Patents

Literature

292 results about "Ferrite pearlite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

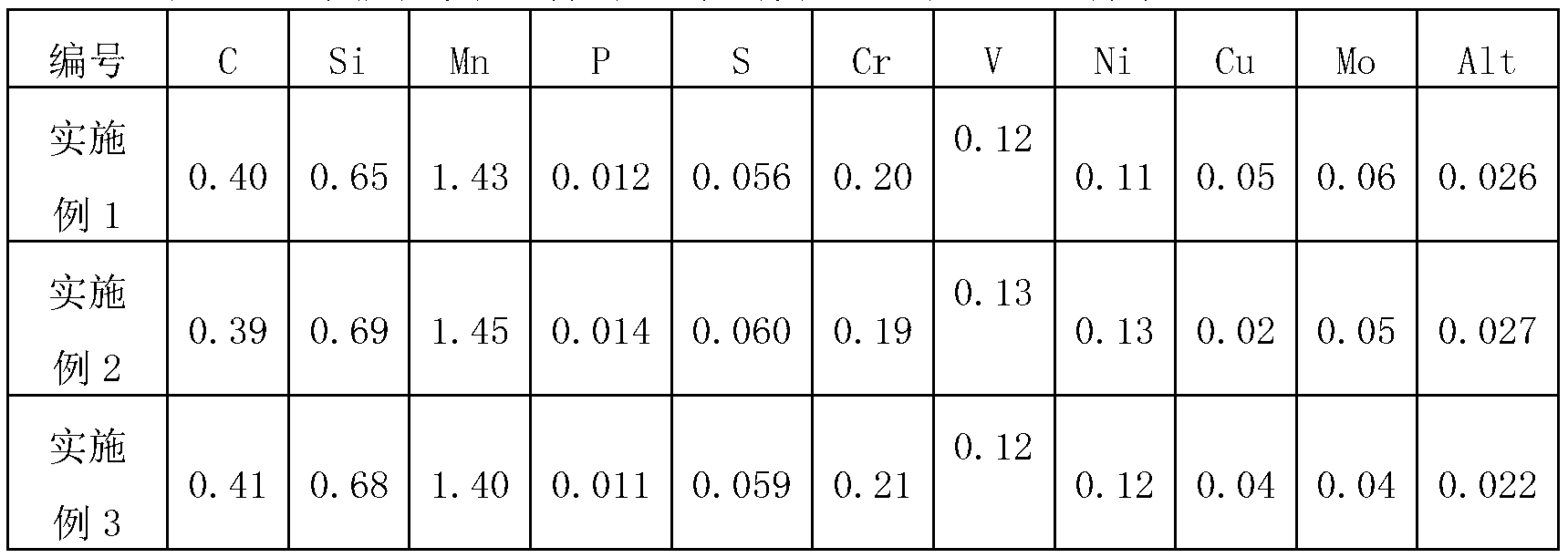

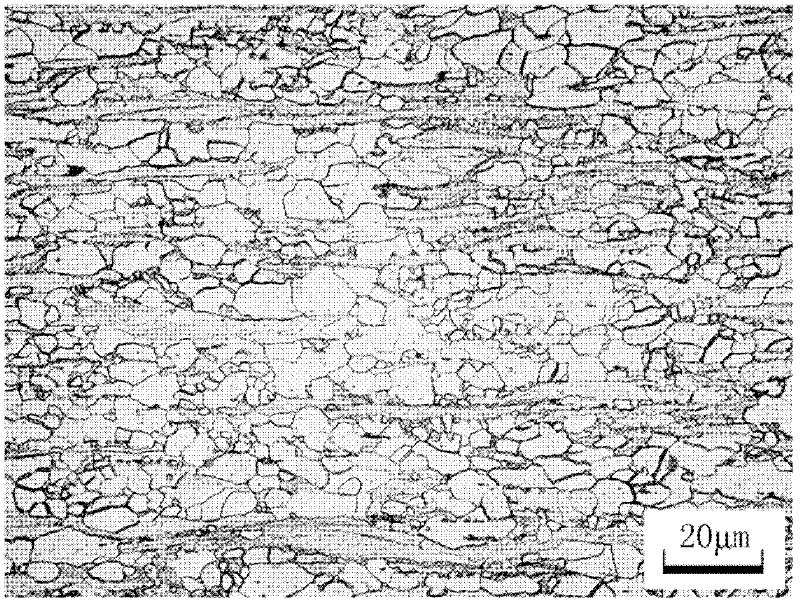

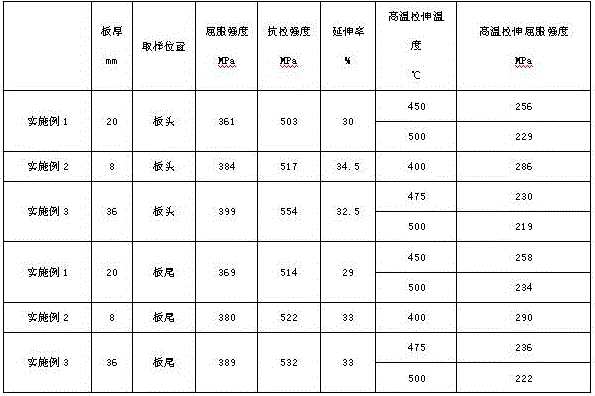

Medium-carbon ferrite-pearlite non-quenched and tempered steel and manufacturing method thereof

ActiveCN103266287AHigh strengthImprove toughnessTemperature control deviceProcess efficiency improvementQuenchingToughness

The invention relates to a medium-carbon ferrite-pearlite non-quenched and tempered steel which comprises the following components in percentage by weight: 0.35-0.43% of C, 0.30-0.80% of Si, 1.00-1.60% of Mn, 0.10-0.30% of Cr, 0.06-0.20% of V, 0.10-0.30% of Ni, at most 0.035% of P, 0.040-0.075% of S, 0.010-0.060% of Alt, 100-200*10<-4>% of N, and the balance of Fe and inevitable impurities. The medium-carbon ferrite-pearlite non-quenched and tempered steel has the characteristics of high strength and high toughness, and the plasticity of the hot rolled steel can still achieve the level of 40Cr or 40MnB quenched and tempered steel under the condition of no quenching and tempering treatment. The invention also relates to a manufacturing method of the medium-carbon ferrite-pearlite non-quenched and tempered steel.

Owner:LAIWU IRON & STEEL GRP

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

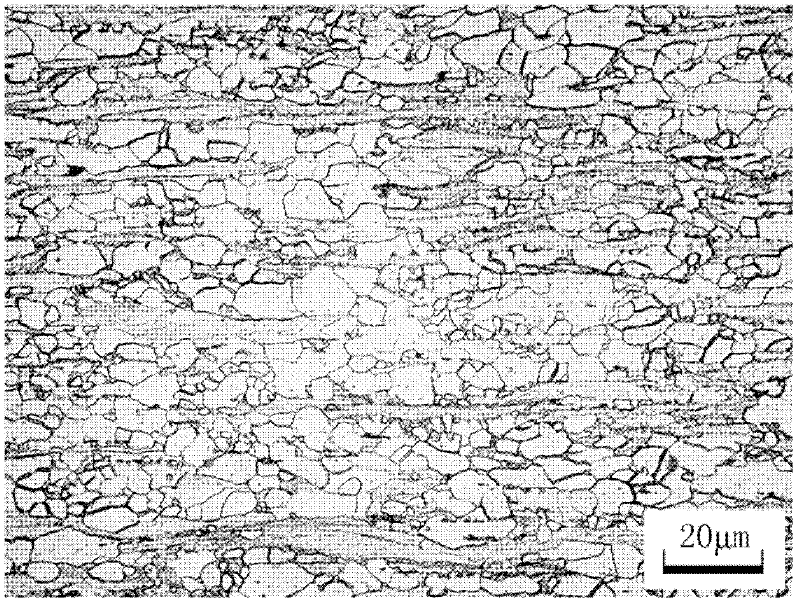

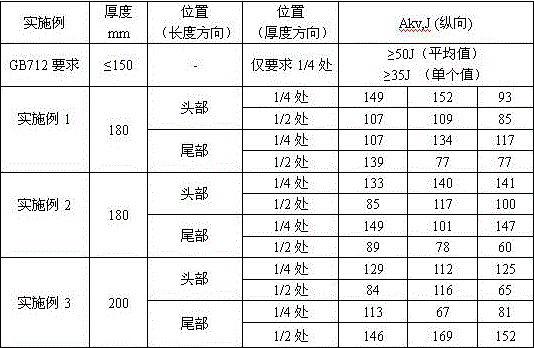

Normalized-condition delivered 180-200mm-thick EH36 steel plate and preparation method thereof

ActiveCN105839003ALow costLow carbon equivalentProcess efficiency improvementSlow coolingMechanical property

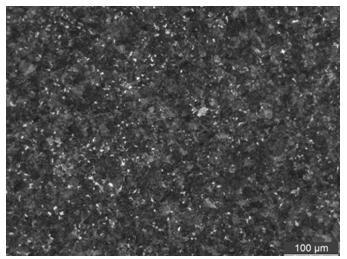

The invention relates to a normalized-condition delivered 180-200mm-thick EH36 steel plate and a preparation method thereof. Chemical components of the steel plate are based on the national standards GB712 or the classification society rule, wherein Al is utilized to substitute an element Ti while V with relatively high content is added. The preparation method comprises the following steps: electric furnace smelting, LF refining, VD refining, die casting, steel ingot heating, break-down rolling, controlled slow cooling, steel billet heating, rolling, normalizing treatment and the like, which are sequentially carried out. The obtained steel plate does not have an obvious gradient structure in a thickness direction, and the structure of the steel plate is mainly a mixed mixture which comprises ferrite pearlite supplemented by little bainite. A microscopic structure is fine and uniform, an average crystal size is 8-12 mum, yield strength ranges from 380 MPa to 430 MPa, tensile strength ranges from 550 MPa to 600 MPa, and ductility is proper. The steel plate has an impact toughness value greater than or equal to 60 J at a temperature of 40 DEG C at a 1 / 4 part and a 1 / 2 part, and has excellent comprehensive mechanical property.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

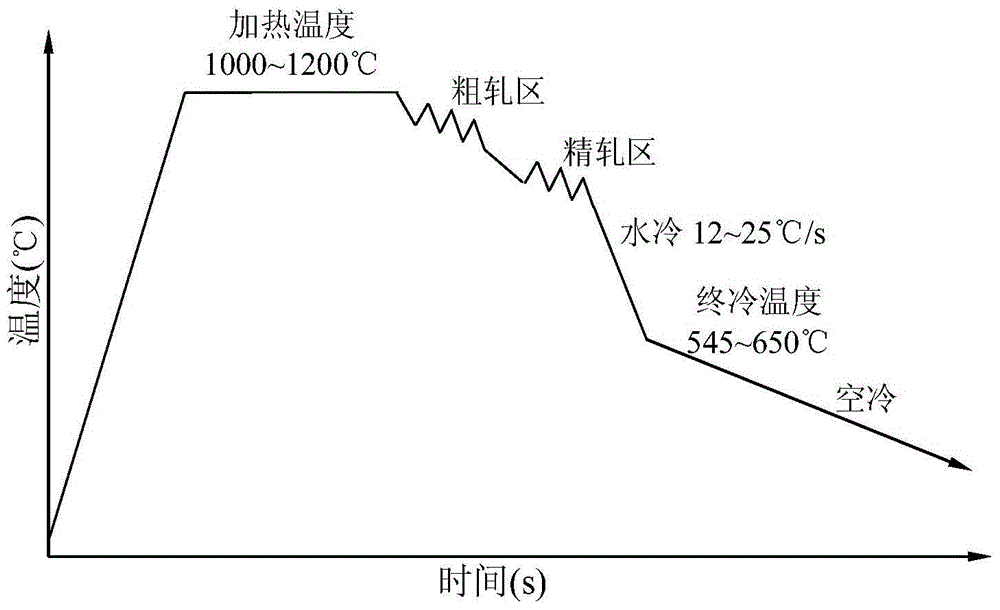

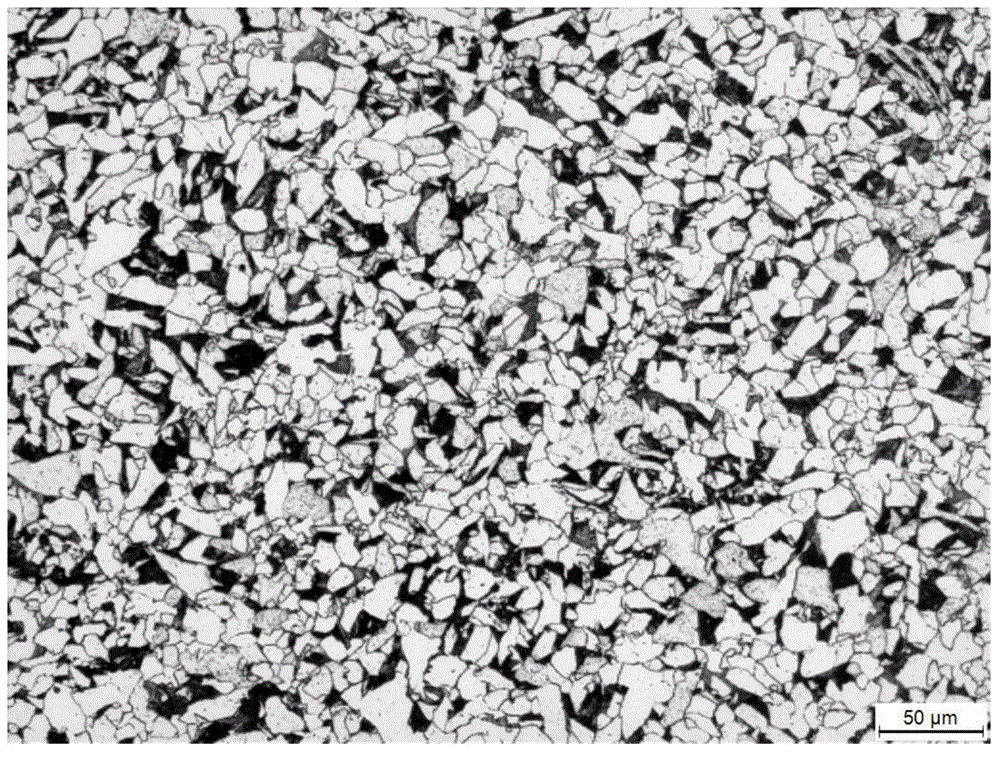

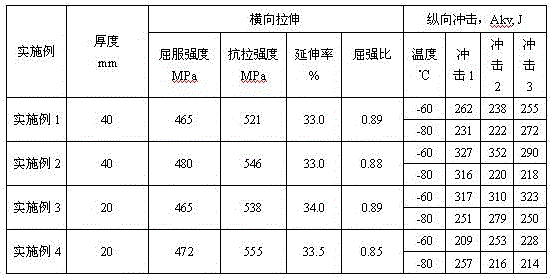

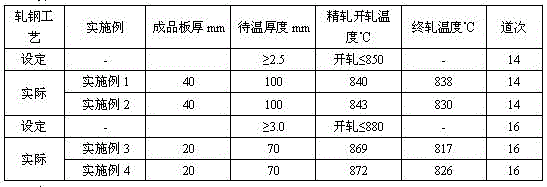

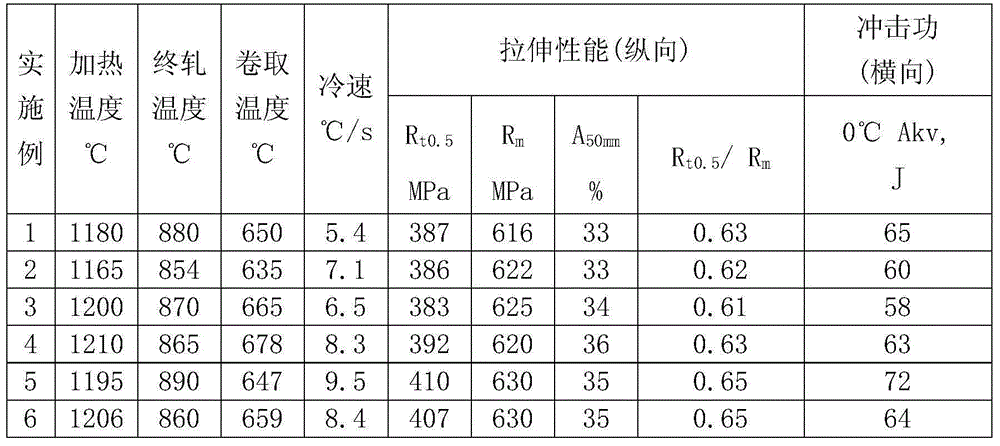

V-N microalloyed Q550 grade medium plate and preparation method thereof

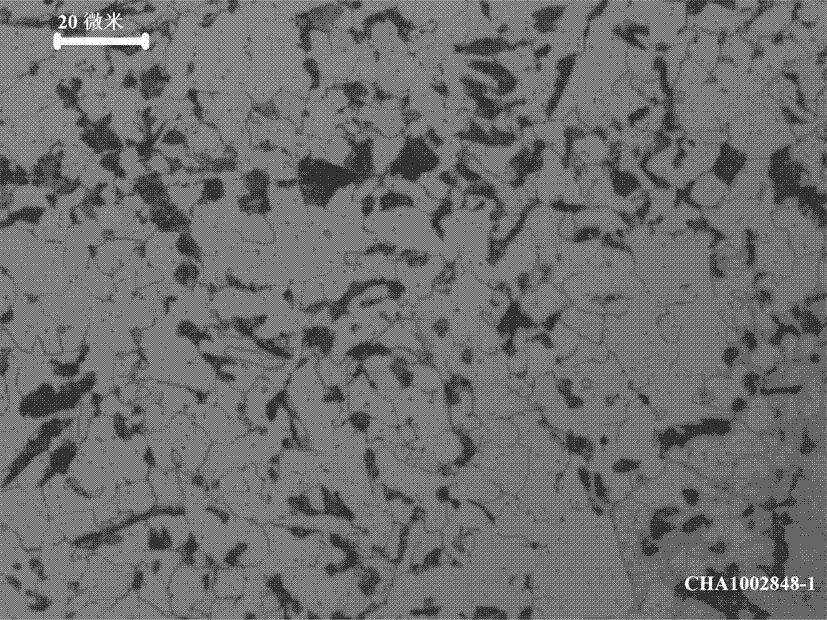

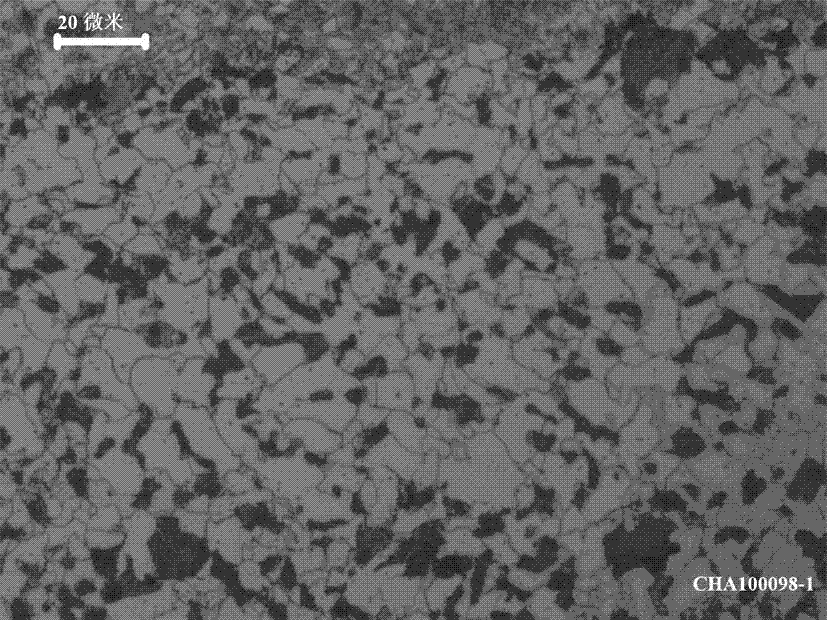

The invention aims at providing a V-N microalloyed Q550 grade medium plate and a preparation method thereof which are specific to the condition that in the prior art, the Q550 grade medium plate expensive alloy is in large consumption and the preparation process is complex. The chemical constitutions of the steel are as follows by weight percentage: 0.06 to 0.12 percent of C, 1.20 to 2.00 percent of Mn, 0.10 to 0.50 percent of Si, 0.002 to 0.01 percent of S, 0.003 to 0.01 percent of P, 0.01 to 0.05 percent of Al, 0.06 to 0.15 percent of V, 0.01 to 0.02 percent of N and the balance of Fe and other unavoidable impurities; the preparation method comprises the steps of heating a steel billet to 1000 to 1200 DEG C along with a furnace and performing heat preservation for 3 to 4 hours, and further carrying out hot rolling on the steel billet to form a hot rolled plate being 20 to 50mm in thickness, wherein the beginning temperature and the finishing temperature in a rough rolling stage are respectively 1030 to 1150 DEG C and 980 to 1020 DEG C, and the beginning temperature and the finishing temperature in a finish rolling stage are respectively 908 to 925 DEG C and 820 to 845 DEG C; cooling the plate by water to 545 to 650 DEG C after the hot rolling, and then cooling by air to room temperature. The plate is a high-toughness ultra-low-carbon medium-manganese medium plate, and the metallographic structure of the plate is a fine crystalline ferrite, a pearlite and an acicular ferrite; the method is simple in operation process, has no need of quenching and tempering treatment, and is easy to realize industrial production.

