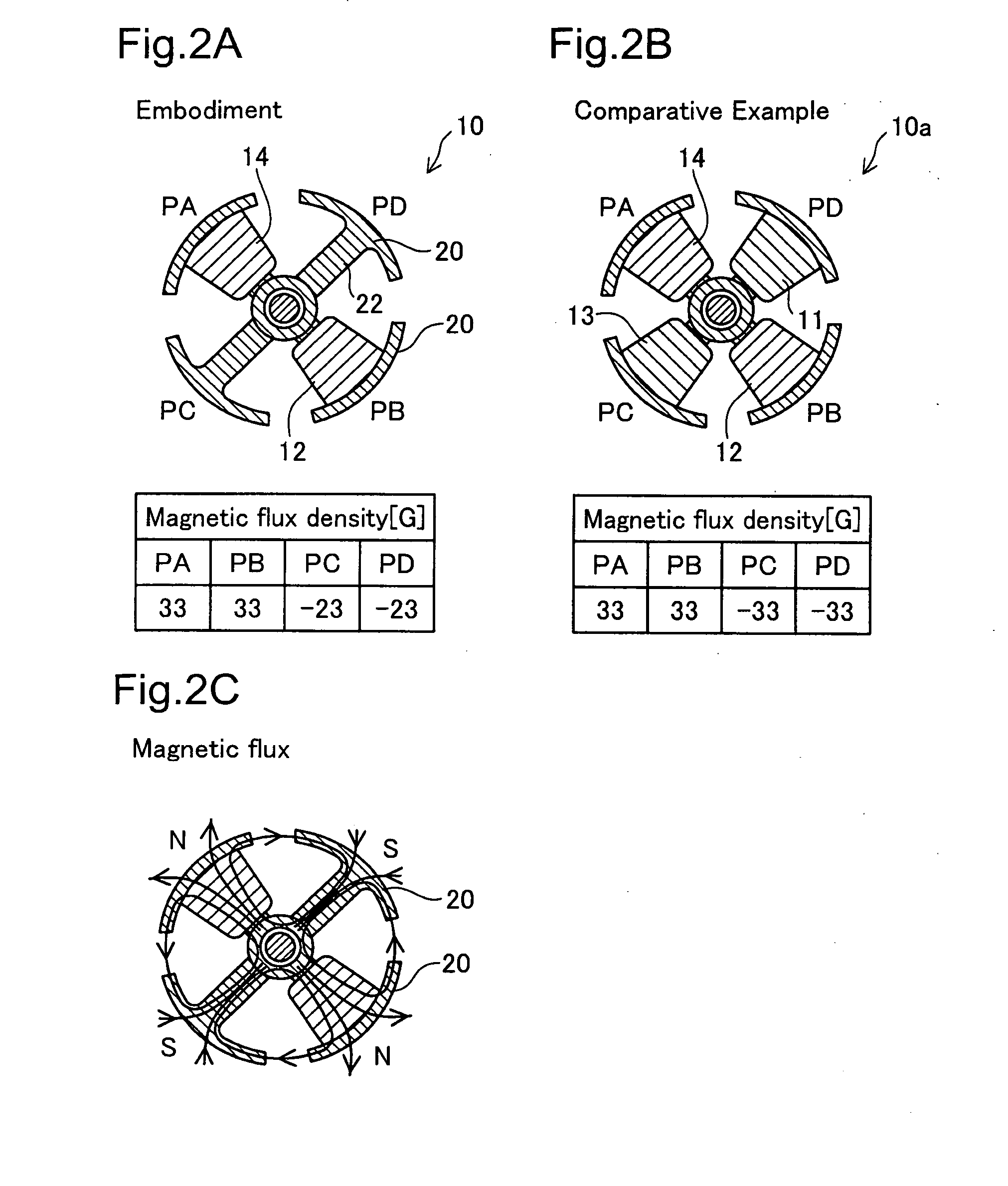

Brushless motor

InactiveUS20080246424A1Average power consumptionIncreased power consumptionAC motor controlSynchronous motors startersBrushless motorsEngineering

The brushless motor has a first and second drive member. The first drive member is equipped with M phase coil groups each having N electromagnetic coils where M is an integer of 1 or greater and N is an integer of 1 or greater. The second drive member has a plurality of permanent magnets, and is able to move relative to the first drive member. The first drive member has 2 (M×N) magnetic body cores. Each phase electromagnetic coil is coiled on a periodically selected magnetic body core at a ratio of 1 to 2M from among the arrangement of 2 (M×N) magnetic body cores.

Owner:GK BRIDGE 1

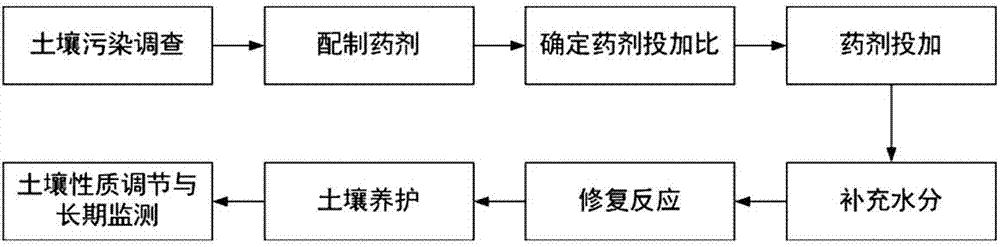

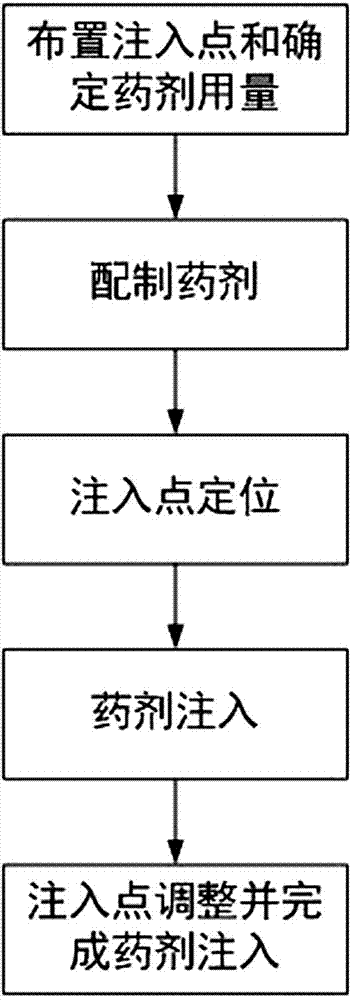

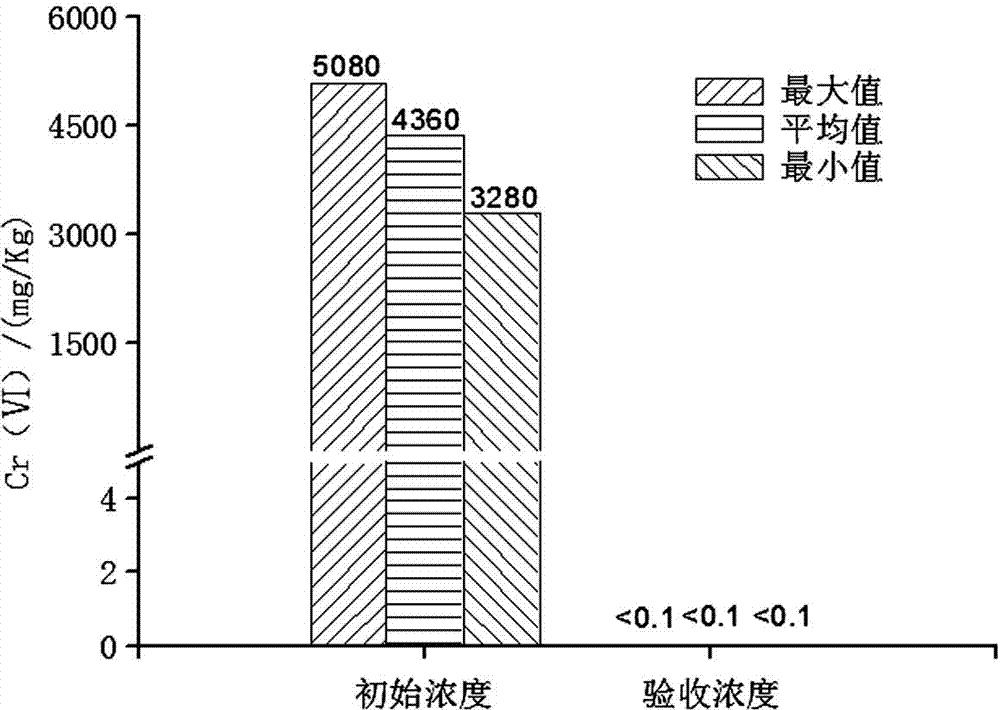

Application and remediation method of calcium polysulfide in chromium-contaminated soil or underground water remediation

ActiveCN104759458AGood repair effectThe repair effect is stableContaminated soil reclamationContaminated soilsEnvironmental chemistry

The invention discloses application and a remediation method of calcium polysulfide in chromium-contaminated soil or underground water remediation. Calcium polysulfide is adopted for chromium contamination remediation, and two remediation methods are particularly related. The method for remediating chromium-contaminated soil by calcium polysulfide comprises the following steps: investigating the chromium contamination degree of soil, preparing a calcium polysulfide water agent, determining the adding ratio of the calcium polysulfide water agent, adding the calcium polysulfide water agent, supplying water, carrying out remediation reaction, maintaining soil and adjusting the nature of the remediated soil. The method for remediating chromium-contaminated underground water by calcium polysulfide comprises the following steps: arranging injection points, determining the amount of a remediation agent, preparing the remediation agent, positioning the injection points, injecting the calcium polysulfide remediation agent, adjusting the positions and amounts of the injection points and the like. According to the invention, the operation process is simple; the agents are stable in source; the reaction speed is high; the remediation effect is good; the chromium-contaminated soil or underground water can be stable for a long time after remediation; the remediation method can be applied to large-scale implementation, is economic and reasonable, and is a relatively ideal chromium-contaminated soil or underground water remediation technique.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

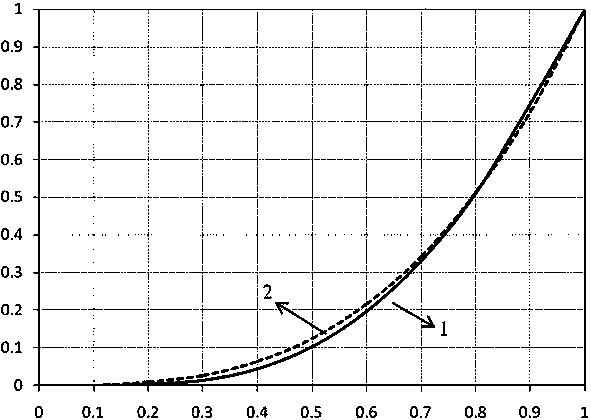

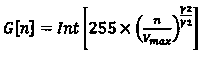

Method for quickly establishing gamma correction lookup table of OLED displayer

ActiveCN104050922AQuick calculationSimple technologyStatic indicating devicesGray levelDisplay device

The invention provides a method for quickly establishing a gamma correction lookup table of an OLED displayer, and belongs to the technical field of display characteristic optimization of OLED displayers. The method for quickly establishing the gamma correction lookup table of the OLED displayer is especially used for conducting Gamma correction according to the display characteristics of the OLED displayer and making the OLED display have a better display effect. The method for quickly establishing the gamma correction lookup table of the OLED displayer is characterized in that correction is achieved through processing of 9-digit output corresponding to 8-digit input. The gamma correction table can be quickly calculated only by measuring 0 gray level brightness offsets alpha of the OLED displayer, indexes gamma 1 of a displayer brightness characteristic curve and gamma coefficients gamma 2 reached by expected correction, and the technology is simple, effective and easy to achieve and popularize.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

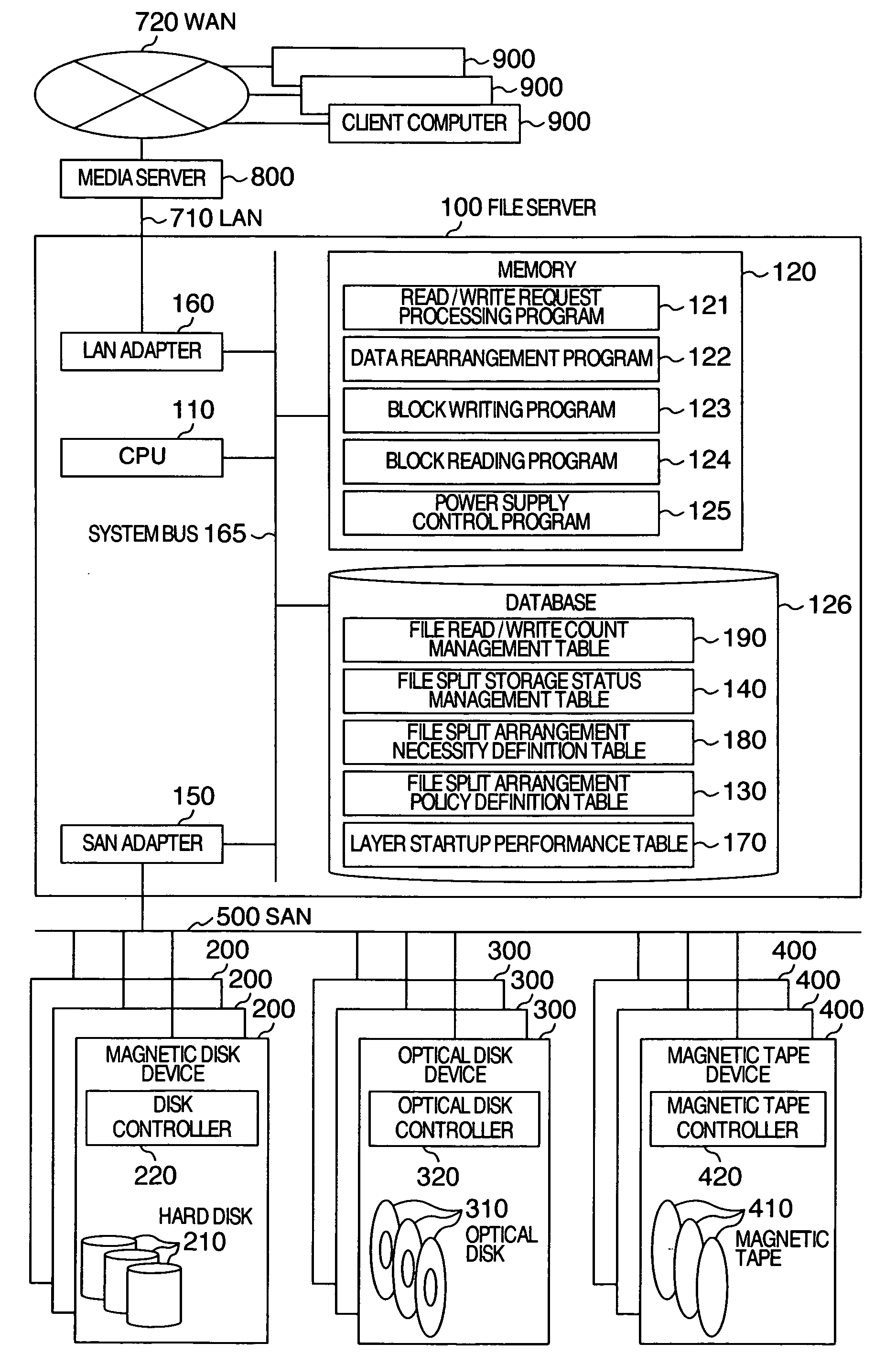

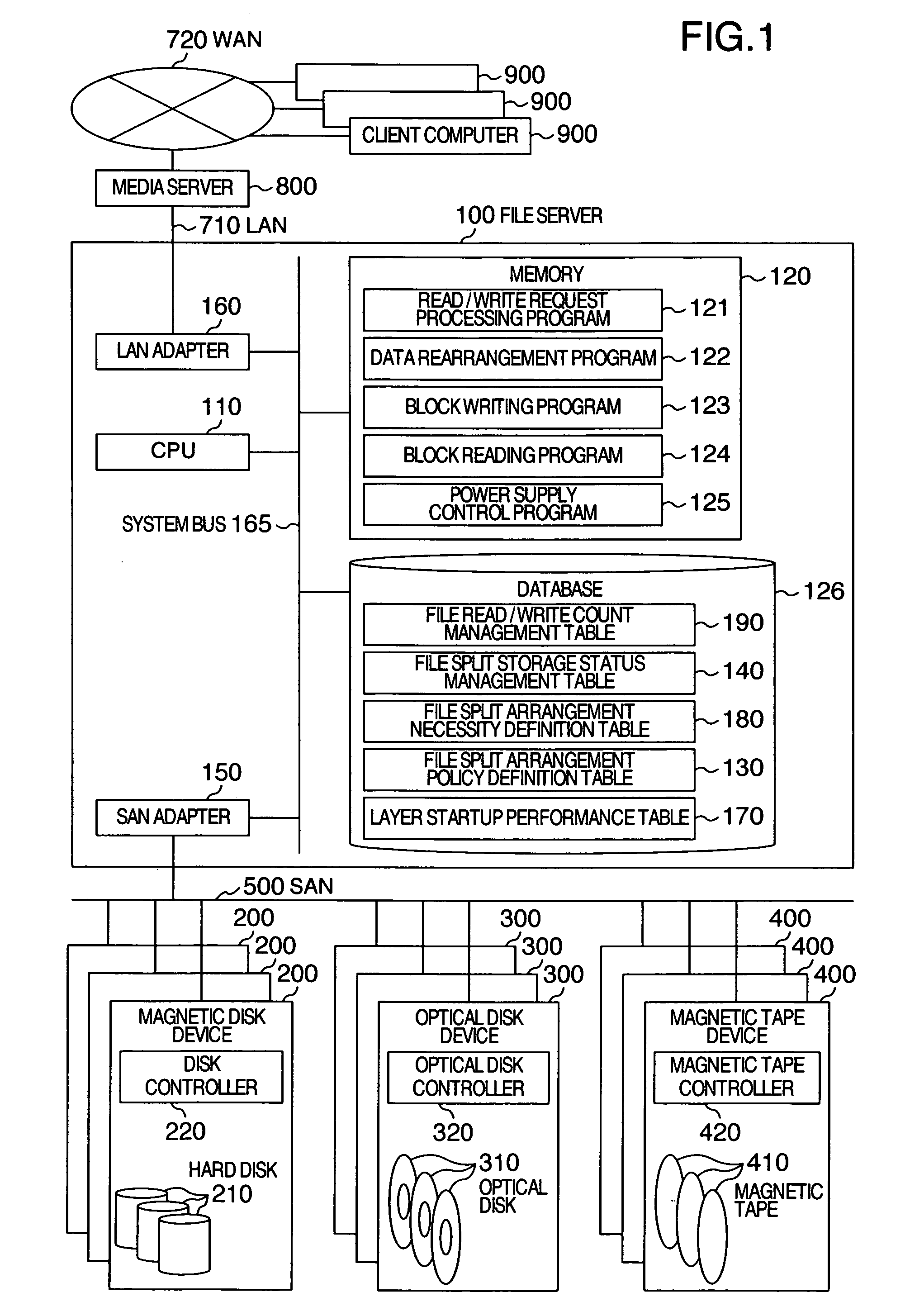

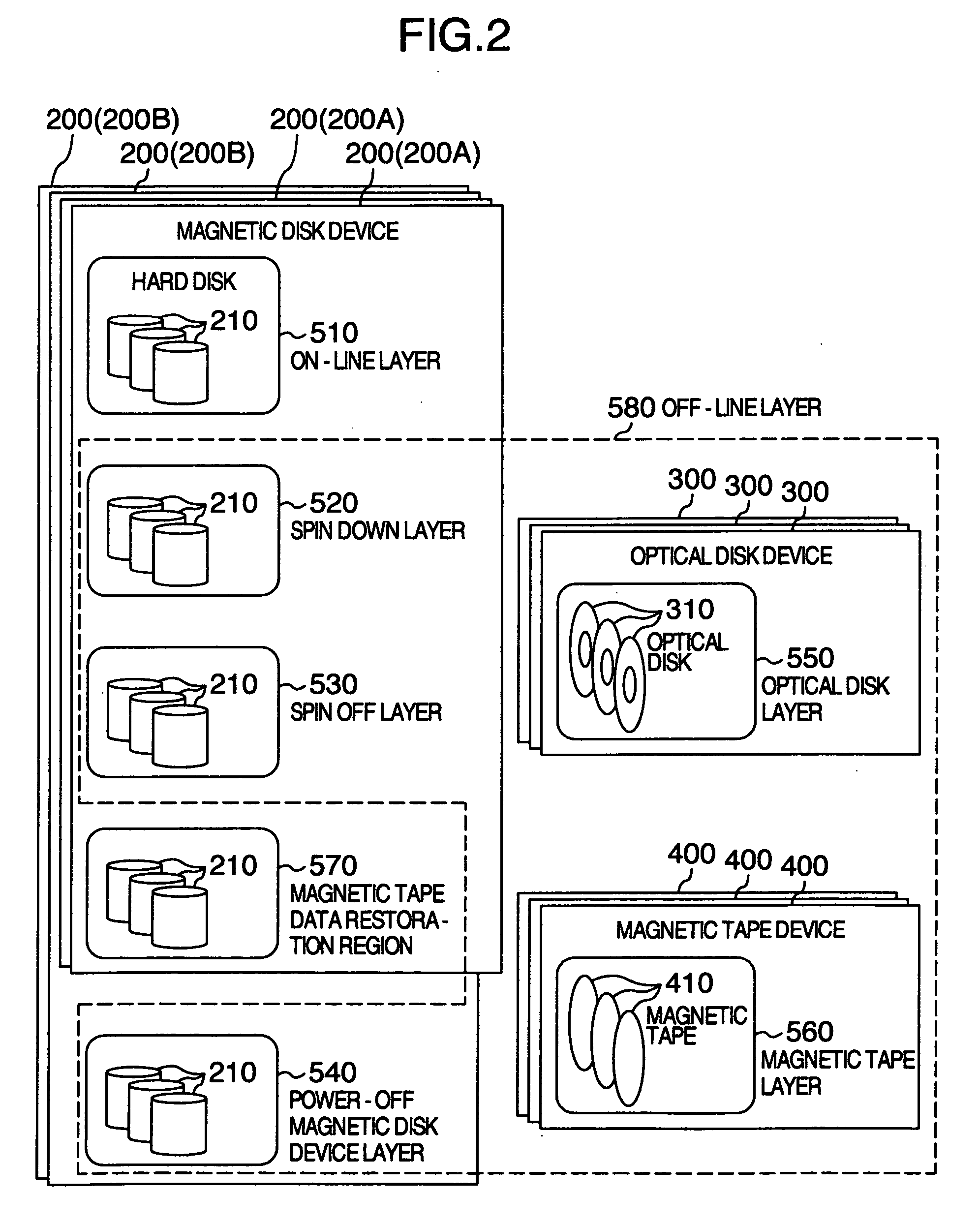

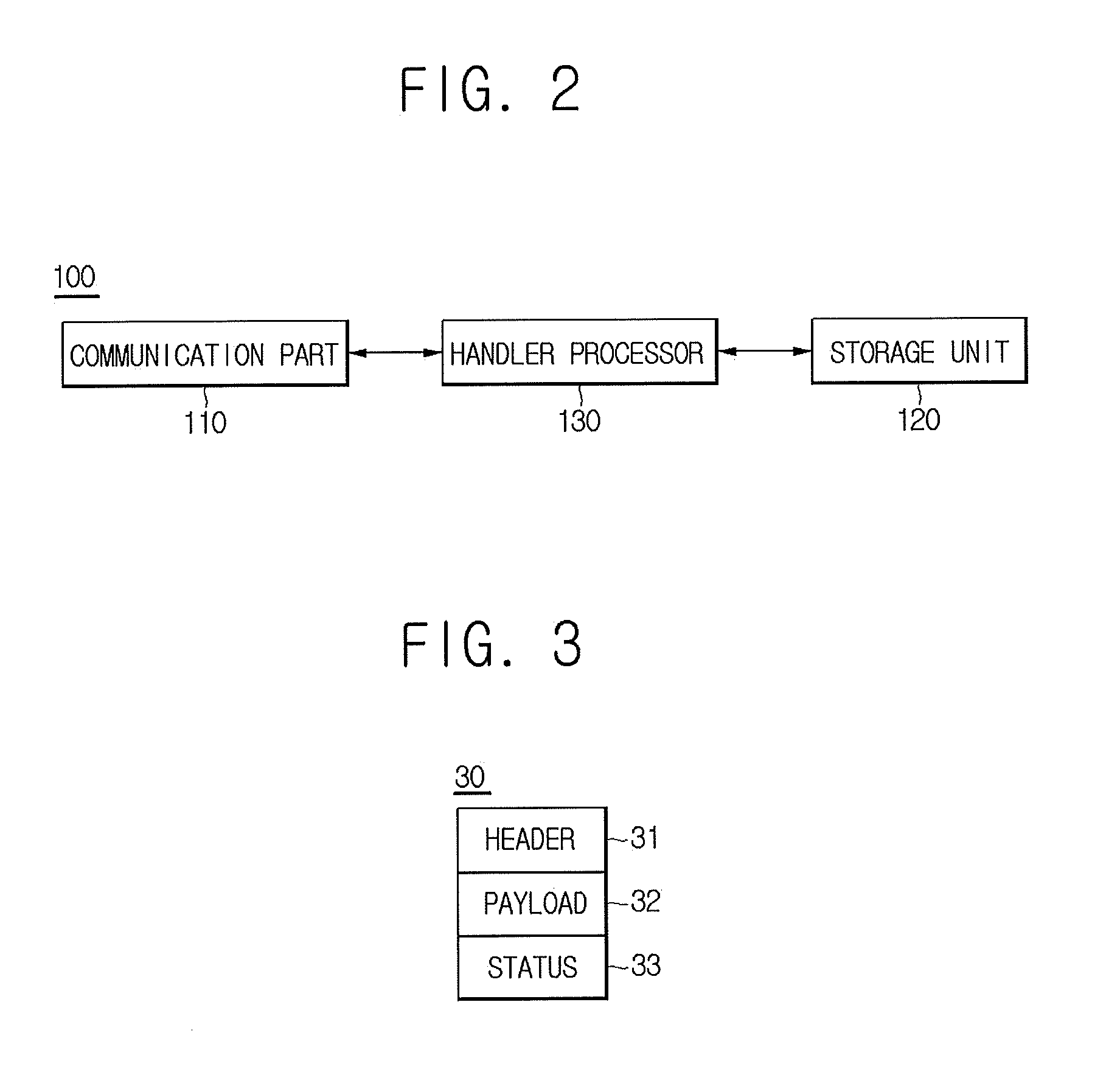

File server and file management method

InactiveUS20100199035A1Sufficient power-saving effectSufficient effectEnergy efficient ICTDigital data processing detailsProcessing elementFile server

A file server achieving sufficient power-saving effect is provided. The file server is capable of operating an on-line storage medium (in a state in which reading / writing can be started immediately in response to a file read / write request) and an off-line storage medium (which has to be started up upon receiving a read / write request). Upon reception of a stream file write request, the file server's processing unit acquires bit rate information from the stream file, calculates the file's splitting position from the bit rate information and startup time of the off-line storage medium, and stores a first part (up to the splitting position) in the on-line storage medium while storing the remaining second part in the off-line storage medium. Upon reception of a stream file read request, the processing unit reads out the first part while starting up the off-line storage medium and reading out the second part.

