Polar region ship steel plate capable of high heat input welding and making method for same

A technology of high-energy-input welding and polar ship, which is applied in the field of iron and steel metallurgy, can solve the problems that cannot fully meet the requirements of polar ship, and achieve the effects of improving resistance to high-energy-input welding, excellent low-temperature aging resistance, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

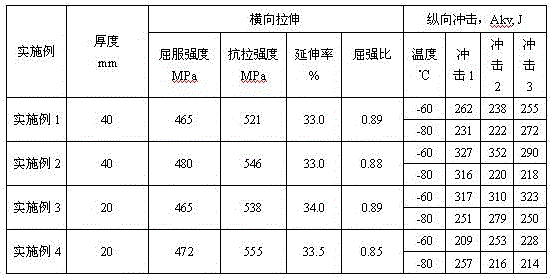

[0035] Below in conjunction with embodiment the present invention is described in further detail.

[0036] The chemical composition of the high heat input weldable low temperature toughness steel corresponding to each embodiment is shown in Table 1. The data in the table are the mass percentage content of each element, and the rest is Fe and unavoidable impurity elements.

[0037] Table 1

[0038]

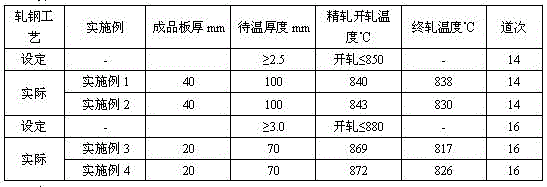

[0039] The production process of steel plate is as follows:

[0040] Smelting and continuous casting process: hot metal pretreatment, KR deep desulfurization, sulfur content less than 0.0020%, converter smelting, out-of-furnace refining, slab continuous casting and other processes, wherein the end point of converter is C≤0.02%, and the tapping process is carried out for 15-20 minutes Bottom blowing argon, nitrogen, LF, RH refining, alloy addition sequence is Al, Si, Mn, Ni, Nb, Cu, Ti, Ca, and finally feed Ti wire and Ca wire to improve the yield of Ti and Ca , to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com