Owner:NORTHEASTERN UNIV LIAONING

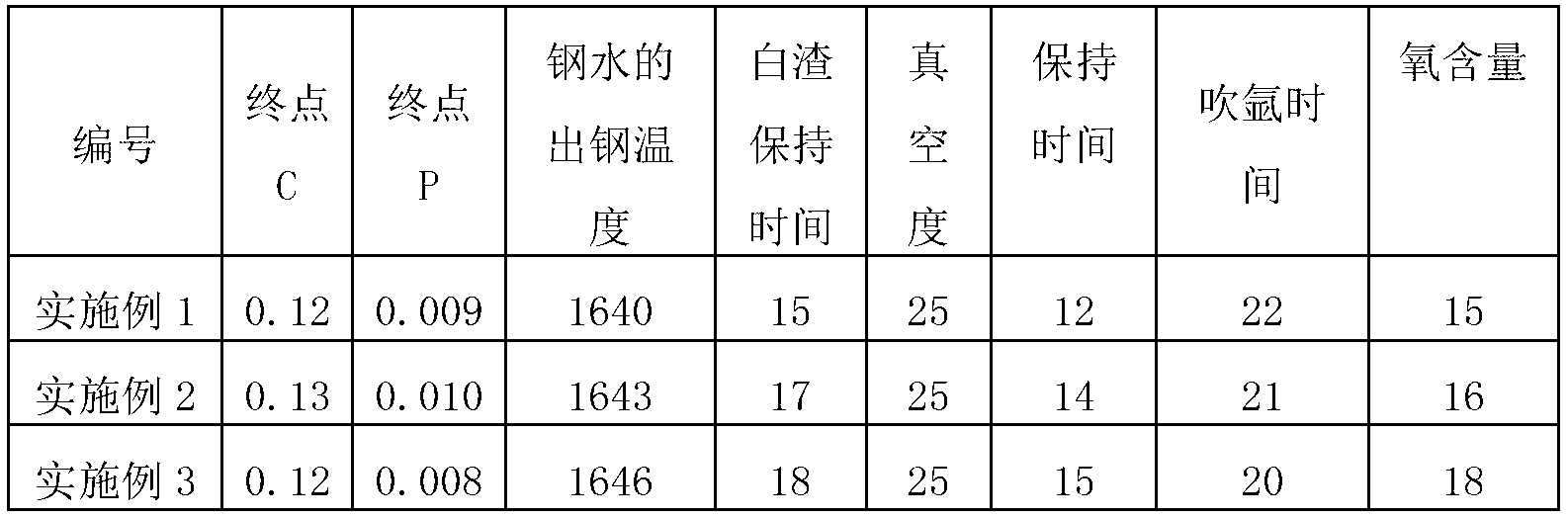

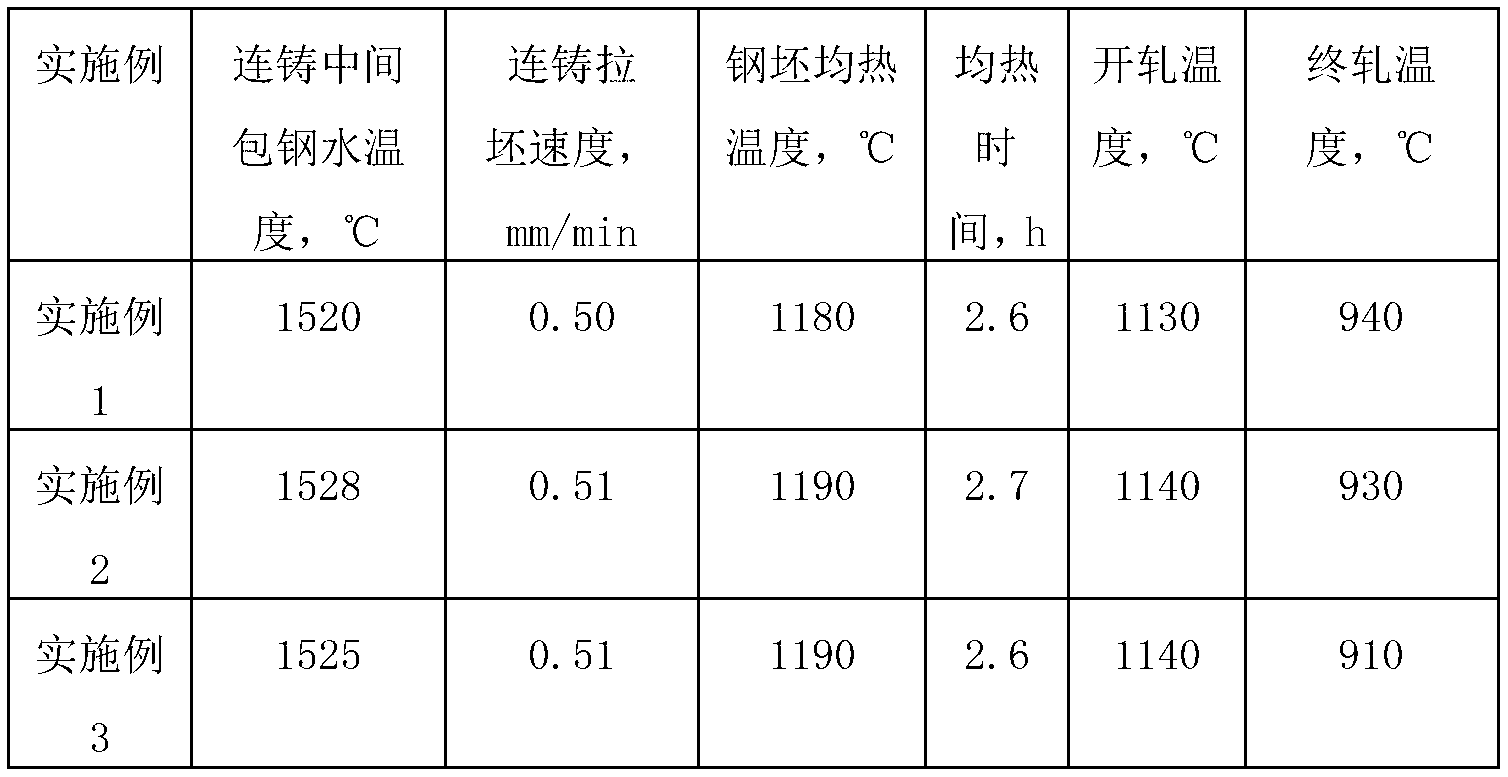

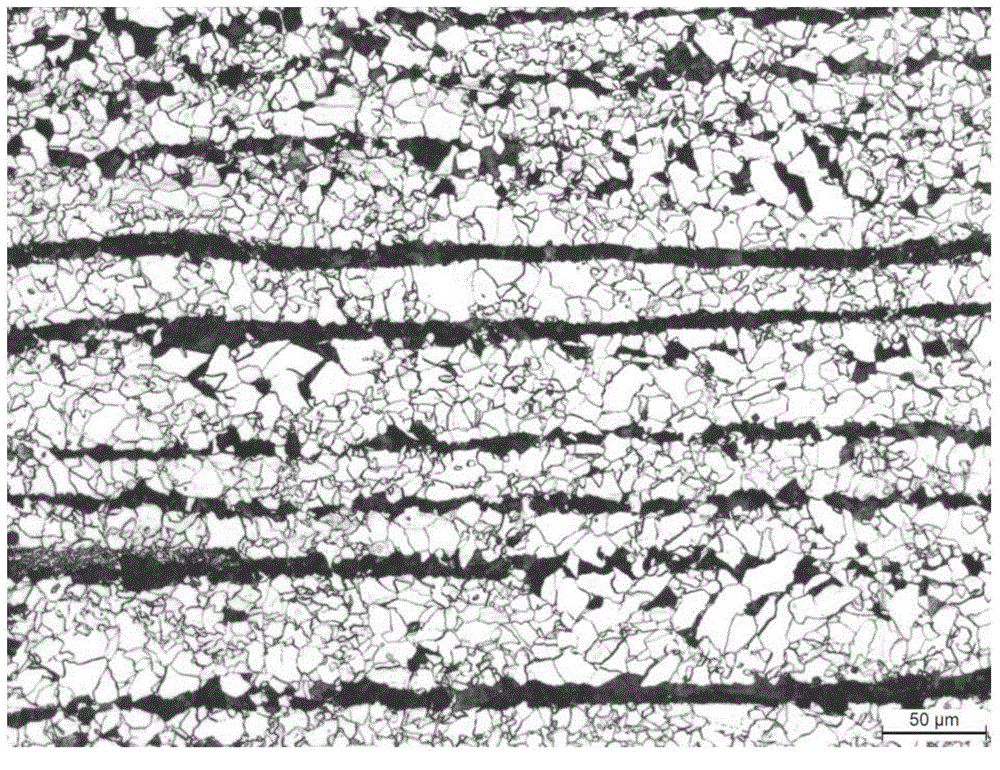

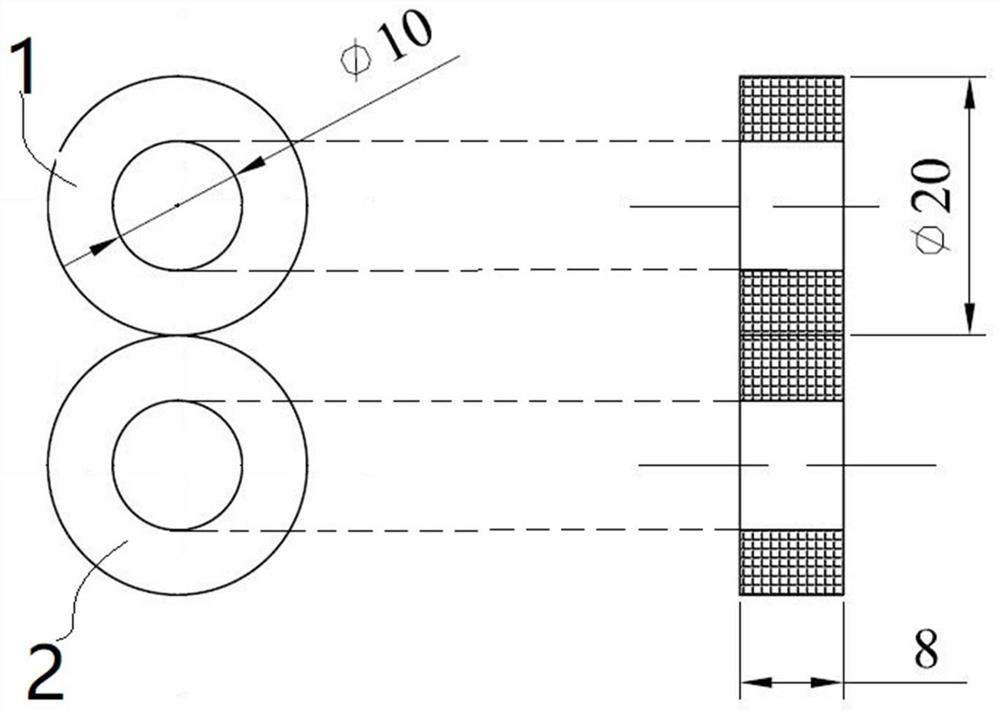

Control method of toothed wheel steel band structure

ActiveCN101381803AMeet needsControl or lighten banding levelsTemperature control deviceHeat treatment process controlBand shapeSteel bar

The invention relates to a method for controlling a strip tissue of pinion steel, which belongs to the technical field of the tissue of the pinion steel. The method adopts the following process flow for producing a continuous casting billet of the pinion steel: the pretreatment of molten iron, primary smelting in a converter, refining in a ladle refining furnace or refining in the ladle refining furnace and a vacuum degassing furnace, and continuous casting; the steel billet is heated and is subjected to continuous rolling through 20 short stress line high-rigidity closed-type red ring rolling machines; and different final rolling temperatures are respectively controlled to produce a hot-rolled round steel bar material in order that the level of a steel ferrite and pearlite strip tissue is less than or equal to 2.5. The method has the advantages that different specifications and different final rolling temperatures of the rolled steel are controlled by cooling and other means to realize the aim of enlightening the level of the strip tissue by the steel material with Phi of between 14 and 80 mm<2>. By effectively controlling the level of the strip tissue, the method can meet the requirement of a user on the high-quality pinion steel and improve the qualification rate of the quality of the high-quality pinion steel.

Owner:SHOUGANG CORPORATION

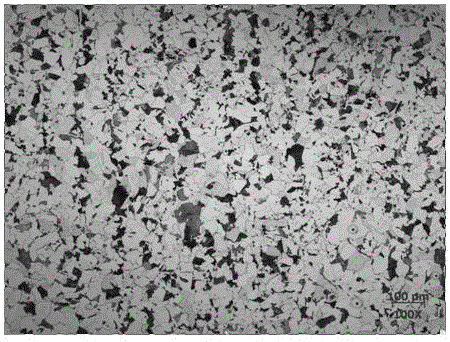

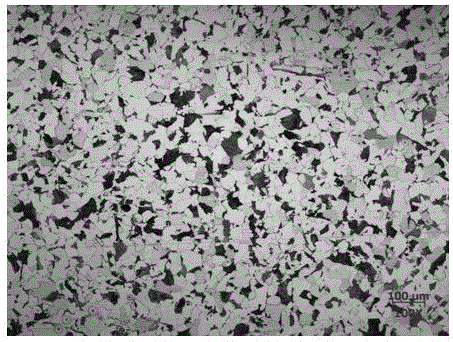

Steel and manufacturing method for Ca microalloying free-cutting high-strength expansion-breaking connecting rod

InactiveCN106939391AImprove breaking performanceReduce cutting actionChemical compositionHigh intensity

The invention relates to steel for a Ca microalloying free-cutting high-strength expansion-breaking connecting rod. The steel is prepared from, by mass percent, 0.25%-0.60% of C, 0.10%-1.20% of Si, 0.40%-1.50% of Mn, 0.05%-0.50% of Cr, 0.02%-0.15% of S, 0.02%-0.15% of P, 0.03%-0.55% of V, 0.0005%-0.0080% of Ca, 0.002%-0.035% of N, 0.002%-0.080% of Al, not larger than 0.02% of Ti and the balance Fe and inevitable impurity elements. The steel is subjected to smelting, continuous casting, heating, hot rolling and cooling, and the structure characteristic is uniform ferrite and pearlite. According to the steel, key elements in the steel are optimized, Ca microalloying is especially adopted, and the steel for the expansion-breaking connecting rod with high strength, good cutting machinability, good expansion-breaking performance and excellent comprehensive performance is obtained, and the design requirements for engine light weight, economical efficiency and driving comfort are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Air cooling hardened spring steel with high obdurability, low-medium-carbon and microalloy and forming and heat treatment process thereof

ActiveCN105112774AAvoid the many disadvantages of quenchingSave energyChemical compositionSpring steel

The invention discloses an air cooling hardened spring steel with high obdurability, low-medium-carbon and microalloy and a forming and heat treatment process thereof. Existing spring steel is high in cost due to components. The air cooling hardened spring steel with the high obdurability, low-medium-carbon and the microalloy comprises, by weight, 0.15%-0.50% of C, 0.30%-2.00% of Si, 0.60%-2.50% of Mn, 0-0.020% of S, 0-0.025% of P, 0.0005% ~ 0.0035% of B, and the balance Fe. After the steel is heated to 900-1500 DEG C and the temperature is kept, metallographic structure containing the major bainite and martensite, a small amount of retained austenite, and no other non-martensitic structures (free ferrite, pearlite and upper bainite) can be obtained by adopting controlled cooling. Then properties can be further improved through low temperature tempering treatment; material mechanical property Rm>=1350 MPa; yield strength Rp0.2>=1050MPa; percentage elongation after fracture A>=10%; section shrinkage Z>=35%. The air cooling hardened spring steel with the high obdurability, the low-medium-carbon and the microalloy is adopted, so that the manufacturing process of springs is simplified, energy is saved, and cost is reduced.

Owner:ZHEJIANG MEILI HIGH TECH

Polar region ship steel plate capable of high heat input welding and making method for same

The invention relates to a polar region ship steel plate capable of high heat input welding. The steel plate comprises the following chemical components in percentage by mass: 0.03-0.07% of C, 0.15-0.30% of Si, 1.10-1.50% of Mn, less than or equal to 0.070% of P, less than or equal to 0.0030% of S, 0.008-0.020% of Ti, 0.0030-0.0060% of N, 0.10-0.30% of Cu, 0.10-0.40% of Ni, 0.010-0.040% of Nb, 0.020-0.050% of Al and the balance of Fe; the matrix structure of the steel plate is ferrite and pearlite; the pearlite is dispersedly distributed among the ferrite crystalline grains; and the size of the ferrite crystalline grains is 4-8 mu m. The steel plate has excellent 60-80 DEG C low-temperature impact toughness and low-temperature strain ageing resistance; and the welding performance is excellent through high-efficient welding of highest heat input of 200 KJ / cm.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Production method of steel plate for heavy-gauge pressure vessel

The invention discloses a steel plate for a heavy-gauge pressure vessel, and a preparation method thereof. Chemical components of the steel plate for the heavy-gauge pressure vessel are obtained through melting the following components, by weight, 0.15-0.18% of C, 0.25-0.50% of Si, 1.50-1.60% of Mn, 0.020% or less of P, 0.012% or less of S, 0.030-0.050% of Nb and 0.020-0.050% of Al; and the steel plate structure is a ferrite and pearlite structure. The design of the chemical components of the steel plate of the invention is characterized in that low price C and Mn are adopted for solution strengthening, small amounts of alloy elements are added, and water cooling is adopted after normalizing to accelerate cooling to make the steel plate have excellent mechanical performances, a uniform structure, good comprehensive performances and welding performances, and an enhanced market competitiveness. The steel plate has the following advantages: 1, the mechanical performances are good, and the yield strength and the tensile strength are largely higher than thinner specification performance indexes; 2, the low temperature impact energy is high, and the impact energy at -20DEG C is above 180J; and the largest thickness of the steel plate can reach 78mm.