Owner:HITACHI LTD

Chinese walnut sowing and seedling-culture method

ActiveCN103703889ASimple technologyEffective technologySeed and root treatmentHorticultureSeed dormancySeedling

The invention discloses a Chinese walnut sowing and seedling-culture method. According to the method, Chinese walnut seeds are used as propagation materials; the dormancy of the seeds is relieved by measures of seed immersion, air-drying, storage in sand, germination acceleration and the like, so that the germination rate of the Chinese walnut seeds is increased. By virtue of the method, the problem of low germination rate of the Chinese walnut seeds is solved, and the propagation efficiency of Chinese walnuts is improved. According to the method disclosed by the invention, the corresponding seedling culture working procedures are simplified; furthermore, the cost is low, the seedling growth speed is high, and the survival rate is high; moreover, effects of high-quality seeds of the Chinese walnuts and rapid family prorogation are achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

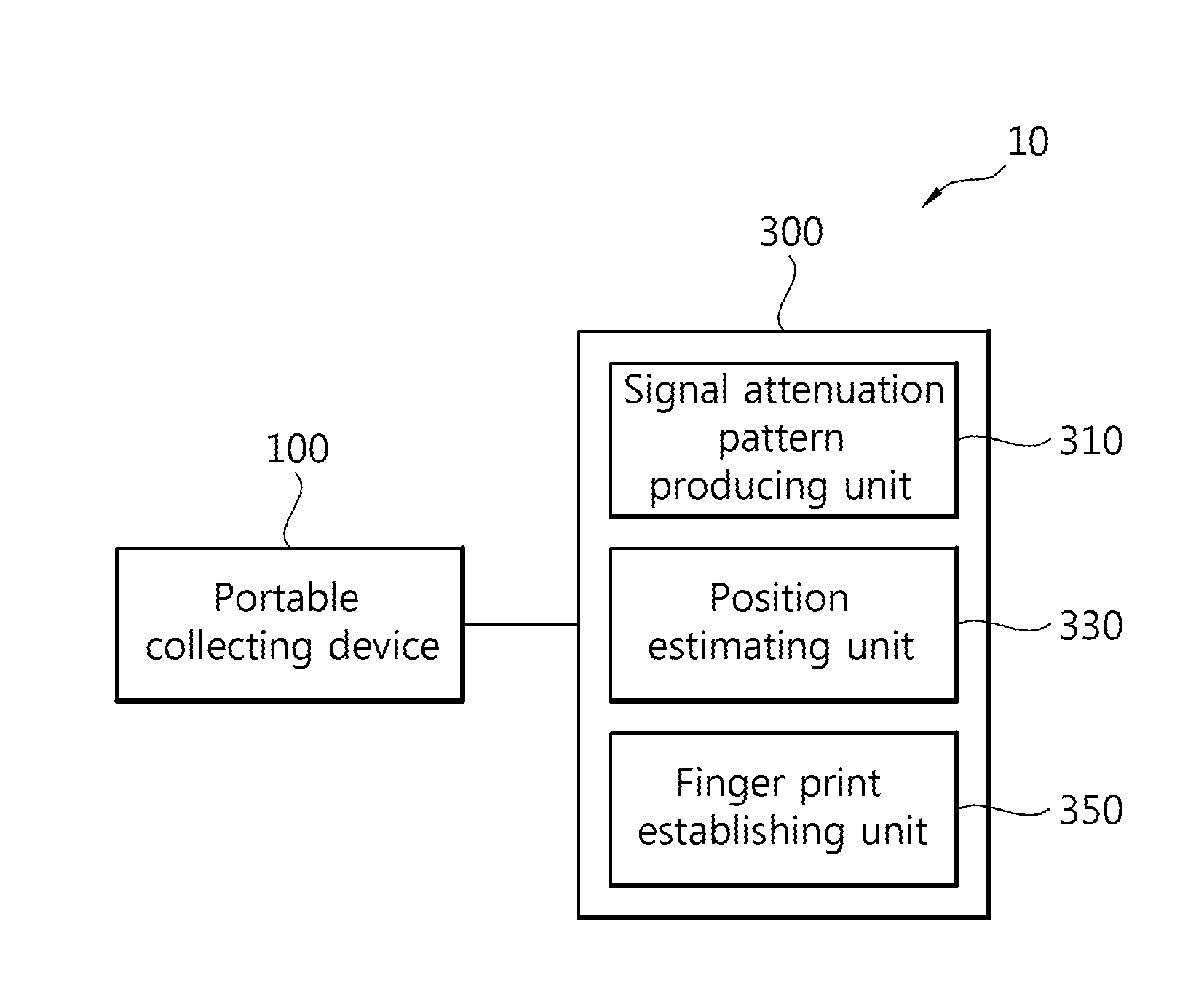

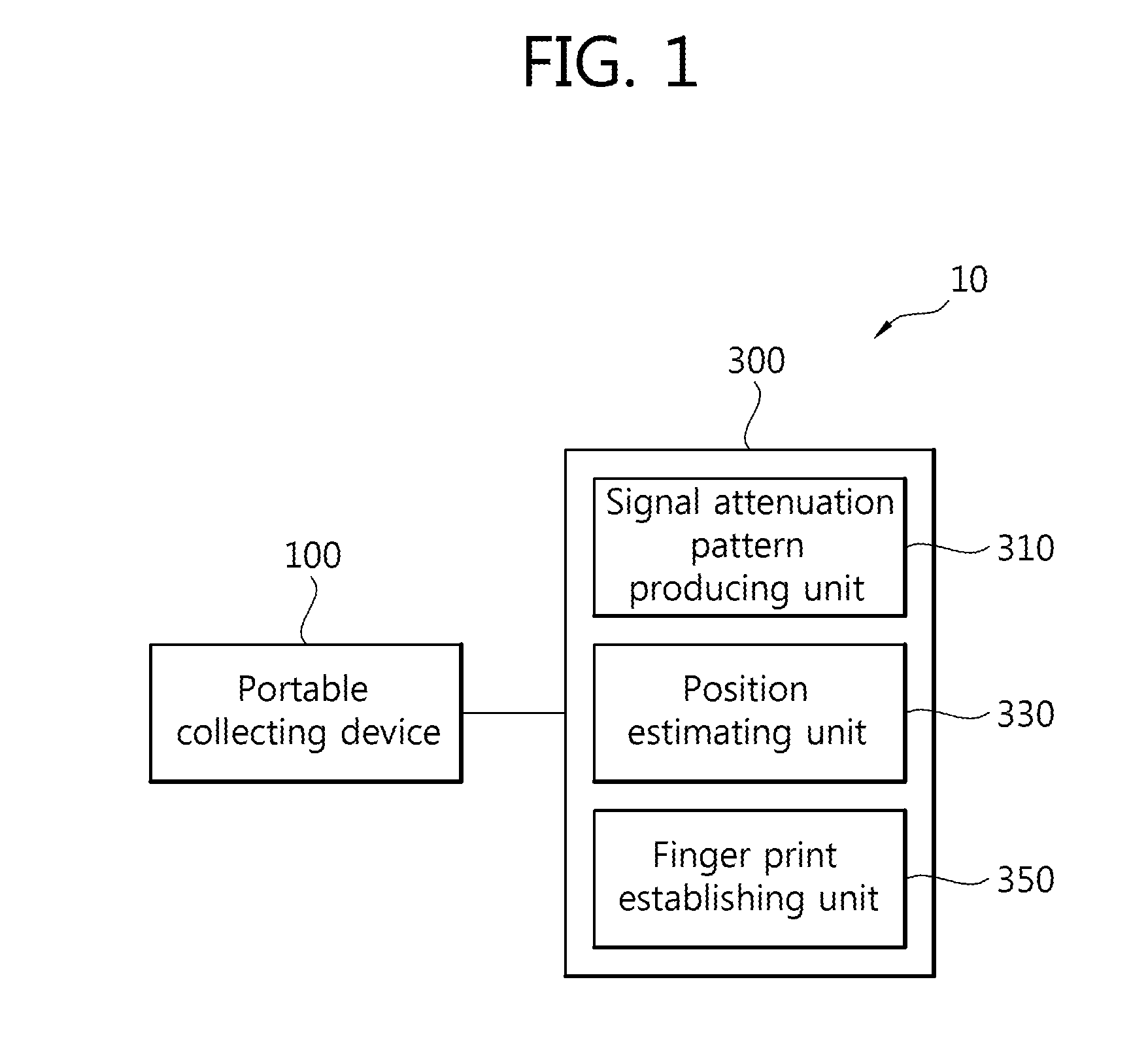

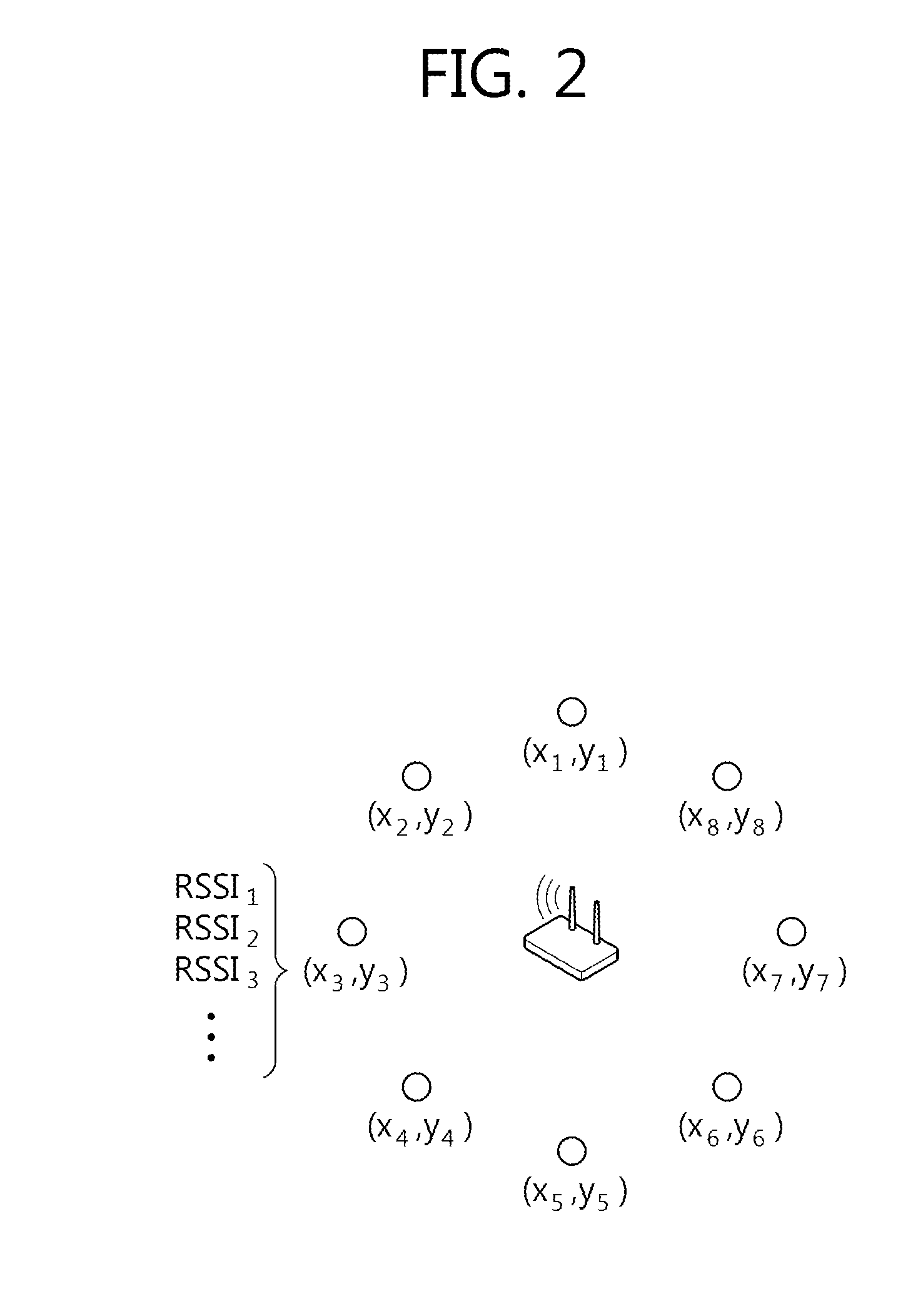

System for estimating position of base station and method of estimating position of base station by the same

InactiveUS20140228058A1Effective technologyImprove efficiencyPosition fixationUsing reradiationUltrasound attenuationTelecommunications

According to the present invention, a system of estimating a position of a base station comprises a portable collecting device that considers a collection distribution for a plurality of base stations, arbitrarily sets positions of the plurality of base stations, and collects signal strengths transmitted from the plurality of arbitrarily set base stations and a server device that measures the signal strengths received from the portable collecting device, produces a signal attenuation pattern according to a distance between an arbitrarily set base station and the portable collecting device, and estimates a position of the base station according to an error between a signal strength estimated value at a specific point as estimated according to the signal attenuation pattern and an actually measured signal strength measured value at the specific point.

Owner:ELECTRONICS & TELECOMM RES INST

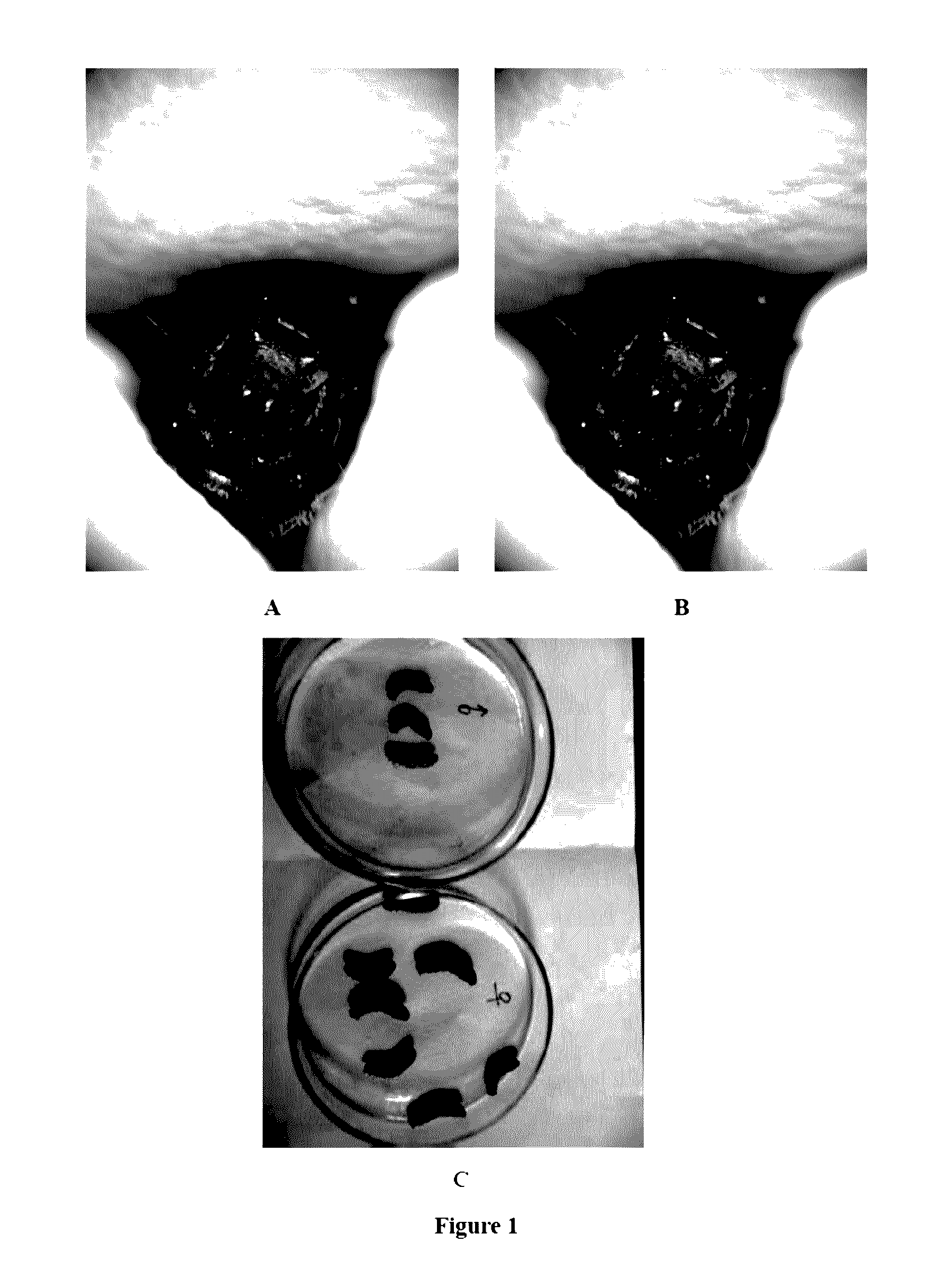

Artificial feeding method at low altitude for host insect ghost moth of ophiocordyceps sinensis

An artificial feeding method at low altitude for a host insect ghost moth of Ophiocordyceps sinensis. This method mainly includes: selecting an appropriate disinfectant for performing surface disinfection on ghost moth eggs, and then placing the disinfected eggs in sterile humus; feeding ghost moth larvae with carrots, disinfecting and detecting the fed carrots, and culturing the larvae till male and female pupae are obtained; identifying male and female pupae of the ghost moths, placing them at different culture temperatures, wherein the culture temperature for the male pupae is 2-6° C. lower than that of the female pupae, resulting synchronously emerged male and female adults; placing the emerged male and female adults in an adult cage with simulated plants for mating and staying of the adults, maintaining a humidity over 80%, and employing 50-100 Lux shimmer for facilitating activity and mating of the adults, thus improving fertilization opportunity and hatchability of eggs when the adults after mating lay eggs.

