Mo-containing steel plate being high in high-temperature strength and good in low-temperature impact toughness, and manufacturing method thereof

A low-temperature impact toughness and high-strength technology, applied in the field of metallurgical steel plates, can solve the problems of unfavorable low-temperature impact properties of steel plates, deteriorate the low-temperature impact toughness of steel plates, and affect the welding performance of steel plates, and achieve uniform performance, suppression of welding cracks, and excellent welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

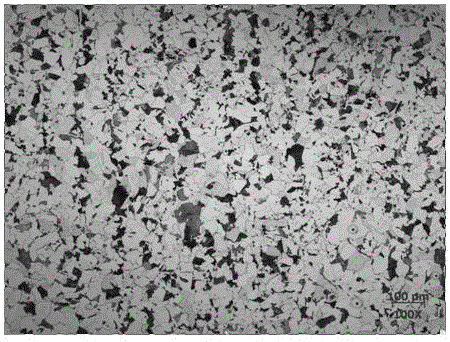

Image

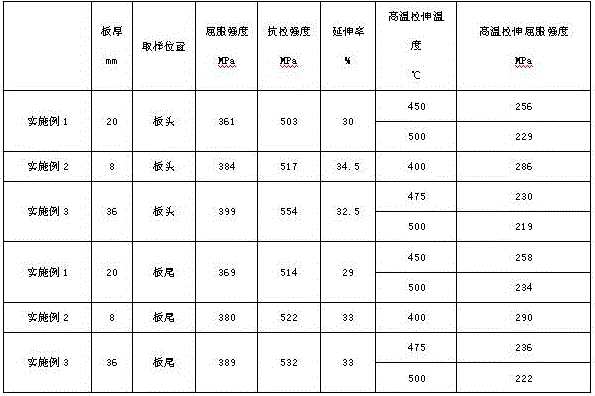

Examples

Embodiment 1

[0042] Steel plate rolling specification 20mm*2000mm*6000mm (thickness*width*length)

[0043] The manufacturing process of steel plate is converter-LF refining-vacuum degassing-continuous casting-slow cooling-heating-rolling-controlled cooling-slow cooling-heat treatment-fine inspection-flaw detection-performance inspection-packaging and storage;

[0044] The specific operation of the main process is

[0045] Smelting steps: blast furnace molten iron is blown by converter, and the C in the molten iron is removed by top and bottom blowing, and P is removed by oxidizing atmosphere to ensure slag-free tapping of the converter and prevent return of P; the tapping temperature is 1620°C, and the tapping process adds Deoxidizer deoxidation, then sent to LF refining furnace for refining, strengthen deoxidation, control the shape of inclusions, the effective refining time is 35min; the molten steel enters the RH vacuum treatment with the furnace, the vacuum degree is 66Pa, the holding ...

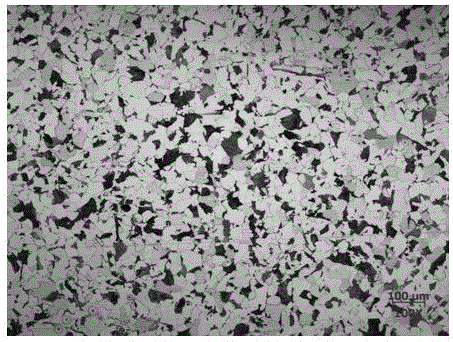

Embodiment 2

[0051] Steel plate rolling specification 8mm*2200mm*7000mm (thickness*width*length)

[0052] The manufacturing process of steel plate is converter-LF refining-vacuum degassing-continuous casting-slow cooling-heating-rolling-controlled cooling-slow cooling-heat treatment-fine inspection-flaw detection-performance inspection-packaging and storage;

[0053] The specific operation of the main process is

[0054] Smelting steps: blast furnace molten iron is blown by converter, and the C in the molten iron is removed by top-bottom double blowing, and P is removed by oxidizing atmosphere to ensure slag-free tapping of the converter and prevent return of P; the tapping temperature is 1624°C, and the tapping process adds The deoxidizer is deoxidized, and then sent to the LF refining furnace for refining, to strengthen deoxidation, control the shape of inclusions, and the effective refining time is 37min; the molten steel enters the RH vacuum treatment with the furnace, the vacuum degre...

Embodiment 3

[0060] Steel plate rolling specification 36mm*2000mm*6000mm (thickness*width*length)

[0061] The manufacturing process of steel plate is converter-LF refining-vacuum degassing-continuous casting-slow cooling-heating-rolling-controlled cooling-slow cooling-heat treatment-fine inspection-flaw detection-performance inspection-packaging and storage;

[0062] The specific operation of the main process is

[0063] Smelting steps: blast furnace molten iron is blown by converter, and the C in the molten iron is removed by top-bottom double blowing, and P is removed by oxidizing atmosphere to ensure slag-free tapping of the converter and prevent return of P; the tapping temperature is 1626°C, and the tapping process adds Deoxidizer deoxidation, then sent to LF refining furnace for refining, strengthen deoxidation, control the shape of inclusions, the effective refining time is 31min; the molten steel enters the RH vacuum treatment with the furnace, the vacuum degree is 66Pa, the holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com