Owner:WUYANG IRON & STEEL +1

60kg-level low-cost and high-toughness steel plate and production method thereof

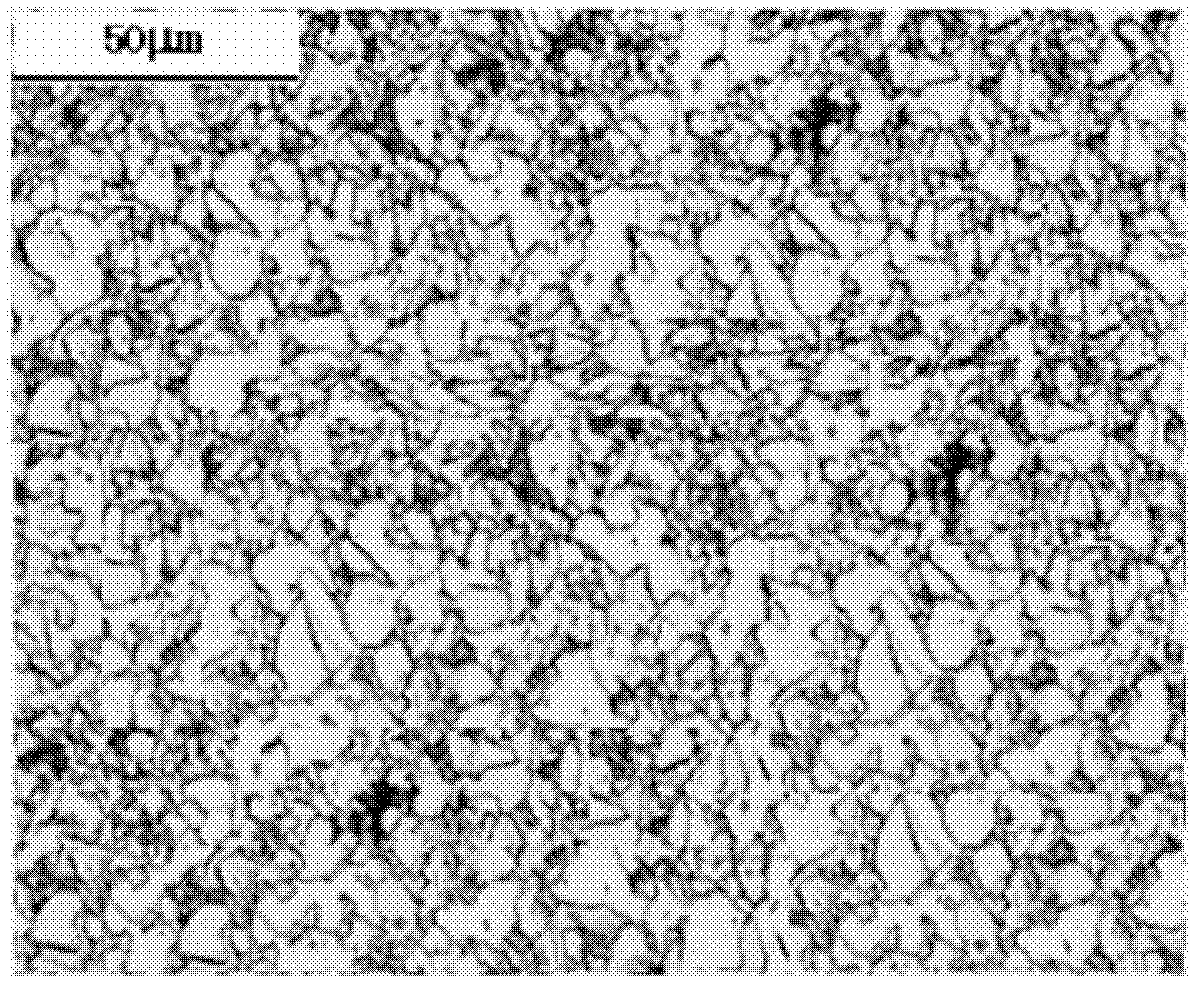

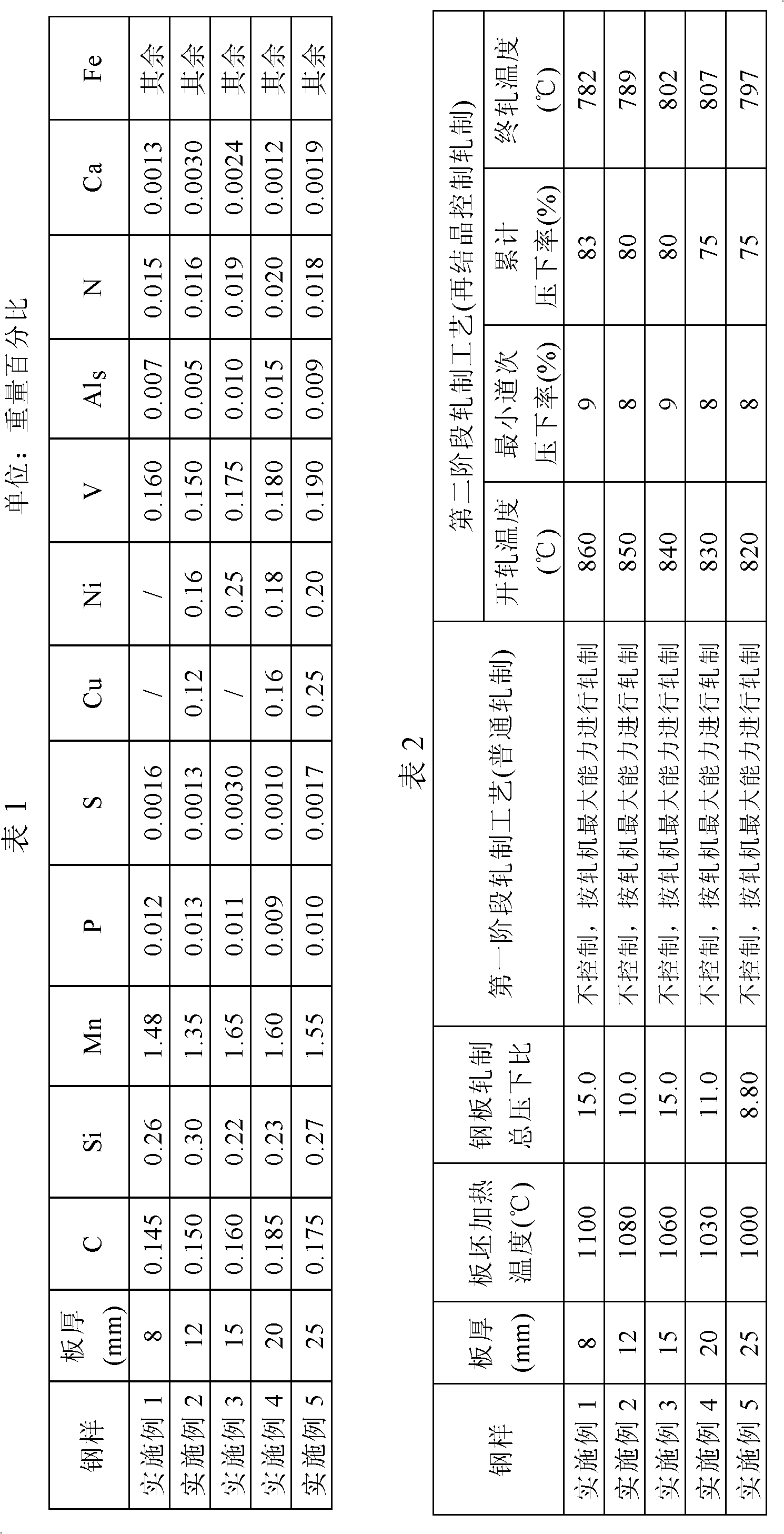

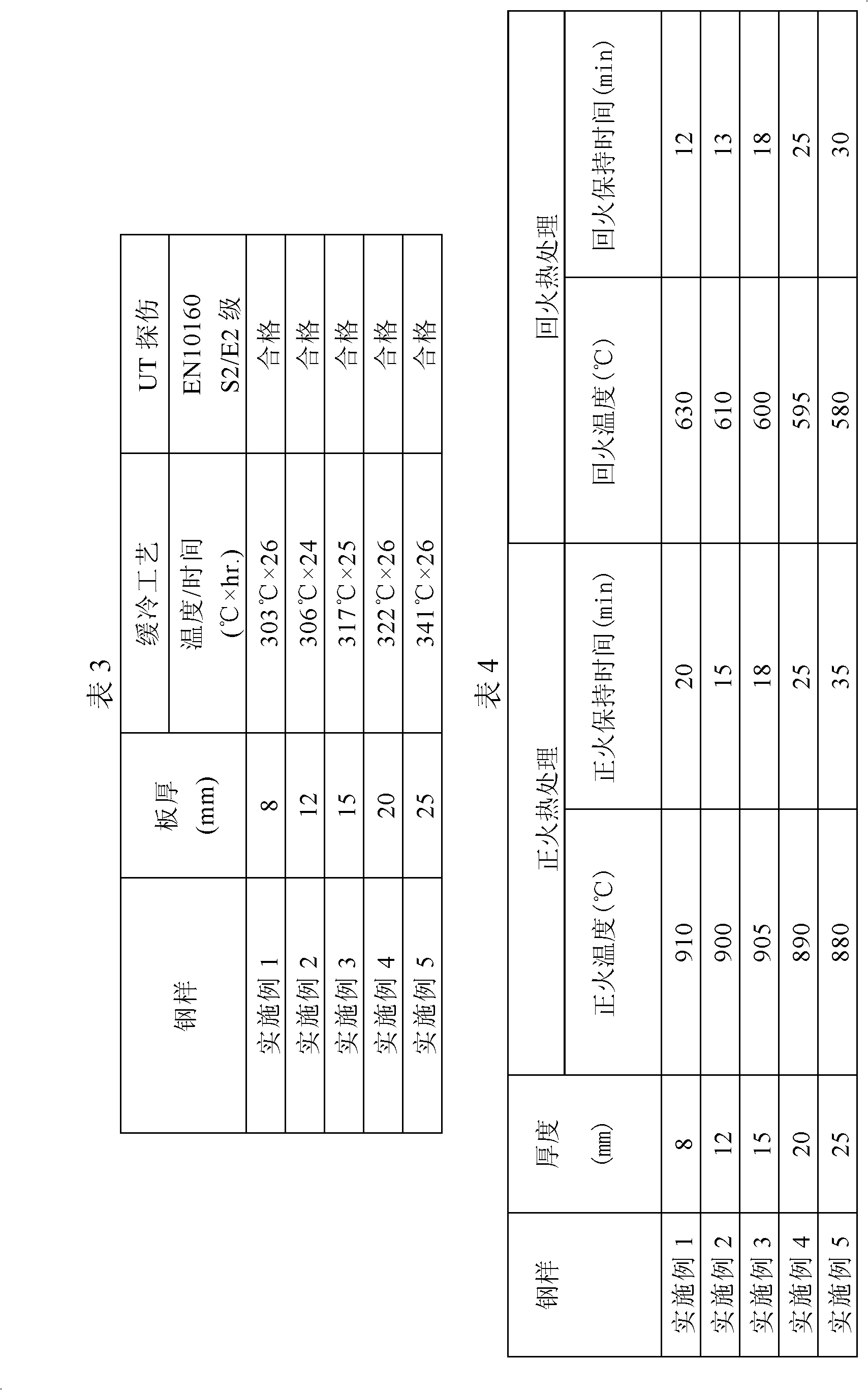

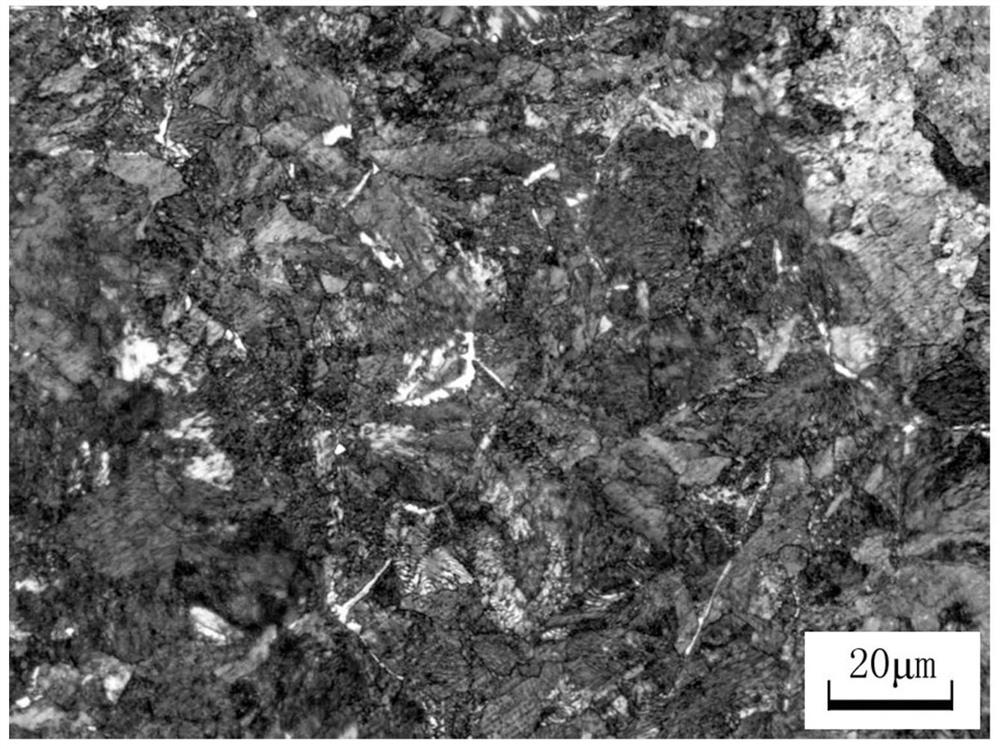

Disclosed are a 60kg-level low-cost and high-toughness steel plate and a production method thereof. The 60kg-level low-cost and high-toughness steel plate comprises, in weight percentage, 0.145%-0.185% of C, not less than 0.30% of Si, 1.35%-1.65% of Mn, not less than 0.013% of P, not less than 0.003% of S, not less than 0.25% of Cu, not less than 0.25% of Ni, 0.005%-0.015% of AlS, 0.150%-0.190% of V, 0.015%-0.020% of N, 0.001%-0.003% of Ca, and the balance of Fe and unavoidable impurities. Based on an alloyed component system of medium C, low Si, high Mn, ultralow AlA and high V with metallurgical technical control, RCR-NT (recrystallization controlled rolling-normalized tempering) processes are optimized, the microstructure of the finished steel plate includes even and small ferrite, pearlite and trace granular bainite, average grain size of the ferrite is smaller than 15 micrometers, even and fine match of high toughness and high plasticity is obtained, and the steel plate has extremely fine low-temperature toughness. The steel plate is especially applicable to large-sized steel structured containers, such as bearing components, petroleum storage tanks, mobile tankers and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Corrosion-resistant high-strength pearlite steel rail and preparation method thereof

ActiveCN111607738AControl reachedEasy to useFurnace typesManufacturing convertersRefining (metallurgy)Impurity

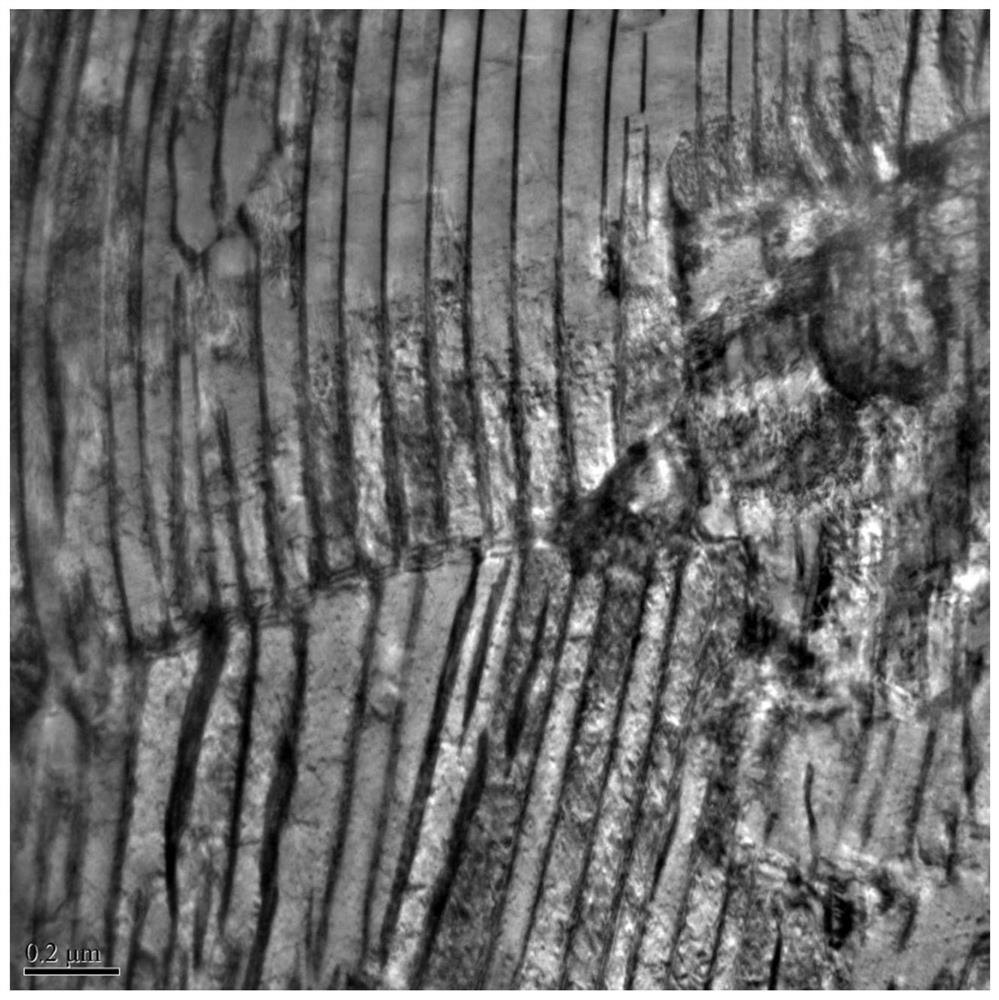

The invention discloses a corrosion-resistant high-strength pearlite steel rail and a preparation method thereof, and belongs to the technical field of metallurgy. The steel rail comprises the following chemical components of, in percentage by mass, 0.65%-0.80% of C, 0.45%-0.85% of Si, 1.0%-1.5% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.68%-0.95% of Cr, 0.03%-0.06% of Nb, 0.8%-1.6% of Cu, 0.002%-0.006% of B, the balance Fe and unavoidable impurities. The steel rail is prepared through the processes of molten iron pretreatment, converter smelting, refining,vacuum treatment, continuous casting, rolling, online heat treatment and the like. According to the the steel rail designed by the preparation method, the room-temperature structure is fine lamellar pearlite and a small amount of ferrite, the lamellar spacing of the pearlite is 90-120nm, the tensile strength Rm is 1280-1350 MPa, the elongation A is 11%-13%, the tread hardness is 360-390 HB, and the room-temperature impact energy AKU is greater than 20 J.

Owner:武汉钢铁有限公司

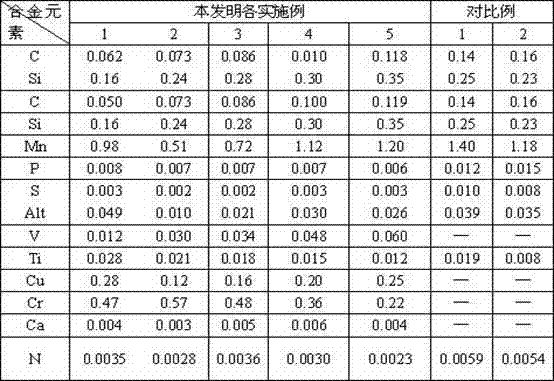

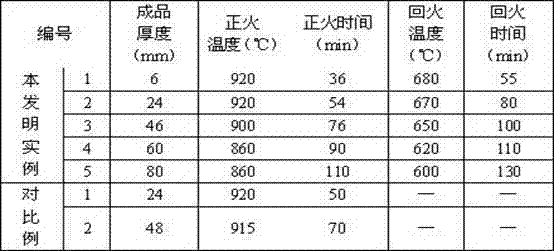

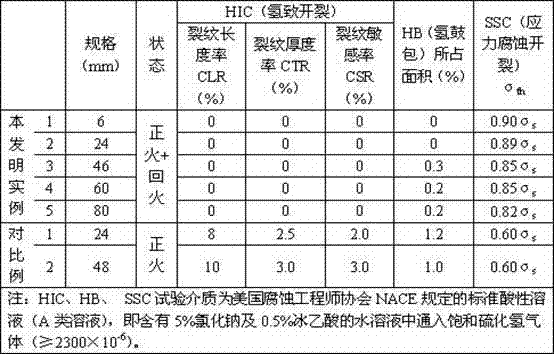

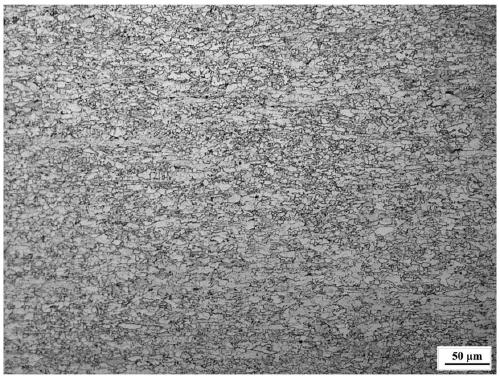

Steel for hydrogen sulfide stress corrosion resisting pressure container and production method of steel

ActiveCN102925814AExcellent resistance to hydrogen sulfide stress corrosionStrong enoughChemical compositionAlloy

The invention provides steel for a hydrogen sulfide stress corrosion resisting pressure container and a production method of the steel. The steel comprises the chemical components in percentage by weight of 0.05-0.12 percent of C, 0.15-0.35 percent of Si, 0.50-1.20 percent of Mn, less than or equal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.010-0.050 percent of Alt, 0.01-0.06 percent of V, 0.010-0.030 percent of Ti, 0.10-0.30 percent of Cu, 0.20-0.60 percent of Cr, 0.002-0.006 percent of Ca and less than or equal to 0.004 percent of N. The production method comprises the steps of: adopting molten iron desulphurization; smelting; refining; continuously casting into blanks; heating blanks; roughly rolling; precisely rolling; normalizing; tempering; and preparing for use. Low carbon and low alloy are adopted, and contents of P, S and N are strictly controlled, so that the steel has excellent hydrogen sulfide stress corrosion resisting capacity. A stable ferrite-pearlitic structure is obtained by using normalizing and tempering. The steel can be used for manufacturing pressure container devices used in various kinds of acid medium environments.

Owner:武汉钢铁有限公司

440 MPa-grade continuous-annealed and cold-rolled structural steel plate and production process thereof

The invention discloses a 440 MPa-grade continuous-annealed and cold-rolled structural steel plate and a production process thereof. The steel plate comprises the following components in percentage by mass: 0.06-0.12% of C, 0-0.10% of Si, 1.25-1.50% of Mn, 0.002-0.006% of N, 0-0.025% of P, 0-0.010% of S, 0.015-0.050% of Als, and the balance of Fe and unavoidable impurities, as well as ferrite with a volume ratio of 90-95% and pearlite with a volume rate of 5-10%; and the production method of the steel plate comprises the steps of continuous casting, hot rolling, cooling, coiling, cold rolling, continuous annealing and the like. According to the steel plate and the production process thereof disclosed by the invention, a 'low C-low Si-Mn' micro-alloying process thought is adopted in combination with techniques such as external refining, a controlled rolling and controlled cooling process, a process for controlling a relatively low cold rolling reduction ratio, a process of continuous annealing in a two-phase region, and the like, a fine-grained ferrite and pearlite structure containing cold-rolled structural steel plate is obtained.

