Production method of cold-rolled weathering steel with yield strength of 310 MPa or above

A technology of yield strength and production method, which is applied in the field of steel rolling, can solve problems such as polluting the environment, increasing maintenance costs, and difficulty in the application of large components, and achieves the effects of reducing production costs, stable mechanical properties, excellent forming and atmospheric corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

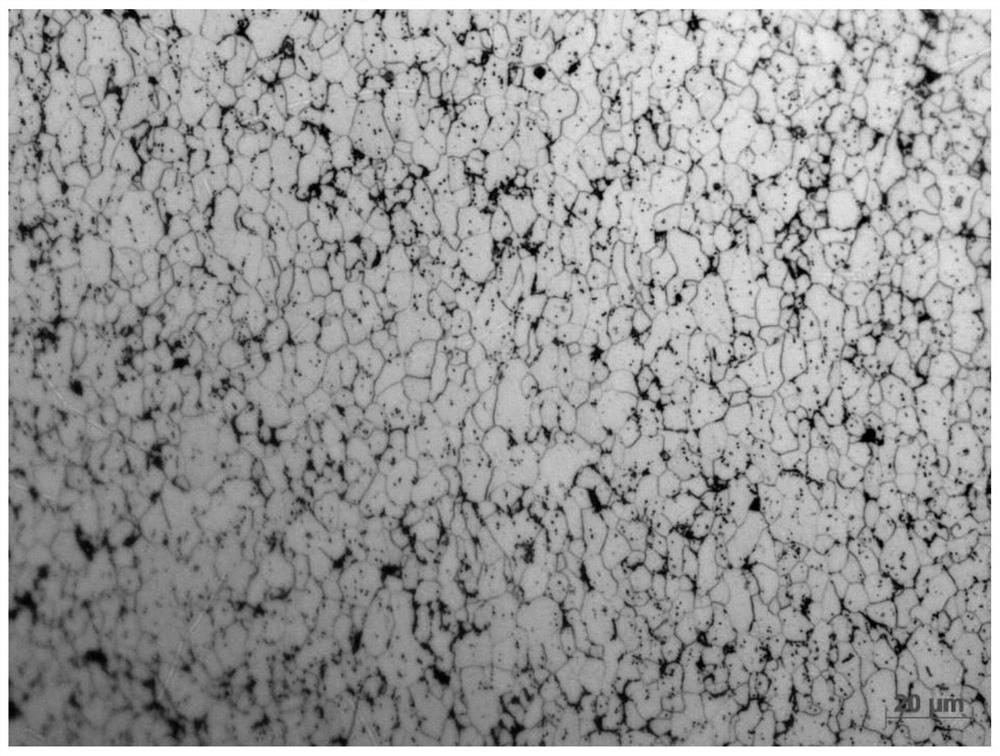

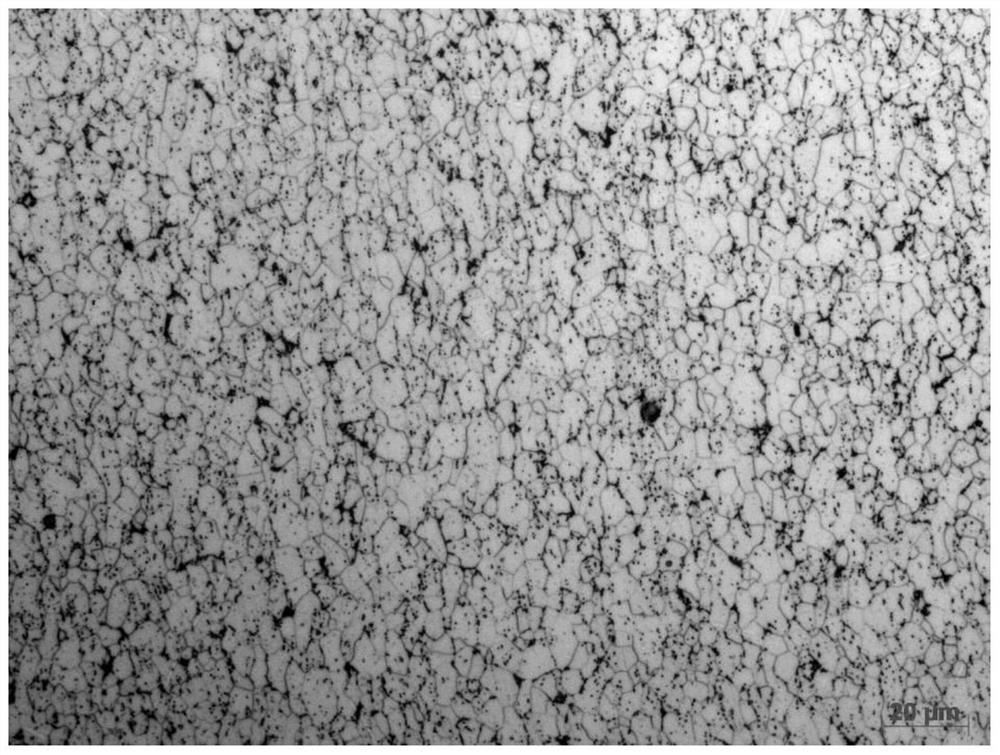

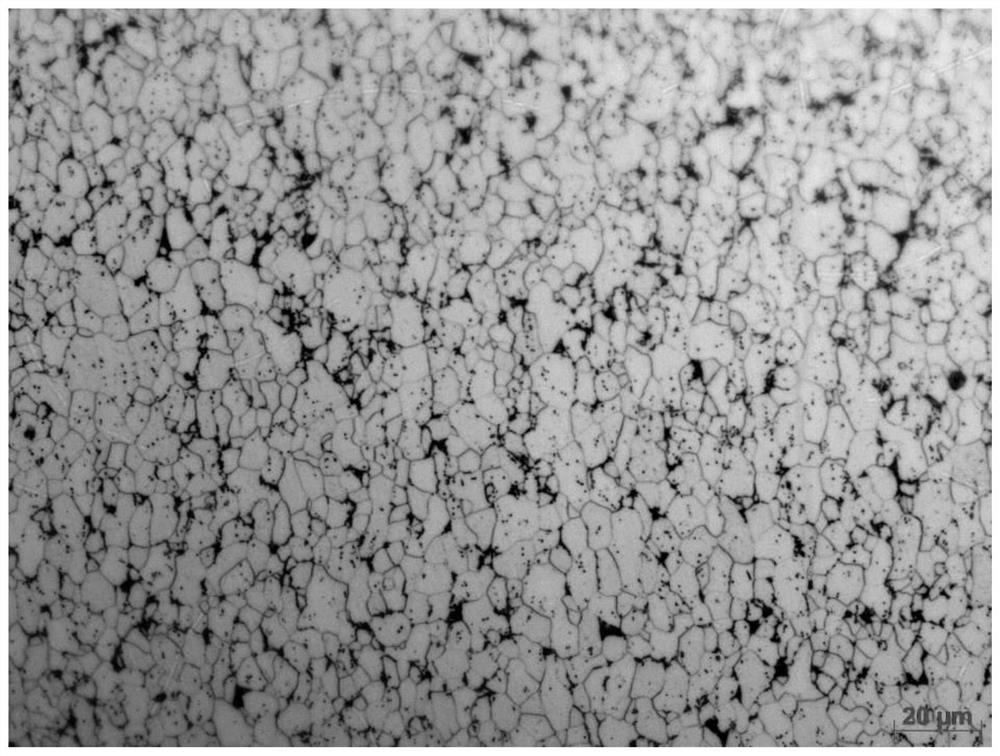

Image

Examples

Embodiment Construction

[0020]The following are specific embodiments of the present invention to further describe the technical solutions of the present invention, but the protection scope of the present invention is not limited to these embodiments. Any changes or equivalent substitutions that do not deviate from the concept of the present invention are included in the protection scope of the present invention.

[0021]In each example, a furnace of molten steel meeting the required chemical composition was obtained after KR desulfurization, converter smelting and LF refining. The molten steel was continuously cast to produce a slab with a thickness of 230 mm. The specific components of each embodiment are shown in Table 1.

[0022]Table 1 Table of main chemical components of molten steel in Examples 1-3

[0023]

[0024]In each embodiment, the continuous casting slab is sent to the hot-rolling heating furnace for heating. After the slab is discharged from the furnace, it passes through the rough rolling double-stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com