Owner:GUANGDONG ENTOMOLOGICAL INST

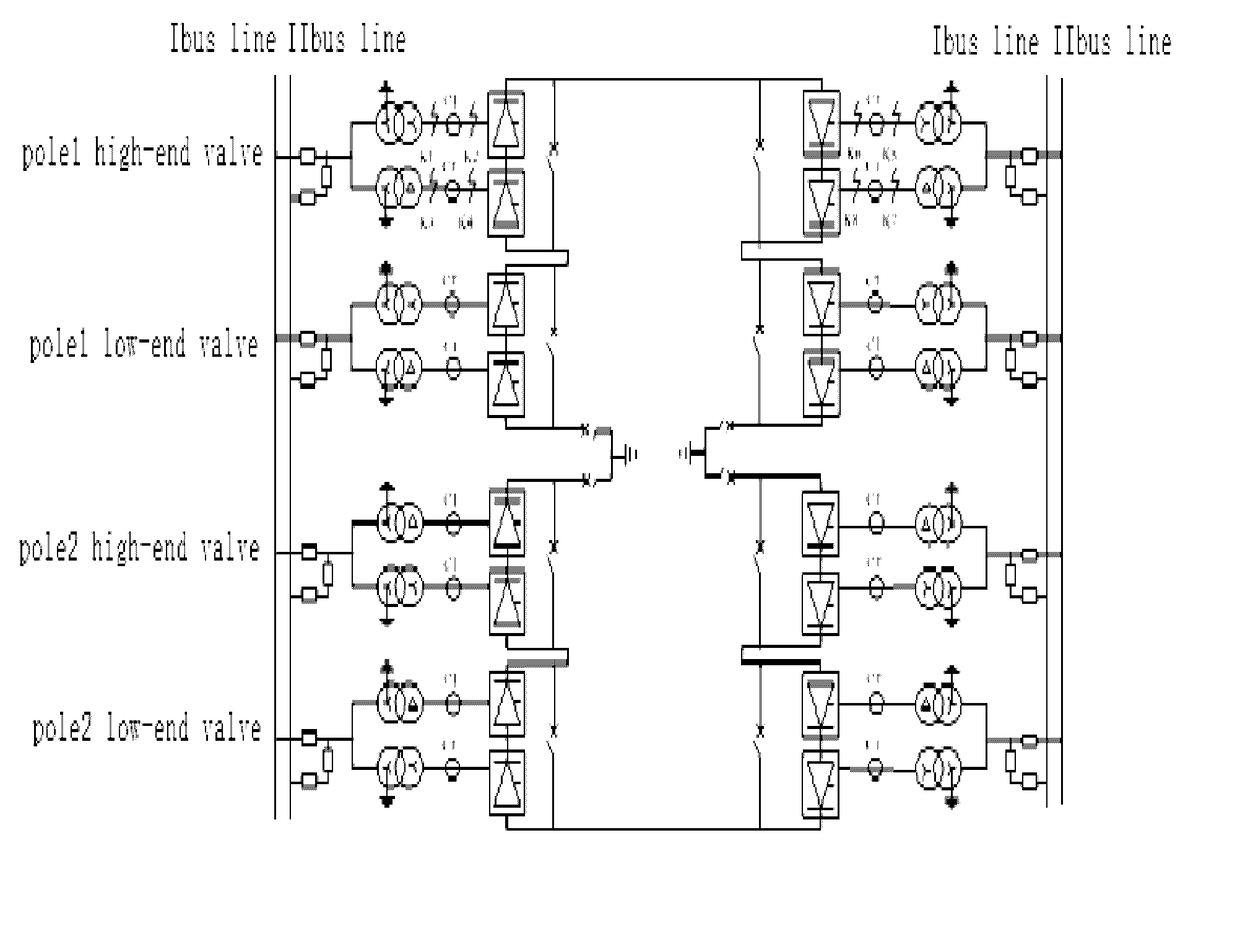

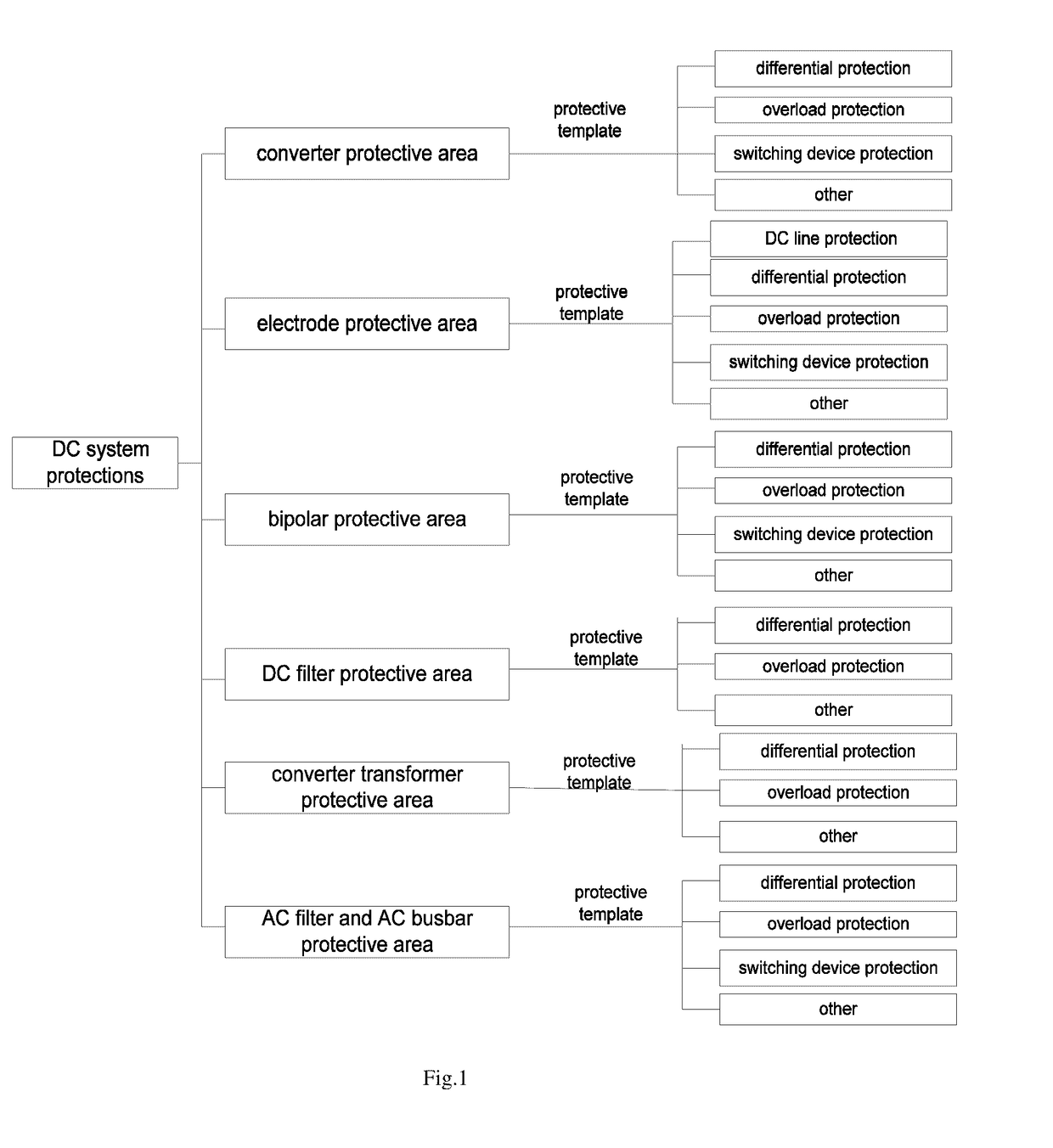

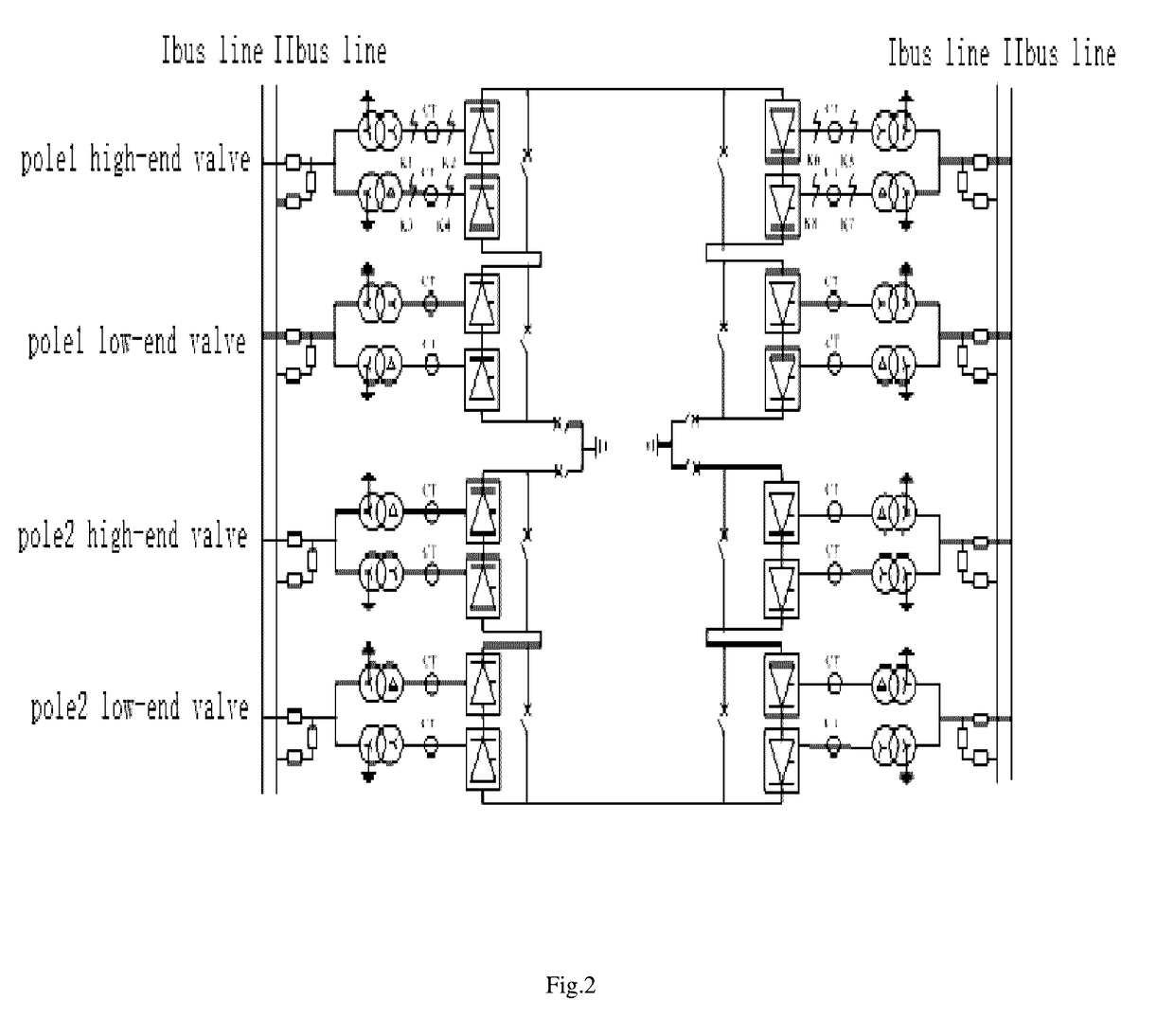

Setting and coordination calculation method for protection setting value of DC system

InactiveUS20170085076A1Overcome defectsEffective technologyParameter calibration/settingDesign optimisation/simulationTransient stateMathematical model

A setting and coordination calculation method for protection setting value of DC system is introduced. A protective template library is built by classifying the DC system protections to various protective areas and classifying each protective area. Based on project configuration, a mathematical model of converter station is built, the parameters of equipment components and locations of short circuit are given. The short-circuit current value and the parameters of equipment component are regarded as process parameters during the setting and coordination. The electromagnetic transient simulation is carried out at first in this method. And a specified and standard project of the setting and coordination is formed by abstracting and standardizing the process of the setting and coordination, which makes present setting and coordination of DC transmission engineering independent of the electromagnetic transient simulation software. This ensures the rationality of the protection setting value, reduces protection operation-failure or malfunction of the system.

Owner:XUJI GRP +2

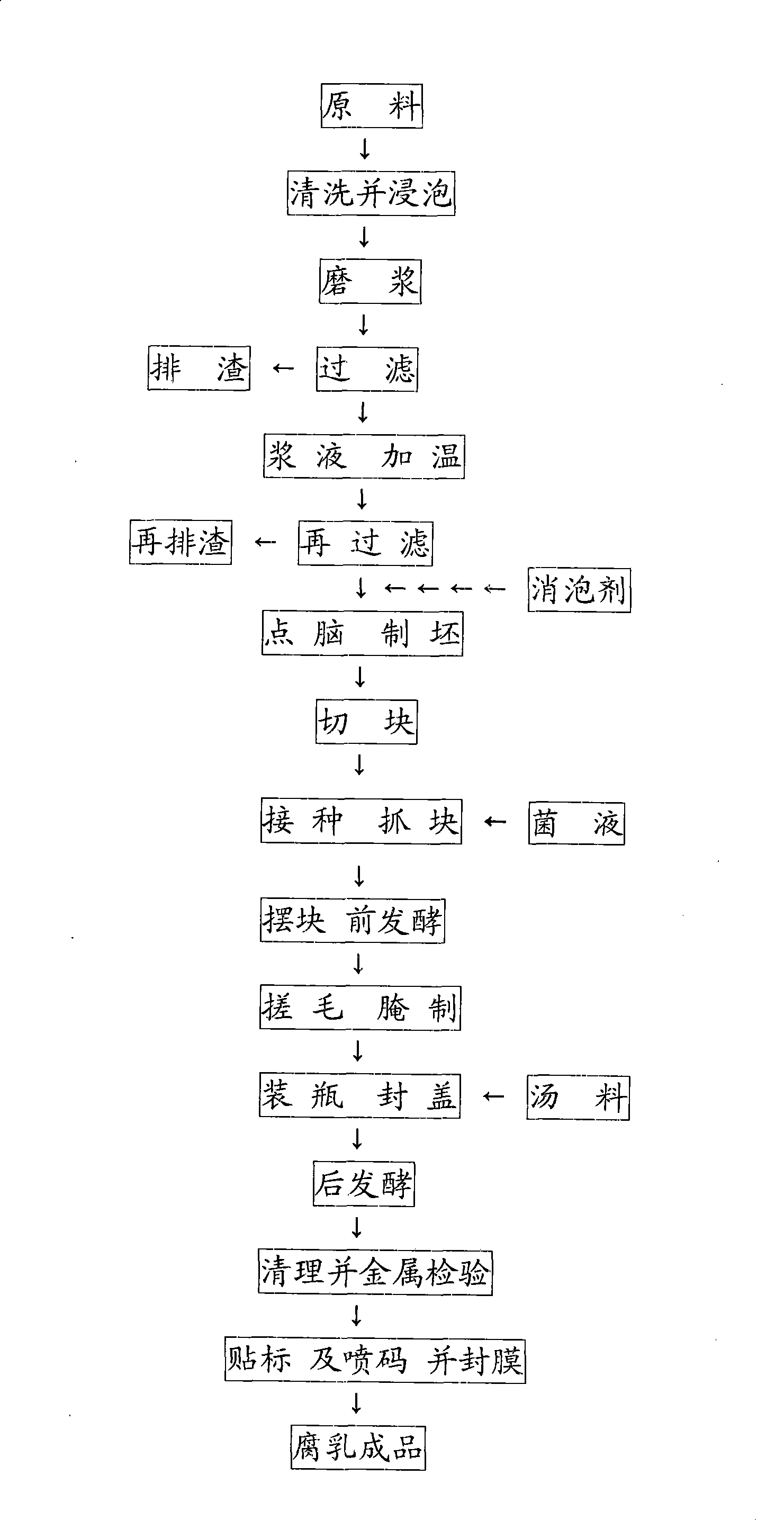

Production method of preserved beancurd

The invention relates to a method for preparing a preserved beancurd product, which belongs to the production field of the preserved beancurds. Primary fermentation and after fermentation are the key steps. The production process of the preserved beancurd comprises the following steps: soybean soaking, jordaning, filtering, warming, refiltration, defoaming, adding coagulant and blank forming, dicing, inoculating, primary fermentation, pickling, bottling, adding soup, covering and after fermentation. The raw materials of GMO free and green food are that protein contained in the soy bean is more than or equal to 38%, slag contained in the soy milk is less than or equal to 15%, crude protein contained in the bean dregs is less than or equal to 28%, and the final temperature of the soy milk in the final siruping tank of overflow tanks is more than or equal to 90 DEG C. When the jellied bean curd is 50%, turning over is carried out slowly and the flow rate of the coagulant is reduced, and when the jellied bean curd is 80%, turning over and the flow of the coagulant are stopped for standing statically; the squeezing is carried out at 8-10Mpa, the moisture content of white blank is 66-73%, the inoculation is carried out at the temperature of 40 DEG C, the primary fermentation is carried out for 36-48 hours and cages are exchanged for three times, and the first exchange, the second exchange and the third exchange are carried out respectively at the temperature of 23-28 DEG C, 22-26 DEG C and 18-22 DEG C. wherein, the relative humidity in the three exchanges are all 60%; pickling is carried out for 3-5 days, then after fermentation is carried out at the temperature of 15-30 DEG C for 45-60 days, and the finished product contains 3.5-18% of salt. The method of the invention can be used for preparing the preserved beancurd.