Owner:攀钢集团西昌钢钒有限公司 +1

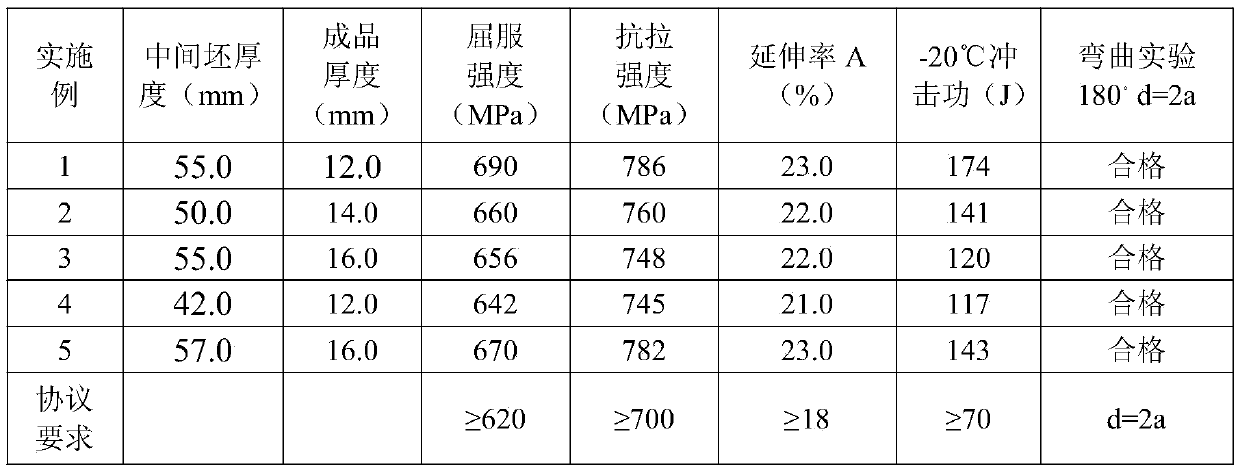

12.0-16.0 mm thick high-toughness 700MPa grade automobile beam steel and production method thereof

InactiveCN111549288AHigh strengthImprove low temperature impact toughnessUltimate tensile strengthToughness

The invention discloses 12.0-16.0 mm thick high-toughness 700MPa grade automobile beam steel and a production method thereof. The beam steel comprises the following chemical components of, in percentage by weight, 0.06 %-0.0 9 % of C, 0.10 %-0.30 % of Si, 1.60 %-1.90 % of Mn, smaller than or equal to 0.020 % of P, smaller than or equal to 0.005 % of S, 0.020 %-0.050 % of Alt, 0.04 %-0.06 % of Nb,0.06 %-0.10 % of Ti, smaller than or equal to 0.0050 % of N, and the balance Fe and inevitable impurities. The invention also discloses the production method of the beam steel. According to the beam steel and the method, the metallographic structure of the automobile beam steel is ferrite and pearlite, wherein the content of the pearlite is smaller than 10 %, and the grain size is larger than or equal to 12 level; and a rolling technology is optimized to produce the automobile beam steel which is thick and good in strength and toughness matching, so that the specification range of the automobile beam steel with the strength level is widened.

Owner:BAOTOU IRON & STEEL GRP

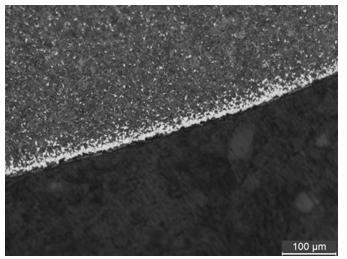

High-strength electric resistance welding casing pipe and manufacturing method thereof

The invention provides a high-strength electric resistance welding casing pipe and a manufacturing method thereof. The casing pipe comprises, by weight percentage, 0.26-0.30% of C, 0.15-0.30% of Si, 1.30-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.008% of S, 0.010-0.030% of Ti, 0.02-0.05% of Als, 0.36-0.46% of Cr, less than or equal to 0.008% of N and the balance Fe and inevitable elements. The manufacturing method comprises the steps of smelting and continuous casting, reheating of a casting blank, rolling, cooling, reeling, pipe manufacturing conducted through ERW and heat treatment conducted on the whole pipe, wherein hot continuous rolling is conducted after heating is completed, the finish rolling temperature is 840-900 DEG C, and a rolled steel strip is cooled at the cooling speed of 5-10 DEG C / s and reeled at the temperature of 630-680 DEG C; and after pipe manufacturing conducted through ERW is completed, the whole pipe is heated to 880-940 DEG C, the temperature is preserved for 60-80 minutes, and water cooling is conducted. According to the high-strength electric resistance welding casing pipe and the manufacturing method thereof, medium carbon and Cr-containing design is adopted, and alloy cost is low; the plate roll structure in the hot-rolling state is ferrite-pearlite, and subsequent pipe manufacturing and formation can be conducted easily; and the whole pipe is subjected to quenched-tempered heat treatment, the final structure is tempered sorbite, the casing pipe is at the level of P110 in performance, and performance consistency of a pipe body and welding seams is guaranteed.

Owner:ANGANG STEEL CO LTD

Ultrathin-specification broad hot strip with tensile strength as 600MPa and producing method thereof

The invention relates to an ultrathin-specification broad hot strip with the tensile strength as 600MPa and a producing method thereof. The ultrathin-specification broad hot strip comprises the chemical components, by weight percentage, of 0.06-0.10% of C, smaller than or equal to 0.30% of Si, 0.90-1.10% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.015% of S, 0.030-0.050% of Nb, 0.01-0.03% of Ti, 0.010-0.045% of Als, the balanced of Fe and unavoidable impurity elements. The producing method comprises the steps of smelting of molten iron through a rotary kiln, LF refining, continuous casting of slabs, slab heating, scale removal through high-pressure water, controlled rolling, controlled-rolling cooling and winding. The ultrathin-specification broad hot strip can be manufactured through the steps of the producing method. The thickness of the broad hot strip is reduced to 1.2mm, the tensile strength of the broad hot strip is larger than 600MPa, the yield strength of the broad hot strip is larger than 500MPa, and the elongation of the broad hot strip is larger than 30%. The organization of the broad hot strip is ferrite and pearlite, the ferrite occupies about 10%, and the grain size of the broad hot strip is larger than or equal to grade 12. The broad hot strip is mainly used as a high-intensity cold-bent structural member, and the structural self weight and the raw material cost are greatly reduced.

Owner:HEBEI IRON AND STEEL

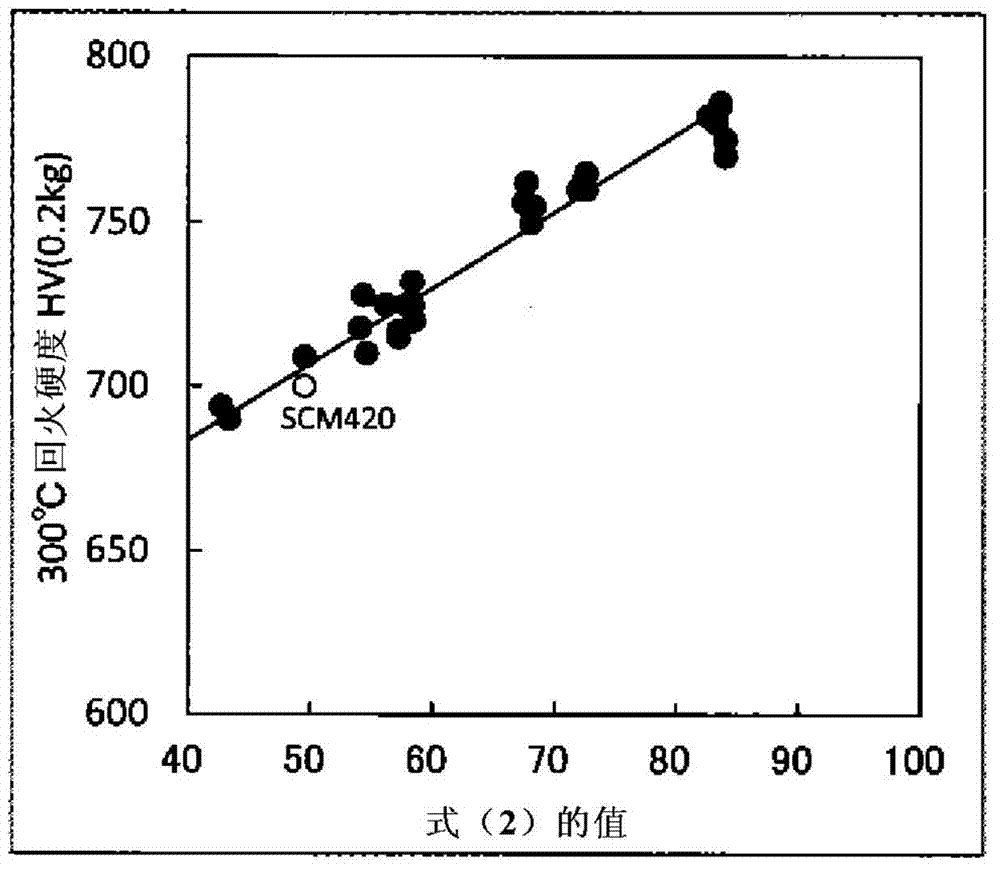

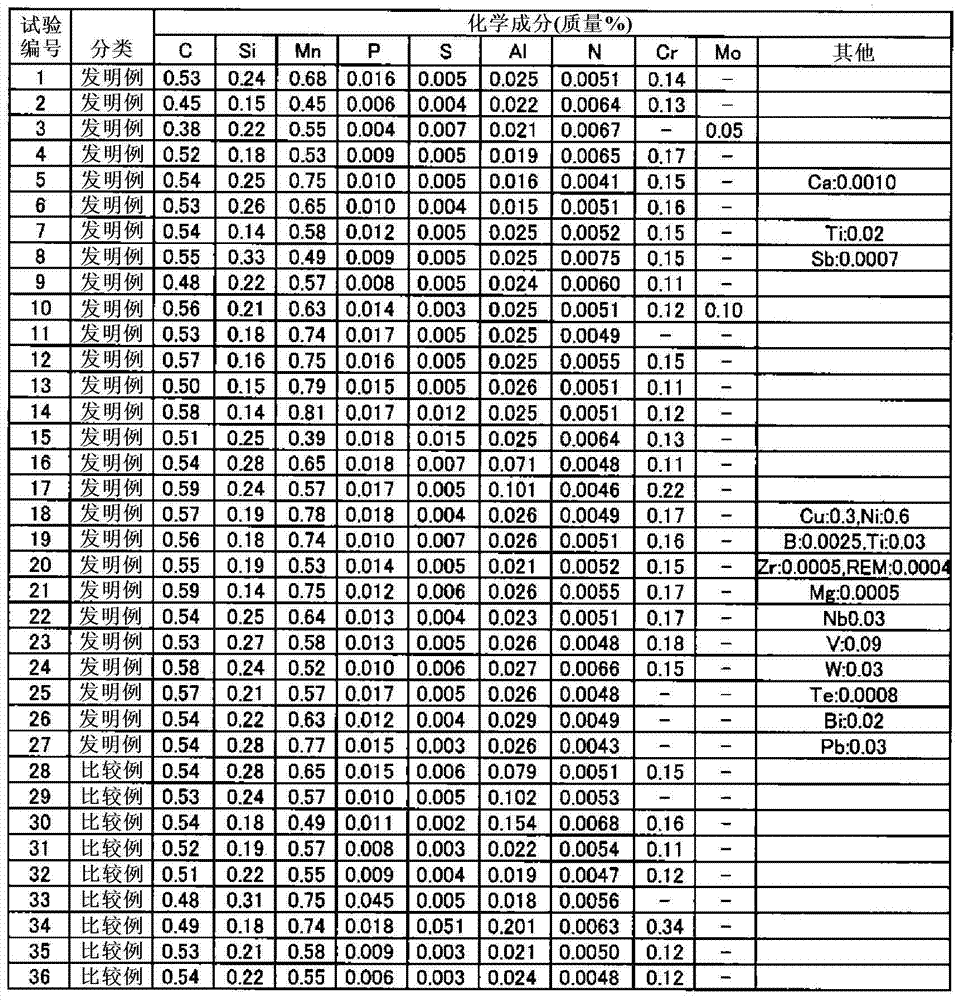

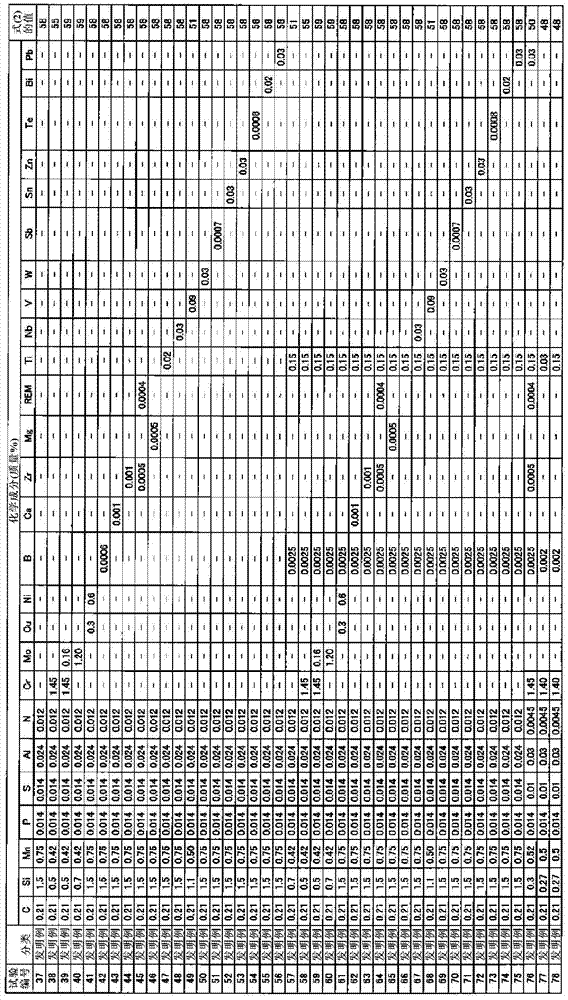

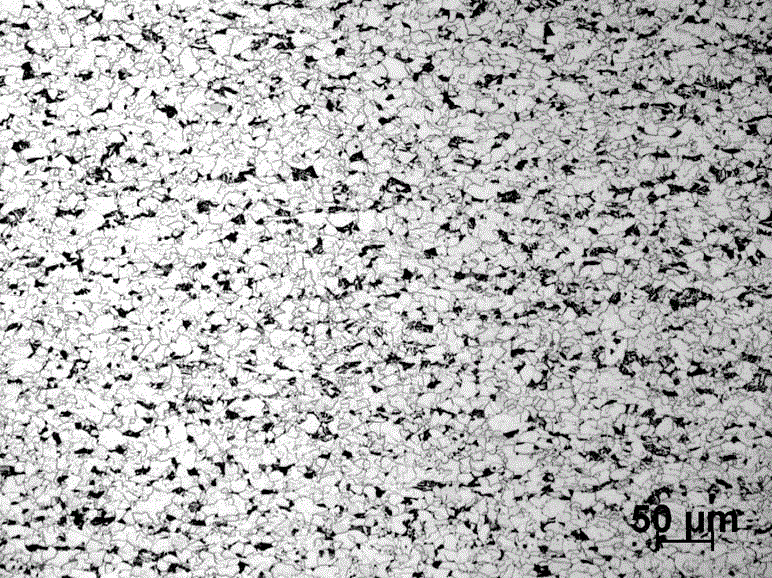

Steel wire rod or steel bar having excellent cold forgeability

This invention provides a steel wire rod / steel bar having excellent cold forgeability. This steel wire rod / steel bar is provided with a predetermined chemical component composition in the condition immediately after hot rolling, wherein the depth d (mm), from the surface, of a surface layer region having a mean hardness HV0.2 that is at least 20 higher than the mean hardness HV0.2 of the region from the cross-section radius (R)×0.5 (mm) to the center satisfies formula (1); the steel structure of the surface layer region comprises ferrite in a fraction of 10% or less by area ratio, with the balance being made up of one or more types of steel structure from amongst martensite, bainite, and pearlite; the steel structure from the cross-section radius (R)×0.5 (mm) to the center is a ferrite-pearlite or ferrite-bainite steel structure; and the surface roughness (Ra) in the circumferential direction when scales adhering to the surface have been removed is equal to or less than 4 mum.

Owner:NIPPON STEEL CORP

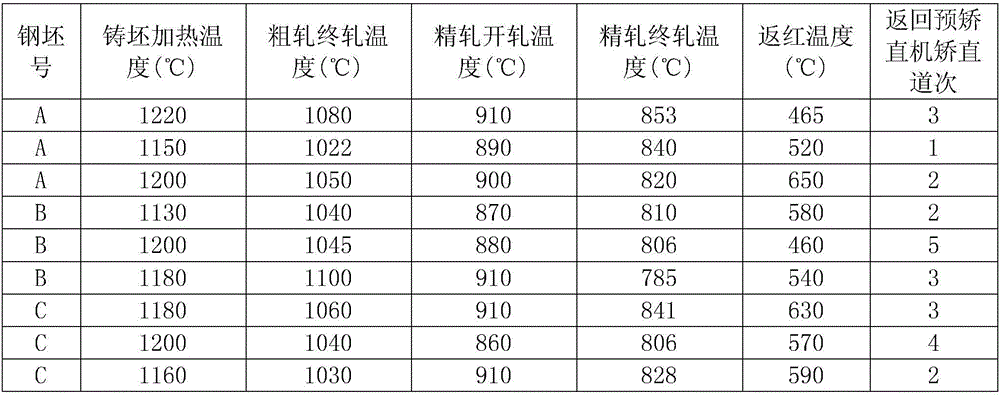

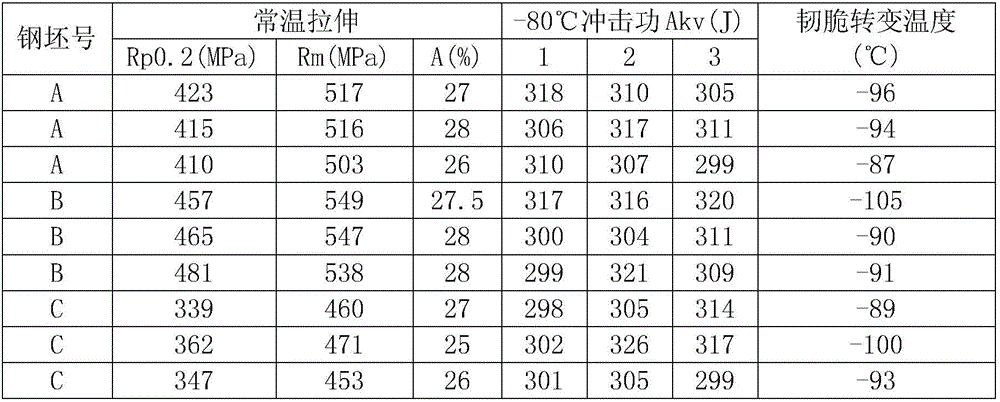

Carbon manganese low-temperature steel for liquefied gas boat and manufacturing method of carbon manganese low-temperature steel

The invention discloses carbon manganese low-temperature steel for a liquefied gas boat and a manufacturing method of the carbon manganese low-temperature steel. The carbon manganese low-temperature steel comprises, by weight, 0.03%-0.08% of C, 0.10%-0.30% of Si, 0.60%-1.30% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.010%-0.080% of Nb, 0.010%-0.060% of Al and the balance Fe and inevitable impurities. The clean steel smelting-continuous casting process is adopted in the method, and a high-purity homogenous continuous casting slab is manufactured; and through two-stage control rolling and control cooling, a wee ferrite and pearlitic structure is obtained. The carbon manganese low-temperature steel for the liquefied gas boat has the beneficial effects that the steel is pure, the texture is even, the grain size is in the 10.0 level to 13.5 level, and the ductile-brittle transition temperature is lower than -80 DEG C; building requirements of a cargo tank and a boat body structure of the liquefied gas boat are met; and meanwhile, the carbon manganese low-temperature steel has the beneficial effects of being simple in chemical component and low in cost.

