Method for preparing hydrated sodium-cobalt-oxygen superconducting material

A technology of hydrated sodium cobalt oxide and superconducting materials, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high conducting conductors, etc. It can solve the problems of insufficient reaction between compounds, poor material performance, high reaction temperature, etc. Problems, to achieve the effect of shortening the production cycle, reducing costs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

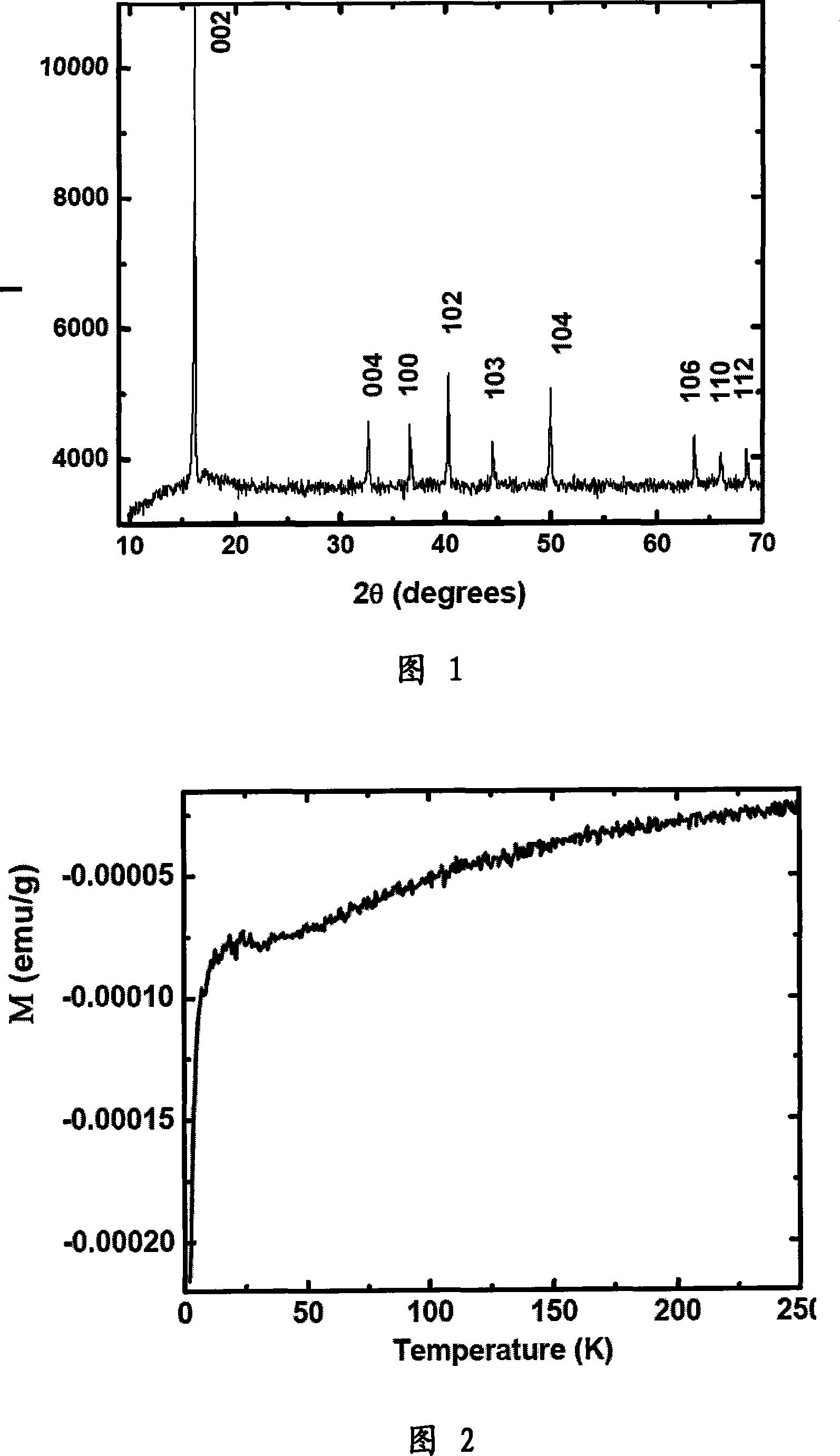

Image

Examples

Embodiment 1

[0031] A method for preparing a hydrated sodium cobalt oxide superconducting material, the steps of which are precursor preparation, oxidation and doping, and hydration in sequence. The method of precursor preparation is:

[0032] Sodium cobaltoxide Na x COO 2 , x=0.7, the stoichiometric ratio of the mol ratio Na of middle sodium, cobalt Na:Co=0.7:1 weighs raw material sodium carbonate Na 2 CO 3 with cobalt oxalate CoC 2 o 4 ), the raw materials were dissolved in 28% ammonia water for reaction, and the reacted solution was sprayed into liquid nitrogen with a nebulizer, and placed in a vacuum desiccator for lyophilization and vacuum drying to obtain a mixed powder.

[0033]First raise the temperature of the mixed powder to 300°C, keep it warm for 0.5 hours, carry out preheating and decomposition, then raise the temperature to 600°C, keep it warm for 12 hours, and carry out thermal decomposition; finally raise the temperature to 800°C, keep it warm for 18 hours for sinterin...

Embodiment 2

[0037] This example is basically the same as Example 1, the difference is only:

[0038] According to the preparation material sodium cobalt oxide NaxCoO 2 , the stoichiometric ratio of x=0.5, that is, the molar ratio Na:Co=0.5:1 Weigh the raw material Na 2 CO 3 with CoC 2 o 4 . The resulting NaxCoO 2 The chemical formula of superconducting material precursor is Na 0.5 CoO 2 . Experiments have shown that the Na prepared in this example 0.3 CoO 2 1.3H 2 The superconducting transition temperature of O superconducting material is 3.0K.

[0039] Then put the mixed powder into the concentration of 0.1mol / L bromo-acetonitrile (CH 3 CN) solution, take it out after soaking for 1 day, rinse with acetonitrile, and then rinse with deionized water for oxidation and doping. , and finally place it in water vapor for 1 day for hydration, and the hydrated sodium cobalt oxide superconducting material Na 0.3 CoO 2 1.3H 2 O.

Embodiment 3

[0041] This example is basically the same as Example 1, the difference is only:

[0042] According to the preparation material sodium cobalt oxide NaxCoO 2 , the stoichiometric ratio of x=1.0, that is, the molar ratio Na:Co=1:1 Weigh the raw material Na 2 CO 3 with CoC 2 o 4 . The chemical formula of the prepared material precursor is NaCoO 2 . Experiments have shown that the Na prepared in this example 0.3 CoO 2 1.3H 2 The superconducting transition temperature of the O superconducting material is less than 2.0K.

[0043] Then put the mixed powder into the concentration of 2mol / L bromo-acetonitrile (CH 3 CN) solution, take it out after soaking for 7 days, rinse with acetonitrile, and then rinse with deionized water for oxidation and doping. Finally, after placing it in water vapor for 5 days for hydration, the hydrated sodium cobalt oxide superconducting material Na 0.3 CoO 2 1.3H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com