Owner:北京王致和食品有限公司

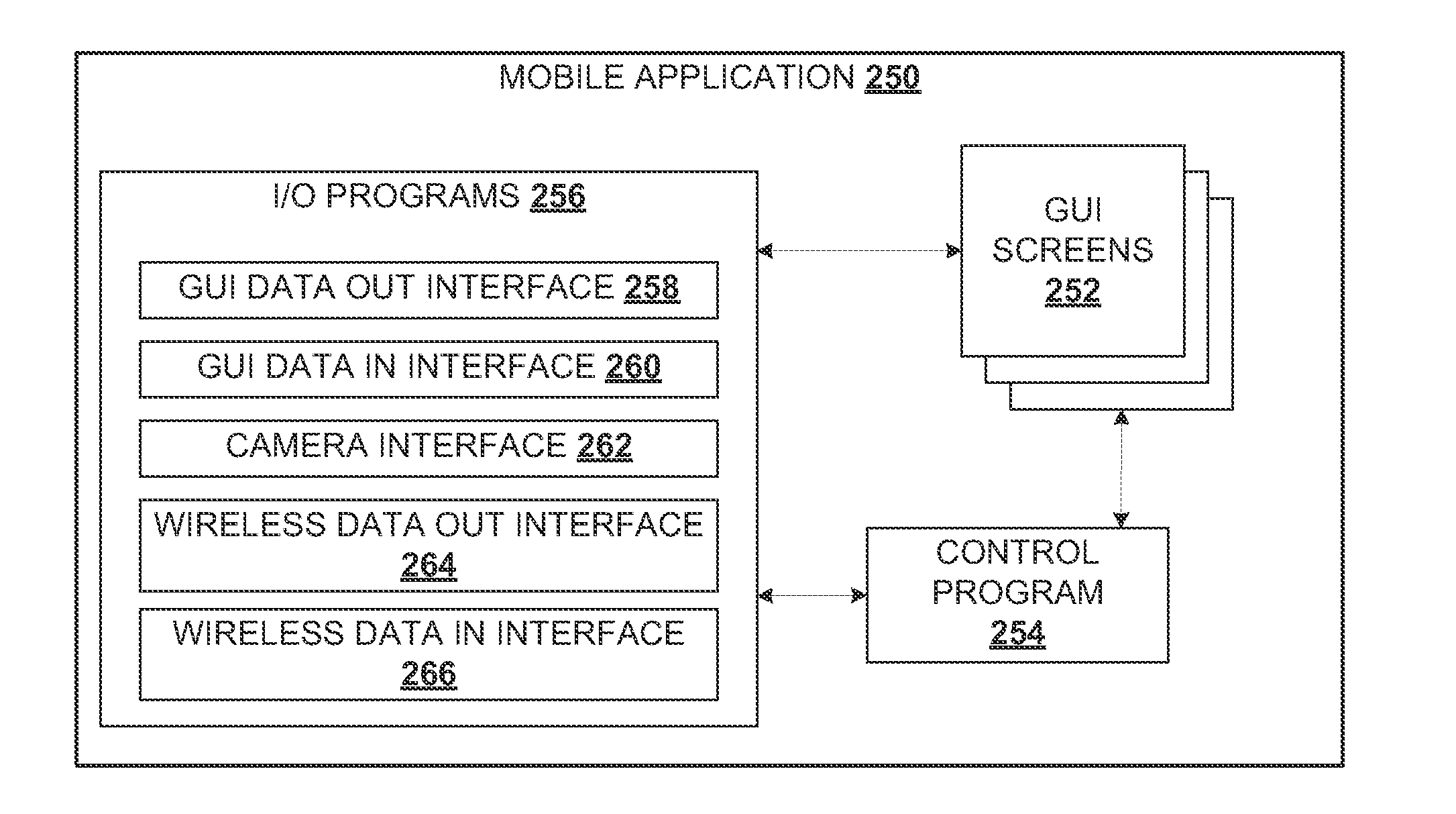

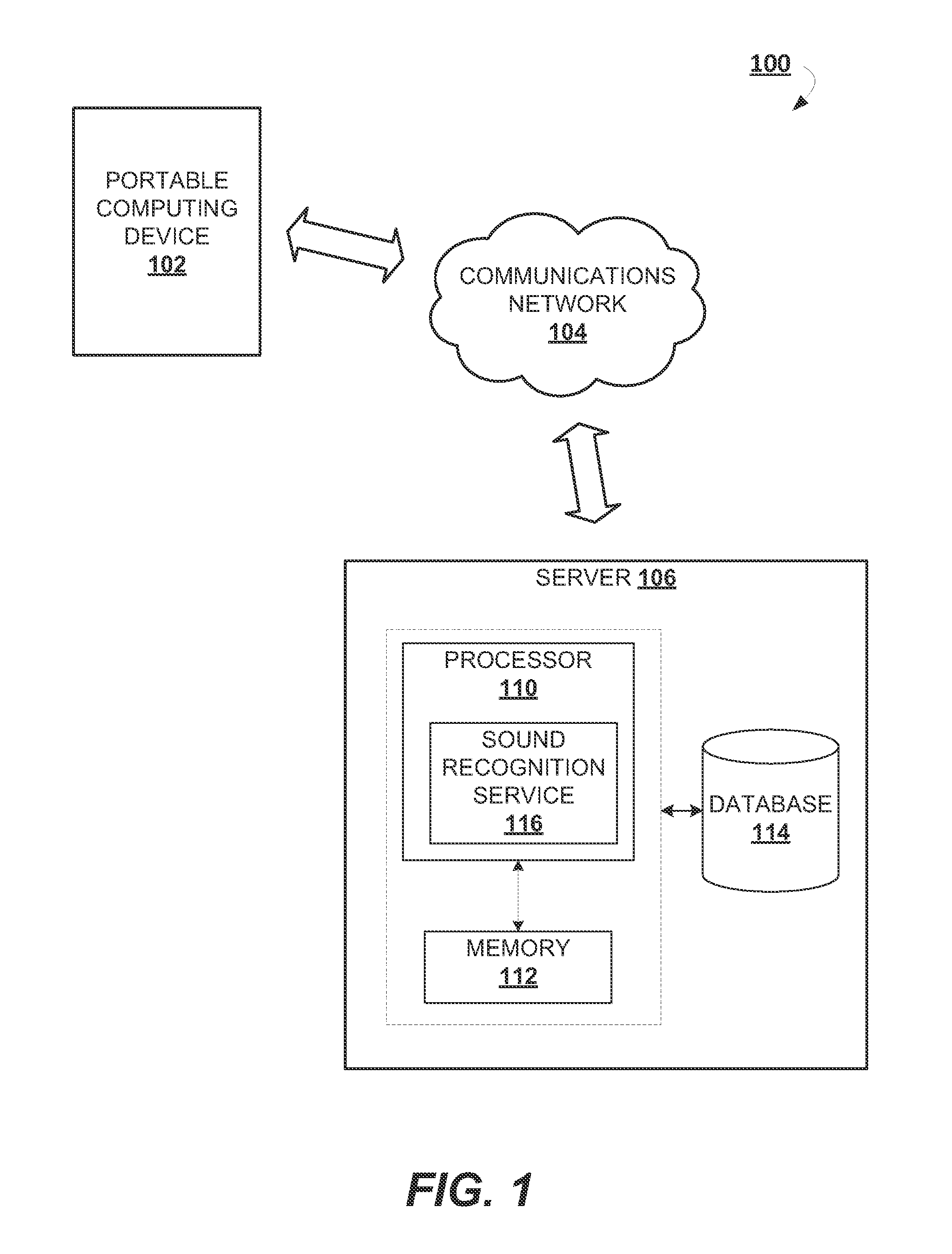

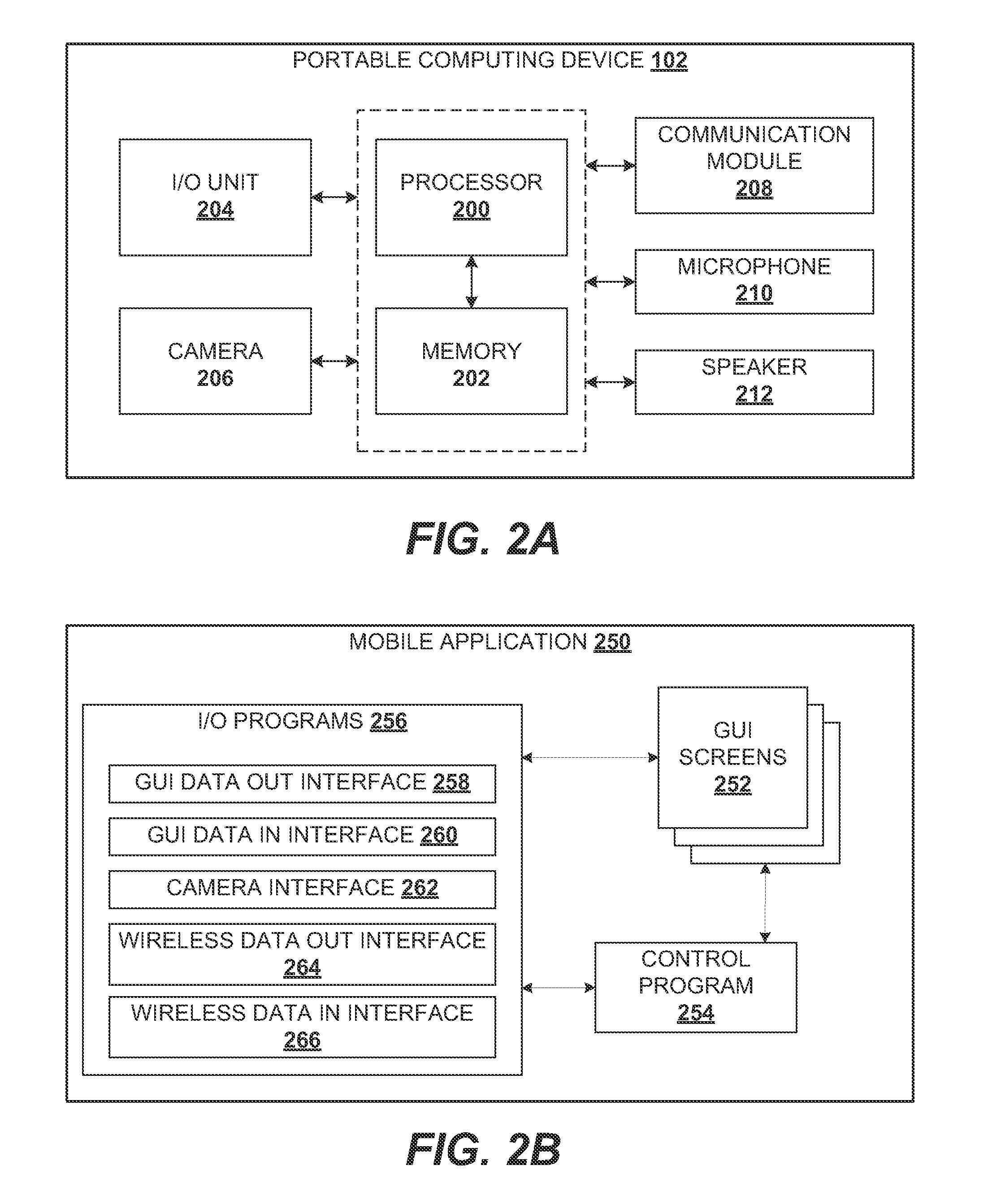

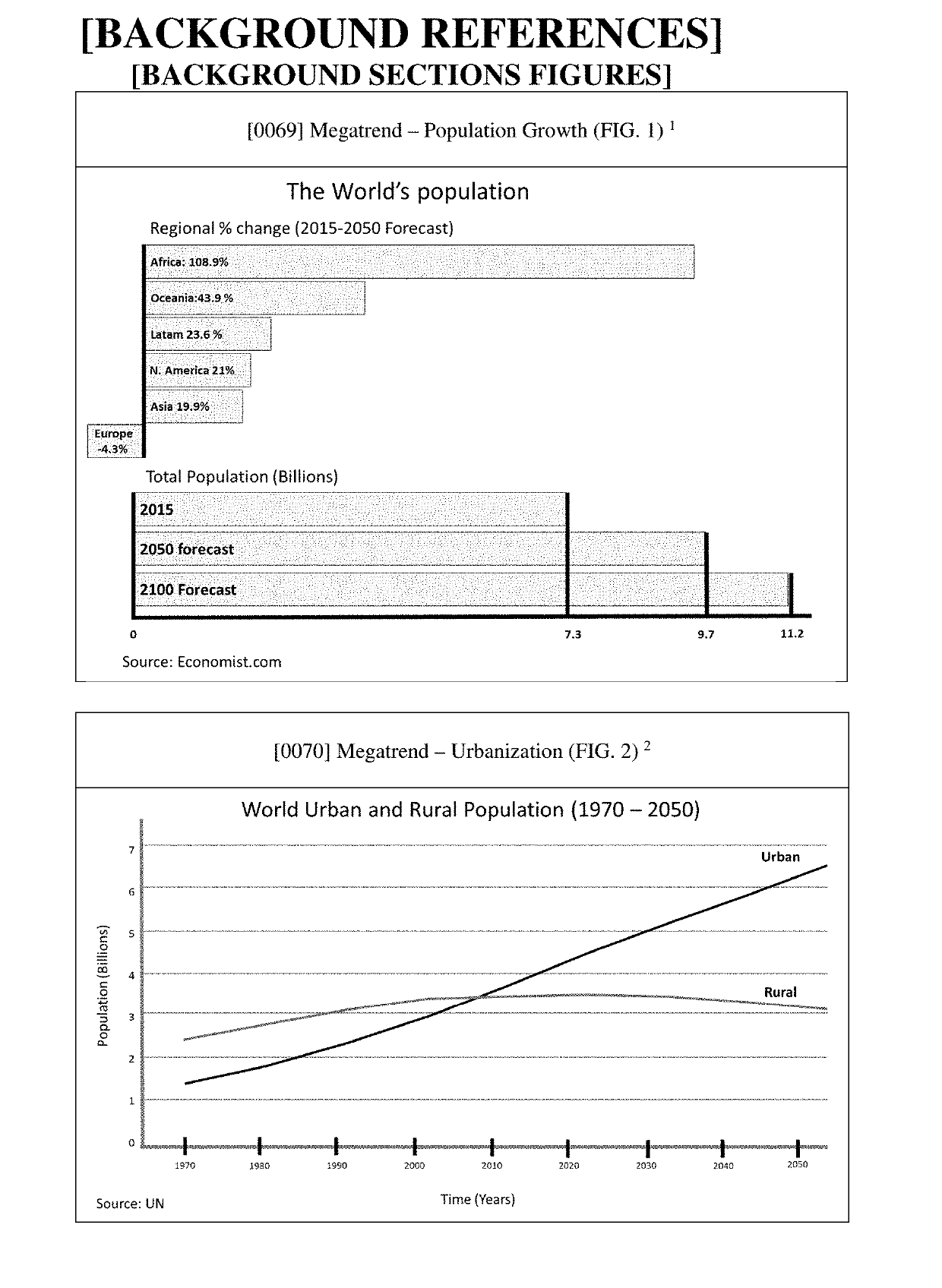

Methods and systems for capturing information-enhanced images

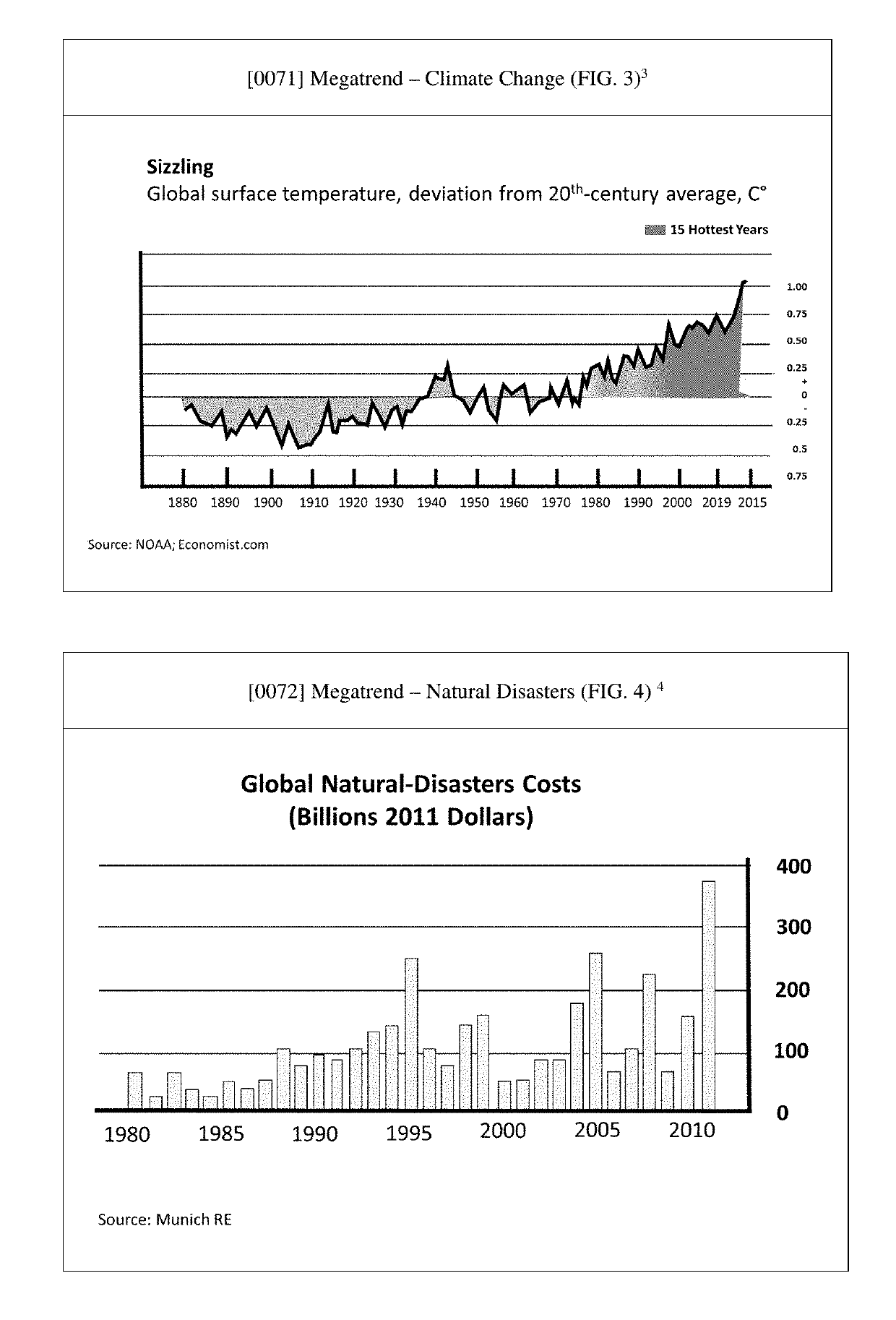

InactiveUS20140013193A1Visual nature of be enhanceBoost sensory and memory experienceNatural language data processingSpecial data processing applicationsSmart phoneTablet computer

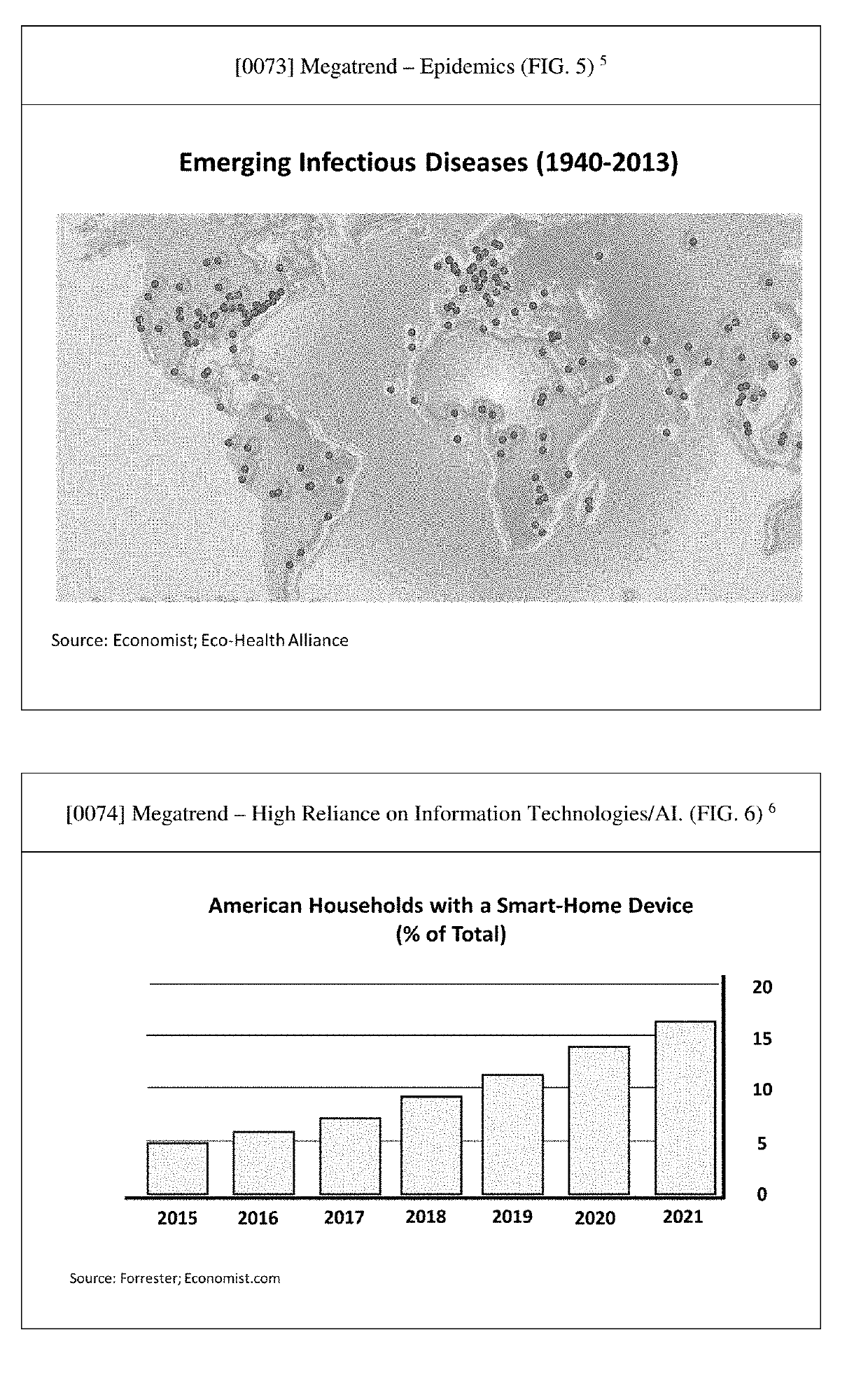

The approaches of the present disclosure provide for the efficient technology of intelligent association of still images with contextual information relating to sounds such as a sound that may have been ambient when a still image was captured. In particular, a user may use a media device, such as a smart phone or tablet computer, to capture a still image and record first audio, for example, at the time of capturing the still image for a predetermined period of time. The first audio may be then processed and analyzed so as to recognize a particular song or melody, and then a high quality second audio related to the recognized song or melody is downloaded and associated with the still image. Accordingly, the visual nature of still images is enhanced with data relating to contextual auditory information, which boosts the sensory and memory experience for the user.

Owner:SELINGER JOSEPH JOHN +1

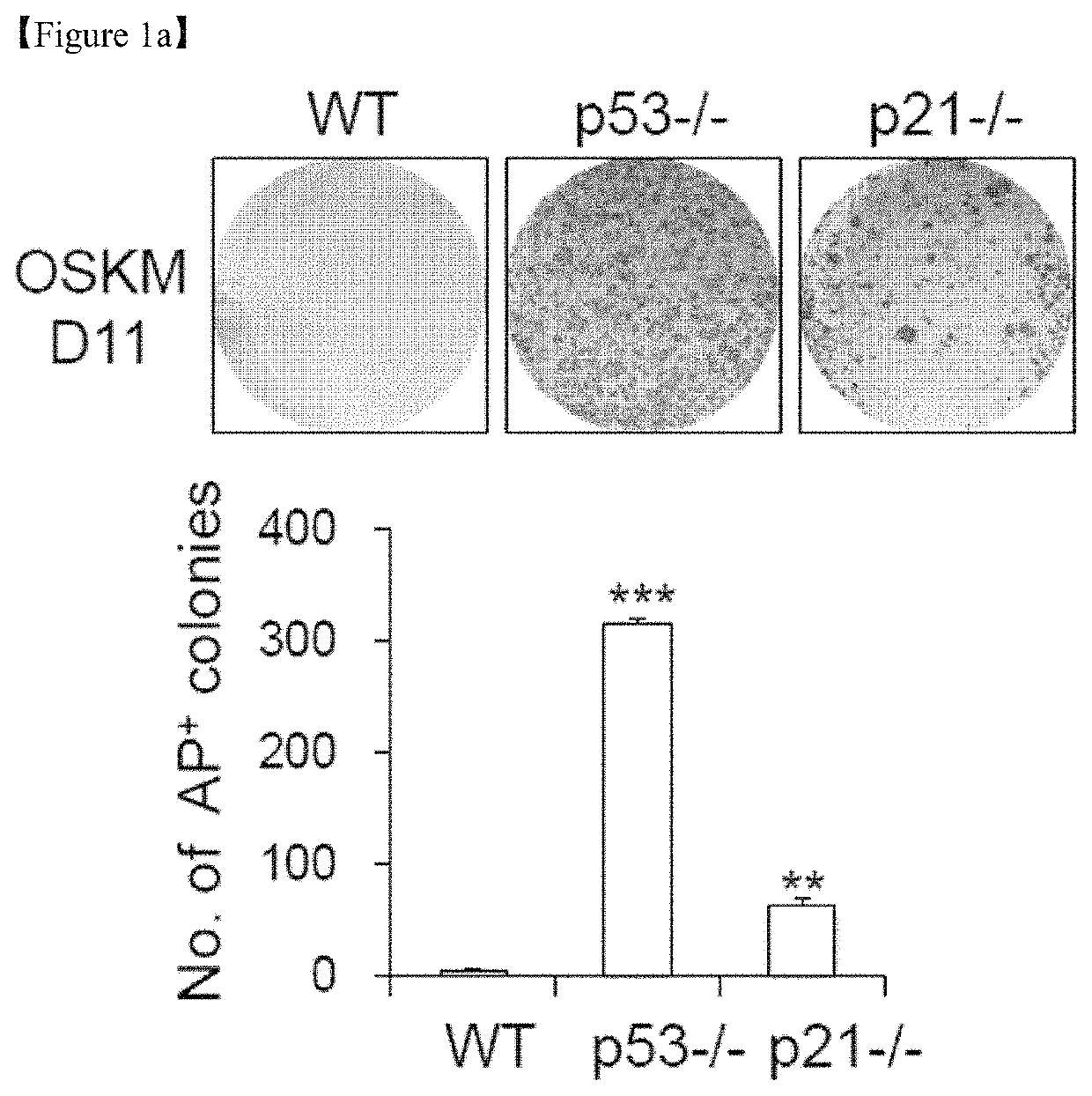

Method for configuring and managing channels in a wireless communication system using AMC channels and diversity channels, transmission/reception apparatus thereof, and system thereof

InactiveUS8310994B2Effective technologyError preventionFrequency-division multiplex detailsCommunications systemEngineering

Provided is a method for configuring and managing a channel in a wireless communication system that divides a full frequency band into a plurality of sub-bands. The method comprises selecting at least one sub-band from the plurality of sub-bands and allocating each of a plurality of Adaptive Modulation and Coding (AMC) channels using the selected at least one sub-band; puncturing sub-carriers of at least one of the plurality of AMC channels according to a predetermined pattern; and allocating a diversity channel using the punctured sub-carriers.

Owner:QUALCOMM INC

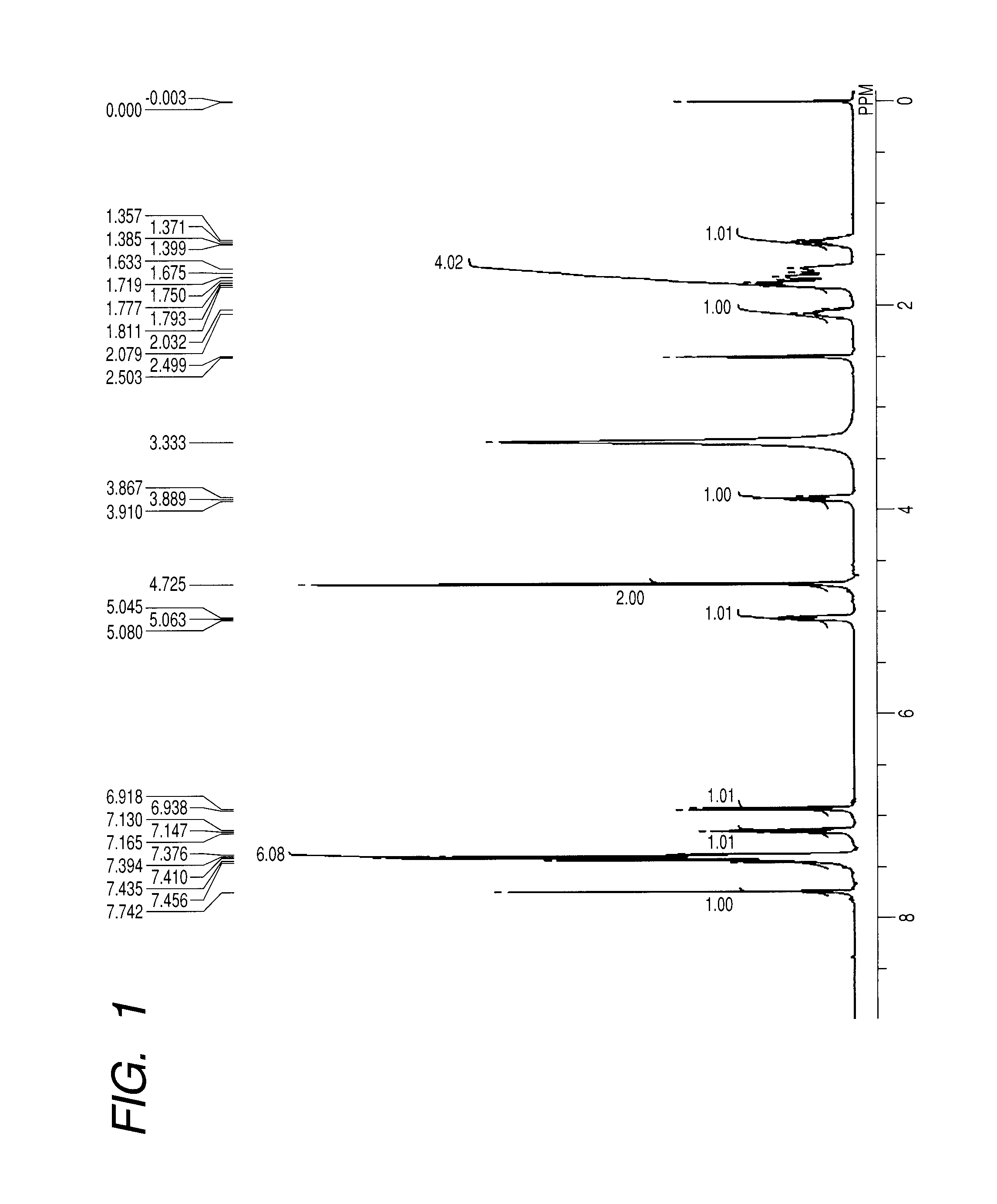

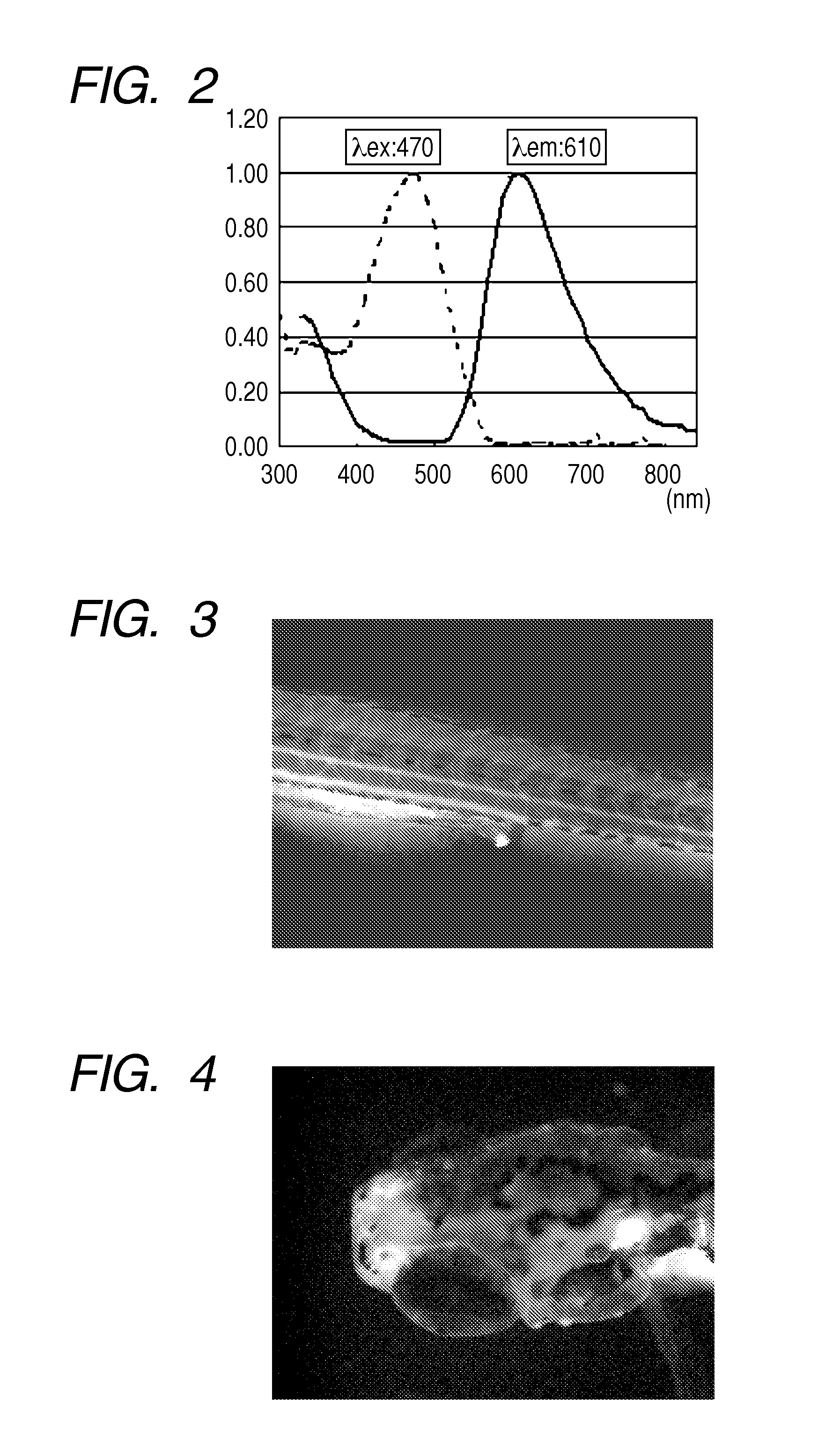

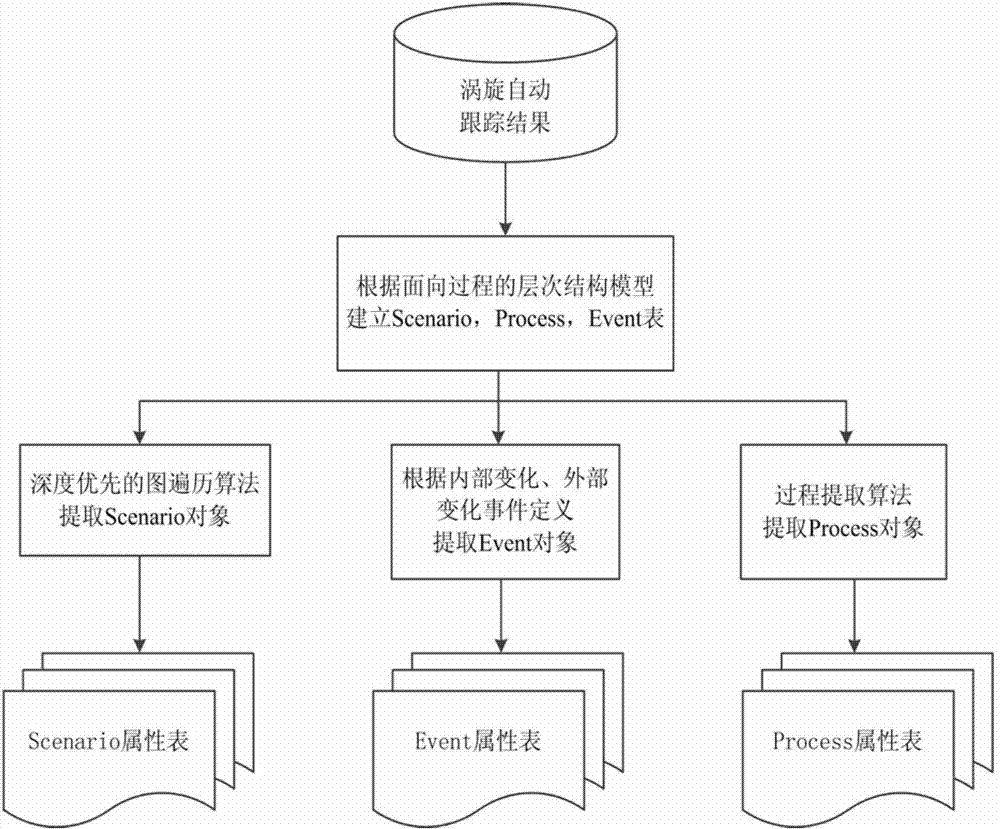

Probe for a biological specimen and labelling method and screening method using the probe

InactiveUS20110243850A1Improve featuresGood storage stabilityCompounds screening/testingCompound screeningBio-SpecimenActive agent

Provided is a novel probe for a biological specimen for labelling by itself and clearly visualizing one of a specific cell and a specific cell organ in a living body, the probe having excellent spectral characteristics and exhibiting excellent storage stability. The probe for a biological specimen contains, as an active agent, at least one kind of compound represented by a general formula (I).

