Carbon manganese low-temperature steel for liquefied gas boat and manufacturing method of carbon manganese low-temperature steel

A technology for a liquefied gas ship and a manufacturing method, applied in the field of alloy steel manufacturing, can solve the problems of high cost, poor safety, and high alloy cost, and achieve the effects of reducing alloy cost, high toughness weldability, and high and low temperature toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

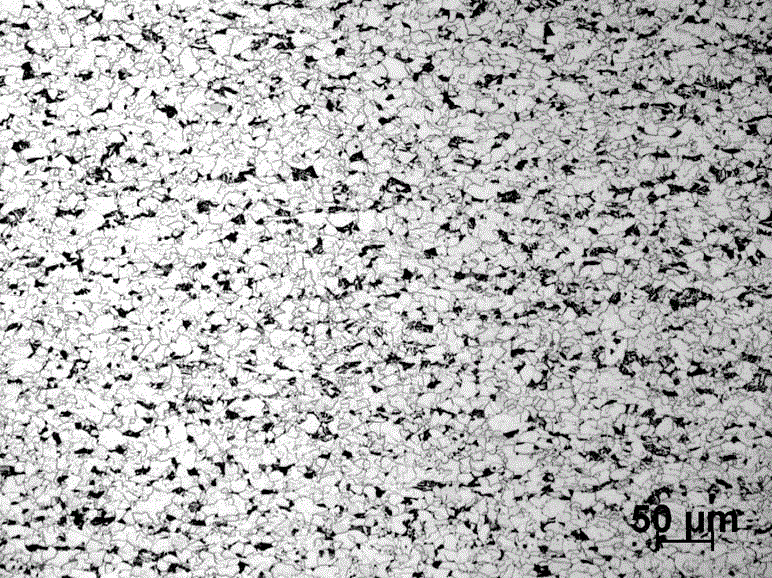

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than all the embodiments.

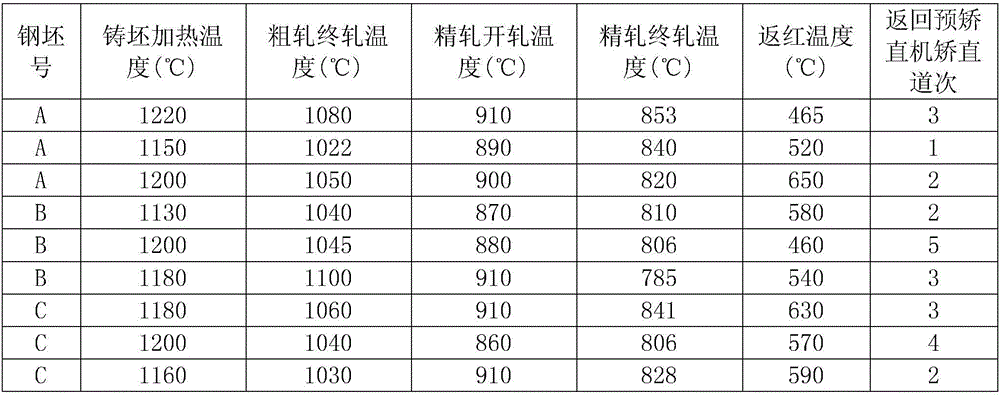

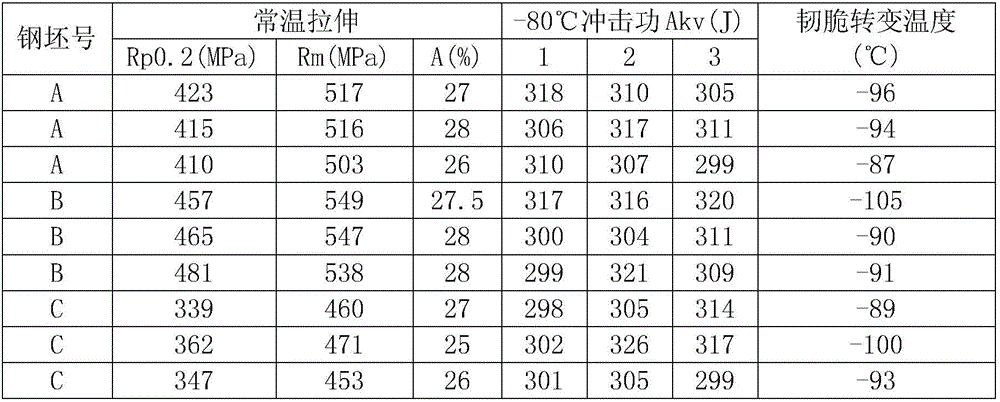

[0025] The steel slabs of the embodiments of the present invention are produced by converter smelting, LF refining, and continuous casting. There are 3 examples of chemical composition, and the chemical composition is shown in Table 1.

[0026] The manufacturing method includes the following steps:

[0027] Smelting and casting process: use converter or electric furnace for smelting, continuous casting for casting; target sulfur ≤ 0.005% after desulfurization of molten iron, converter smelting to prevent the end point from returning to S, strictly do a good job in converter tapping to prevent slag, LF furnace adopts white slag operation, refining total The time is guaranteed to be ≥30 minutes, and the RH high vacuum degree is ≤5.0mbar to main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com