Owner:NANJING IRON & STEEL CO LTD

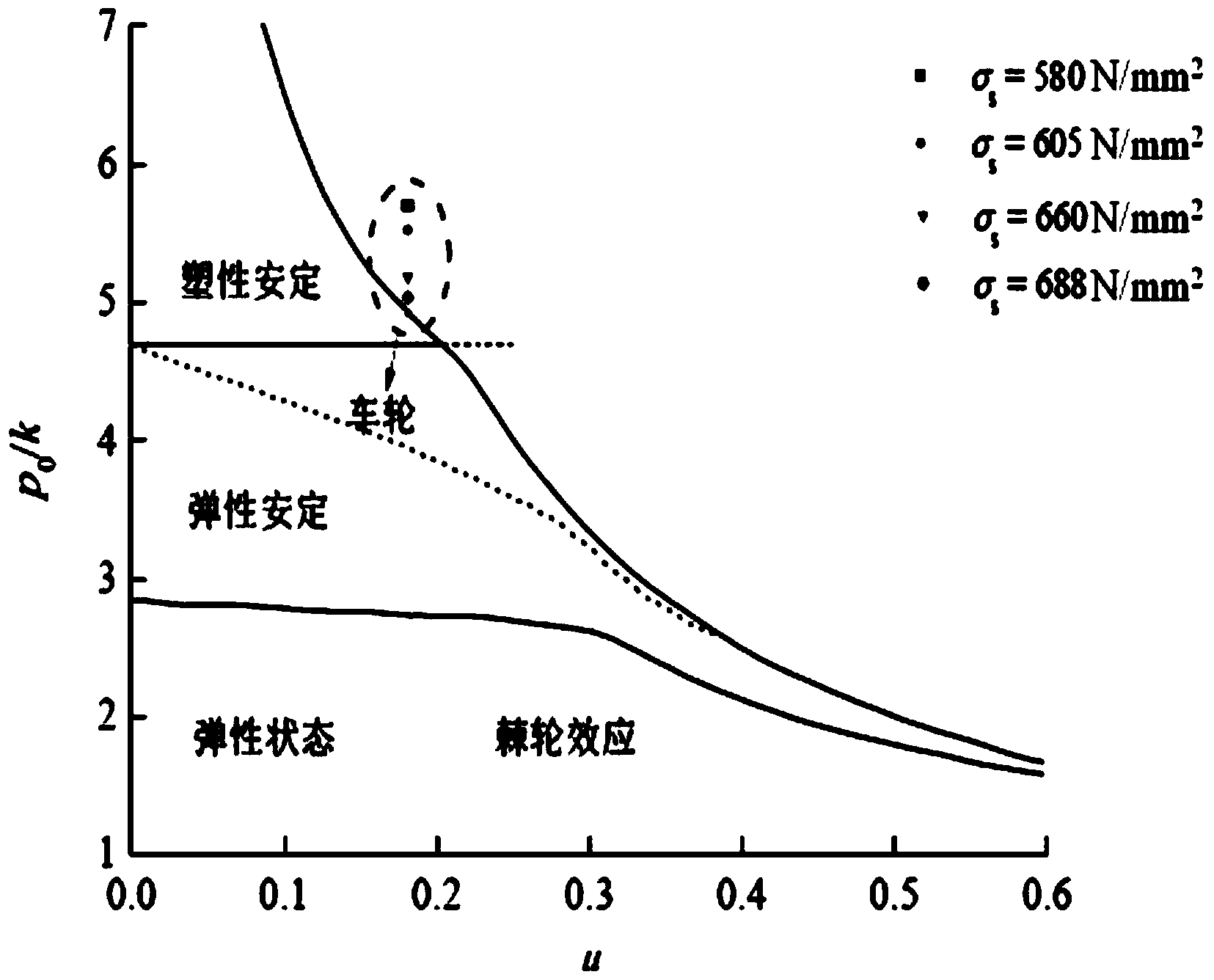

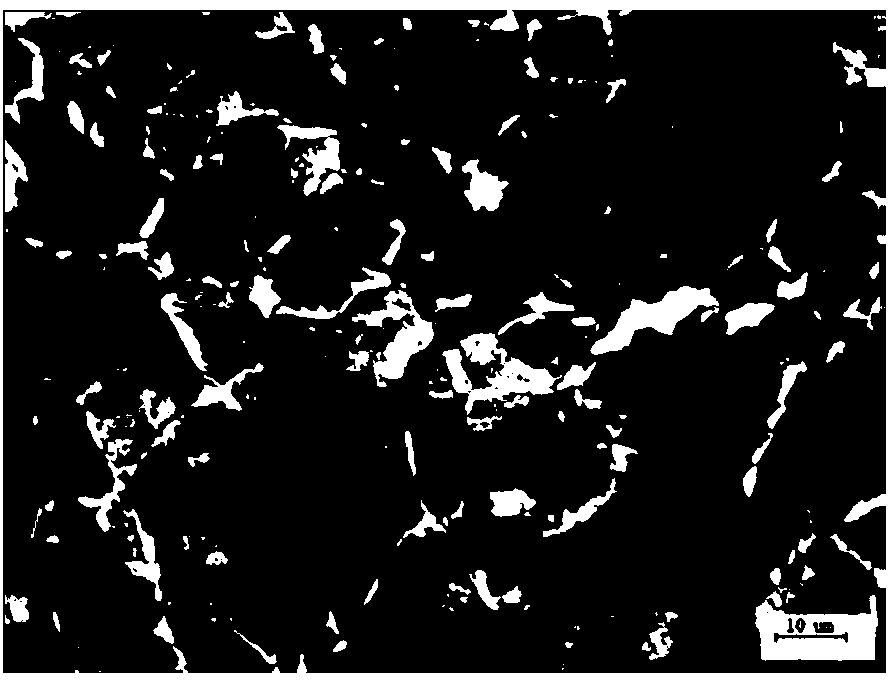

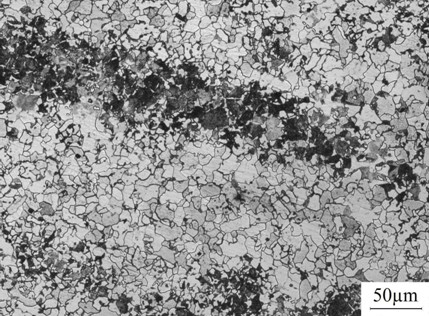

Medium-carbon low-alloy wheel steel for metro and manufacturing method of wheel steel

The invention relates to medium-carbon low-alloy wheel steel for metro and a manufacturing method of the wheel steel. The medium-carbon low-alloy wheel steel is composed of the following chemical components in percentage by weight: 0.50-0.60% of C, 0.80-1.20% of Si, 0.90-1.10% of Mn, 0.15-0.35% of Cr, 0.010-0.030% of Als, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurity elements. The manufacturing method comprises an electric furnace smelting step, an ingot slicing and rolling step and a thermal treatment step. A wheel manufactured by use of the wheel steel is obviously improved in strength and hardness while the tenacity of the rim of the wheel basically keeps unchanged; the wear-resisting property of the wheel is effectively improved, and the probability of stripping and abrasion of the wheel in the use process is reduced. Meanwhile, the wheel manufactured by use of the wheel steel is capable of keeping the ferrite-pearlite structure state of the previous wheel without increasing the wheel manufacturing difficult.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

High-strength untempered steel for fracture splitting and steel component for fracture splitting