Owner:CANON KK

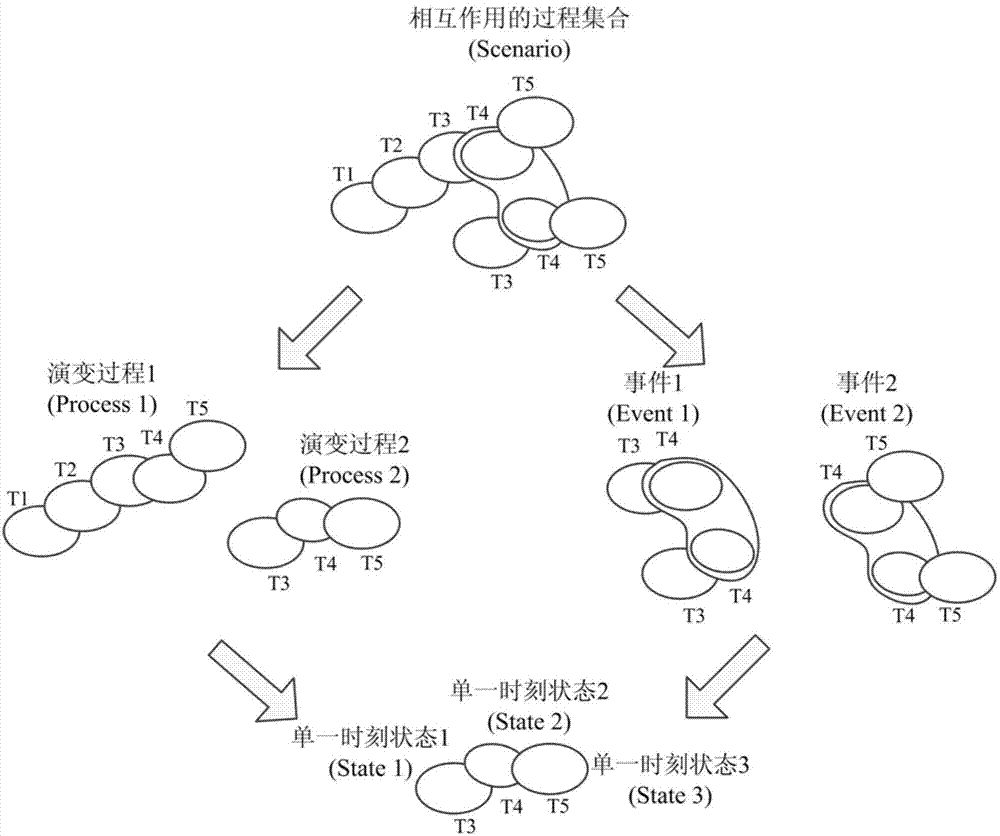

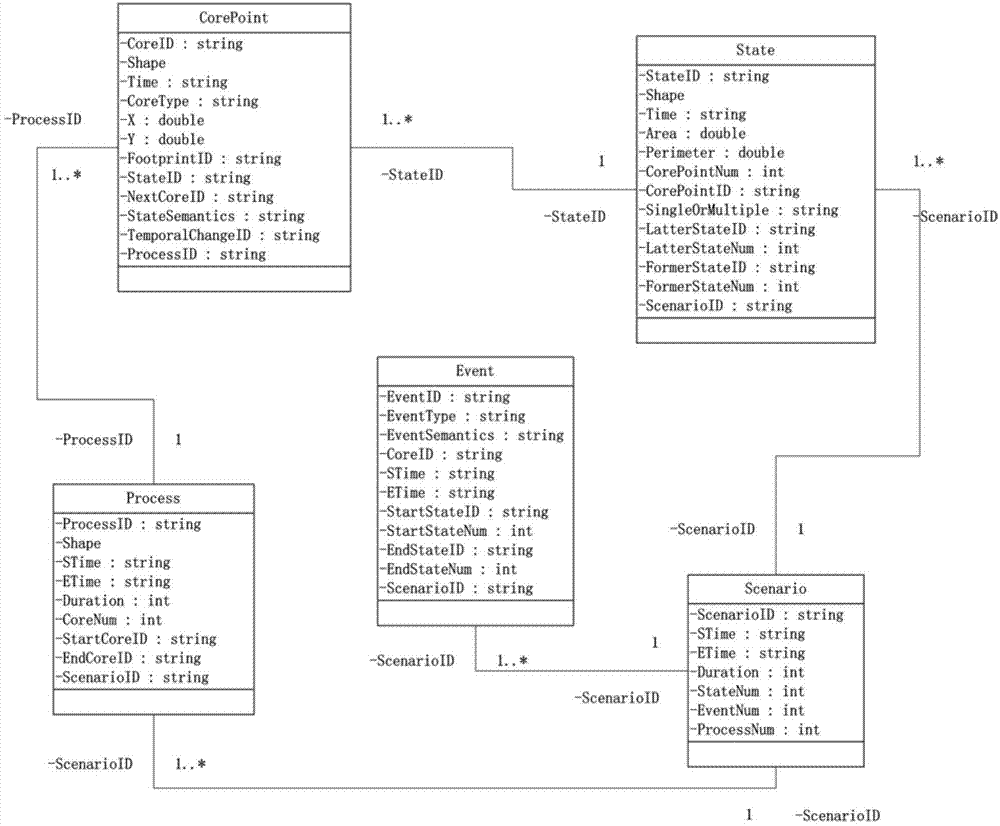

Method of information extraction for ocean eddy evolution process

InactiveCN103399905AEffective technologyValid data supportSpecial data processing applicationsProcess orientedData set

The invention relates to a method of information extraction for ocean eddy evolution process and belongs to the technical field of ocean information. The method is mainly applied to extract detailed evolution process information of eddies automatically from an eddy tracking data set and, technically, includes: establishing a process-oriented hierarchical data organization model, abstracting and recording the evolution process information of eddies by process, event and scenario objects, tracing the eddy evolution process by depth-first graph traversal algorithm and the like, automatically extracting detailed spatial-temporal information of process, event and process interaction, explicitly expressing and recording the process information, originally implied in the eddy tracking results, into a spatial-temporal database, and providing effective technical and data support for the analysis and discovery of eddy motion feature and law.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

