Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

A technology of yield strength and production method, applied in the direction of coating, metal material coating process, hot dip plating process, etc., can solve the problem of increasing the production cost of structural color-coated sheets, failing to achieve yield strength, and corrosion-resistant color-coated sheets. Sexual decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 0.6mm, the steps:

[0021] 1) Smelting: hot metal desulfurization, converter smelting, continuous casting to form components and weight percentages: C: 0.05%, Si: 0.013%, Mn: 0.25%, P: 0.015%, S: 0.012%, Als: 0.05% , N: 0.0021%, Ti: 0.002%, Nb: 0.001%, the rest is continuous casting of Fe and unavoidable impurities and hot rolling;

[0022] 2) pickling;

[0023] 3) Carry out cold rolling, and control the cumulative reduction rate at 65%;

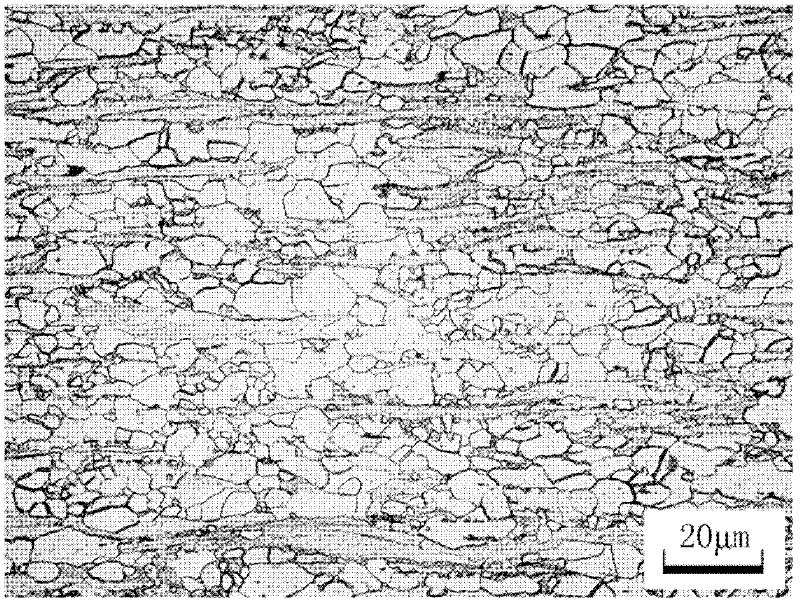

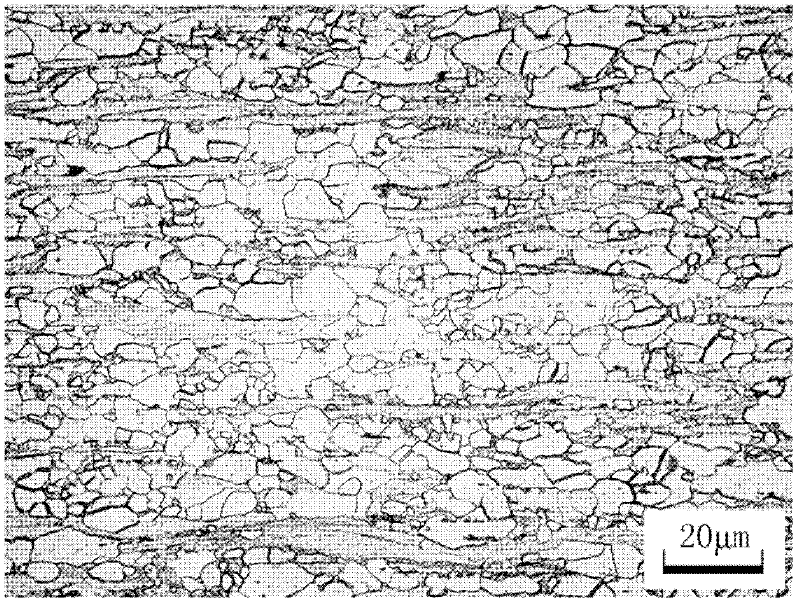

[0024] 4) Carry out continuous annealing, the annealing temperature is controlled at 600 ° C ~ 605 ° C, and the annealing time is 60 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0025] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 150g / m 2 , the composition and weight percentage of the coating are: A...

Embodiment 2

[0029] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 0.8 mm, the steps:

[0030] 1) Smelting: Desulfurization of molten iron, converter smelting, and continuous casting to form components and weight percentages: C: 0.04%, Si: 0.011%, Mn: 0.20%, P: 0.02%, S: 0.011%, Als: 0.06% , N: 0.0015%, Ti: 0.003%, Nb: 0.002%, the rest is continuous casting slab of Fe and unavoidable impurities and hot rolling;

[0031] 2) pickling;

[0032] 3) Carry out cold rolling, and control the cumulative reduction rate at 61%;

[0033] 4) Carry out continuous annealing, the annealing temperature is controlled at 615 ° C ~ 620 ° C, and the annealing time is 50 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0034] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 120g / m 2 , the composition and weight percentage of the ...

Embodiment 3

[0038] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 1.0 mm, the steps:

[0039]1) Smelting: hot metal desulfurization, converter smelting, continuous casting to form components and weight percentages: C: 0.03%, Si: 0.020%, Mn: 0.18%, P: 0.01%, S: 0.009%, Als: 0.02% , N: 0.0025%, Ti: 0.001%, Nb: <0.001%, and the rest are continuous casting slabs of Fe and unavoidable impurities and hot rolling;

[0040] 2) pickling;

[0041] 3) Carry out cold rolling, and control the cumulative reduction rate at 58%;

[0042] 4) Carry out continuous annealing, the annealing temperature is controlled at 645 ° C ~ 650 ° C, and the annealing time is 20 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0043] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 60g / m 2 , the composition and weight percentage of the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com