Quick normalizing heat treatment method for Q345R steel

A kind of normalizing heat treatment and rapid technology, applied in heat treatment furnaces, heat treatment equipment, furnaces and other directions, can solve the problems affecting the production efficiency of heat treatment furnaces, excess heat treatment process capacity, long heat treatment cycles, etc., to shorten the heating time and holding time, improve The effect of shortening heat treatment capacity and heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

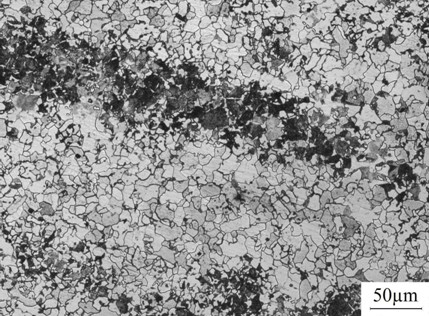

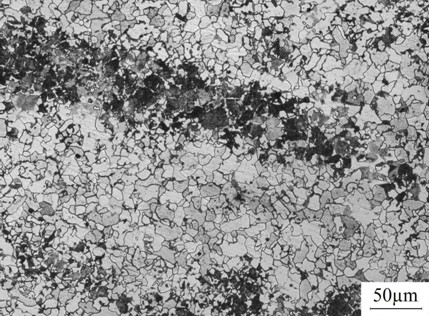

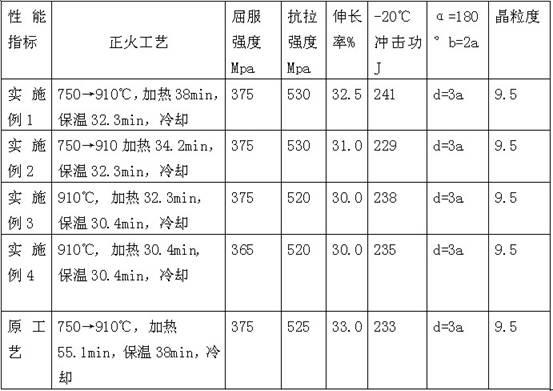

Embodiment 1

[0018] For a 38mm thick Q345R steel plate, the normalizing temperature is 910°C, the steel plate enters the furnace at a temperature of 750°C from room temperature, the heating time is 38min (ie 1.0min / mm), heated to the target temperature of 910°C, and the holding time is 32.3min (ie 0.85min / mm), and then air-cooled to room temperature. After normalizing, the microstructure is still ferrite-pearlite banded structure, but the size of ferrite grains and pearlite clusters is significantly smaller than that before normalizing, and the uniformity of the structure is also significantly improved, with a grain size of 9.5 Grade, (according to Chinese national standard GB / T6394-2002 "Measurement method of average grain size of metal"), see attached figure 1 . The various performance indicators are shown in Table 1, all of which meet the requirements of GB713-2008 "Steel Plates for Boilers and Pressure Vessels". The heating time of the slab in the furnace was successfully shortened b...

Embodiment 2

[0020] For the 38mm thick Q345R steel plate, the steel plate enters the furnace at a furnace temperature of 750°C from room temperature, the heating time is 34.2min (ie 0.9min / mm), heated to the target temperature of 910°C, and the holding time is 32.3min (ie 0.85min / mm ), and then air-cooled to room temperature. After normalizing, the microstructure is still ferrite-pearlite banded structure, but the size of ferrite grains and pearlite clusters is significantly smaller than that before normalizing, and the uniformity of the structure is also significantly improved, with a grain size of 9.5 Grade (Using Chinese National Standard GB / T6394-2002 "Measurement Method for Average Grain Size of Metal"), see attached drawing 2. The various performance indicators are shown in Table 1, all of which meet the requirements of GB713-2008 "Steel Plates for Boilers and Pressure Vessels". The heating time of the slab in the furnace was successfully shortened by 28.6%, so as to achieve rapid n...

Embodiment 3

[0022] For the 38mm thick Q345R steel plate, the normalizing temperature is 910°C, the steel plate directly enters the furnace at a temperature of 910°C from room temperature, the heating time is 32.3min (ie 0.85min / mm), and the holding time is 30.4min (ie 0.8min / mm ), and then air-cooled to room temperature. After normalizing, the microstructure is still ferrite-pearlite banded structure, but the size of ferrite grains and pearlite clusters is significantly smaller than that before normalizing, and the uniformity of the structure is also significantly improved, with a grain size of 9.5 Grade (Using Chinese National Standard GB / T6394-2002 "Measurement Method for Average Grain Size of Metal"), see attached drawing 2. Various performance indicators are shown in Table 1, all of which meet the requirements of GB713-2008 "Steel Plates for Boiler and Pressure Vessels". The heating time of the slab in the furnace has been successfully shortened by 32.7%, so as to achieve rapid normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com