High-strength untempered steel for fracture splitting and steel component for fracture splitting

A non-quenched and tempered steel, high-strength technology, applied in the field of non-quenched and tempered steel for high-strength fracture splitting, can solve the problems of poor yield strength and durability strength, reduced ductility, etc., and achieve excellent fracture splitting and small deformation , Excellent thermal ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

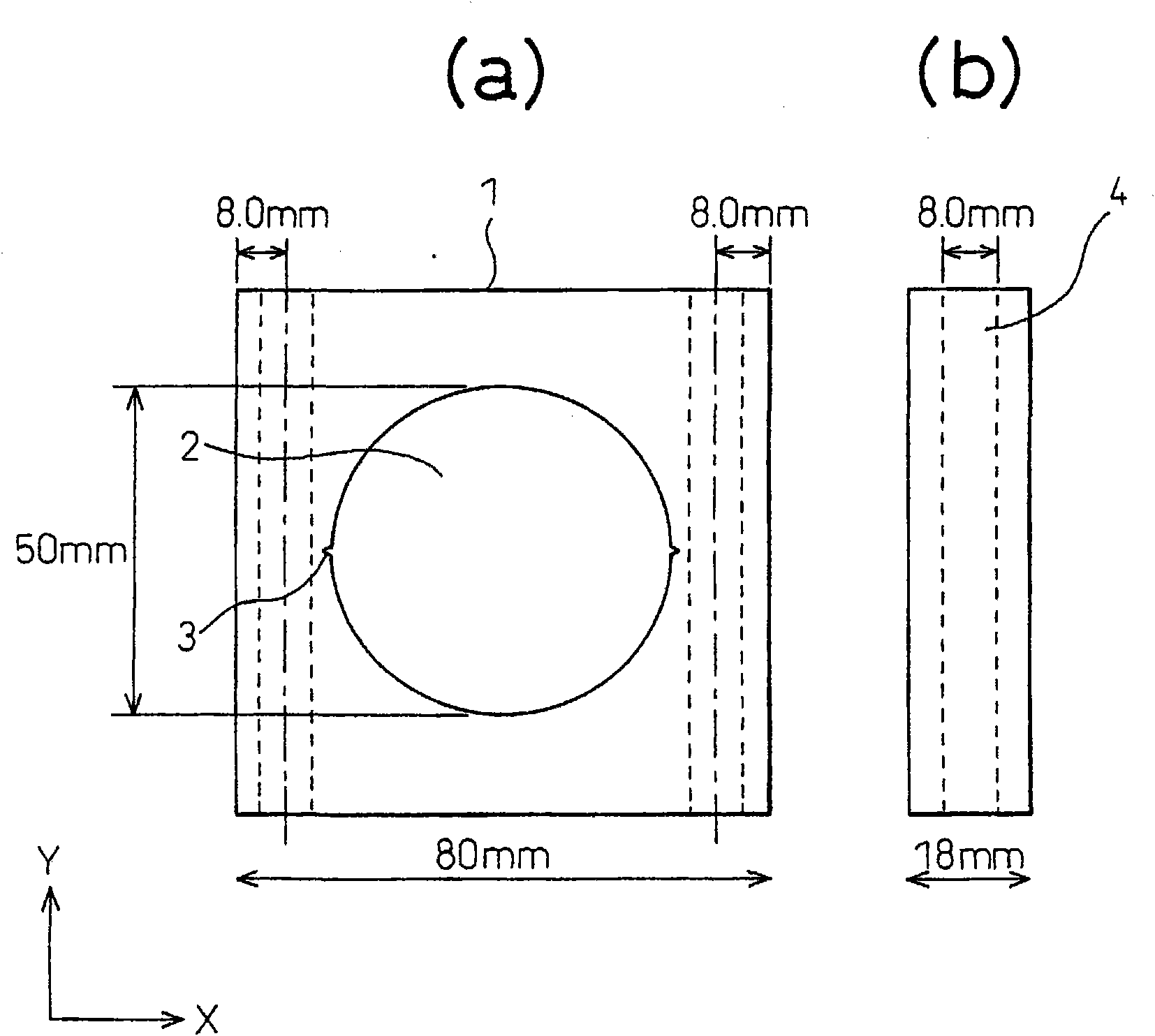

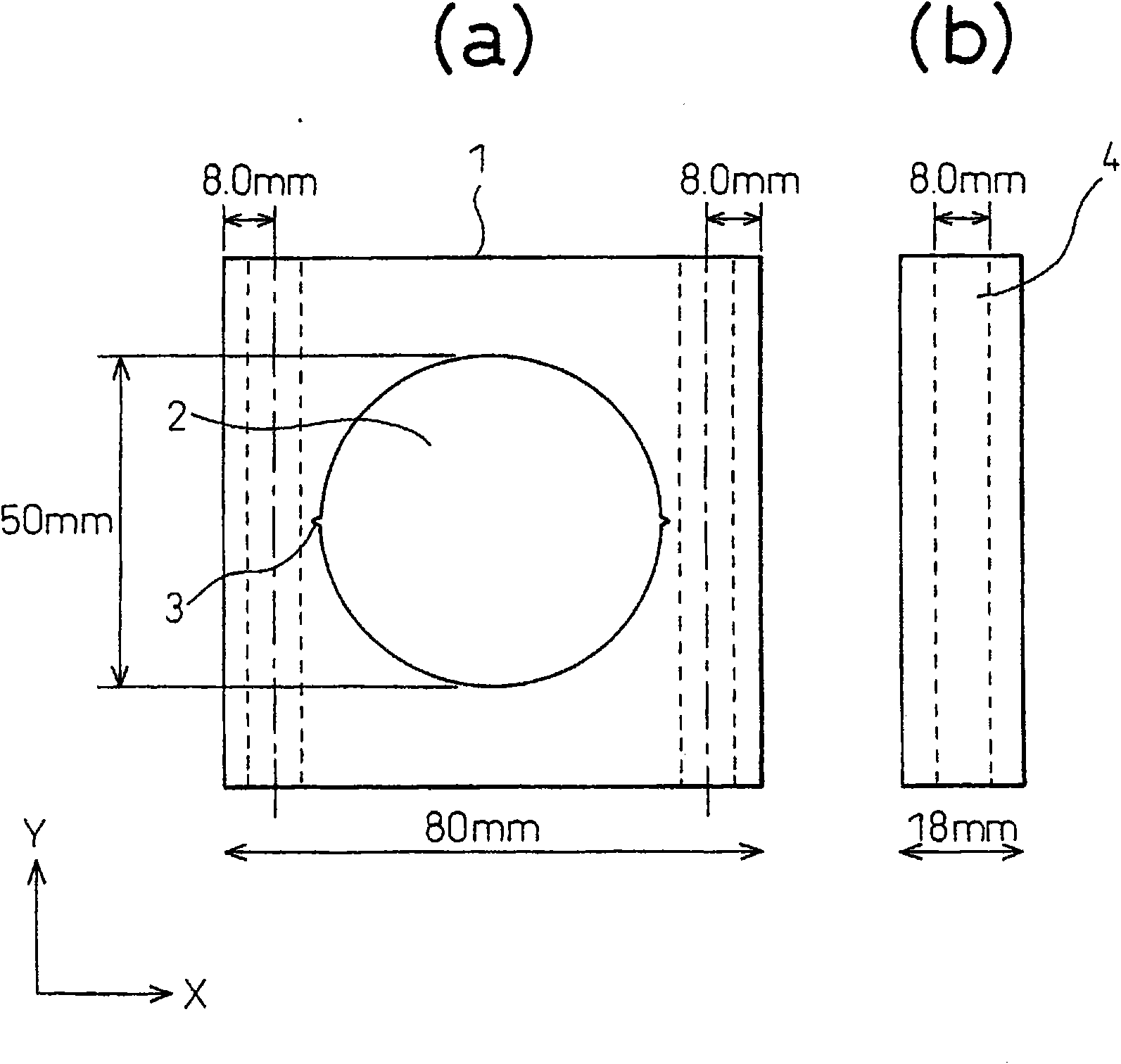

[0183] Hereinafter, the present invention will be described in detail based on examples.

