Single-face metallic waveguide Terahertz quantum cascaded laser and production method thereof

A technology of quantum cascade and fabrication method, applied in semiconductor lasers, lasers, phonon exciters, etc., can solve the problems of infeasible lasers, the substrate cannot act as a mode confinement layer, and it takes a long time to shorten the fabrication time. The effect of time, pollution reduction, and manufacturing process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

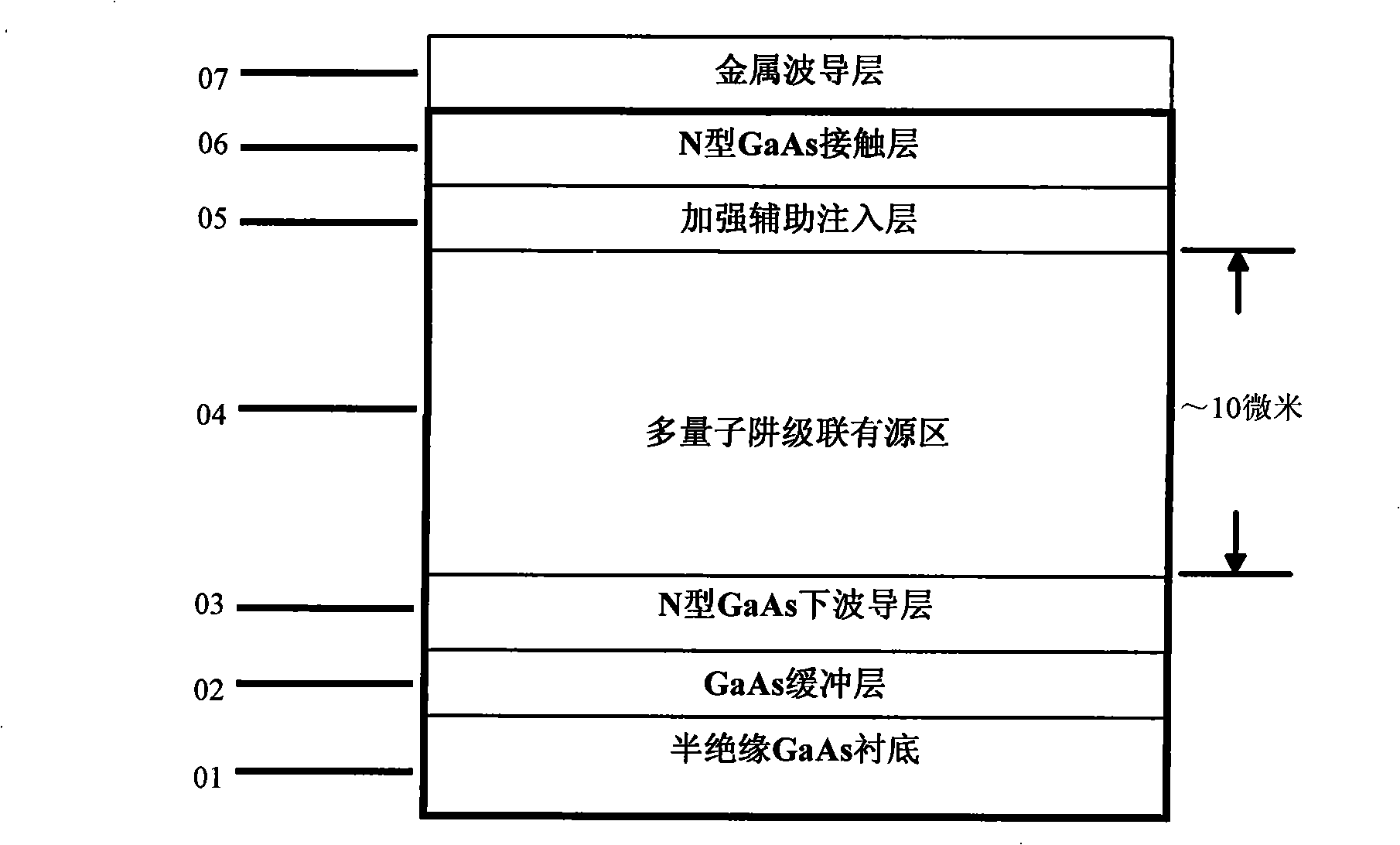

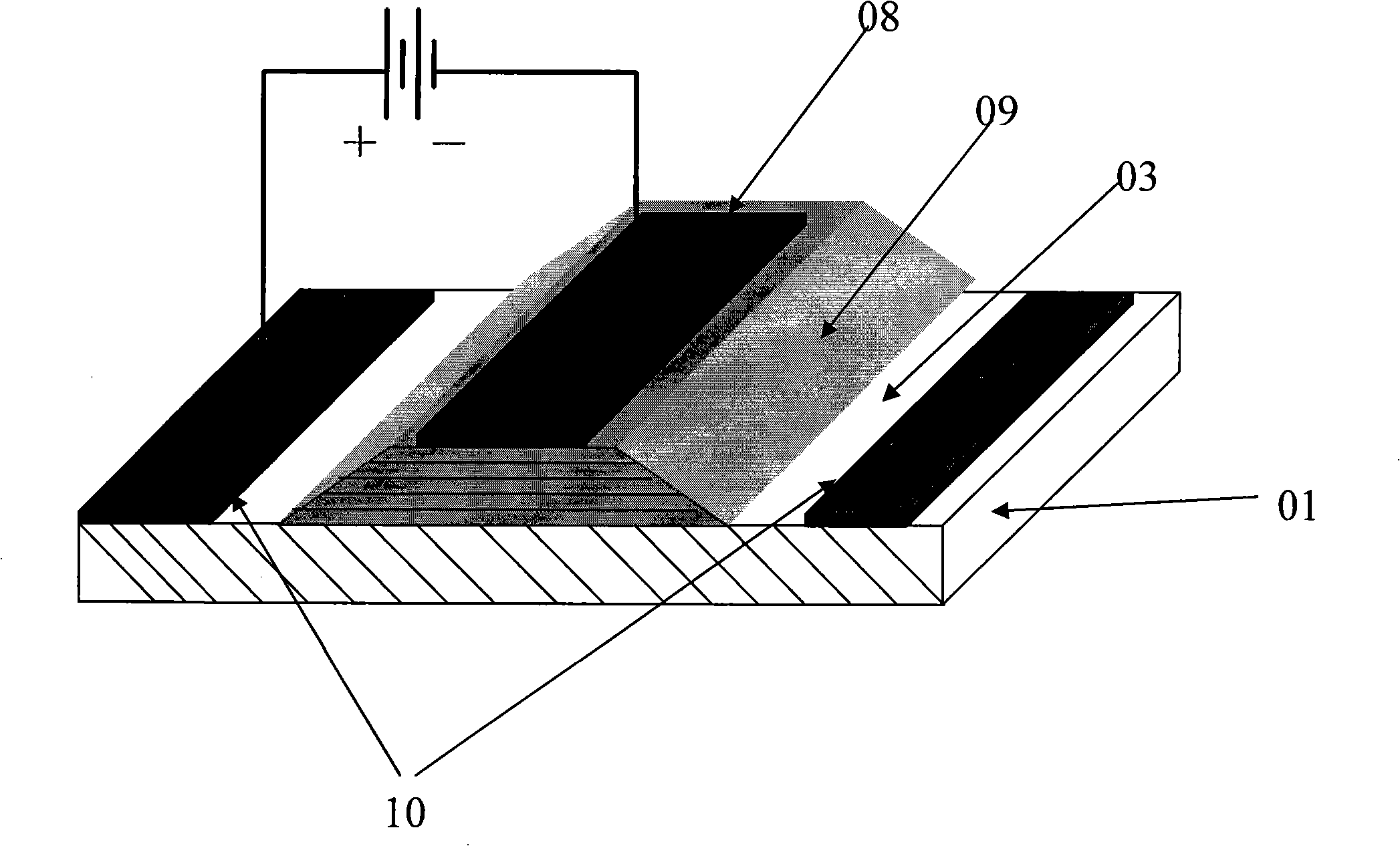

[0020] see figure 1 The waveguide structure of the single-sided metal waveguide terahertz quantum cascade laser of the present invention mainly includes: a semi-insulating GaAs substrate 01, a GaAs buffer layer 02 grown on the semi-insulating GaAs substrate, and a GaAs buffer layer grown on the GaAs buffer layer The upper N-type GaAs lower waveguide layer 03, the multi-quantum well cascade active region 04 grown on the lower waveguide layer and used to emit terahertz light, grown on the multi-quantum well cascade active region and The reinforced auxiliary injection layer 05 for enhancing the electrical injection of the multi-quantum well cascaded active region, the N-type GaAs contact layer 06 grown on the reinforced auxiliary injection layer, and the metal waveguide grown on the contact layer Layer 07.

[0021] Wherein, the multi-quantum well cascaded active region has multiple repeating periods, and there are multiple layers of AlGaAs / GaAs alternating layers in each period,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com