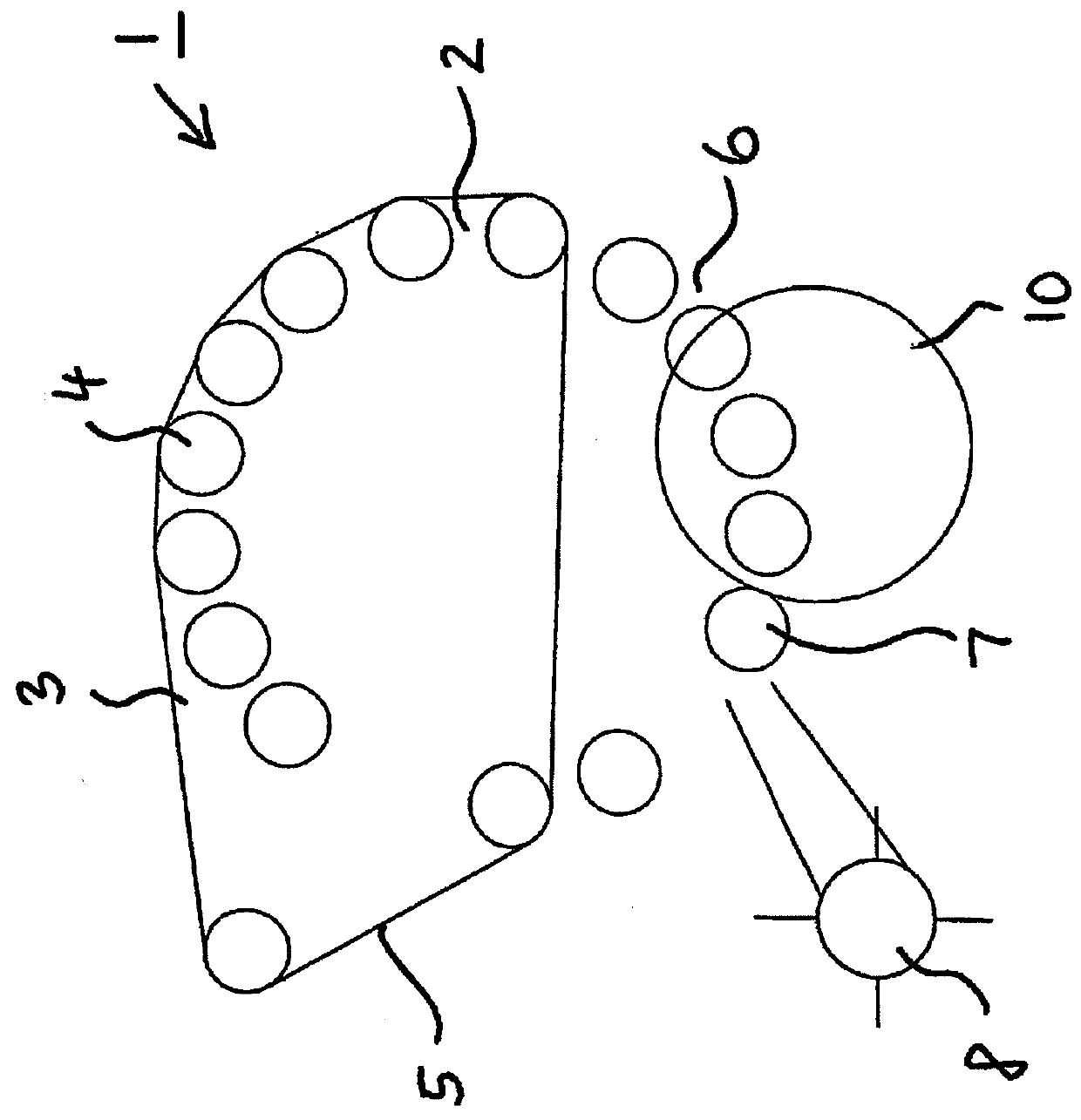

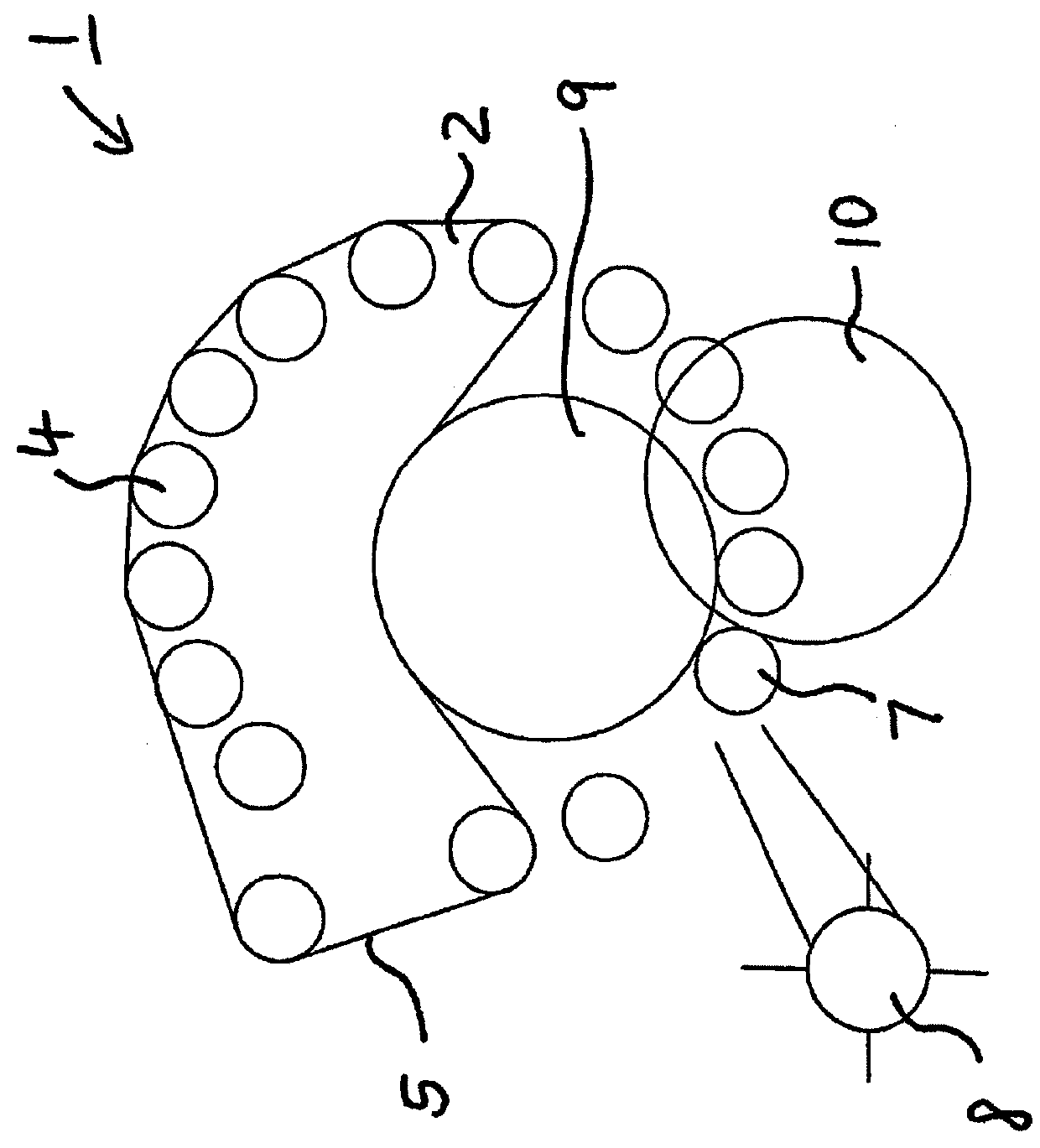

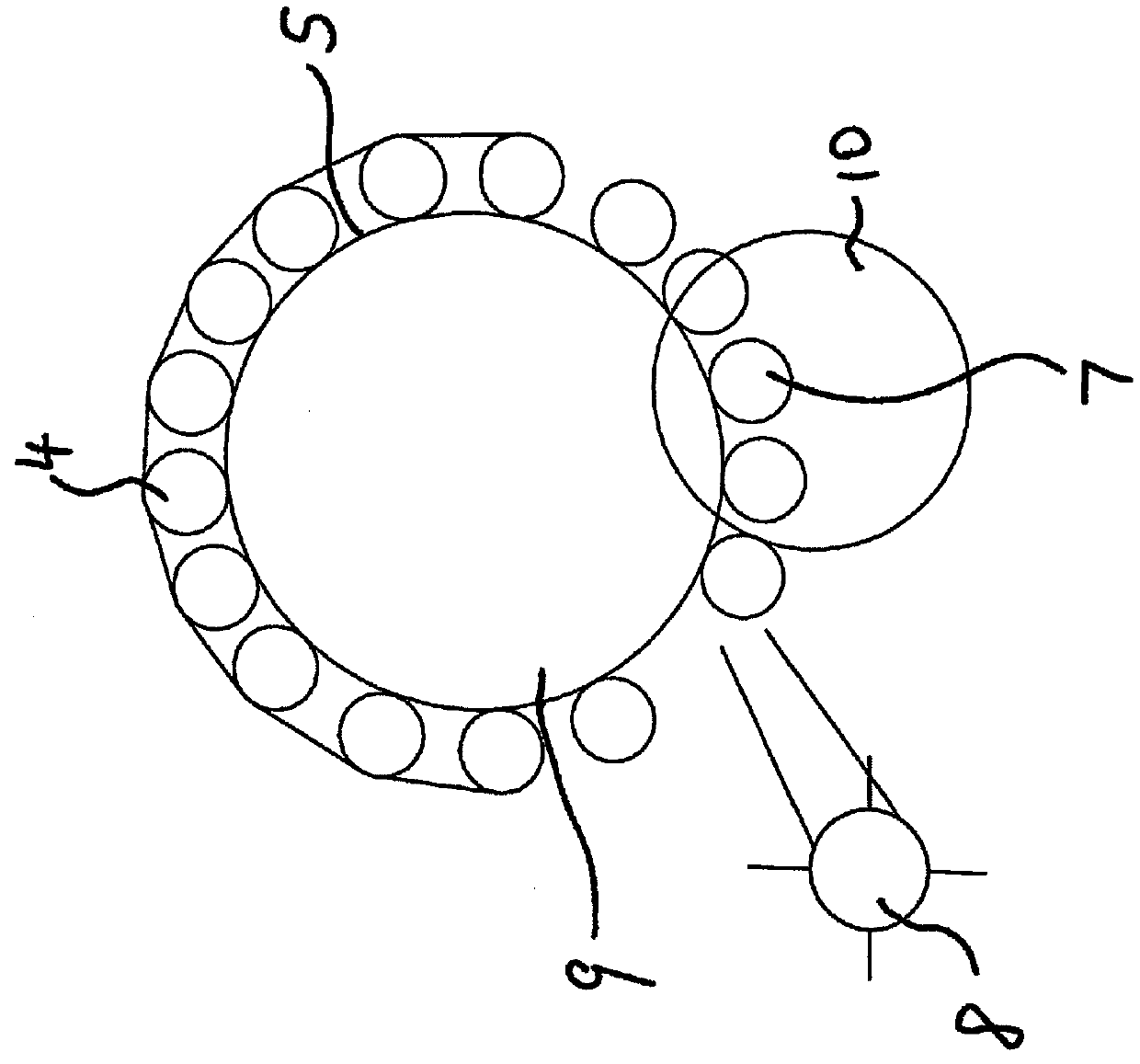

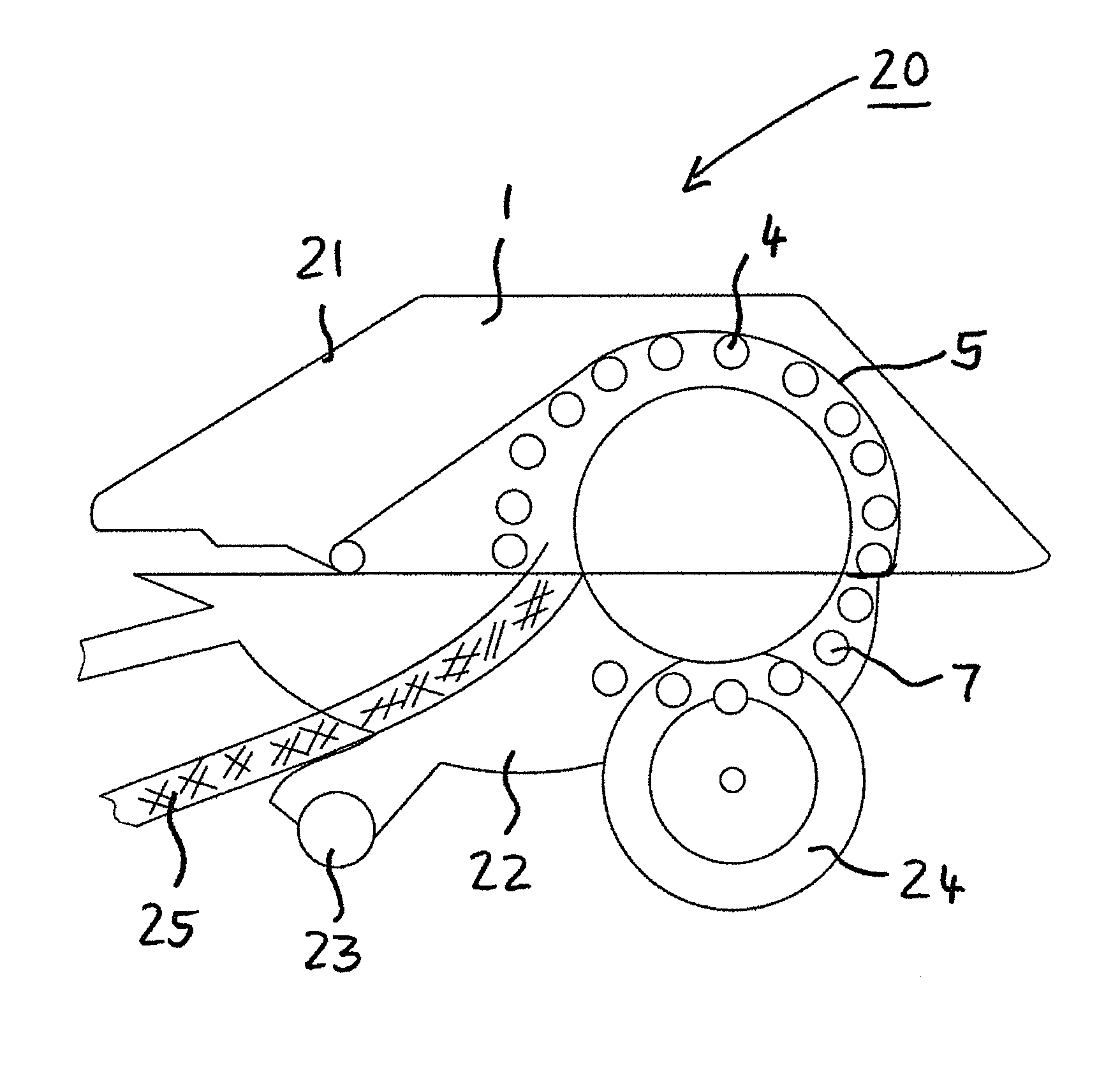

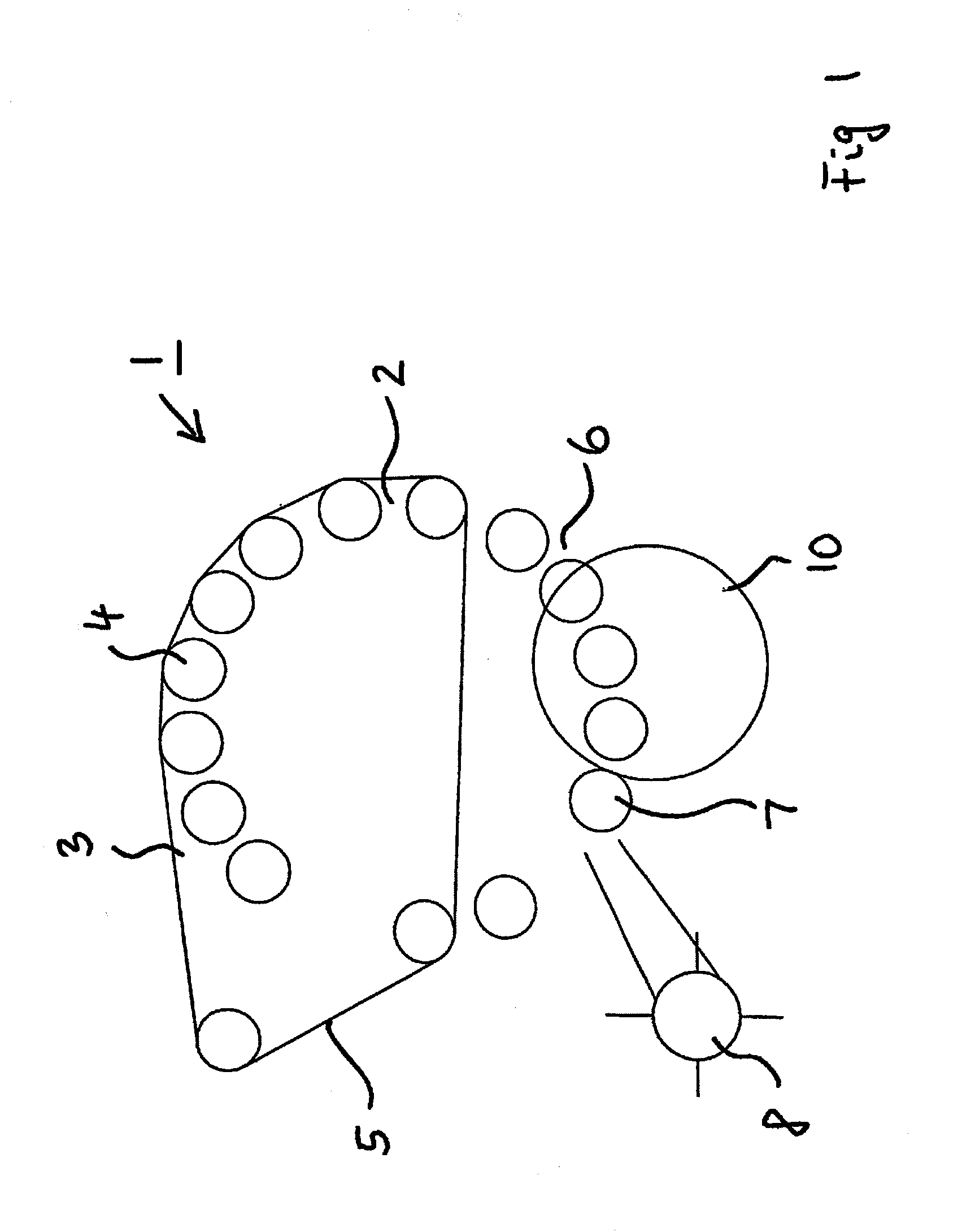

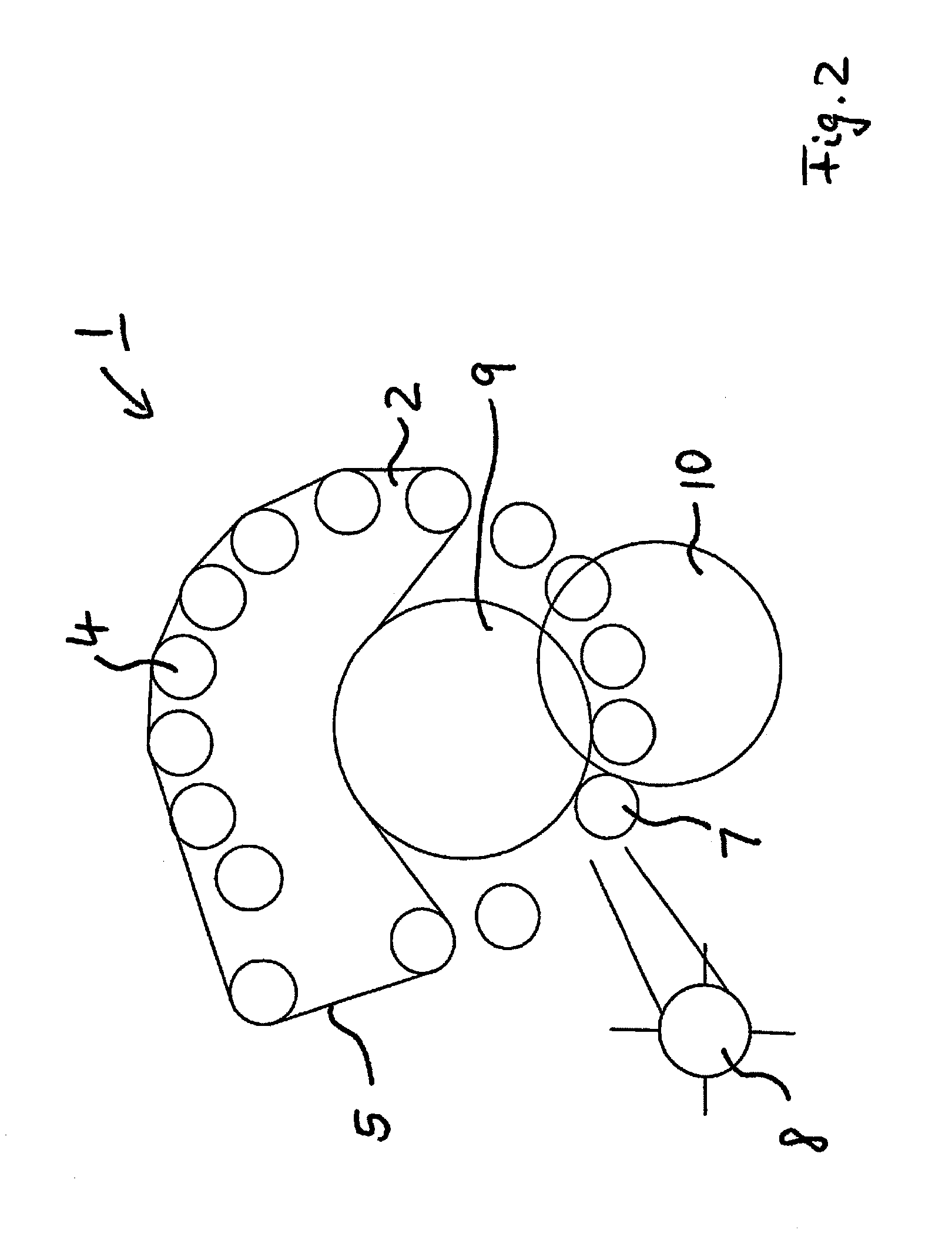

Combined method for compacting material into a bale and wrapping the bale and a combined baler and bale wrapping apparatus

An apparatus and method for compacting material into a bale and wrapping the bale with a wrapping material is set forth. The method comprises steps of supplying a material to be baled to a baling chamber of a combined baler and bale wrapping apparatus, and forming a bale of the material in the baling chamber, opening a cover of the baling chamber, securing the bale by a securing-mechanism operatively assigned to the baling chamber in the baling chamber, applying a wrapping material supplied from a dispenser to the secured bale, thereby providing one or more securing layers of the wrapping material encircling the bale, and releasing the bale from securing by the securing-mechanism, and wrapping the bale with the wrapping material by supplying further wrapping material from the dispenser to the bale, and expelling the wrapped bale from the baling chamber.

Owner:KVERNELAND AS

Combined method for compacting material into a bale and wrapping the bale and a combined baler and bale wrapping apparatus

ActiveUS20120318152A1Effective technologyBalingBinding material applicationCombined methodMaterial supply

An apparatus and method for compacting material into a bale and wrapping the bale with a wrapping material is set forth. The method comprises steps of supplying a material to be baled to a baling chamber of a combined baler and bale wrapping apparatus, and forming a bale of the material in the baling chamber, opening a cover of the baling chamber, securing the bale by a securing-mechanism operatively assigned to the baling chamber in the baling chamber, applying a wrapping material supplied from a dispenser to the secured bale, thereby providing one or more securing layers of the wrapping material encircling the bale, and releasing the bale from securing by the securing-mechanism, and wrapping the bale with the wrapping material by supplying further wrapping material from the dispenser to the bale, and expelling the wrapped bale from the baling chamber.

Owner:KVERNELAND AS

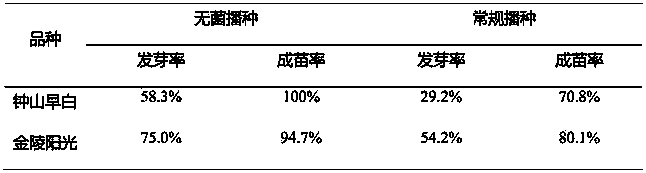

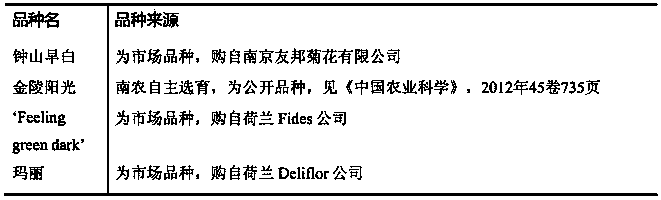

Efficient chrysanthemum cross-breeding method

ActiveCN103828710AImprove germination rateScale upPlant genotype modificationHybrid seedHigh effectiveness

The invention discloses an efficient chrysanthemum cross-breeding method, and belongs to the field of biotechnological breeding. The method comprises the following steps: sterilizing hybrid seeds by 75 percent ethanol for 1 minute, sterilizing the hybrid seeds by 5 percent sodium hypochlorite for 50 minutes, sowing the seeds on a 15g.L<-1> sucrose-containing MS culture medium, and performing further expanding propagation and subculture to obtain a great number of aseptic seedlings by combining a tissue culture technology. According to the method, the germination rate and seedling rate of the hybrid seeds are reliably increased; moreover, for a part of chrysanthemum varieties with cross incompatibility, aseptic seedlings obtained by a small number of hybrid seeds can be subcultured and propagated in the current year to obtain a large group of strains, so that the breeding cycle is shortened, and chrysanthemum breeding methods are further enriched.

Owner:NANJING AGRICULTURAL UNIVERSITY

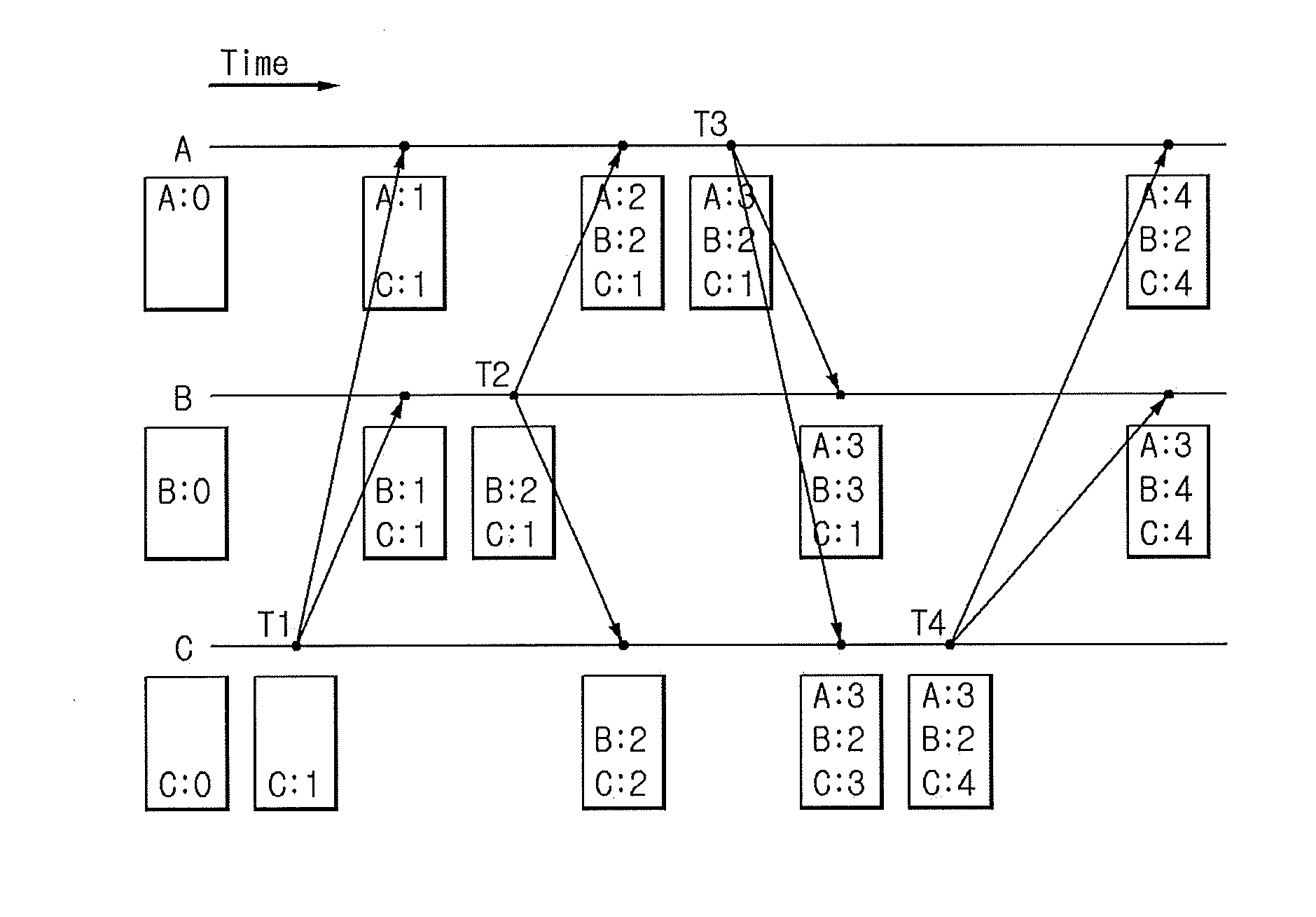

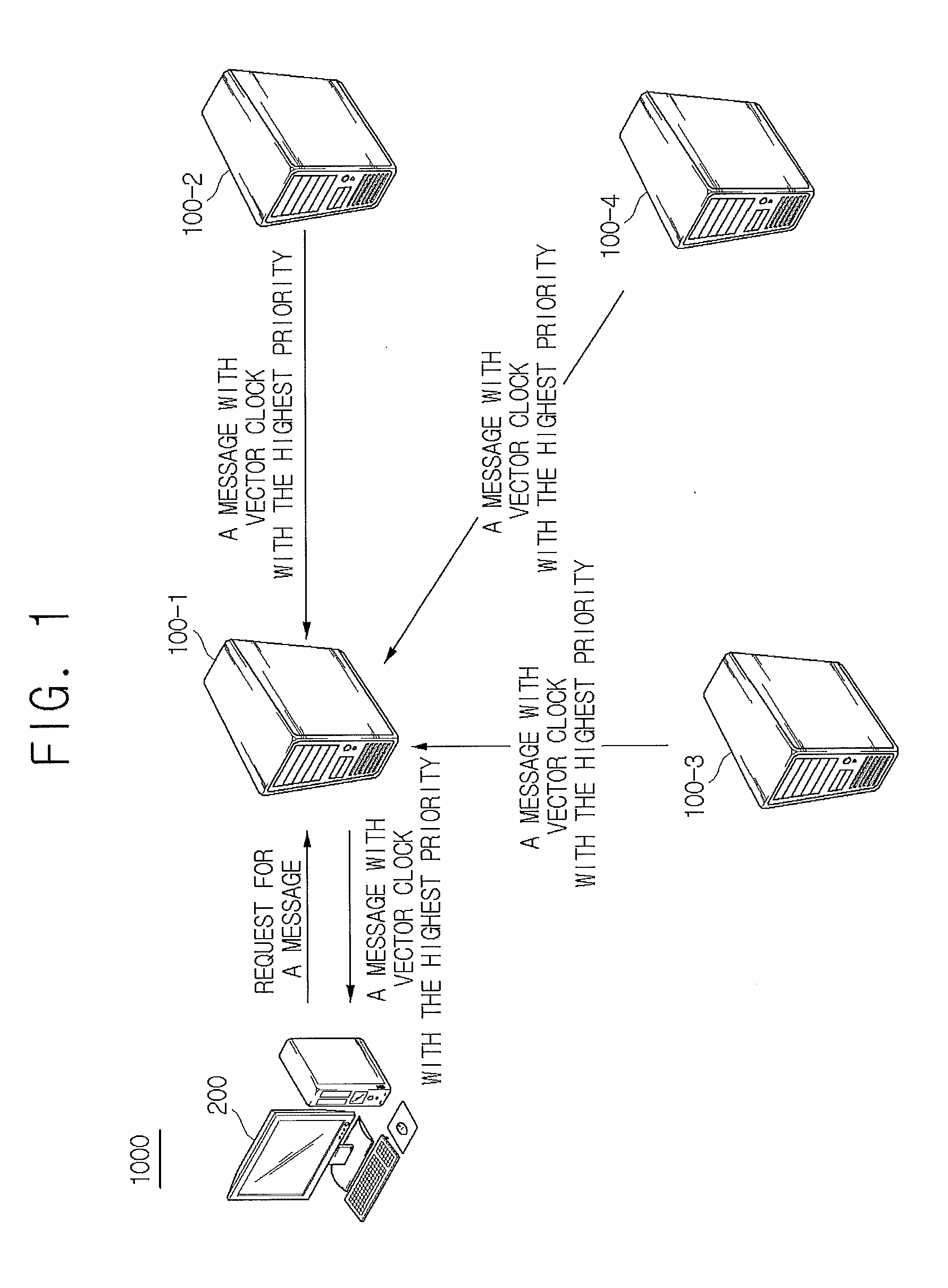

Method and server for assigning relative order to message by using vector clock and delivering the message based on the assigned relative order under distributed environment

ActiveUS20160337470A1Transmitting messages effectivelyGuaranteed normal transmissionData switching networksDistributed serversDistributed computing

A method for assigning relative order to messages by using vector clocks under a distributed server environment is disclosed. The method includes the steps of: (a) a server assigning a vector clock to a message and storing the message to which the vector clock is assigned if the message required to be assigned relative order is acquired through a network; and (b) the server transmitting an increased vector clock to one or more other servers connected with itself through the network and supporting said other servers to update their vector clocks by referring to the increased vector clock.