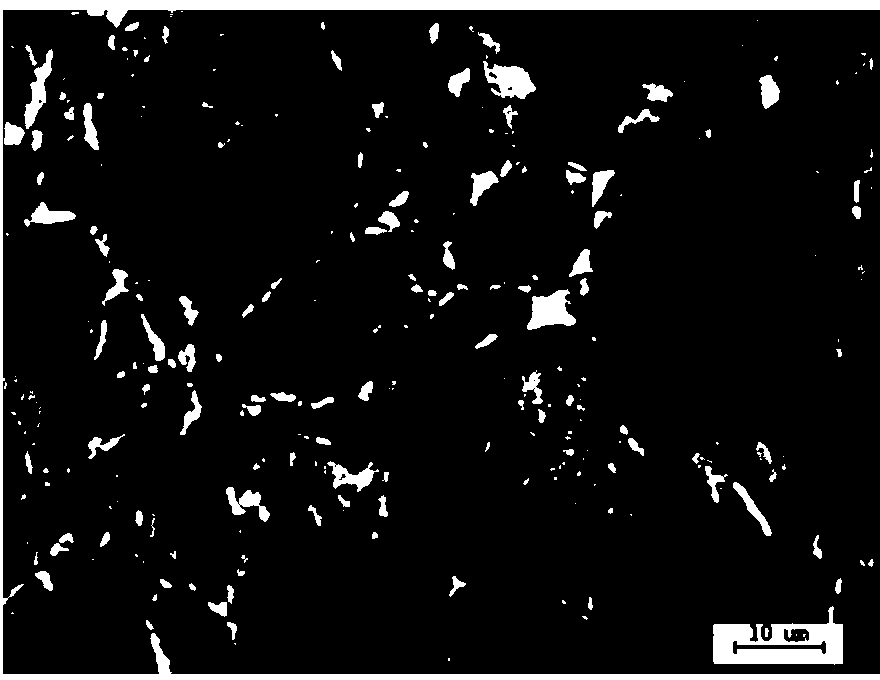

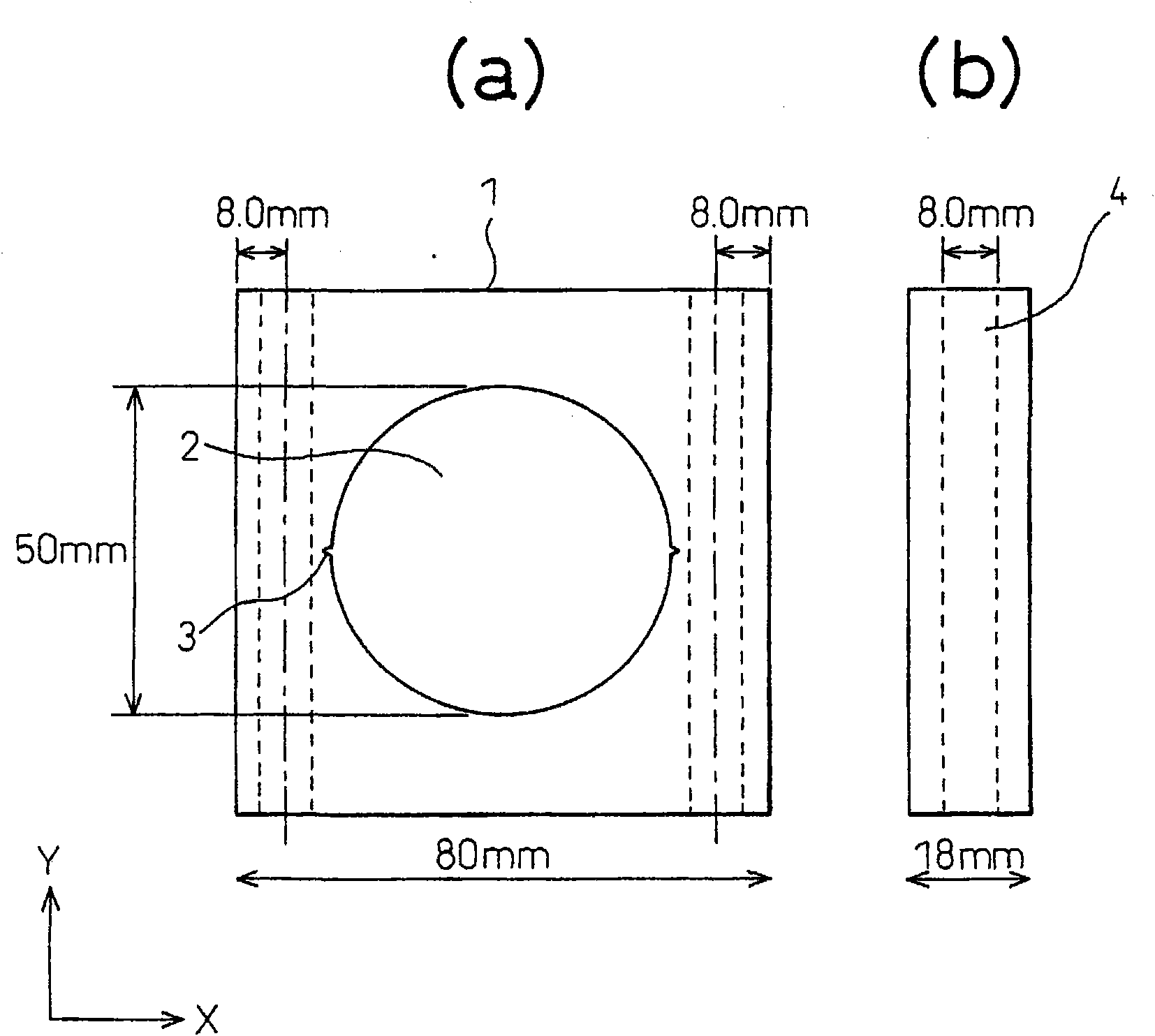

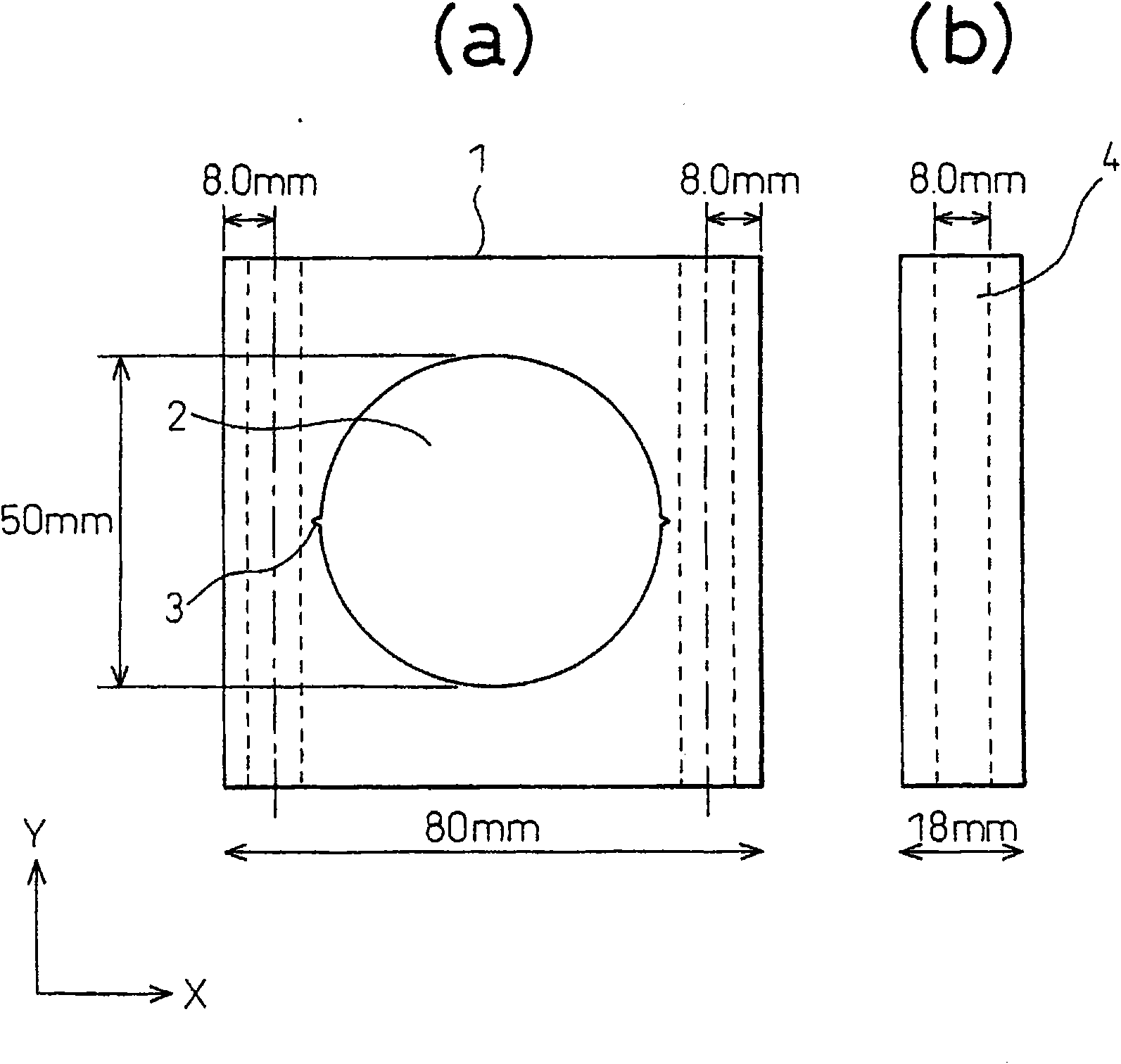

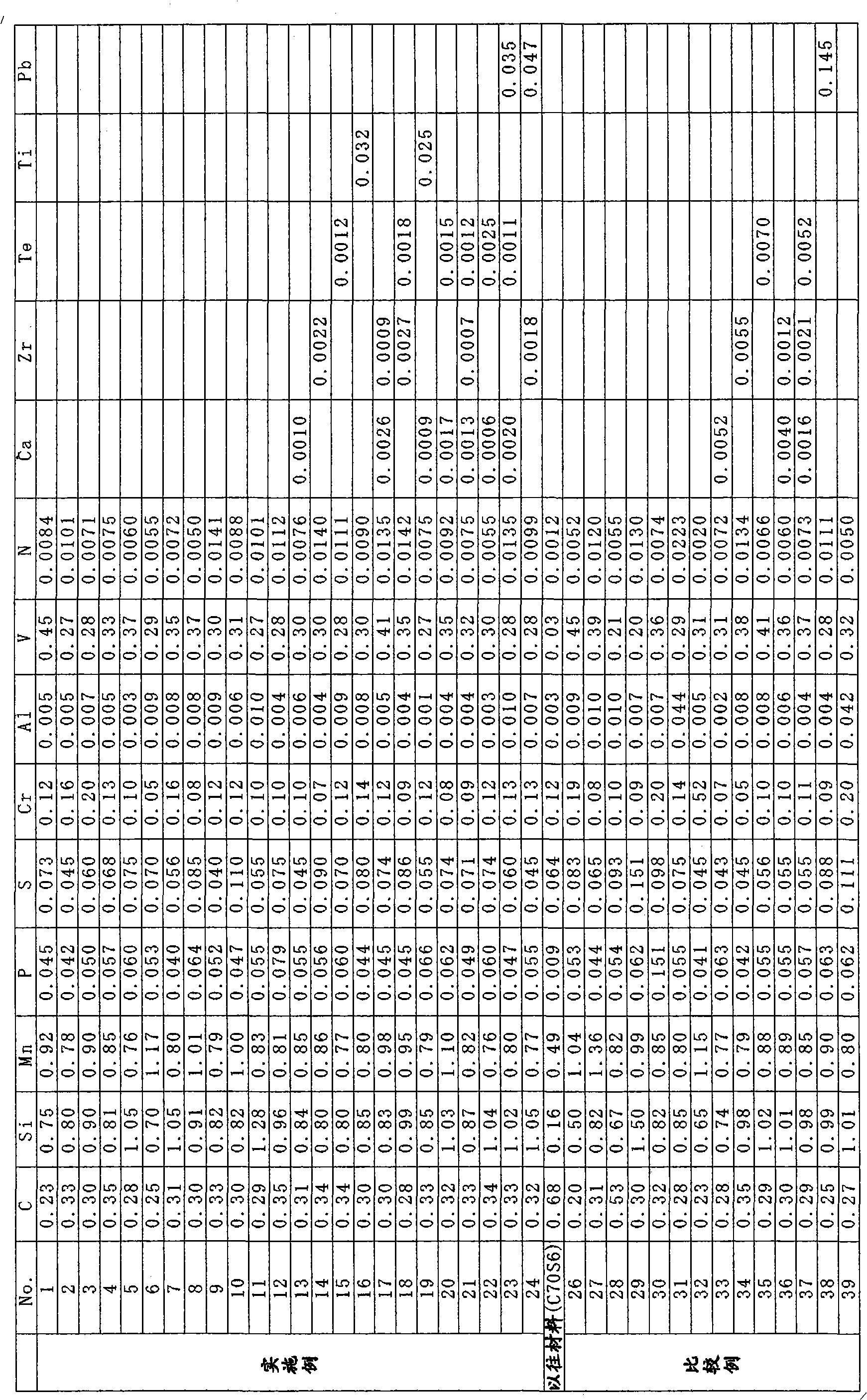

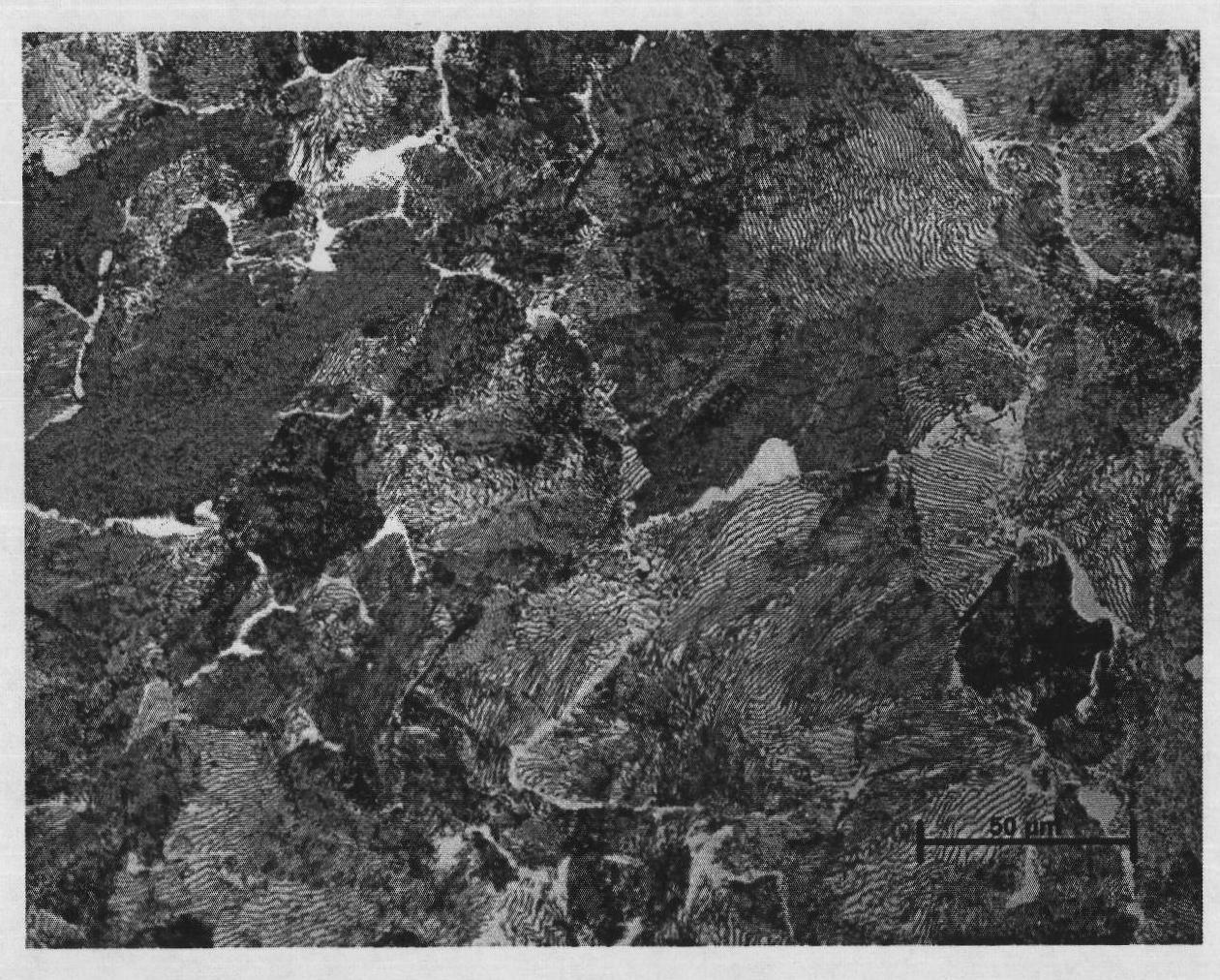

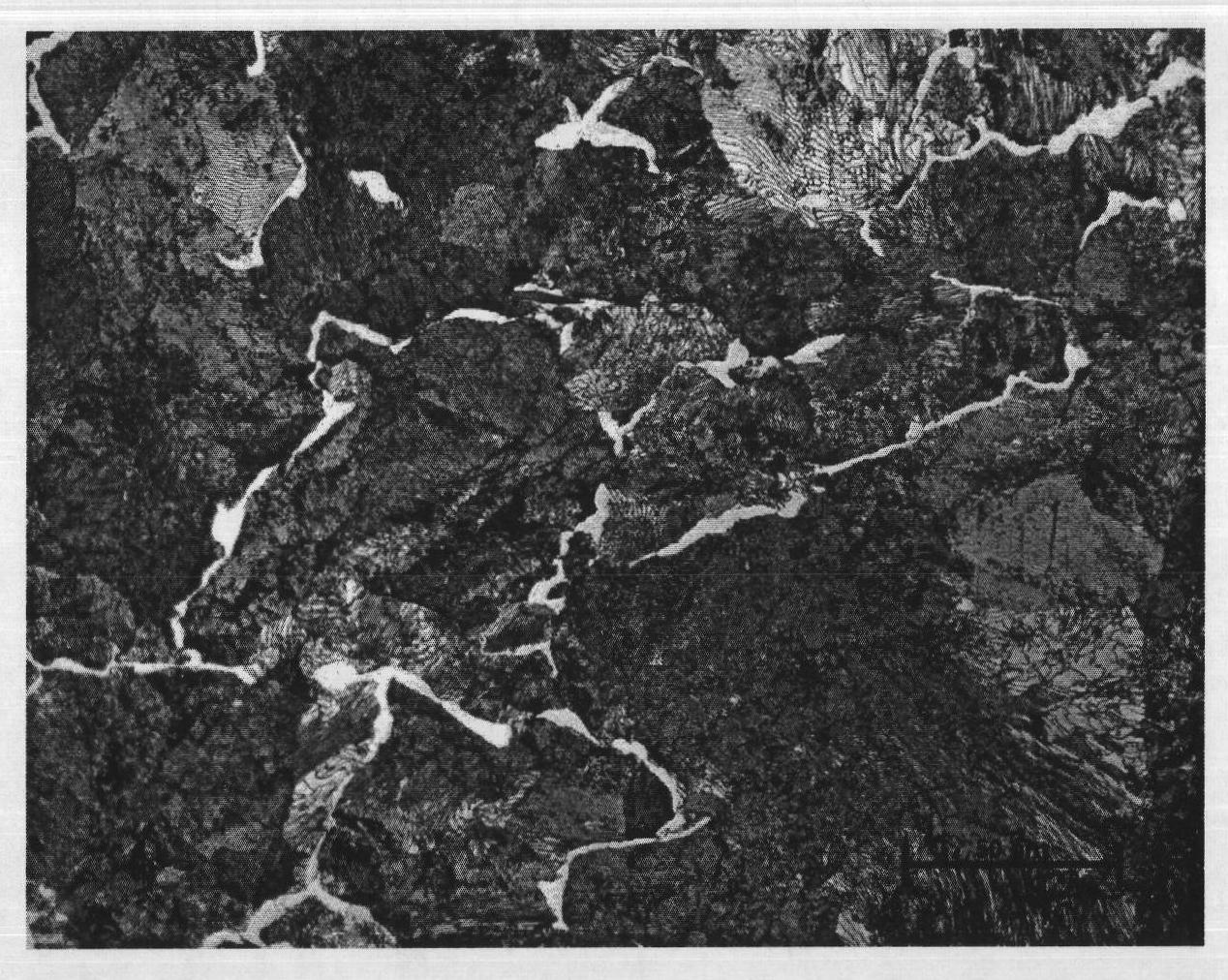

A high-strength untempered steel for fracture splitting and a steel component for fracture splitting comprising C: 0.23-0.35%, Si: 0.70-1.30%, Mn: 0.76-1.17%, P: 0.040-0.080%, S: 0.040-0.118%, Cr: 0.05-0.20%, Al: 0.010% or less, V: 0.27-0.45%, N: 0.0050-0.0145%, by mass percent, and the remainder Fe and unavoidable impurities, and comprising a ferrite-pearlite structure wherein the values of the composition restraints for three components satisfy the prescribed values, hot rolling properties are ensured, and the ferrite fraction is at least 60% when air cooled or cooled with forced air after hot casting.

Owner:NIPPON STEEL CORP +1

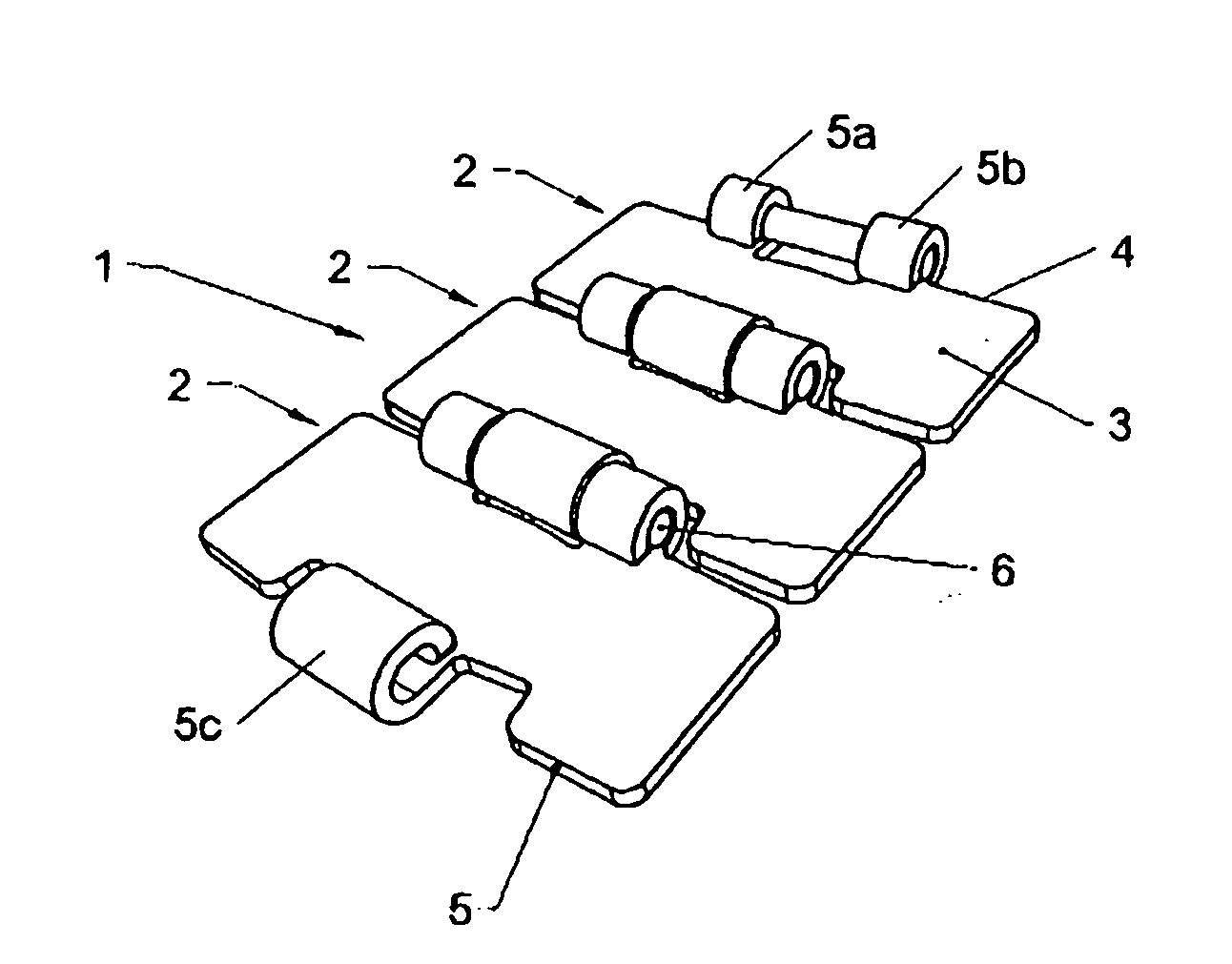

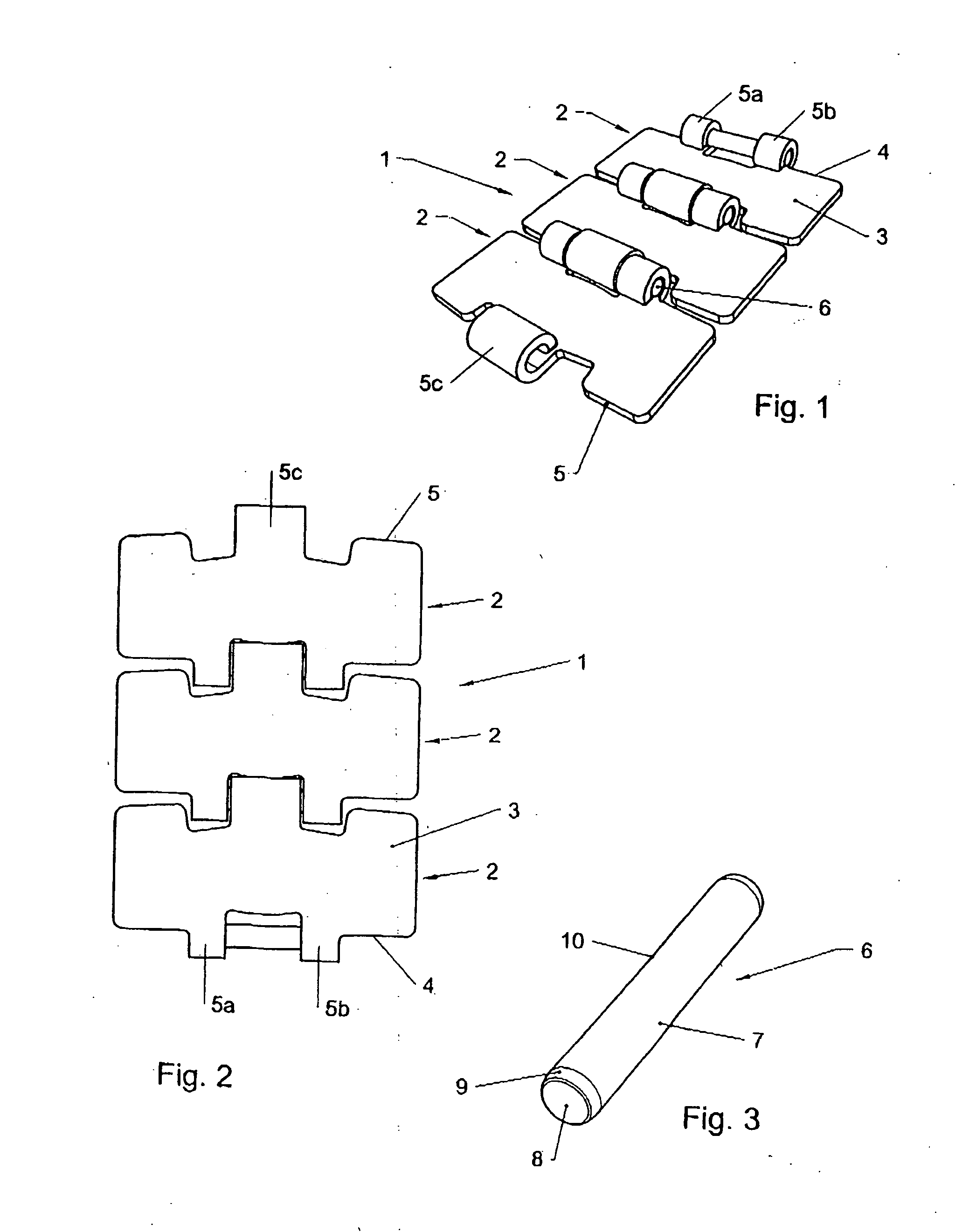

Chain pin for hinge conveyor chains

A method of assembling a hinge conveyor chain includes providing adjacent conveyor links formed from a ferritic-pearlitic stainless steel, wherein the adjacent links have interdigitating link ends with openings for receiving a pin, and inserting a pin having a radially outwardly facing surface formed from a steel alloy with more than 0.6 wt. % of carbon and more than 12 wt. % of Cr through the openings of the interdigitating link ends to pivotally link the adjacent links.

