High-performance water-based two-component epoxy primer and preparation method thereof

A water-based two-component, epoxy primer technology, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problem that the corrosion resistance is not as good as that of solvent-based coatings, optimize the production process, reduce product costs, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

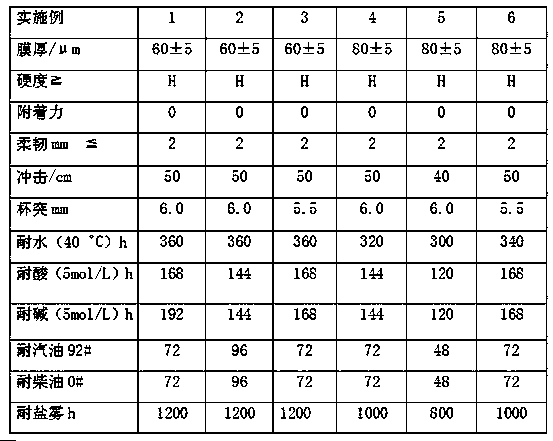

Examples

Embodiment 1

[0027] Embodiment 1: A kind of high-performance waterborne two-component epoxy primer, is made of A component and B component, and A component and B component mass ratio are 5:1,

[0028] Component A includes the following components in grams by weight: 40g of water-based epoxy resin emulsion (E-POS1011), 1g of surface additive (TEGO BYK), 15g of film-forming additive (DOW DPNB), anti-rust filler (SNCZ PZ04 ) 15g,

[0029] Anti-settling agent (HDK-H30) 2g, adhesion promoter (BYK5413) 1g, thickener (PUR60) 1g, pigment (R706 MA-100) 15g, deionized water 10g;

[0030] Component B includes the following components in grams by weight: Aliphatic amine curing agent (Q-RIT1701) 64 g,

[0031] Anti-flash rust additive (179) 5 g, deionized water 3 l.

[0032] A kind of preparation method of above-mentioned high-performance waterborne two-component epoxy primer, comprises the steps:

[0033] The first step: Group A preparation:

[0034] Step 1) In the dispersing equipment, ensure tha...

Embodiment 2

[0041] Embodiment 2: A high-performance water-based two-component epoxy primer, the mass ratio of component A and component B is 5:1.

[0042] Component A includes the following components in grams by weight: water-based epoxy resin emulsion (EXA8420) 50g, surface additive (TEGO BYK ) 1g, film-forming additive (DOW DPNB) 10g, anti-rust filler (SNCZ PZ04) 10g , anti-settling agent (AQE600) 2g, adhesion promoter (BYK5413) 1g, thickener (105A) 1g, pigment (190) 15g, deionized water 10g.

[0043] Component B includes the following components in grams by weight: Aliphatic amine curing agent (WN-720Z) 70 g,

[0044] Anti-flash rust additive (X-150) 5 g, deionized water 25 g.

[0045] Preparation method is with embodiment 1.

Embodiment 3

[0046] Embodiment 3: A kind of high-performance water-based two-component epoxy primer, the mass ratio of A component and B component is 5:1.

[0047] Component A includes the following components in grams by weight: water-based epoxy resin emulsion (AR555) 55g, surface additive (TEGO BYK ) 1g, film-forming additive (DOW DPNB) 5g, anti-rust filler (NUBIROX106) 15g, Anti-settling agent (HDK-H30) 2g, adhesion promoter (HMB-F) 1g, thickener (WT105A) 1g, pigment (R706 MA-100) 10g, deionized water 10g.

[0048] Component B includes the following components in grams by weight: Aliphatic amine curing agent (BANCO901) 65 g,

[0049] Anti-flash rust additive (X-150) 5 g, deionized water 30 g.

[0050] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com