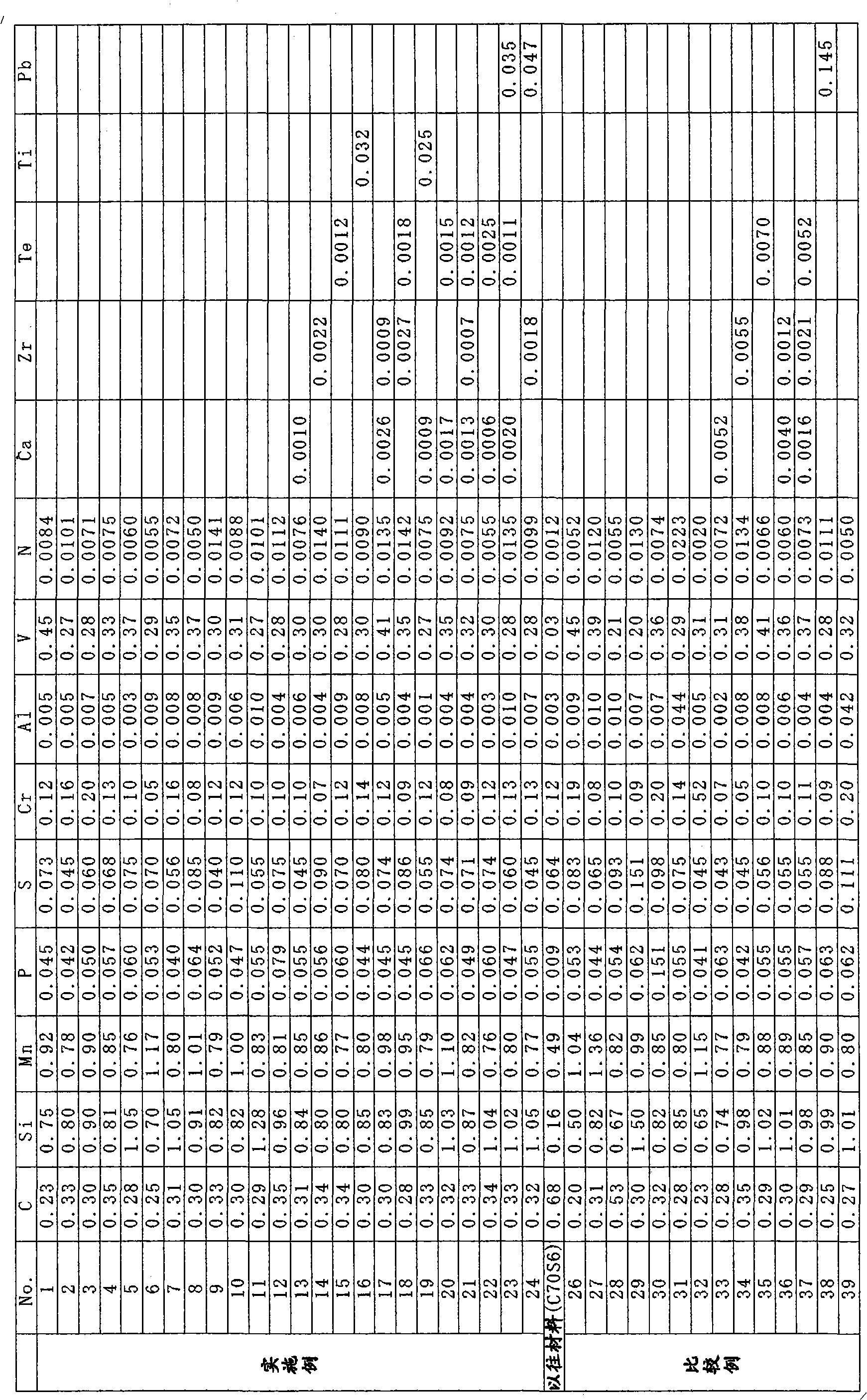

[0184] 16 kg each of the inventive steel (Examples 1 to 24) and comparative steel (Comparative Examples 26 to 39 and conventional materials) having the compositions shown in Table 1 were melted into ingots in a vacuum melting furnace. These melted ingots were heated to 1493K, forged and stretched into steel bars with a diameter of 55 mm, and then left to cool to be used as raw materials for evaluation.

[0185] Table 1 is as follows:

[0186]

[0187] First, thermal ductility in the period immediately after melting-solidification of raw materials was evaluated by a thermal tensile test. The test piece was made into a rod shape with a diameter of 1.0 mm and a length of 100 mm, the center of the test piece was covered with a quartz tube, and a thermocouple was attached.

[0188] Install it on an electric heating device equipped with a tensile device, and while cooling both ends with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com