Owner:REXNORD FLATTOP EURO BV

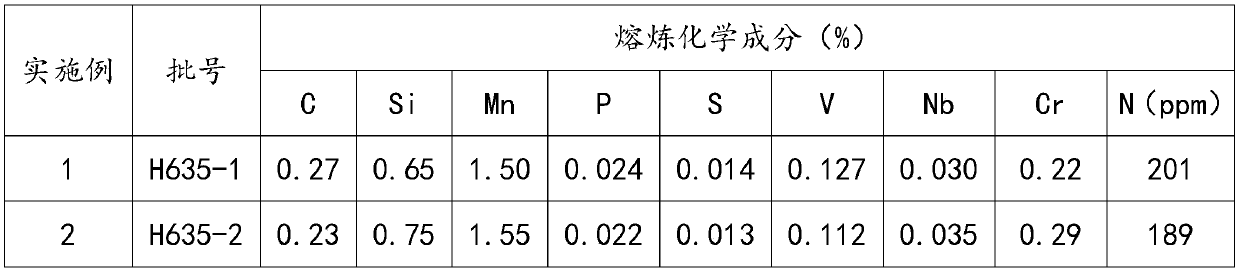

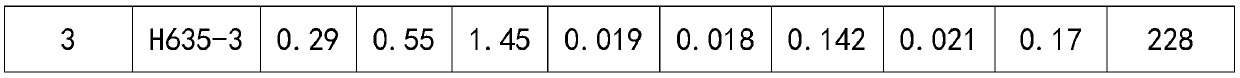

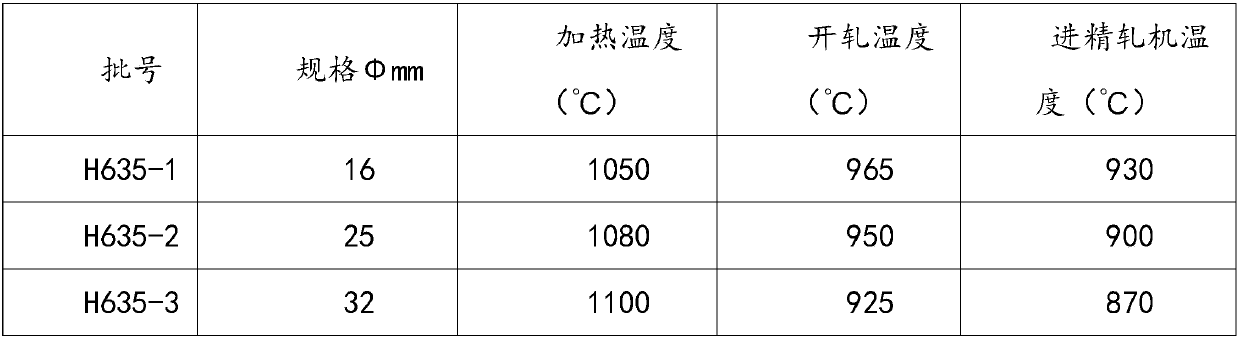

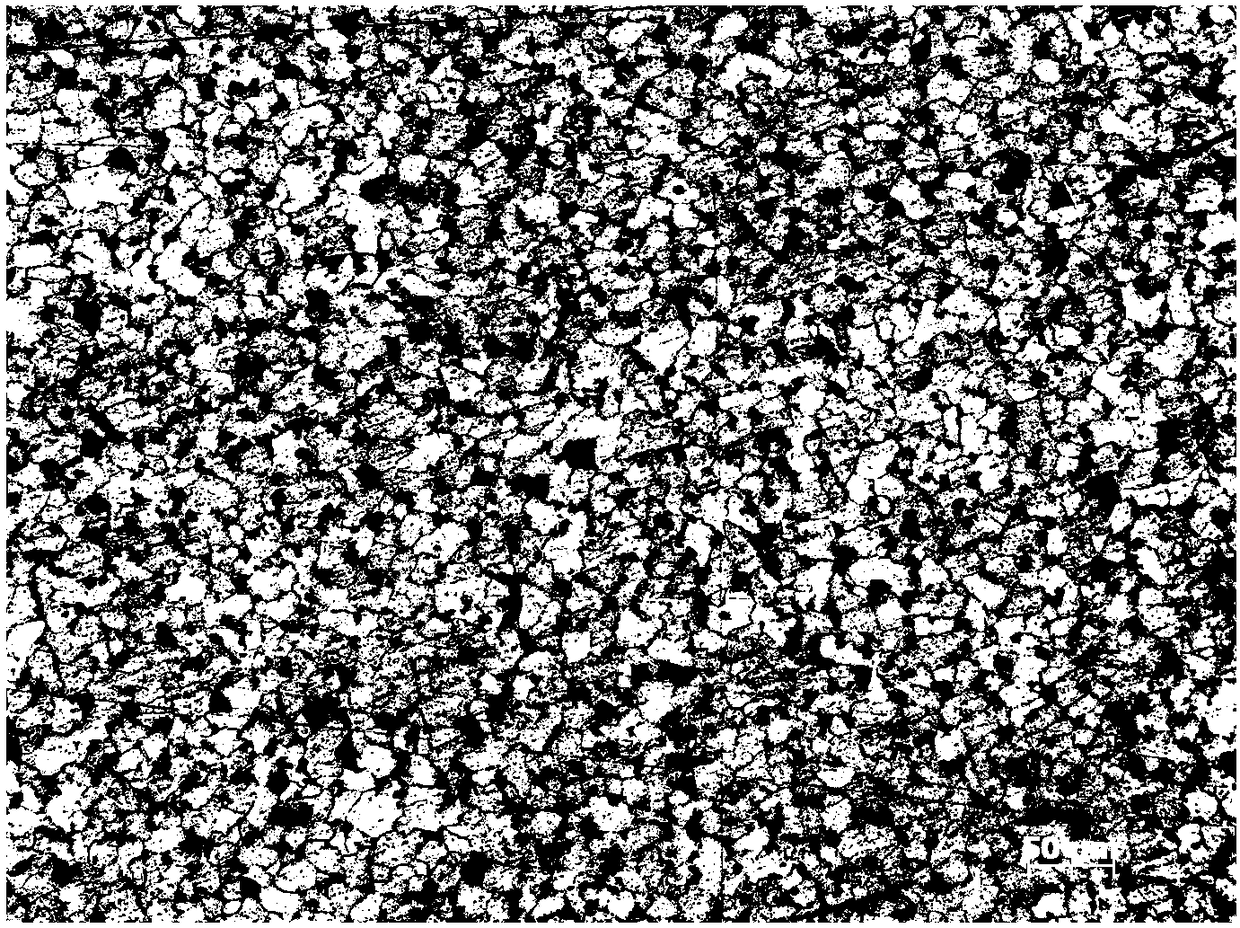

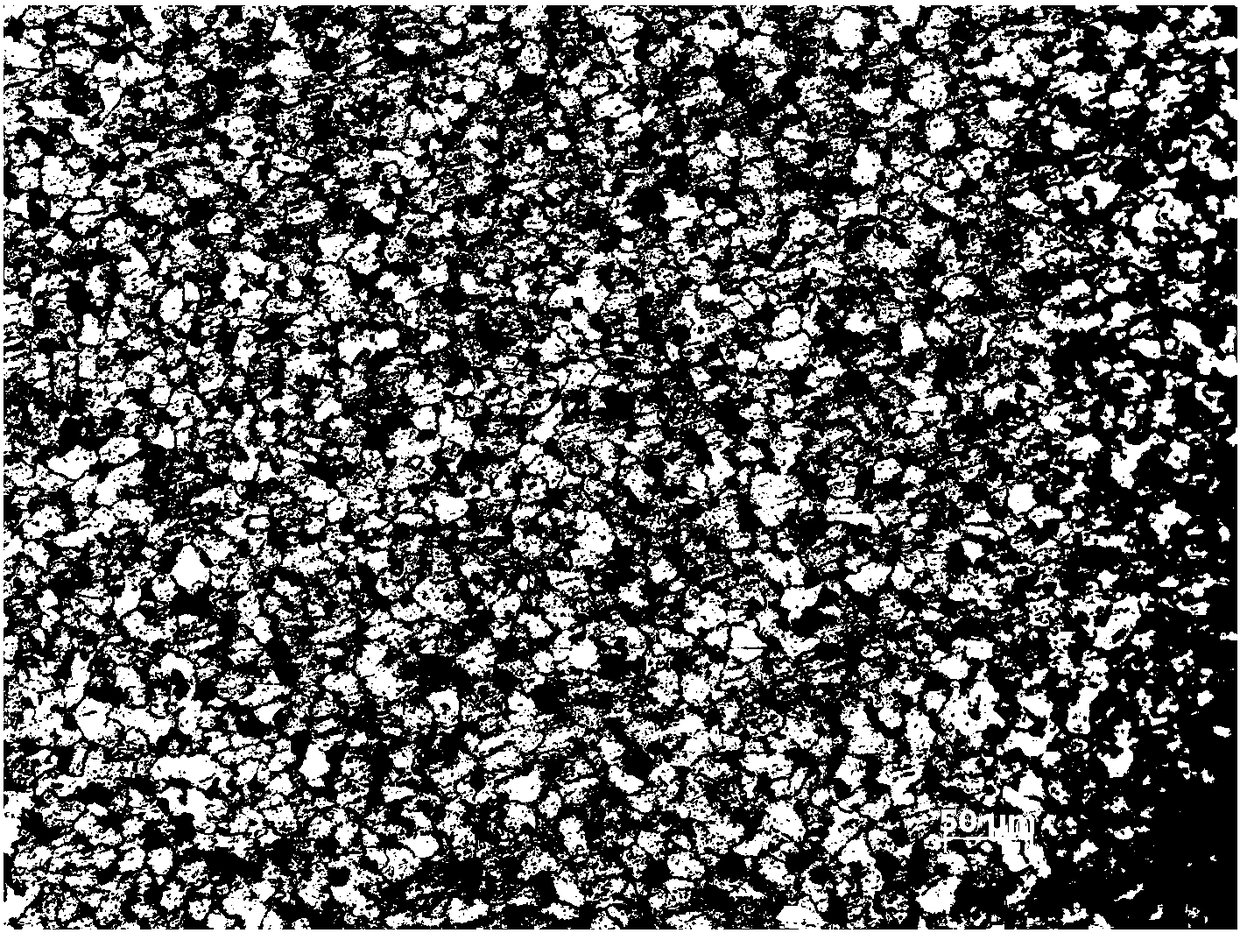

Steel for 635 MPa level high-strength hot-rolled steel bar

The invention relates to the technical field of hot-rolled ribbed steel bars, and discloses steel for a 635 MPa level high-strength hot-rolled steel bar. The steel is prepared from, by weight, 0.22-0.30% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 0.015-0.035% of Nb, 0.105-0.145% of V, 0.15-0.35% of Cr, 0.018-0.025% of N and the balance Fe. According to the steel for the 635 MPa level high-strength hot-rolled steel bar and a machining method thereof, by adopting C, C is a cheap element, the strength of the steel can be remarkably improved, the extension performance of the steel can be lowered, meanwhile, the cold brittleness and aging sensitivity of the steel are improved, the integrated ingredients are reasonable, the comprehensive performance of the whole steel is improved, the stability of the steel performance is enhanced, the overall performance of the steel on the aspects of yield strength, tensile strength, the high yield ratio, the percentage elongation after fracture, the total elongation percentage under the maximum force and the like is good, meanwhile, the steel metallographic structure is ferrite+pearlite, the granularity is 11.5, the good fatigue resistance is achieved, the steel is suitable for large-scale industrial production, and benefits are remarkable.

Owner:安徽吾兴新材料有限公司

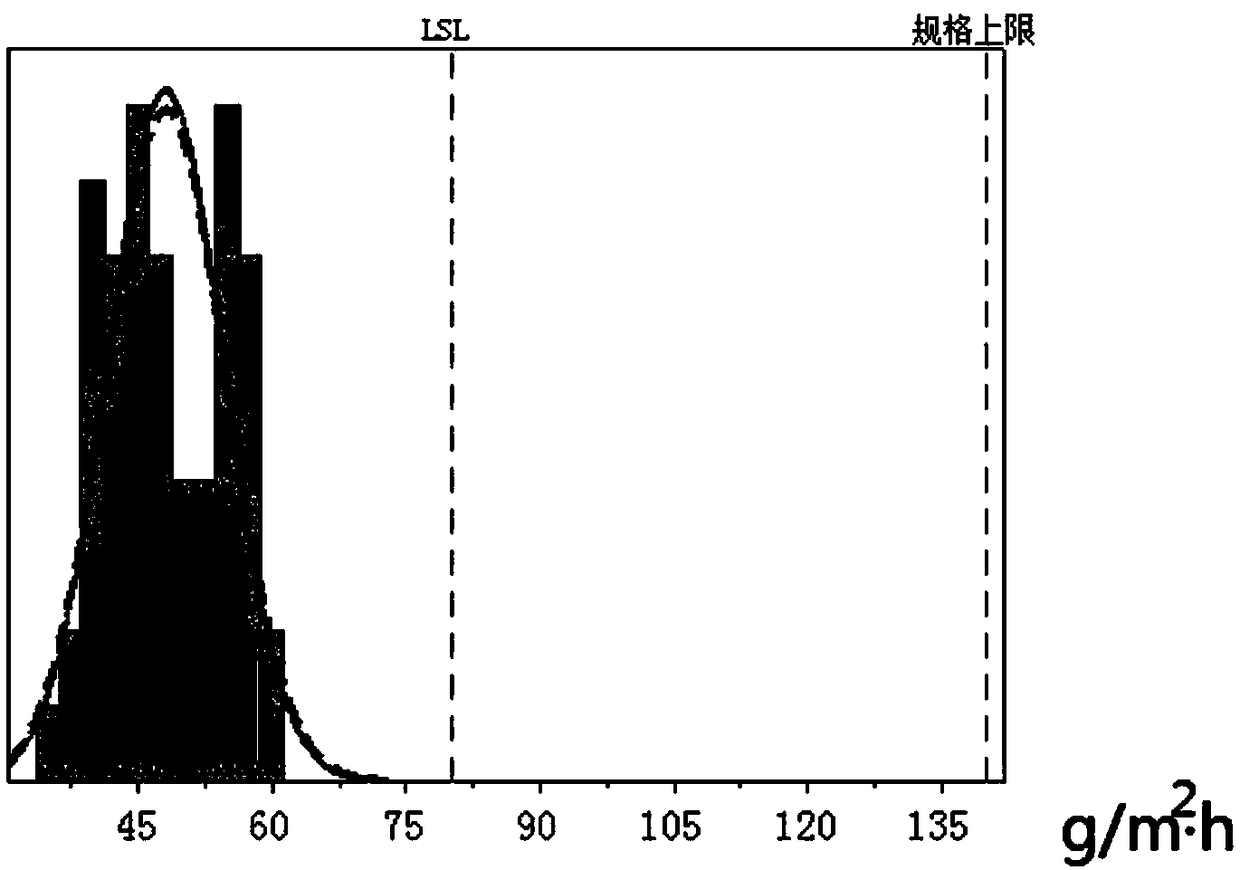

Sulfuric-acid-corrosion-resistant low-alloy steel, steel pipe, steel plate and manufacturing methods of steel pipe and steel plate

The invention discloses sulfuric-acid-corrosion-resistant low-alloy steel. The microstructure of the low-alloy steel is a ferrite and a pearlite. The sulfuric-acid-corrosion-resistant low-alloy steelcomprises the chemical elements of, by mass, greater than 0 and less than or equal to 0.15% of C, 0.1-0.4% of Si, 0.28-0.85% of Mn, 0.004-0.02% of S, 0.25-0.9% of Cr, 0.02-0.35% of Cu, 0.01-0.04% of Sb, 0.01-0.03% of Sn and the balance Fe and other inevitable impurities, wherein the value of (Sb+Sn) / S is 1 to 15. In addition, the invention further discloses a steel plate and a steel pipe made of the sulfuric-acid-corrosion-resistant low-alloy steel and manufacturing methods of the steel plate and the steel pipe. According to the sulfuric-acid-corrosion-resistant low-alloy steel, the sulfuric acid resistance is high, meanwhile relatively high hardness and strength are achieved, and the abrasive wear resistance is high.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of cold-rolled weathering steel with yield strength of 310 MPa or above

The invention relates to a production method of cold-rolled weathering steel with the yield strength of 310 MPa or above. A cold-rolled weathering steel strip product with the thickness of 0.5 mm-2.5mm is obtained through reasonable chemical component design, steelmaking smelting, a hot rolling process, an acid rolling process and continuous annealing process control, and the internal structure of a cold-rolled weathering steel finished product is ferrite, pearlite and cementite; and the mechanical property result of the cold-rolled weathering steel finished product is that the yield strengthis greater than or equal to 310 MPa, the tensile strength is greater than or equal to 450 MPa, the percentage elongation after fracture is greater than or equal to 28%, the mechanical property is stable, the molding and atmospheric corrosion resistance of the steel strip product are excellent, and the cold-rolled weathering steel finished product can be applied to related fields such as air preheater and plate heat exchanger manufacturing. According to the cold-rolled weathering steel product, the addition amount of alloy elements such as Mn, Cu, Cr and Ni is relatively small, and the performance is optimized through steelmaking, hot rolling and cold rolling processes, so that the production cost of the product is reduced.

Owner:SD STEEL RIZHAO CO LTD

Method for manufacturing high carbon steel wheel

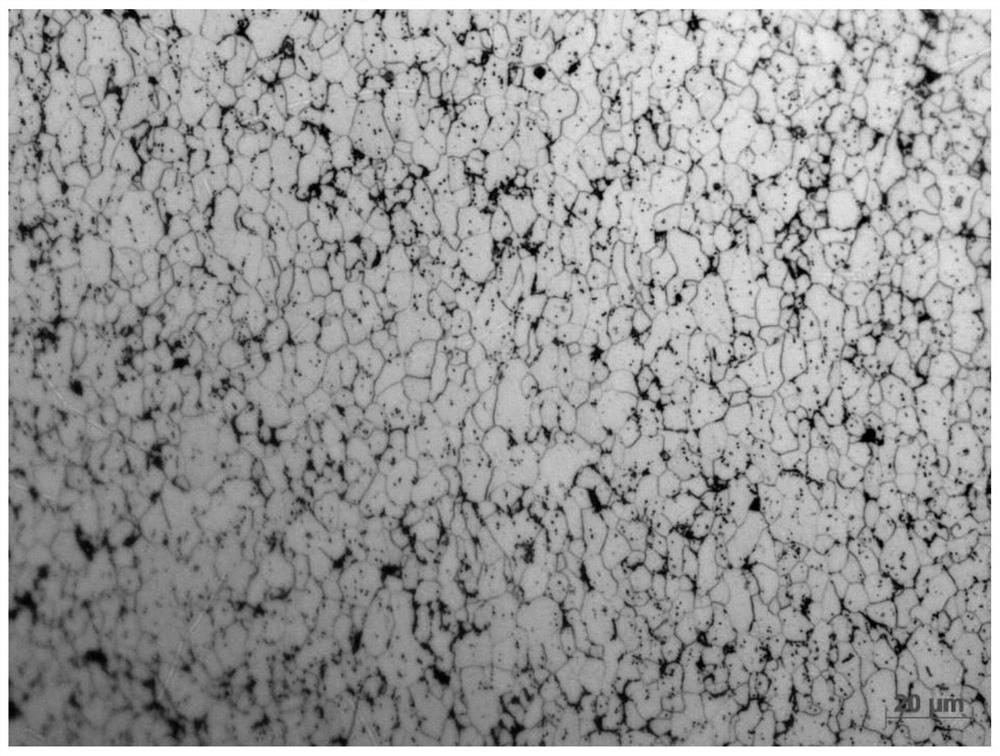

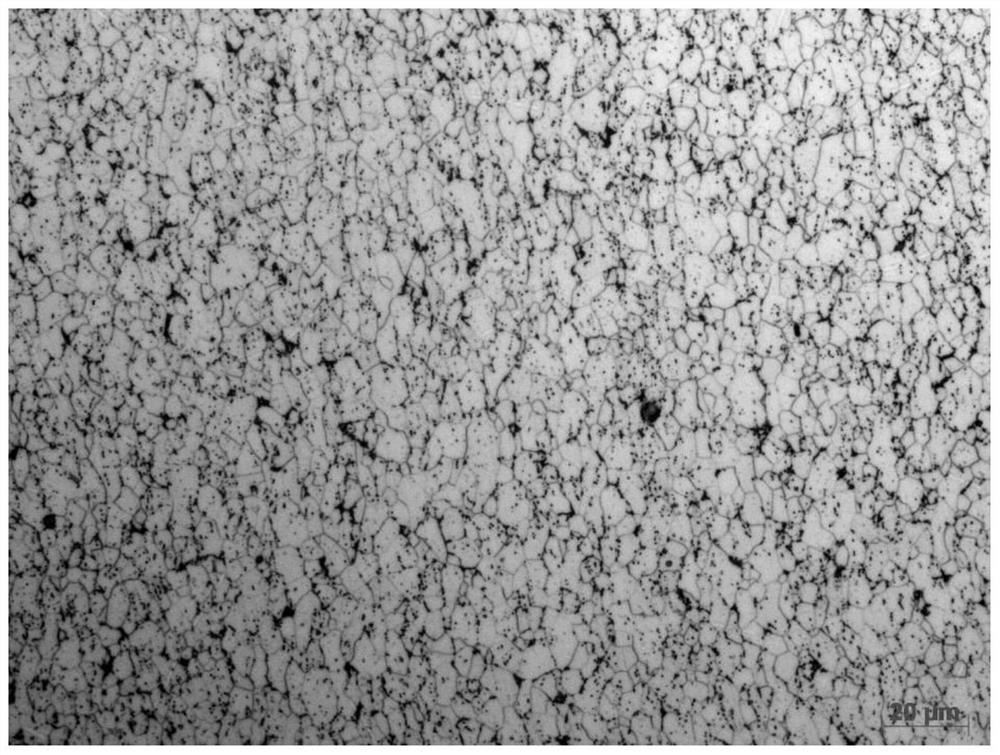

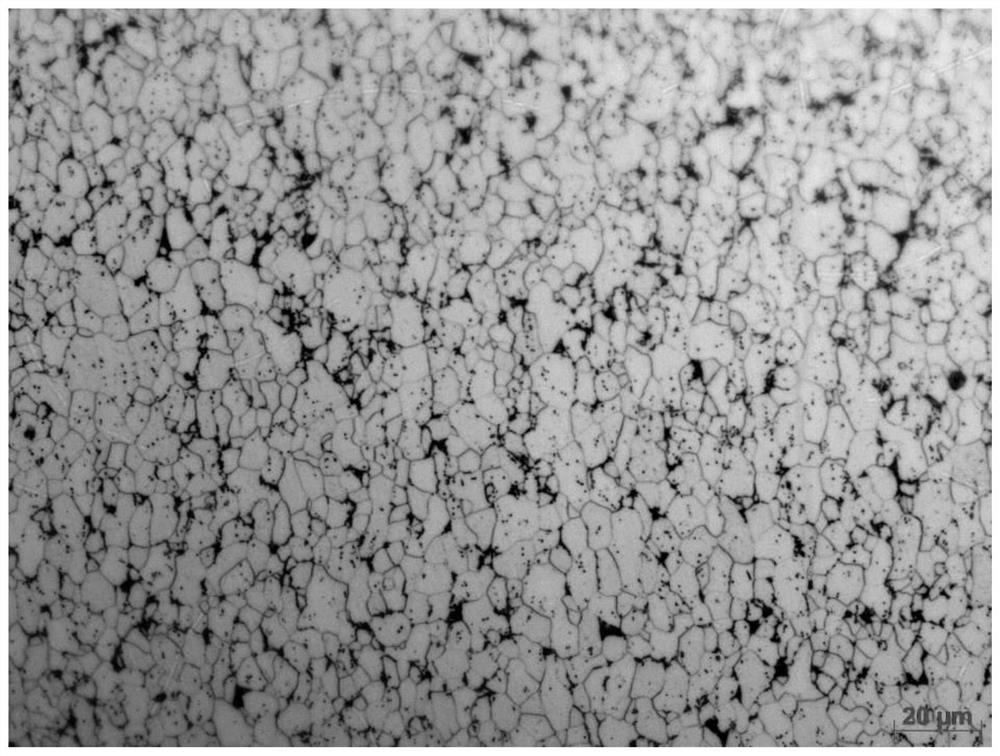

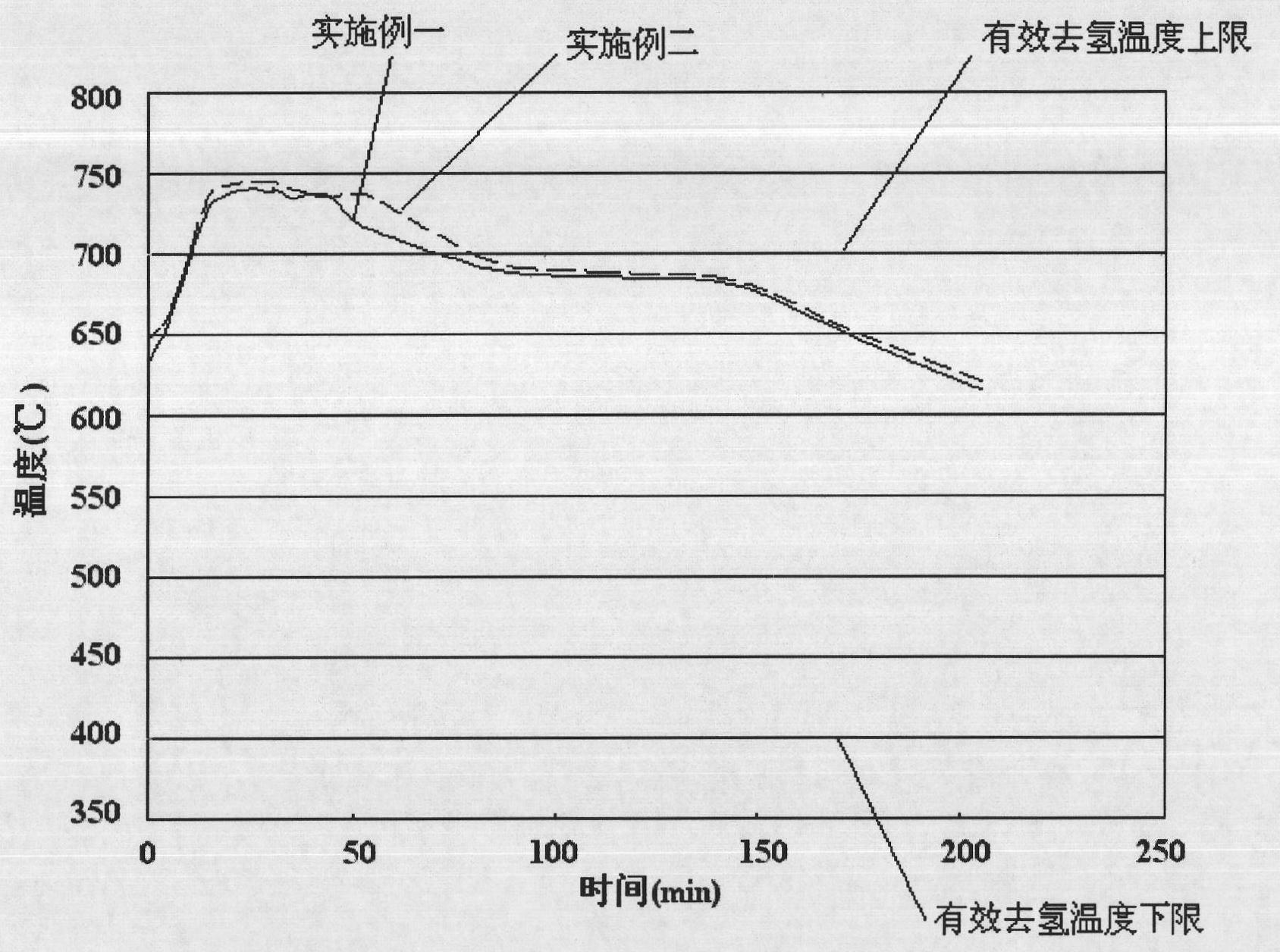

ActiveCN101818236AReduce hydrogen contentReduce difficultyFurnace typesHeat treatment furnacesHeating timeHigh carbon

The invention discloses a method for manufacturing a high carbon steel wheel. A preheating treatment process is set after a forging, stamping and rolling process and before an isothermal process. The process method comprises the following steps of: performing air cooling on the high carbon steel wheel workpiece after being subjected to high temperature forging, stamping and rolling to between 600 and 650 DEG C; heating the high carbon steel wheel workpiece, wherein the heating temperature is between 730 and 750 DEG C; and the heating time is 30 to 40 minutes; performing part of austenite transformation on a wheel rim; performing furnace cooling on the high carbon steel wheel workpiece to between 600 and 630 DEG C; and performing the isothermal process on the wheel workpiece. By adopting the technical scheme, the hydrogen content is reduced, and a hydrogen induced crack is inhibited; and the impact toughness of the high carbon steel wheel rim is effectively improved and the use safety of the product is ensured on the premise of ensuring the intensity and the rigidity of the high carbon steel wheel workpiece basically unchanged and a ferrite-pearlite microscopic structure.