Owner:TMAXSOFT

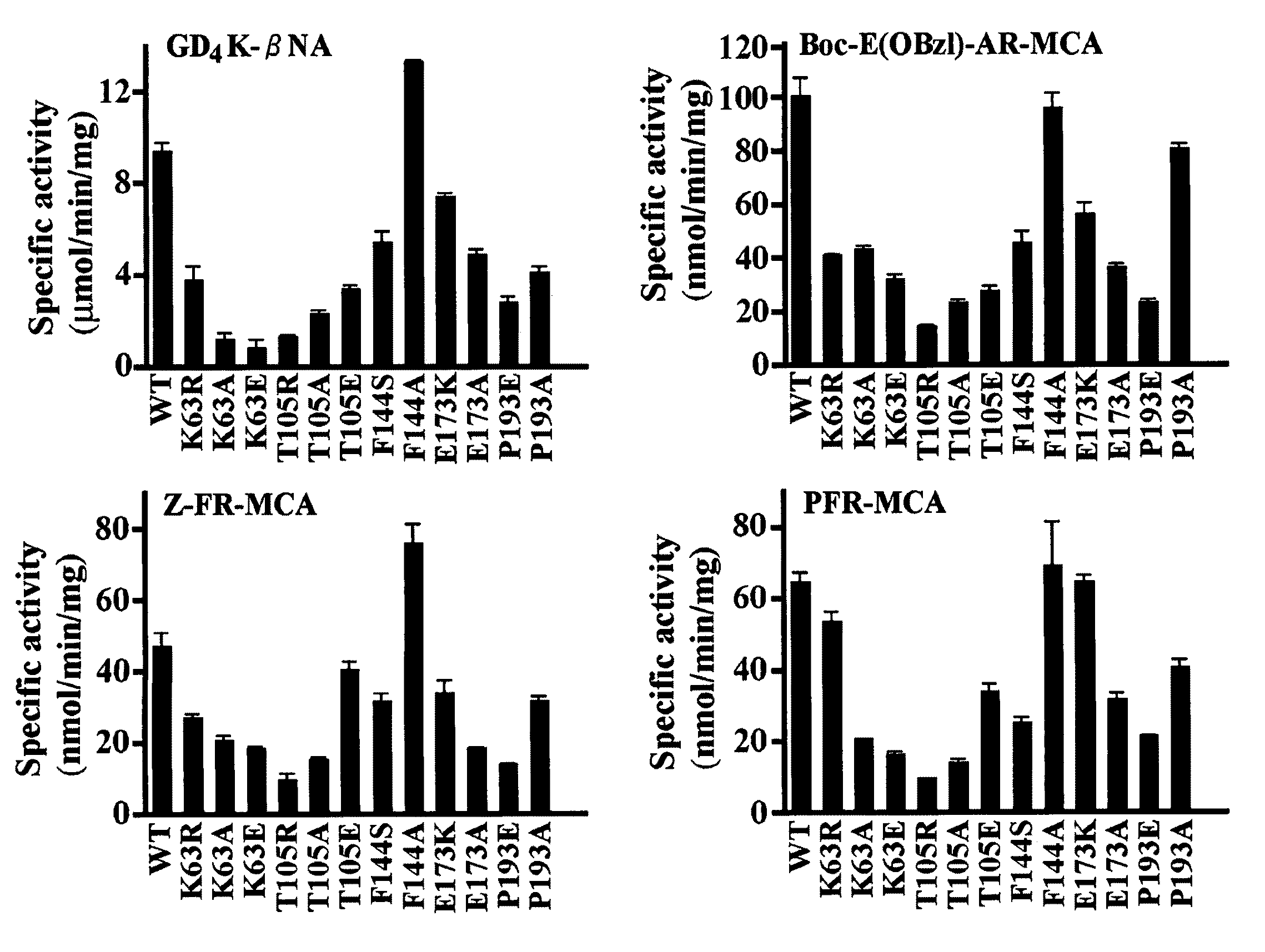

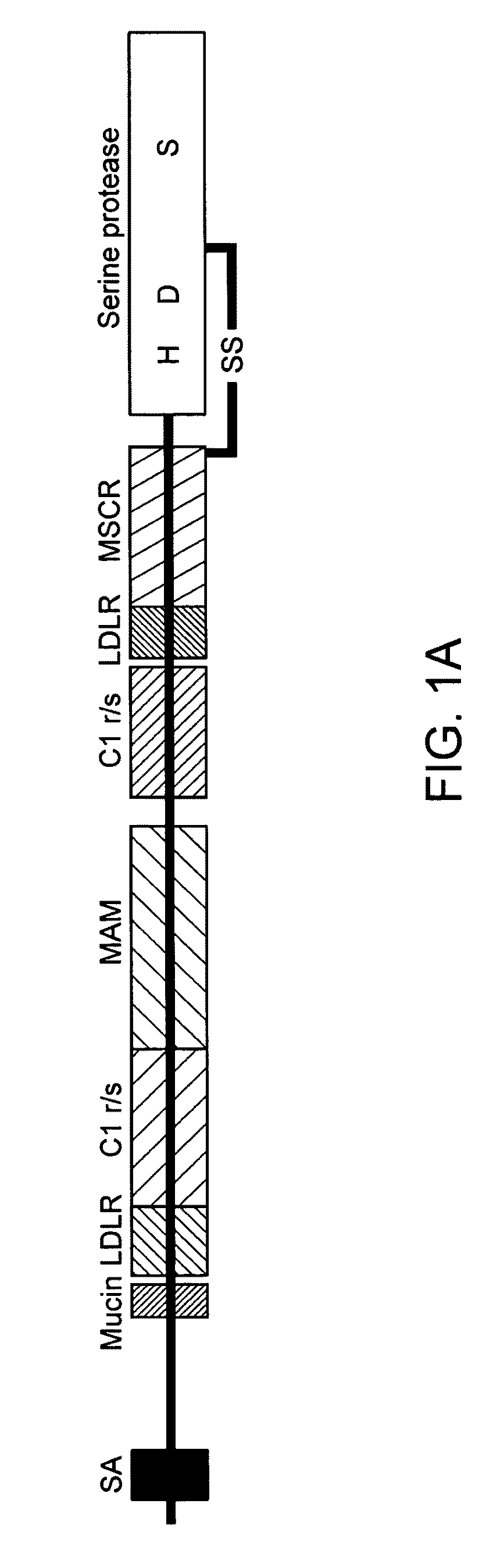

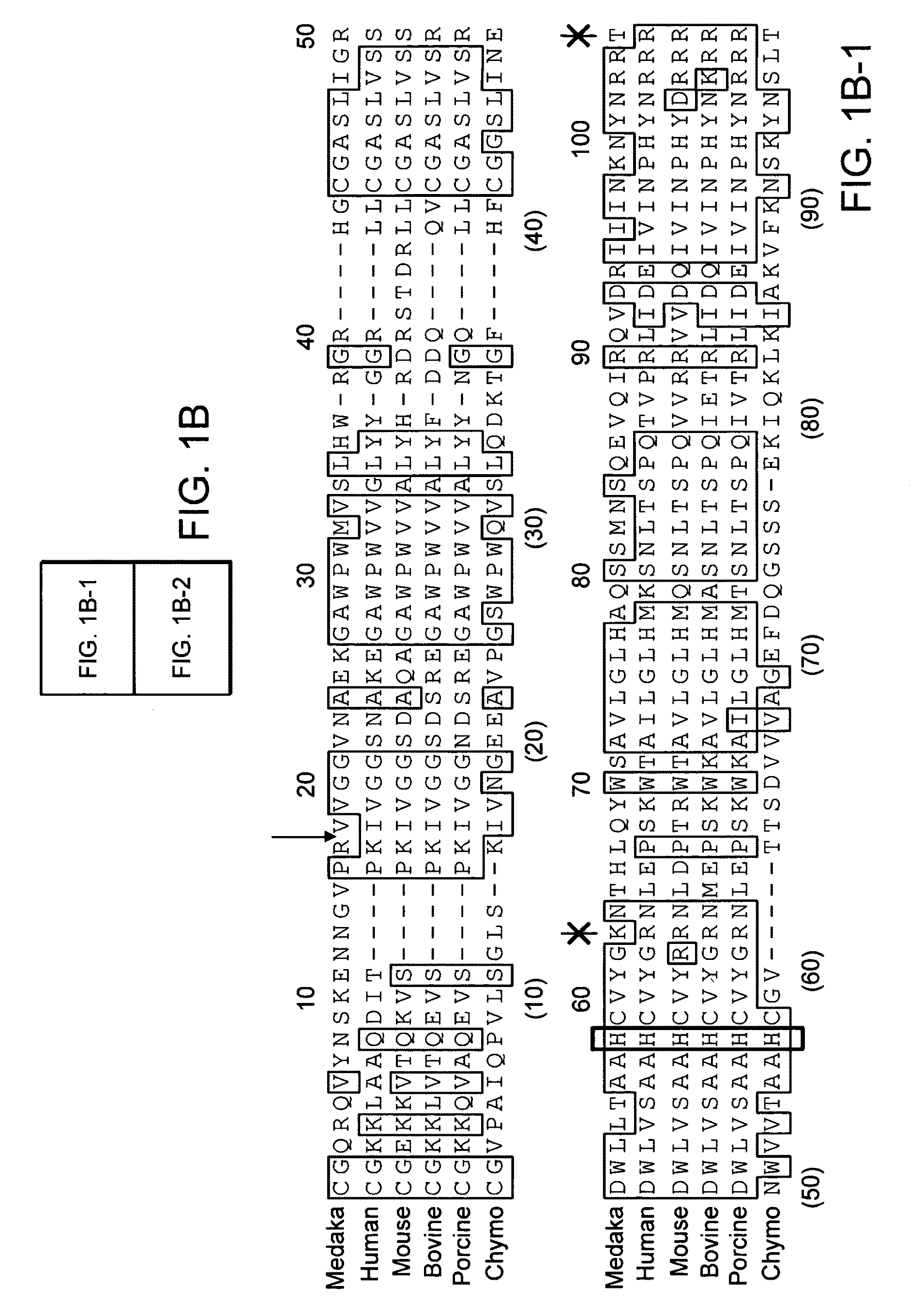

Modified enteropeptidase protein

InactiveUS8013137B2Reduced activityEffective technologySugar derivativesBacteriaEnteropeptidaseNucleotide

Disclosed are novel enteropeptidase polypeptides, polynucleotides encoding the polypeptides, nucleotide constructs, vectors, host cells comprising the polynucleotides, and methods for producing the polypeptides and polynucleotides. Such polypeptides are useful as protein engineering tool for enzymatic cleavage of fusion proteins. Also provided are kits comprising the polypeptides of the invention.

Owner:HOKKAIDO UNIVERSITY

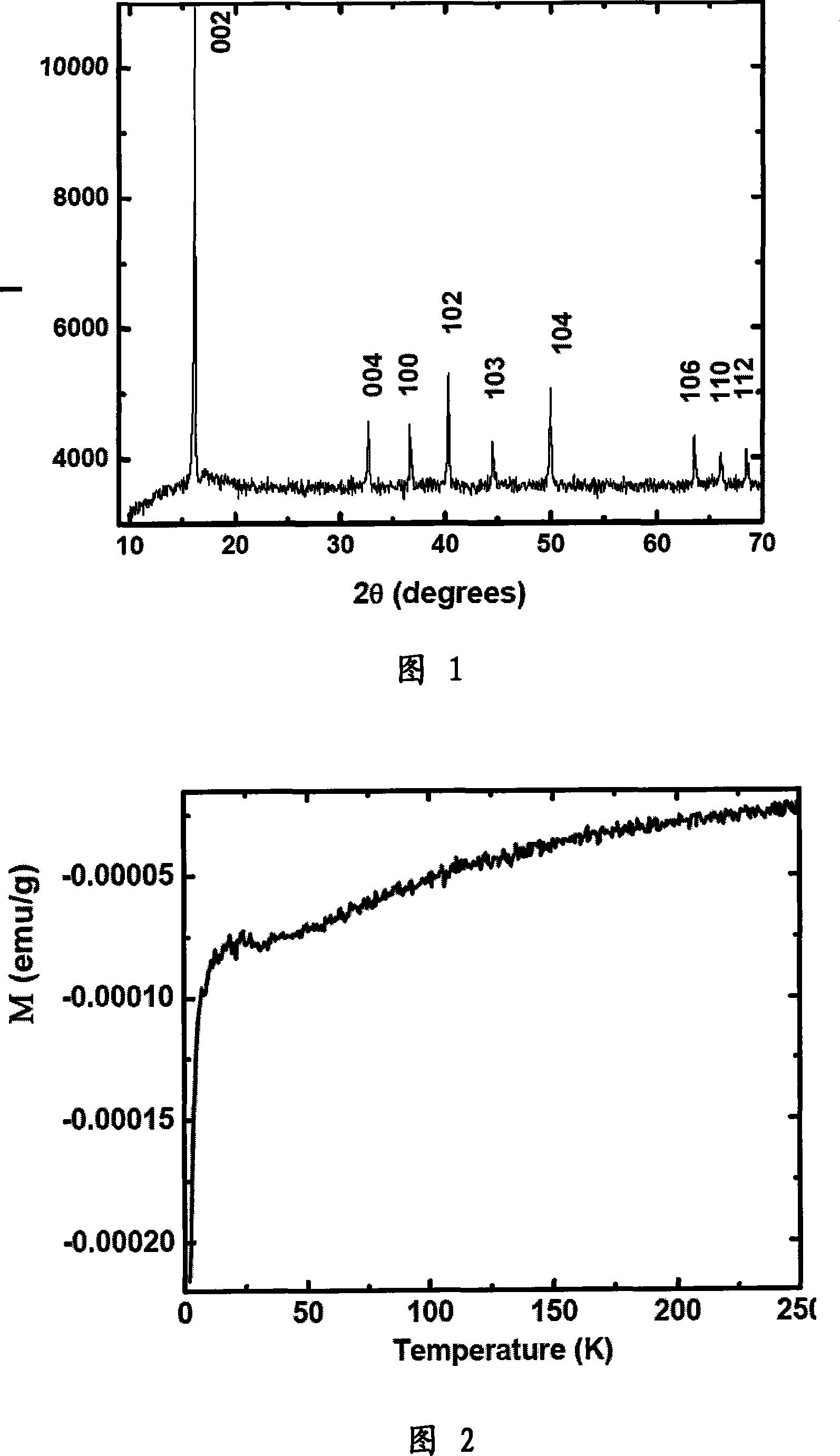

Method for preparing hydrated sodium-cobalt-oxygen superconducting material

InactiveCN101229971AShorten the timeShorten the production cycleSuperconductors/hyperconductorsCobalt compoundsOxygenCobalt

The invention relates to a method for preparing hydration natrium-cobalt-oxygen superconducting materials, wherein, a method for preparing precursor comprises the following steps: according to a molar ratio of the natrium and cobalt in the natrium-cobalt-oxygen (NaxCoO2, x is more than or equal to 0.5 and is less than or equal to 1.0) that Na: Co is x:1, raw material sodium carbonate (Na2CO3) and cobalt oxalate (CoC2O4) are weighed; the raw material is dissolved in aqua ammonia of 25 to 35 percent to carry out reaction; the reacted liquor is sprayed in liquid nitrogen with a sprayer; then the liquid nitrogen is put into a vacuum dryer to carry out freezing vacuum drying to obtain mixed powder which is warmed up to 500 to 700 DEG C and the temperature is preserved for 1 to 20 hours to carry out thermal decomposition; the mixed powder is again warmed up to 700 to 900 DEG C and the temperature is preserved for 1 to 30 hours to carry out sintering; then the mixed powder is naturally cooled to room temperature; the sinter is taken out and is grinded into the powder. The product of the invention has the advantages of definite chemical component, easiness to be prior controlled, even granule, small granularity, good material performance, low preparation temperature, short period and low cost.

Owner:SOUTHWEST JIAOTONG UNIV

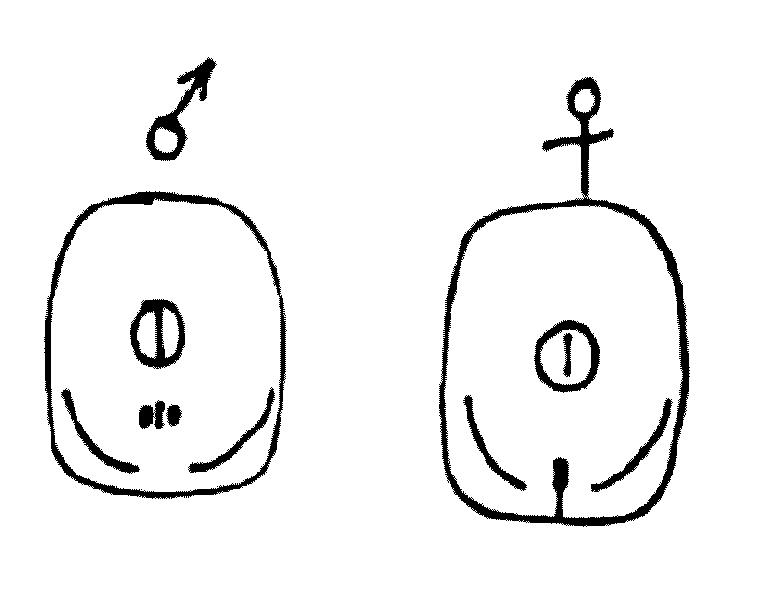

Artificial directional mating method of Scylla paramamosain

InactiveCN102845338ALarge amount of brooding eggsImprove hatchabilityClimate change adaptationPisciculture and aquariaScylla paramamosainEngineering

The invention relates to an artificial directional mating method of Scylla paramamosain. The artificial directional mating method of Scylla paramamosain includes: firstly, selecting black barrels as mating sites, spreading sand 10-15cm in thickness at the bottom of each black barrel, setting an air filling device, burying a nozzle of the air filling device in the sand, injecting fresh sea water, and keeping each black barrel in the dark; secondly, selecting healthy female and male crabs weighing 180-220g as candidate parents, cleaning the crabs with the fresh sea water, and putting two male crabs and two or three female crabs in each black barrel for breeding; thirdly, using Sinonovacula constricta as feed, changing all the water in black barrel every day, and taking the female carbs which finish mating for continual breeding. The artificial directional mating method of Scylla paramamosain has the advantages of simplicity in operation, high success rate, low input cost and the like, selective artificial directional mating can be achieved, and the artificial directional mating method of Scylla paramamosain is applicable to artificial large-scale propagation and selection of Scylla paramamosain.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

