Rolling method of high-strength car spring steel wire rod

A technology for automobile springs and steel wire rods, which is applied in the field of hot rolling of steel wire rods, and can solve the problems that full decarburization cannot be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention provides a rolling method of high-strength automotive spring steel wire rod. The chemical composition and weight percentage of the steel are listed in Table 1. The wire rod specification is Ф12mm, and the heating temperature of the billet in the heating furnace is 1000°C. The total heating time is 97min, the residual oxygen content of the heating furnace is 1.1%, the temperature of entering and finishing rolling is 930°C, and the spinning temperature is 880°C. After spinning, adjust the opening and closing of the insulation cover and the opening of the fan to rapidly cool the wire rod to 780°C. Cooling rate C1 The average cooling rate C2 of the wire rod from 780°C to 600°C is 1.0°C / s.

Embodiment 2-9 and comparative example 1-3

[0023] Examples 2-9 and Comparative Examples 1-3 use the same process as Example 1 to roll spring steel wire rods. The chemical composition and weight percentage of the steel are listed in Table 1. The difference is that Table 2 is used respectively. Listed in the billet in the heating furnace heating temperature, total heating time, residual oxygen in the heating furnace, into the finish rolling temperature, spinning temperature, cooling rate C1, average cooling rate C2, wire rod specification instead of the embodiment 1 Heating temperature, total heating time, residual oxygen in heating furnace, finishing temperature, spinning temperature, cooling rate C1, average cooling rate C2, wire rod specifications.

[0024] Table 1

[0025]

[0026] Table 2

[0027]

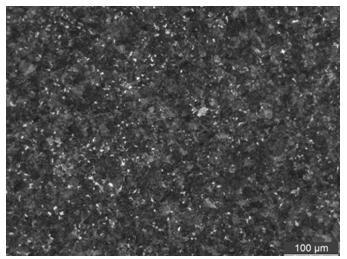

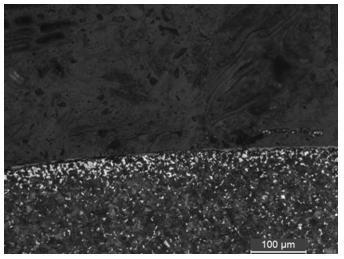

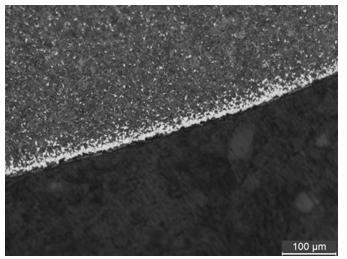

[0028] Utilize optical microscope to check the full decarburization situation on the surface of the wire rods produced in Examples 1-9 and Comparative Examples 1-3, and the test results are listed in Table 3, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com