Owner:MAANSHAN IRON & STEEL CO LTD

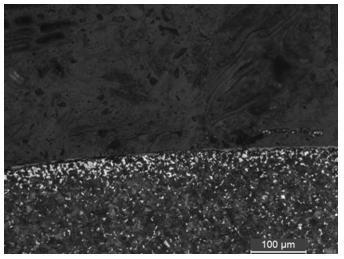

Method for producing level 600MPa fine-grain high-strength aseismic reinforced bars

The invention discloses a method for producing level 600MPa fine-grain high-strength aseismic reinforced bars, which comprises the following steps of firstly, detecting a steel billet and putting the steel billet into a furnace, wherein the steel billet comprises the following chemical compositions in percentage by mass: 0.24-0.28% of carbon, 0.62-0.80% of silicon, less than 1.30% of manganese, less than 0.035% of phosphorus, less than 0.035% of sulfur, 0.10-0.20% of vanadium, 0.20-0.50% of chromium, and the balance of iron; then, heating the steel billet by using a heat furnace, and rolling the steel billet by using a bar mill; enabling the obtained object to pass through water so as to control the obtained object to be cooled; naturally cooling by using a cooling bed, shearing, finishing and warehousing. In the method for producing level 600MPa fine-grain high-strength aseismic reinforced bars, chrome and vanadium microalloyed components are adopted, so that a V (C, N) compound is formed in steel by using vanadium, thereby greatly increasing the strength of the steel; meanwhile, a certain amount of chromium is added, so that the aseismic performance of reinforced bars is obviously improved, and finally, the mechanical performance index of the reinforced bars meets the level 600MPa fine-grain high-strength aseismic requirements. The metallographic structure of each reinforced bar is as follows: an edge part and a core part are respectively of ferrite and pearlite as well as bainite and edge tempered structure having no influence on usability.

Owner:张家港联峰钢铁研究所有限公司 +1

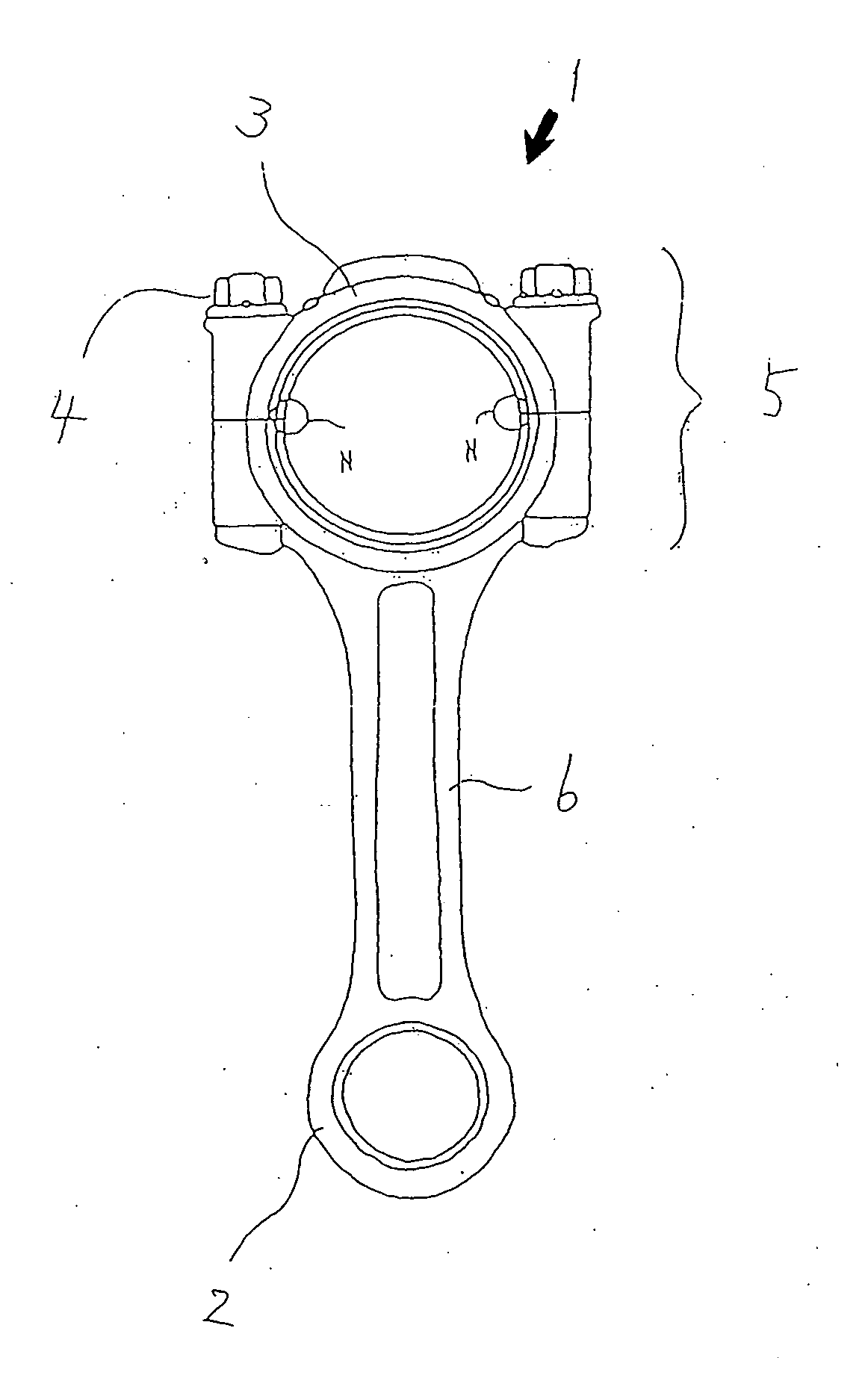

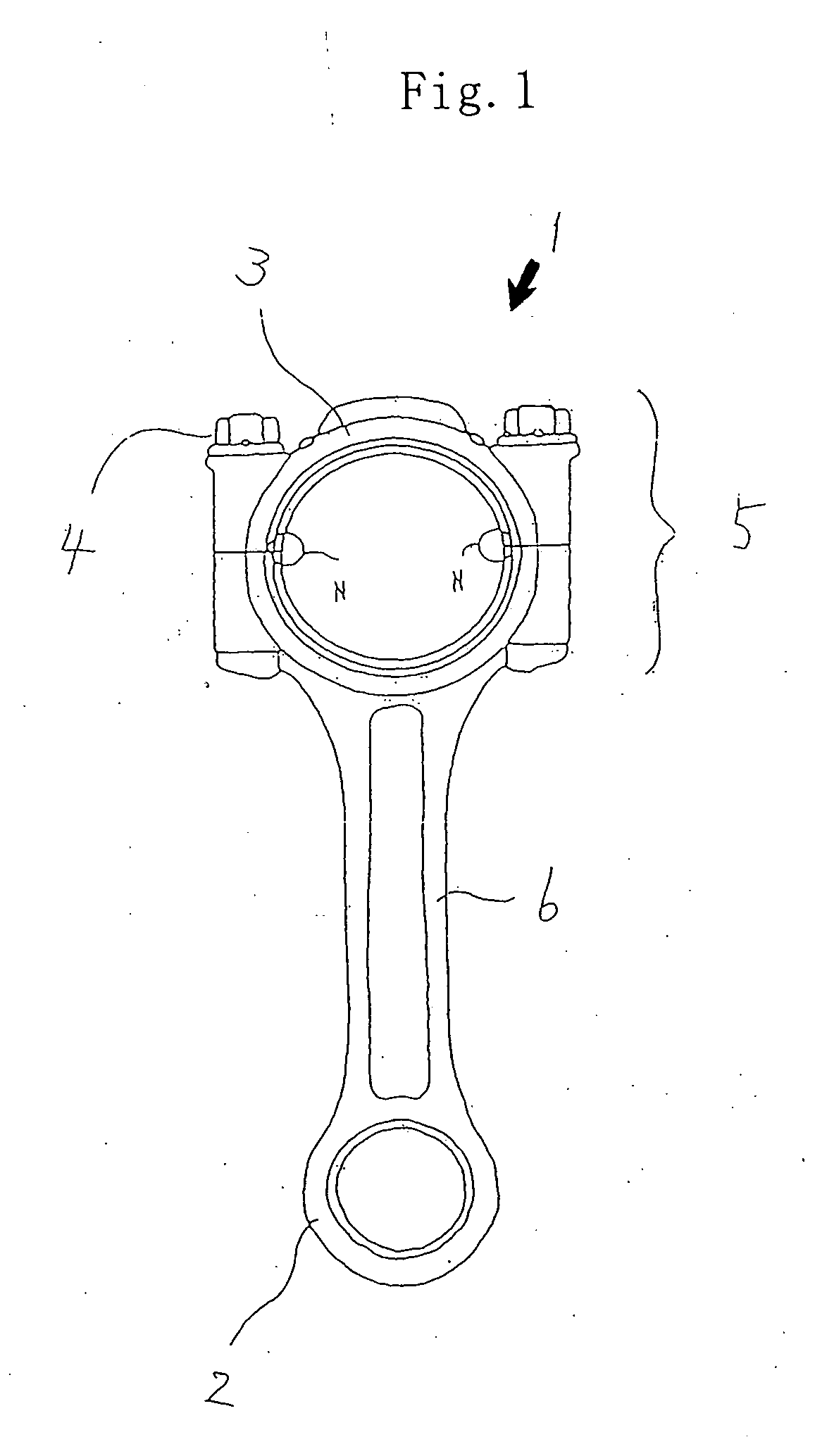

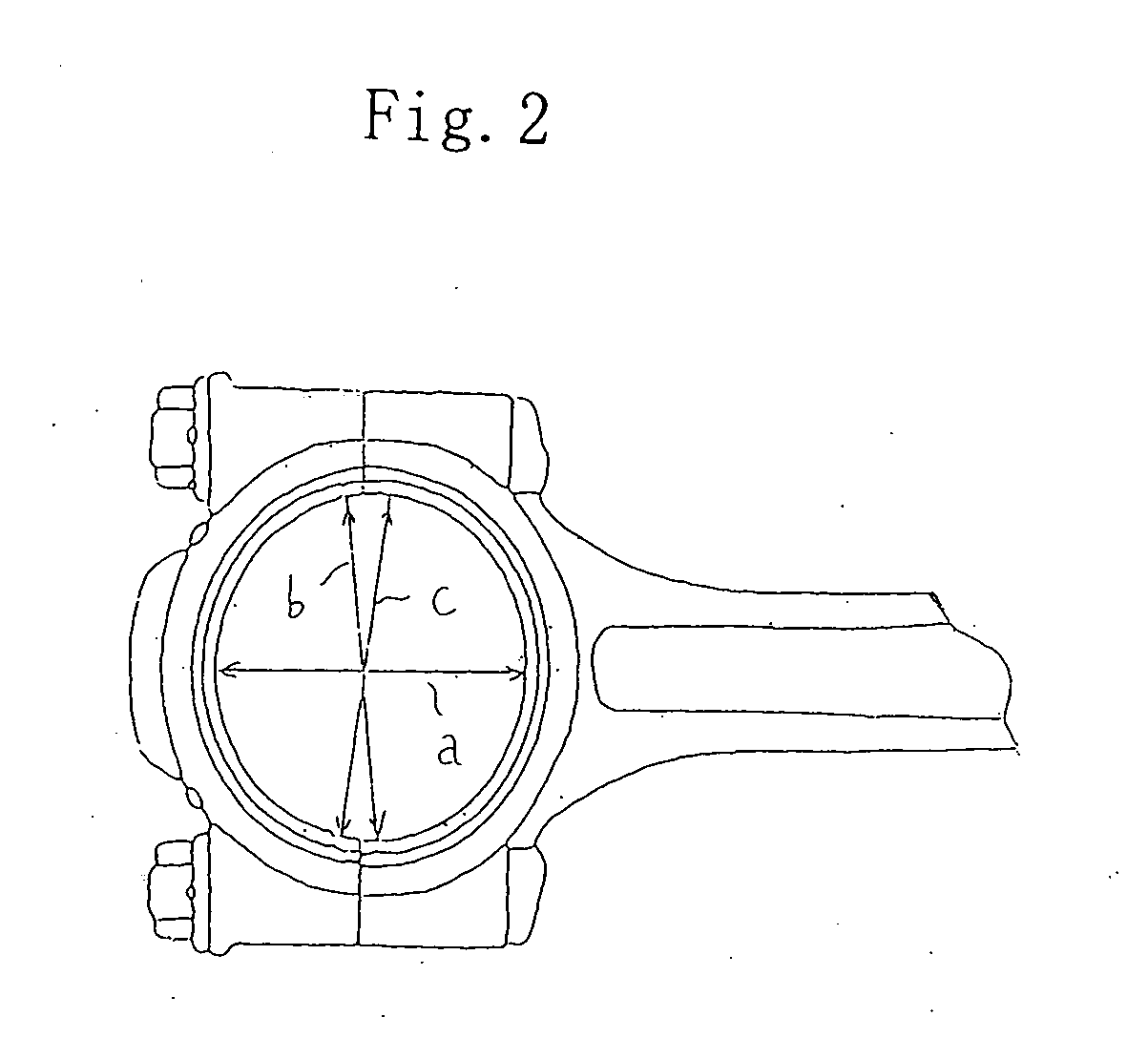

Non-heat treated connecting rod and method of manufacturing the same

ActiveUS20060000088A1Improve machinabilityIncrease resistanceConnecting rod bearingsConnecting rodsChemical compositionHardness

A non-heat treated connecting rod which comprises, by mass %, C: 0.25-0.35%, Si: 0.50-0.70%, Mn: 0.60-0.90%, P: 0.040-0.070%, S: 0.040-0.130%, Cr: 0.10-0.20%, V: 0.15-0.20%, Ti: 0.15-0.20% and N: 0.002-0.020%, and the balance Fe and impurities, with chemical compositions being less than 0.80 in the value of C+(Si / 10)+(Mn / 5)+(5Cr / 22)+1.65 V−(5S / 7) using the symbol of the element as its content, the microstructure of the Big end of the said connecting rod being ferrite-pearlite, all-region hardness of the said big end being 255 to 320 in Vickers hardness, the ferrite-region hardness in the said ferrite-pearlite of the Big end being 250 or more in Vickers hardness and the ratio of the said ferrite-region hardness to the said all-region hardness of the said Big end being 0.80 or more, is excellent in machinability, fracture splitting ability, and fatigue resistance, although no Pb at all is added. Therefore, this non-heat treated connecting rod can be utilized as a low cost type connecting rod in automobile engines or the like.

Owner:NIPPON STEEL CORP

Mo-containing steel plate being high in high-temperature strength and good in low-temperature impact toughness, and manufacturing method thereof

The invention relates to a Mo-containing steel plate being high in high-temperature strength and good in low-temperature impact toughness. The steel plate comprises the following chemical components in percentage by mass: 0.14-0.18% of C, 0.25-0.35% of Si, 0.75-0.85% of Mn, 0.25-0.35% of Mo, 0.02-0.05% of Al, no more than 0.012% of P, no more than 0.05% of S, no more than 0.20% of Cu, no more than 0.20% of Cr, 0.20-0.30% of Ni, 0.010-0.020% of Nb and / or 0.010-0.025% of Ti, and the balance of Fe and inevitable impurities, wherein the following carbon equivalent (Ceq) formula is met: Ceq = [C + Mn] / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15]*100%, that is, the Ceq ranges between 0.36 and 0.40. A technological manufacturing process of the steel plate comprises the following steps: blowing in a converter; LF refining; vacuum degassing; continuous casting; primary slow cooling; heating; rolling; cooling control; secondary slow cooling; heat treatment; fine inspection; flaw detection; performance examination; and packaging and warehousing. The steel plate provided by the invention is relatively high in high-temperature strength; meanwhile, the low-temperature impact toughness is relatively good, the Ceq is relatively low and the welding performance is good; and the steel plate adopts a ferrite-pearlite structure, and is delivered in the normalized state.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Rolling method of high-strength car spring steel wire rod

The invention relates to the field of steel wire rod hot rolling, in particular to a rolling method of a high-strength car spring steel wire rod. The rolling method comprises the procedures of steel blank heating, controlled rolling and controlled cooling. In the heating procedure, the heating temperature of a steel blank in a heating furnace is 1000 to 1080 DEG C, the total heating time is 70 to150 min, the remaining oxygen of the heating furnace is smaller than or equal to 3.0%, in the controlled rolling procedure, the wire rod finish rolling temperature is 850 to 980 DEG C, the spinning temperature is 850 to 950 DEG C, in the controlled cooling procedure, the wire rod after spinning is rapidly cooled to 780 DEG C, the cooling speed C1 is controlled to 5.0 to 10.0 DEG C / s, when the wirerod is from 780 DEG C to 600 DEG C, the average cooling speed C2 is controlled to 0.5 to 4.0 DEG C / s, the obtained wire rod is of a ferrite + pearlite + sorbite structure, and the surface is free offull decarburization.

Owner:XINGTAI IRON & STEEL

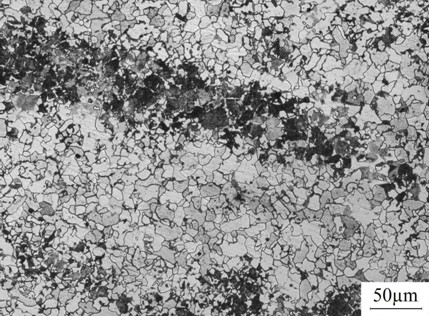

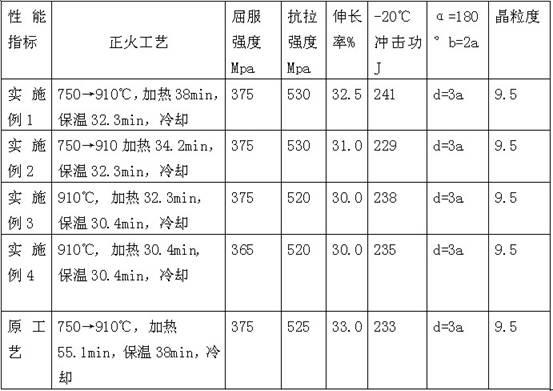

Quick normalizing heat treatment method for Q345R steel

ActiveCN102140569ASolve problems such as capacity refinement and low production capacityImprove uniformityFurnace typesHeat treatment furnacesFurnace temperatureTemperature control

The invention relates to a steel tempering process, in particular to a quick normalizing heat treatment method for Q345R steel, which comprises the following steps of: heating: making a steel plate enter a furnace with the temperature of 750 DEG C from a room temperature state, calculating the heating time according to unit thickness temperature equilibrium time of 0.8-1.1 min / mm, and segmentally heating to the target temperature of 910 DEG C, or uniformly setting temperature control areas of a scale-free roller-type heat treating furnace as 910 DEG C and making the steel plate directly enters the furnace with the temperature of 910 DEG C; keeping the temperature: after the steel plate is heated to 910 DEG C, and calculating the holding time according to unit thickness temperature equilibrium time of 0.8-0.9 min / mm for keeping the temperature; and cooling: cooling to room temperature. On the premise of ensuring that various properties meet requirements, the heating time and the holding time are shortened, the heat treatment capacity is improved, and problems that normalizing warmup time is too long so as to make various mechanical properties of steel meet requirements and ferrite-pearlite zonal textures refined, the capacity is lower and the like in the prior art are solved.

Owner:NANJING IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com