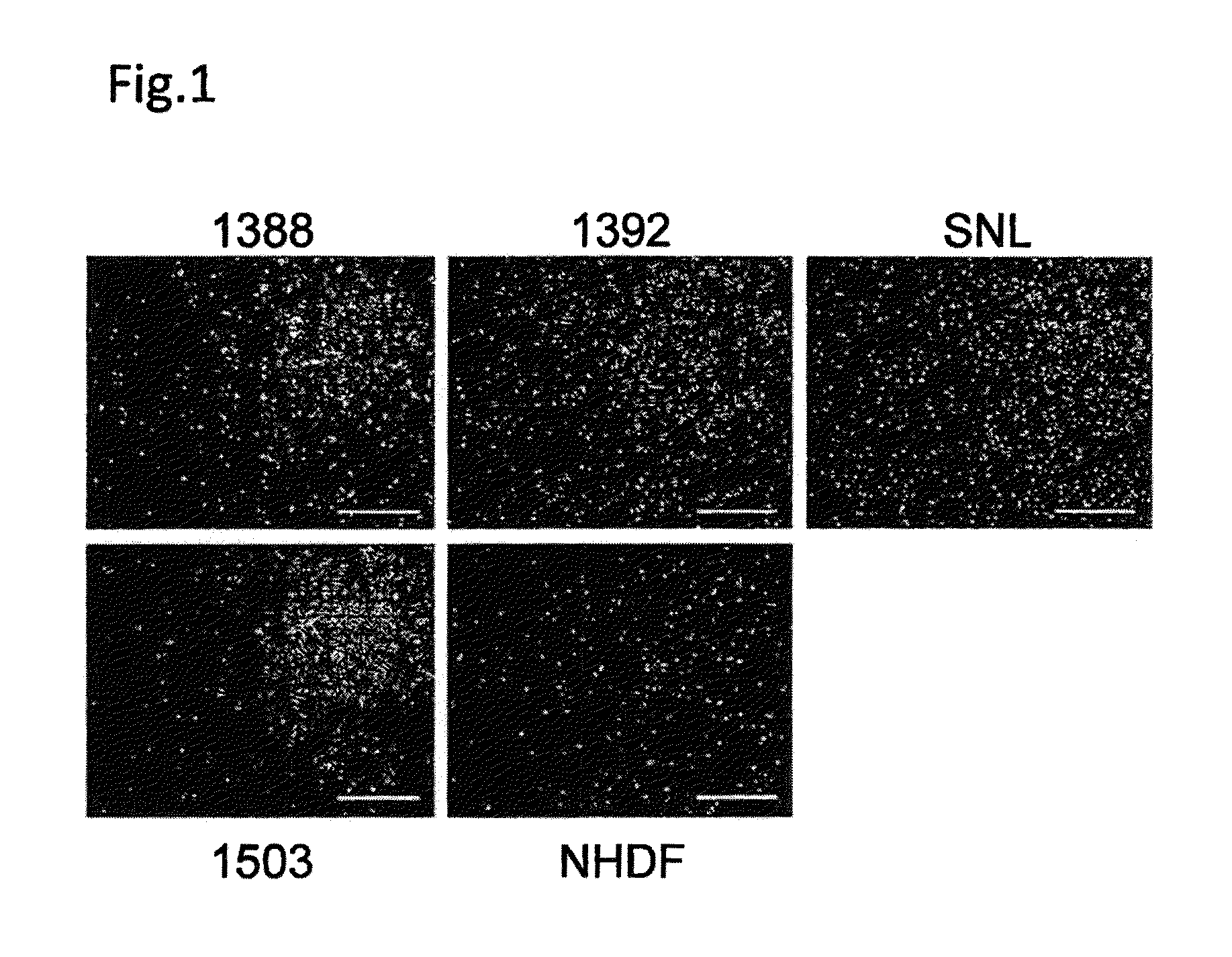

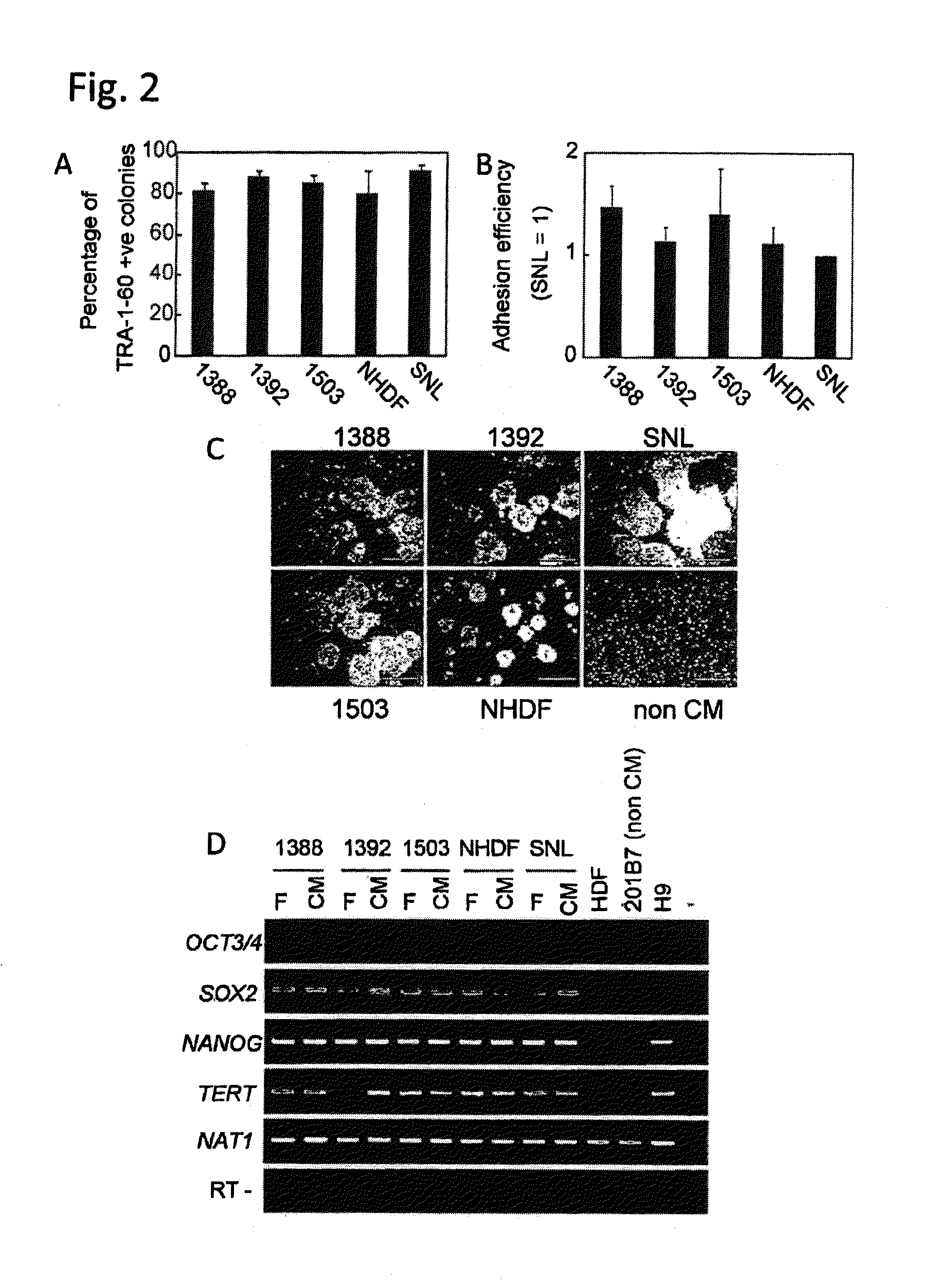

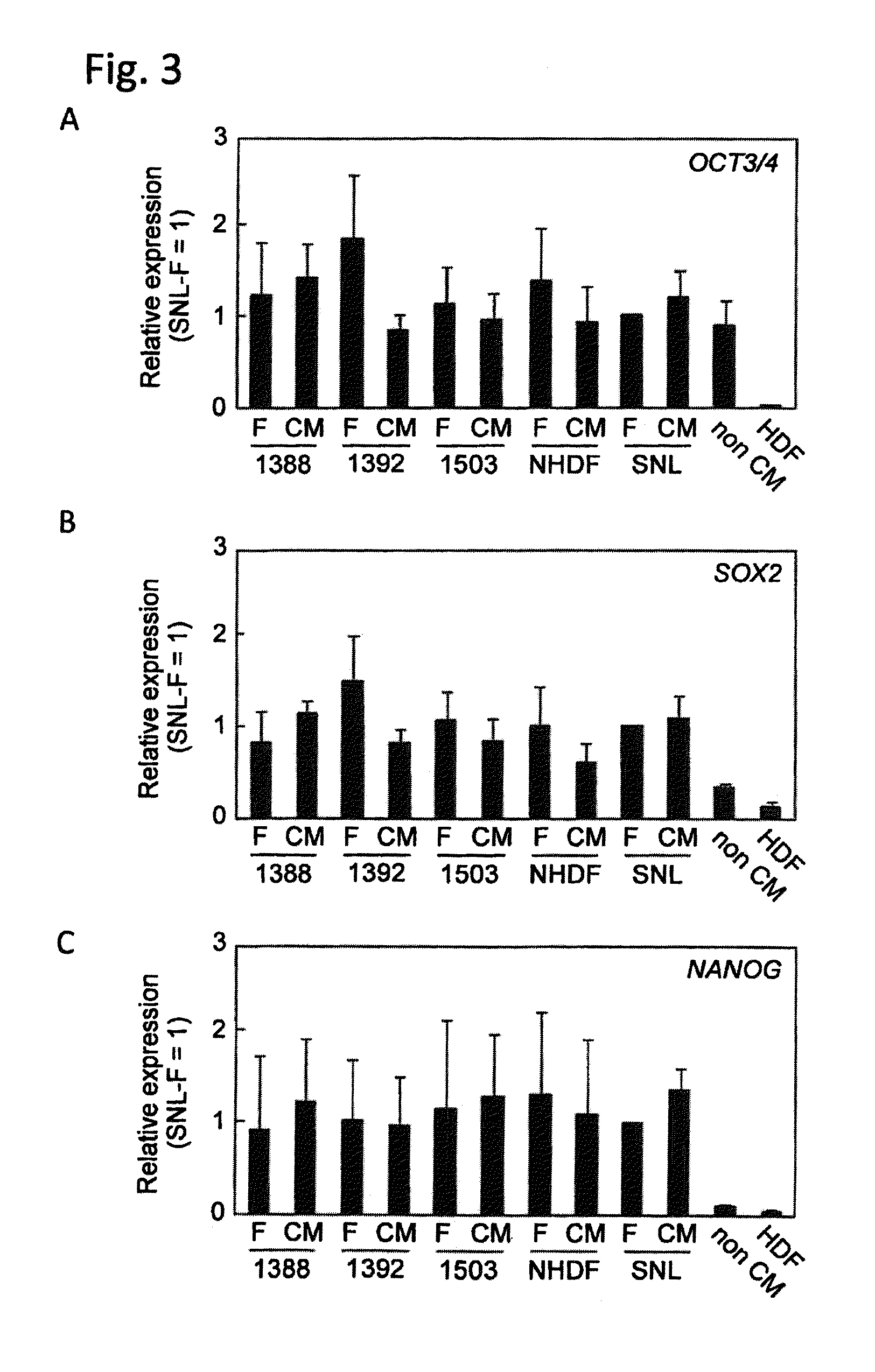

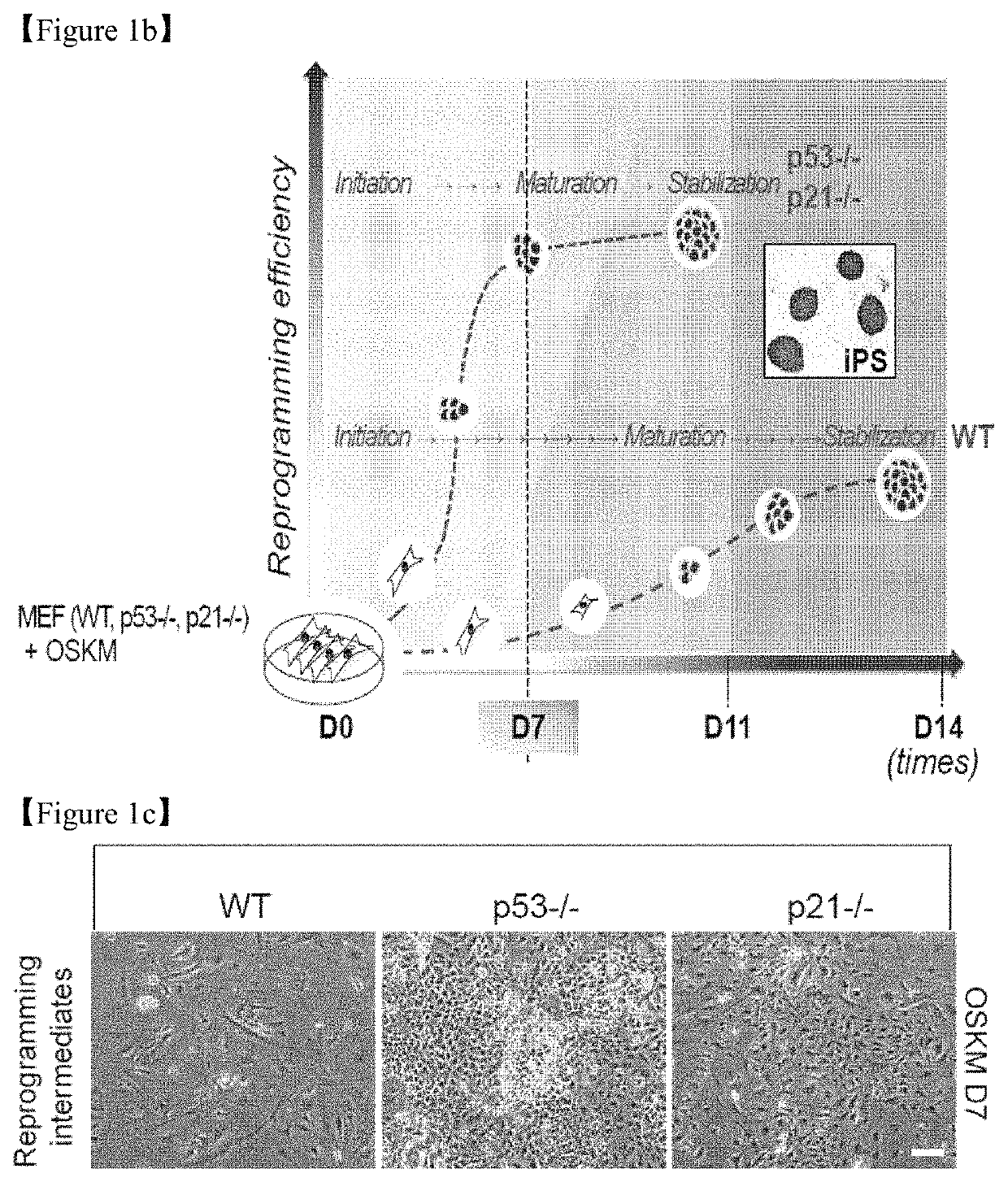

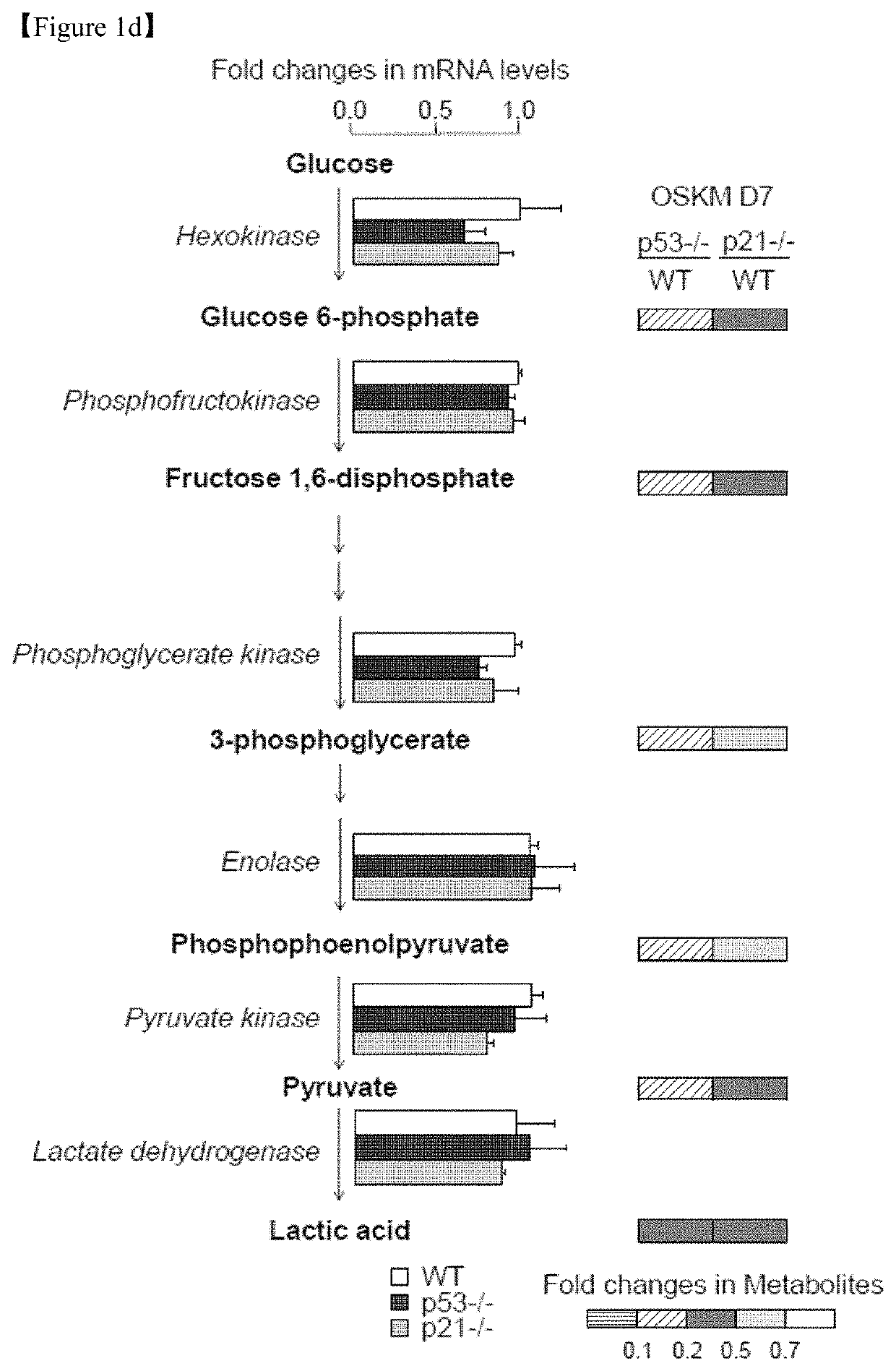

Method for producing induced pluripotent stem cells and method for culturing the same

ActiveUS9045738B2Effective trainingEffective technologyGenetically modified cellsArtificial cell constructsHuman cellSomatic cell

Induced pluripotent stem cells are produced from human somatic cells by co-culturing human somatic cells having a reprogrammed nucleus with human cells as feeder cells. Induced pluripotent stem cells are produced from somatic cells by co-culturing somatic cells having a reprogrammed nucleus with autologous cells as feeder cells. Induced pluripotent stem cells are cultured with culture supernatant of somatic cells.

Owner:KYOTO UNIV

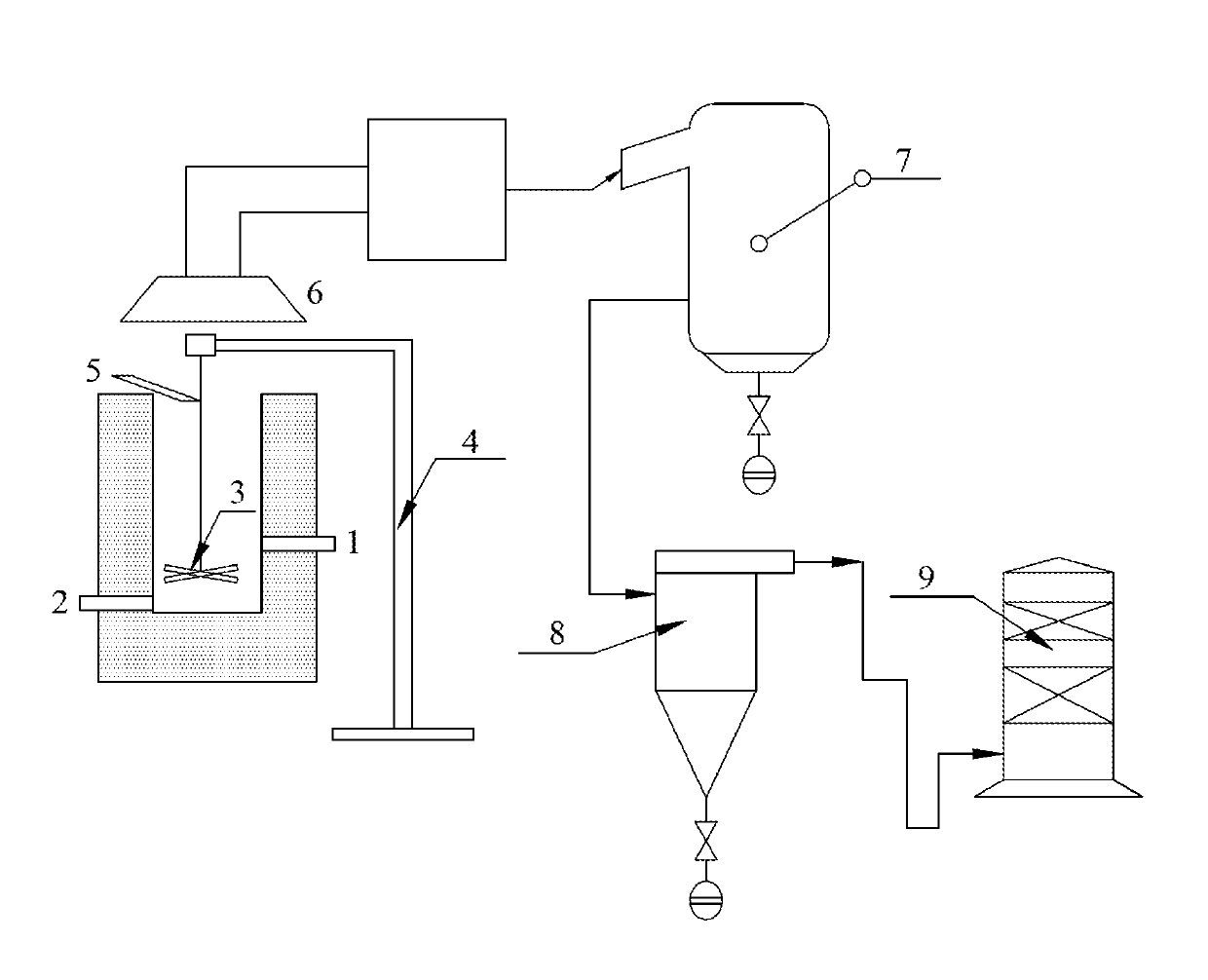

Method for ironmaking by smelting reduction in stir-generated vortex

ActiveUS20190230746A1Low utilization rateIron-containing oxides are rapidly reducedMelt circulation arrangementsCoil arrangementsMolten statePowder mixture

A method for ironmaking by smelting reduction in a stir-generated vortex includes: (1) placing a pig iron in an induction furnace, and then heating the pig iron to a molten state to form a molten iron, and maintaining the molten iron to be greater than or equal to 1450° C.; (2) stirring a center of the molten iron to form a vortex with a height-to-diameter ratio of 0.5-2.5, and continuously performing stirring; (3) mixing and grinding on an iron-containing mineral, a reducing agent and a slag-forming agent in a mass ratio of 1:(0.1-0.15):(0.25-0.4) to obtain a powder mixture, spraying and blowing the powder mixture to a center of the vortex, performing a reduction reaction, and stopping the stirring after the molten iron and molten slags are obtained, wherein a waste gas is produced; and (4) discharging the molten iron and the molten slags respectively, and exhausting a treated waste gas.

Owner:NORTHEASTERN UNIV

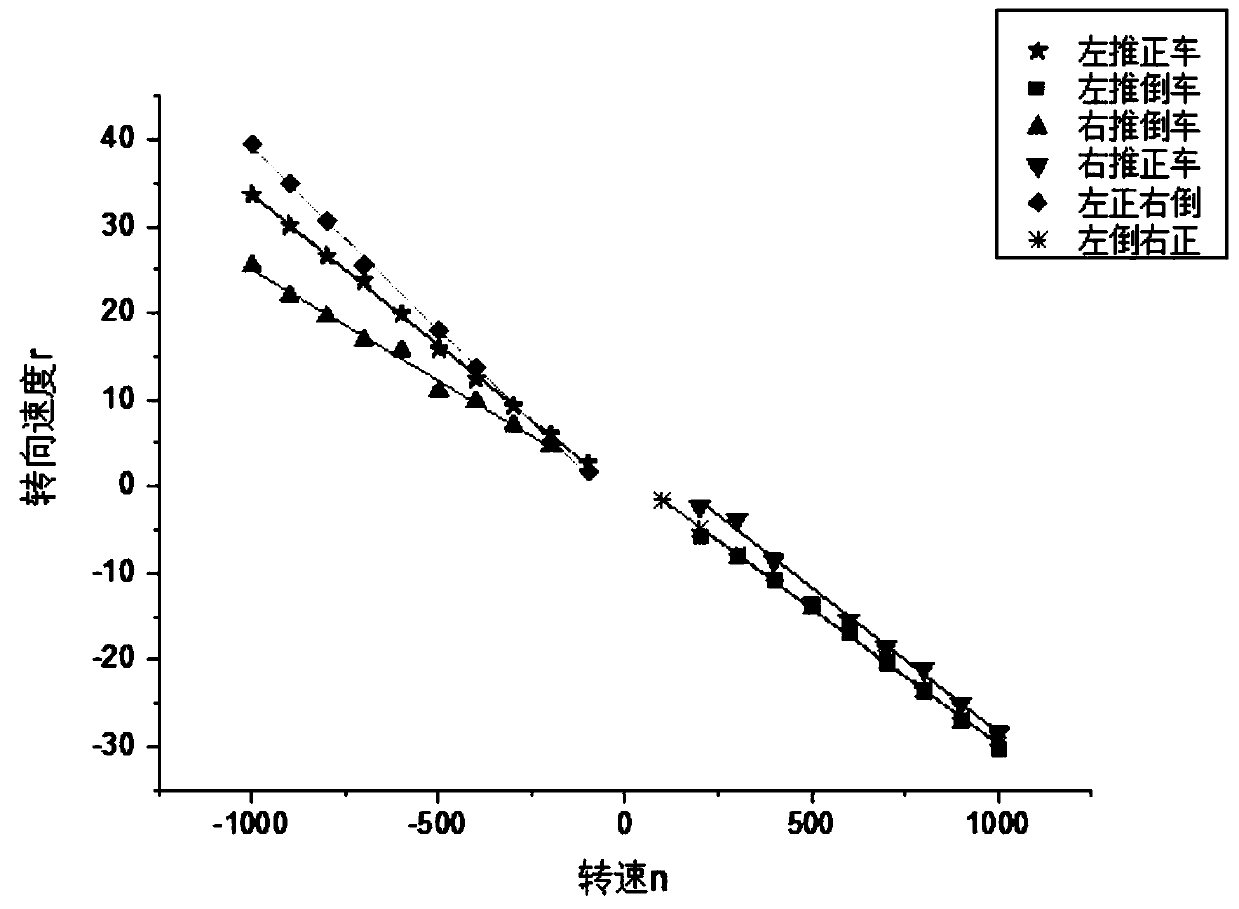

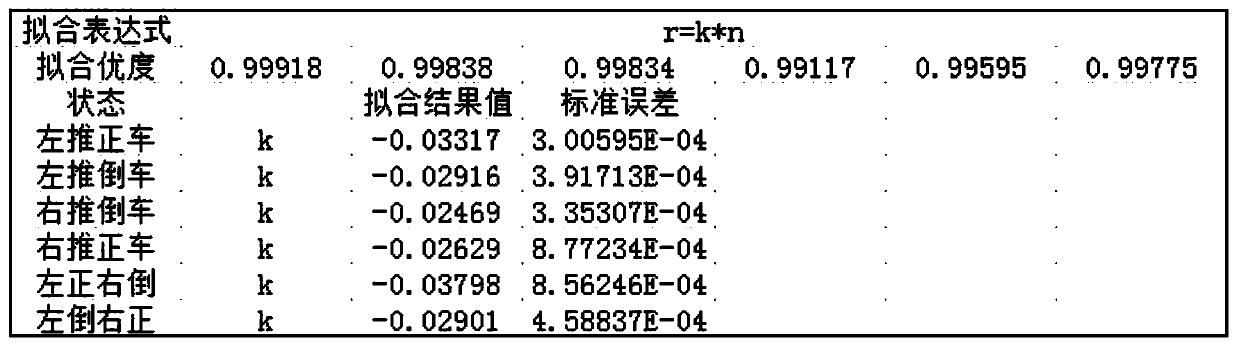

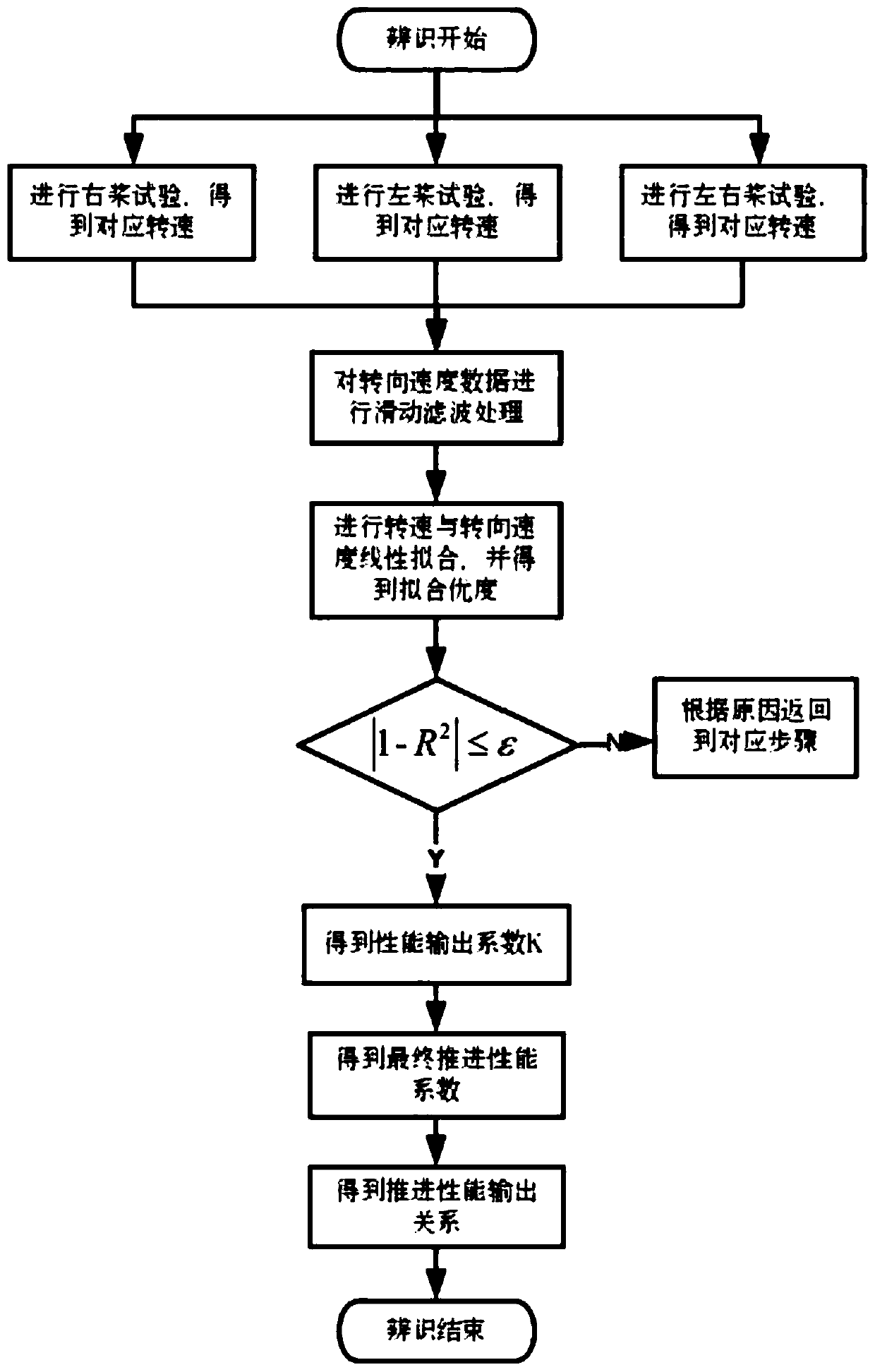

Identification method of dual-propeller propelling performance of ship

ActiveCN110077525AEffective technologyReliable technologyPropulsive elementsPerformance functionPropeller

The invention discloses an identification method of dual-propeller propelling performance of a ship. According to the identification method of the dual-propeller propelling performance of the ship, apropeller output performance function relationship is established, a dual-propeller propelling performance output relationship is obtained, a fitting function relationship r = k*n of the rotating speed and the steering speed is established, wherein k is the fitting coefficient, the propeller output performance is intuitively reflected, the fitting coefficient k in the fitting function expression of a dual-propeller performance test is utilized to express the dual-propeller propelling performance output relationship. The identification method of the dual-propeller propelling performance of theship has the beneficial effects that the propeller output performance is accurately and effectively reflected, the dual-propeller propelling performance relationship is obtained, a reliable parameterbasis is provided for navigation control, and the navigation performance of the ship is optimized.

Owner:HOHAI UNIV

Global digital framework integrated to develop economically competitive municipalities

InactiveUS20190228490A1Improve thinking processesSpeed up the processPayment architectureOffice automationDigital videoCollaborative intelligence

A global digital framework integrated by methods, systems, processes, and new thinking technologies focused on the development of secure, sustainable, collaborative, intelligent, resilient, and economically competitive municipalities. The frameworks intends to provide high quality knowledge, multimedia information, and municipal / city strategies in sectors such as education, security, energy, water, health, information technologies (IT), transportation, construction, food, environment, waste, and fmance; through the use of virtual reality technologies, algorithms, personal computer technology, big-data technologies, smart-phone technology, GPS technology, artificial intelligence systems, digital videos, behavioral change technologies, augmented reality systems, and digital advisory systems among other technologies.

Owner:PRIETO MARQUEZ RICARDO ALEJANDRO +2

Compositions comprising a mitofusin inhibitor for promoting cell reprogramming and a use thereof

ActiveUS10494611B2Improve efficiencyPromotes reprogrammingHydrolasesGenetically modified cellsMitochondrial fusionReprogramming

The present invention relates to a composition comprising a repressor of mitofusin gene expression, an inhibitor of mitofusin protein activity, or a mixture thereof as an active ingredient for promoting reprogramming a differentiated cell into a pluripotent stem cell, and a use thereof. The composition according to the present invention increases the efficiency of reprogramming as well as reduces the time required for reprogramming to produce pluripotent stem cells. Therefore, the present composition can be beneficially used to develop the production technology of high efficiency pluripotent stem cell and secure a large-scale culture system. Further, the present composition can be beneficially used to maintain pluripotent stem cells and screen the compounds capable of promoting the reprogramming into pluripotent stem cells.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com